Extraction method and application of high-activity collagen

An extraction method and collagen technology, applied in the fields of biotechnology and cosmetics, can solve problems such as shortening the extraction time, and achieve the effects of shortening the extraction time, no skin irritation, and improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

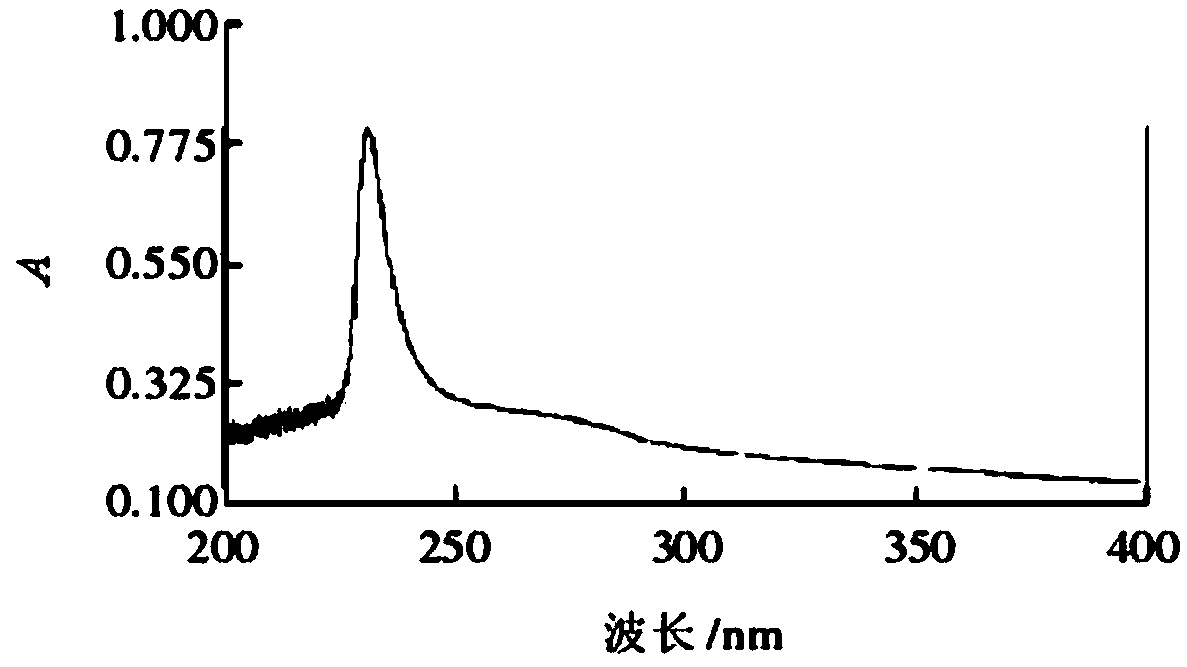

[0034] Example 1: Preparation of baby fish skin collagen

[0035] Step 1: Tissue fragmentation: After thawing the adult (weight 2-3 kg) baby fish (artificially farmed) skin, add water so that the weight ratio of the skin to water is 10:1. The mixture is crushed and ground. Ultrasound is applied at the same time of crushing and grinding, the intensity of ultrasonic is controlled at 800 watts / liter, and the processing time of ultrasonic is 30 minutes to obtain slurry;

[0036] The second step is to remove salt-soluble impurities: mix the slurry with sodium chloride solution (mass concentration 5%), the weight ratio of slurry to sodium chloride solution is 1:5, stir well, soak for 15h, 1500rpm, centrifuge for 10min, Remove the supernatant to obtain the first precipitate;

[0037] Step 3, remove acid-soluble impurities: mix the first precipitate with citric acid solution (mass concentration is 6%), the weight ratio of the first precipitate to acid solution is 1:5, soak for 6h, 1500rpm, ...

Embodiment 2

[0042] Example 2: Preparation of Tilapia Skin Collagen

[0043] Step 1: Tissue fragmentation: After thawing adult tilapia skins (weight 2-3 kg), add water to make the weight ratio of skin to water 10: (0.2-1), crush and grind the mixture , The ultrasonic effect is applied while crushing and grinding, the ultrasonic intensity is controlled at 900 watts / liter, the ultrasonic processing time is 40 minutes, and the slurry is obtained;

[0044] The second step is to remove salt-soluble impurities: mix the slurry with sodium chloride solution (mass concentration 5%), the weight ratio of slurry to sodium chloride solution is 1:5, stir well, soak for 15h, 1500rpm, centrifuge for 10min, Remove the supernatant to obtain the first precipitate;

[0045] Step 3, remove acid-soluble impurities: mix the first precipitate with citric acid solution (mass concentration is 6%), the weight ratio of the first precipitate to acid solution is 1:5, soak for 6h, 1500rpm, centrifuge for 10min, remove the sup...

Embodiment 3

[0050] Example 3: Preparation of cod fish skin collagen

[0051] Step 1: Tissue fragmentation: After thawing adult (2-3 kg) cod skin, add water to make the weight ratio of skin to water 10:0.2-1, crush and grind the mixture, and then Ultrasound is applied at the same time of grinding, the intensity of ultrasonic is controlled at 750 watts / liter, and the processing time of ultrasonic is 60 minutes to obtain slurry;

[0052] The second step is to remove salt-soluble impurities: mix the slurry with sodium chloride solution (mass concentration 5%), the weight ratio of slurry to sodium chloride solution is 1:5, stir well, soak for 15h, 1500rpm, centrifuge for 10min, Remove the supernatant to obtain the first precipitate;

[0053] Step 3, remove acid-soluble impurities: mix the first precipitate with citric acid solution (mass concentration is 6%), the weight ratio of the first precipitate to acid solution is 1:5, soak for 6h, 1500rpm, centrifuge for 10min, remove the supernatant , Get t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com