Resin stereoscopic light-emitting character and manufacturing method thereof

A production method and technology for luminous characters, applied in the field of advertising signs, can solve the problems of high cost, lack of texture, low efficiency, etc., and achieve the effect of reducing the amount of resin, prolonging the service life, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

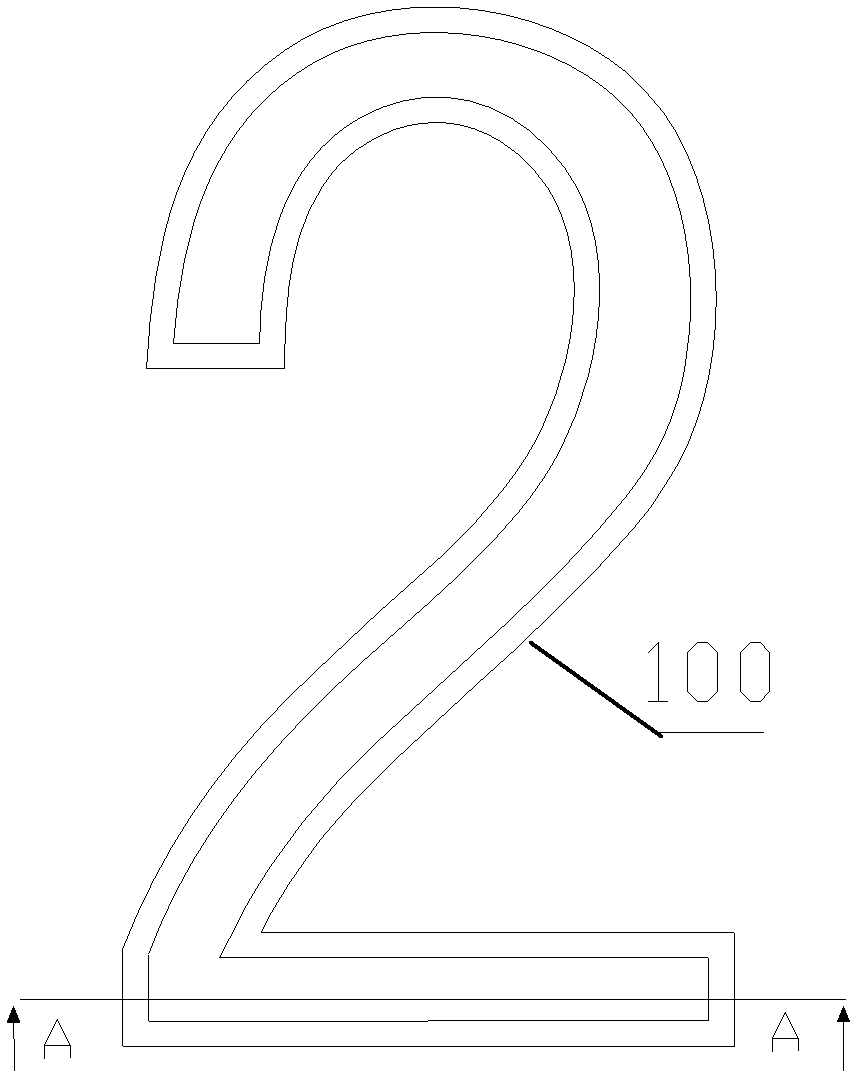

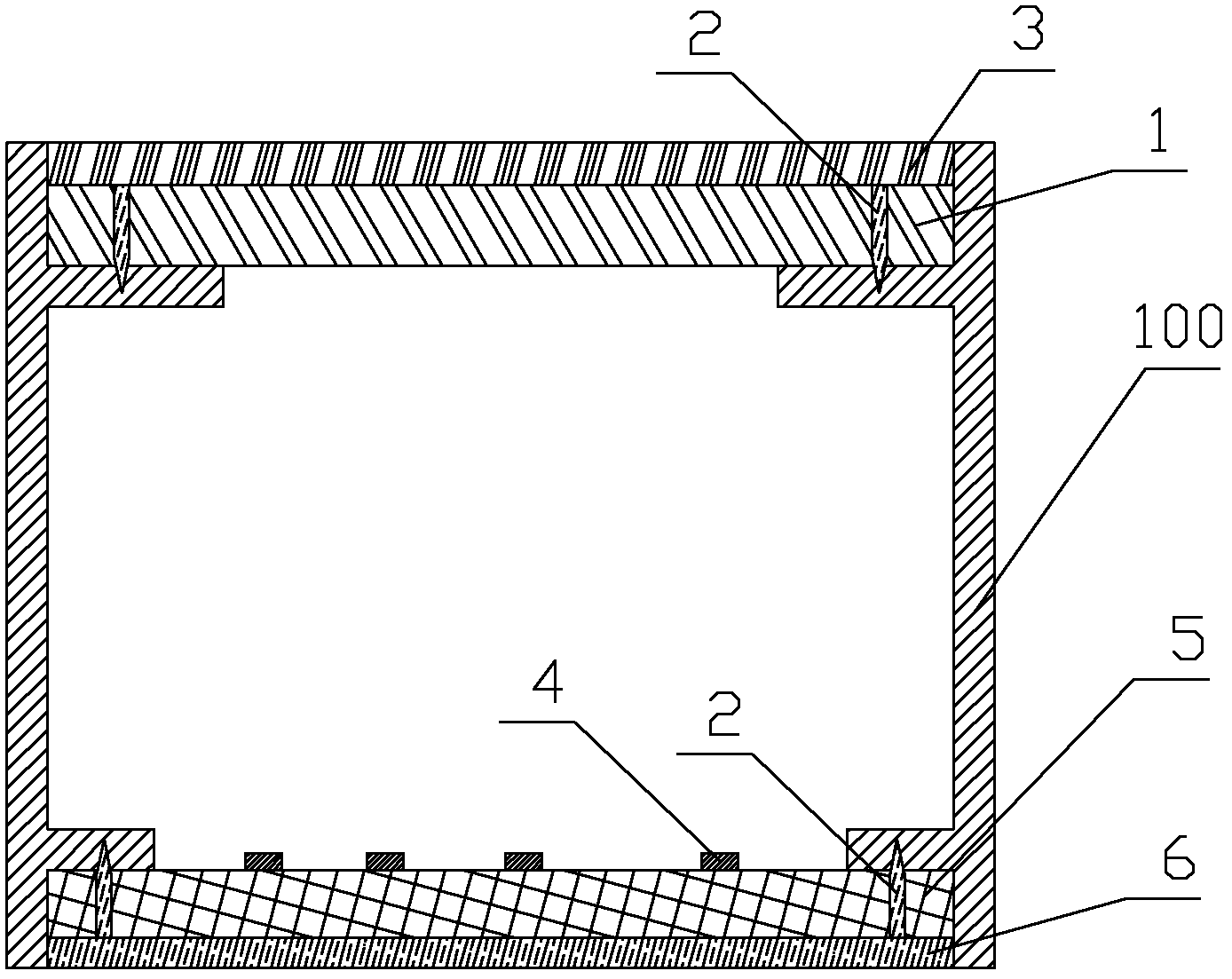

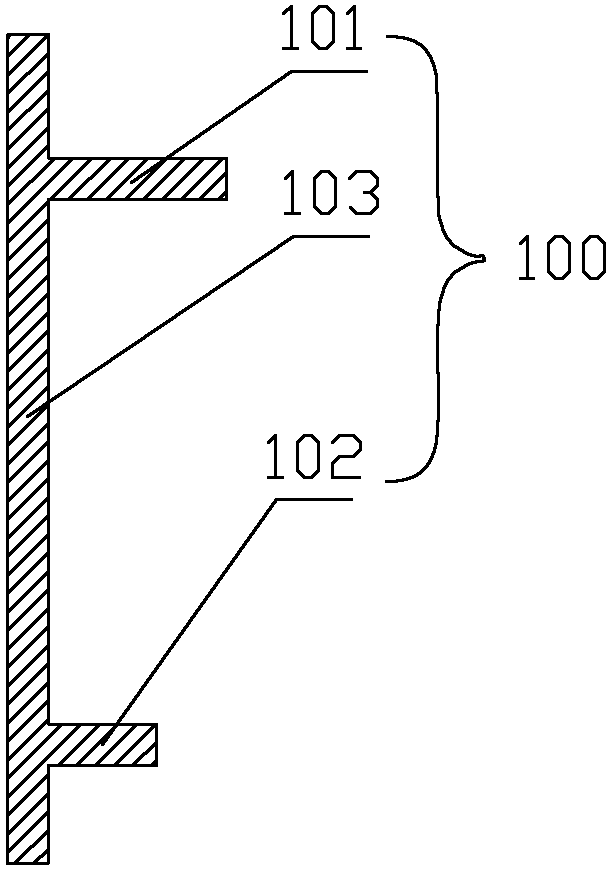

[0048] Such as figure 1 , figure 2 As shown, it is the resin three-dimensional luminous character of the present invention. Taking the number "2" resin three-dimensional luminous character as an example, it includes a panel, a character edge, a bottom plate and an LED light 4. The panel includes a panel auxiliary board 1 and an upper panel covering the panel auxiliary board 1. The resin layer 3; the bottom plate includes the bottom plate auxiliary plate 5 and the bottom plate resin layer 6 covering the bottom plate auxiliary plate 5; The panel auxiliary board 1 is a polypropylene board or a polycarbonate board. The floor auxiliary board 5 is a foamed polyvinyl chloride board. Such as image 3 As shown, the side strip 100 includes a side strip body 103, a panel riveting rib 101 arranged on the side strip body 103 for fixing the panel auxiliary board 1 and a floor riveting rib arranged on the side strip body 103 for fixing the bottom panel auxiliary board 5 102. Such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com