Preparation method of nature sodium base bentonite for precise casting

A sodium-based bentonite and precision casting technology, which is applied in casting molding equipment, clay products, applications, etc., can solve the problems of short weather resistance, poor effect, poor high temperature resistance and weather resistance, and achieve good air permeability , good reusability, high temperature resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of natural sodium bentonite for precision casting, comprising the following steps:

[0019] (1) collect bentonite ore;

[0020] (2) drying the bentonite ore obtained in the above step (1) to a water content of 15-25%, preferably 20%;

[0021] (3) use pulverizer to carry out coarse crushing to the bentonite ore that above-mentioned step (2) obtains, obtain the crushed ore of particle diameter at 0.5-1 centimetre;

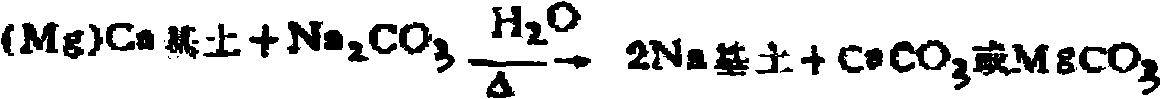

[0022] (4) adjust sodium content, batching, add the soda ash of bentonite ore weight 2% and the caustic soda of 0.5% in the crushed ore that above-mentioned step (3) obtains;

[0023] (5) the coarse ore that the above-mentioned step (4) is regulated sodium content carries out sodiumization by extruding sodiumization machine;

[0024] (6) drying the coarse ore after the sodiumization of the above step (5) to a water content of 5-10%;

[0025] (7) Crushing the coarse ore after the sodiumization in the above step (6) to a diameter of 0.05 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com