Environmentally-friendly super hydrophobic glazed hollow bead grade A fireproof composite insulation board and production method thereof

A vitrified microbead plate and vitrified microbead technology are applied in chemical instruments and methods, heat preservation, fire prevention, etc., which can solve the problems of high water absorption rate of vitrified microbeads, the contradiction between the strength of insulation materials and thermal conductivity, etc. Excellent water performance, stable physical and chemical properties, and improved surface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

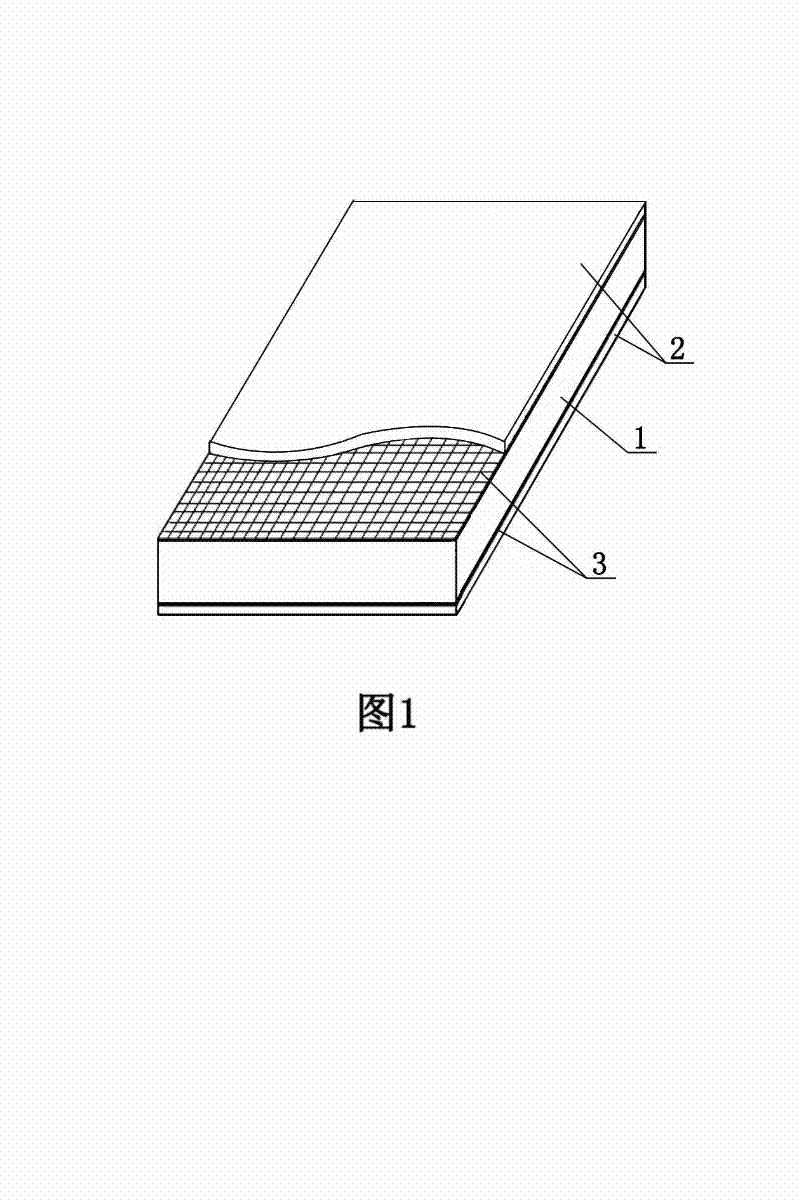

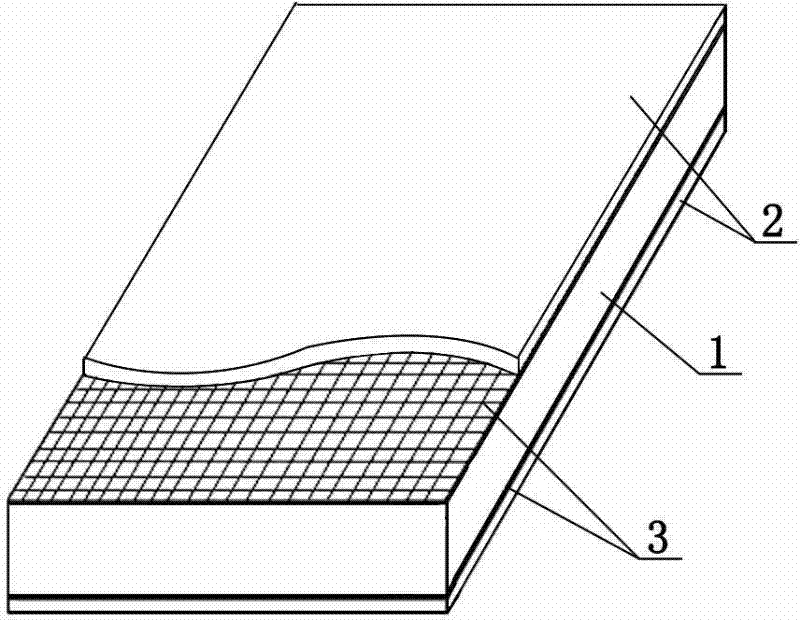

[0053] Examples see figure 1 As shown, this environmentally friendly super-hydrophobic vitrified microbead A-class fireproof composite thermal insulation board includes a thermal insulation layer, a mortar layer and a non-woven fabric. The super-hydrophobic vitrified bead plate is formed by extruding at low temperature, then extruded and shaped by a mold, and cooled and cut. Layer 2 is compounded; the thickness of the super-hydrophobic vitrified microbead plate 1 is 7 cm, and the thickness of the mortar layer 2 is 15 cm.

[0054] The super-hydrophobic vitrified microbeads are formed by impregnating vitrified microbeads with a two-component water-repellent agent, filtering, and drying. The two-component water-repellent agent is composed of monomethylsiloxane organic water repellent and The reactive polydimethylsiloxane aqueous emulsion is mixed at a weight ratio of 1:1.5 to prepare an aqueous solution with a concentration of 2‰.

[0055] The vitrified microbeads can adopt a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com