Adapter for measuring a physical variable

An adapter, variable technology for measuring heat, measuring instrument components, measuring devices, etc., that solves problems such as time and cost, down tube or flange plate distortion, lack of fusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

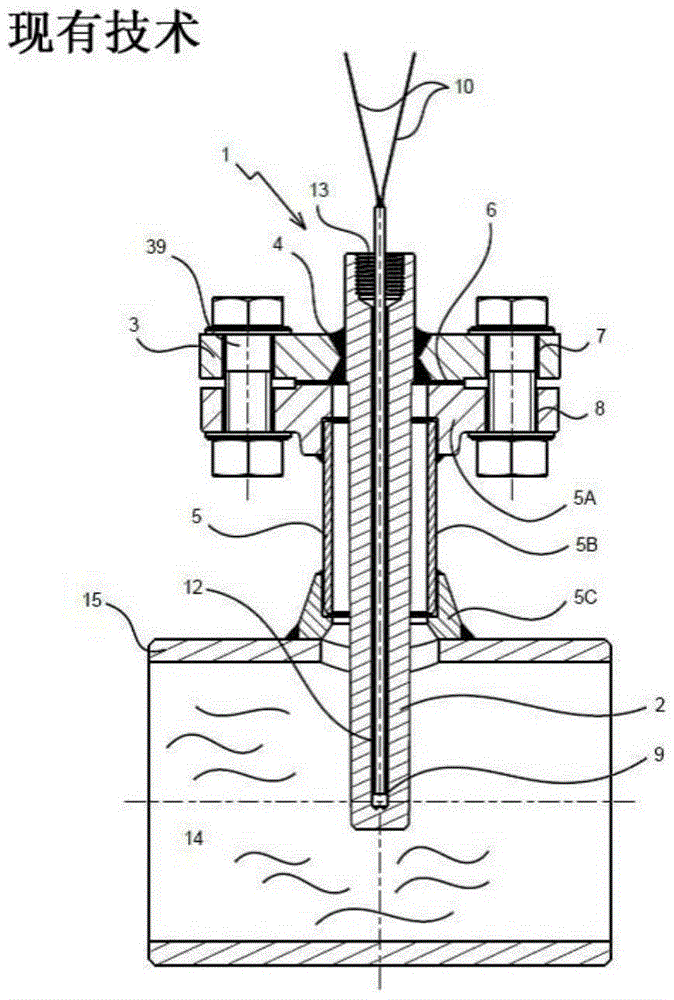

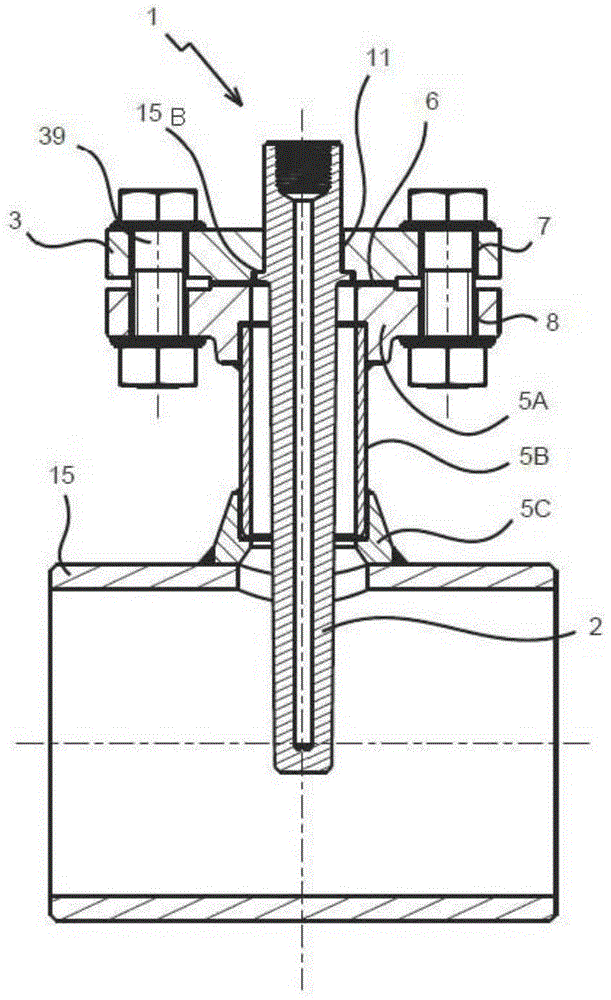

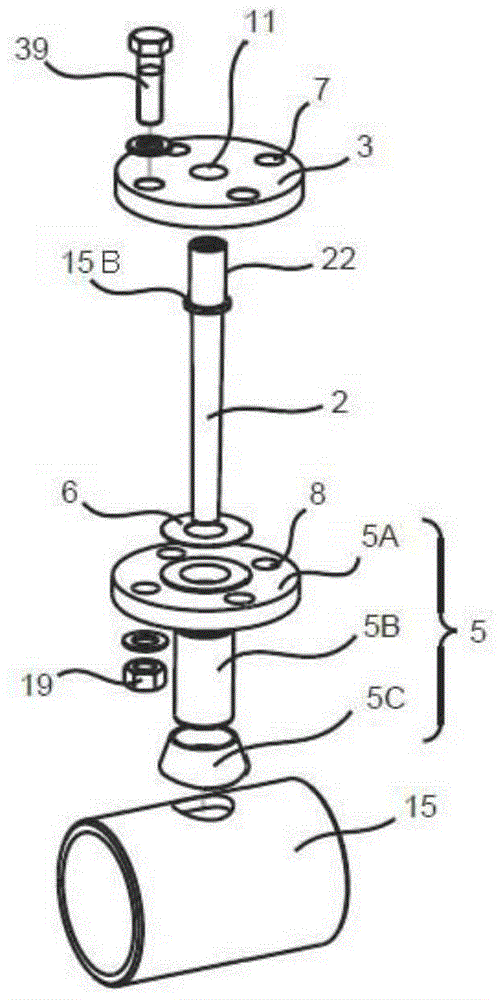

[0046] figure 1 The prior art is shown in the form of a normal welded adapter 1, consisting of a downtube 2 and a flange plate 3, where the downtube is joined to the flange plate and is welded to the flange plate typically in several passes in the circumferential direction. 3 welded together.

[0047] Then, the finished adapter is fitted into the connection opening 5 . The finished adapter comprises, for example, a flange plate 5A, which is sealingly connected to the system part 15 through an extension tube 5B, usually by means of a weld-on sleeve 5C.

[0048] Due to the complicated welding, such adapters, so-called "full penetration parts" or "full penetration welding protection tubes" have in fact been tested on the market, but are expensive to manufacture due to the long welding times. Furthermore, such structures are often misaligned with respect to each other, making rotation difficult or impossible.

[0049] After being assembled to the connection opening 5 by means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com