Method and adjusting installation for producing a stretch of railway

An adjustment mechanism and railway technology, applied in the directions of roads, paved tracks, tracks, etc., can solve the problem of difficult and precise positioning of long tracks, achieve precise independent positioning, ensure horizontal and vertical, and ensure the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

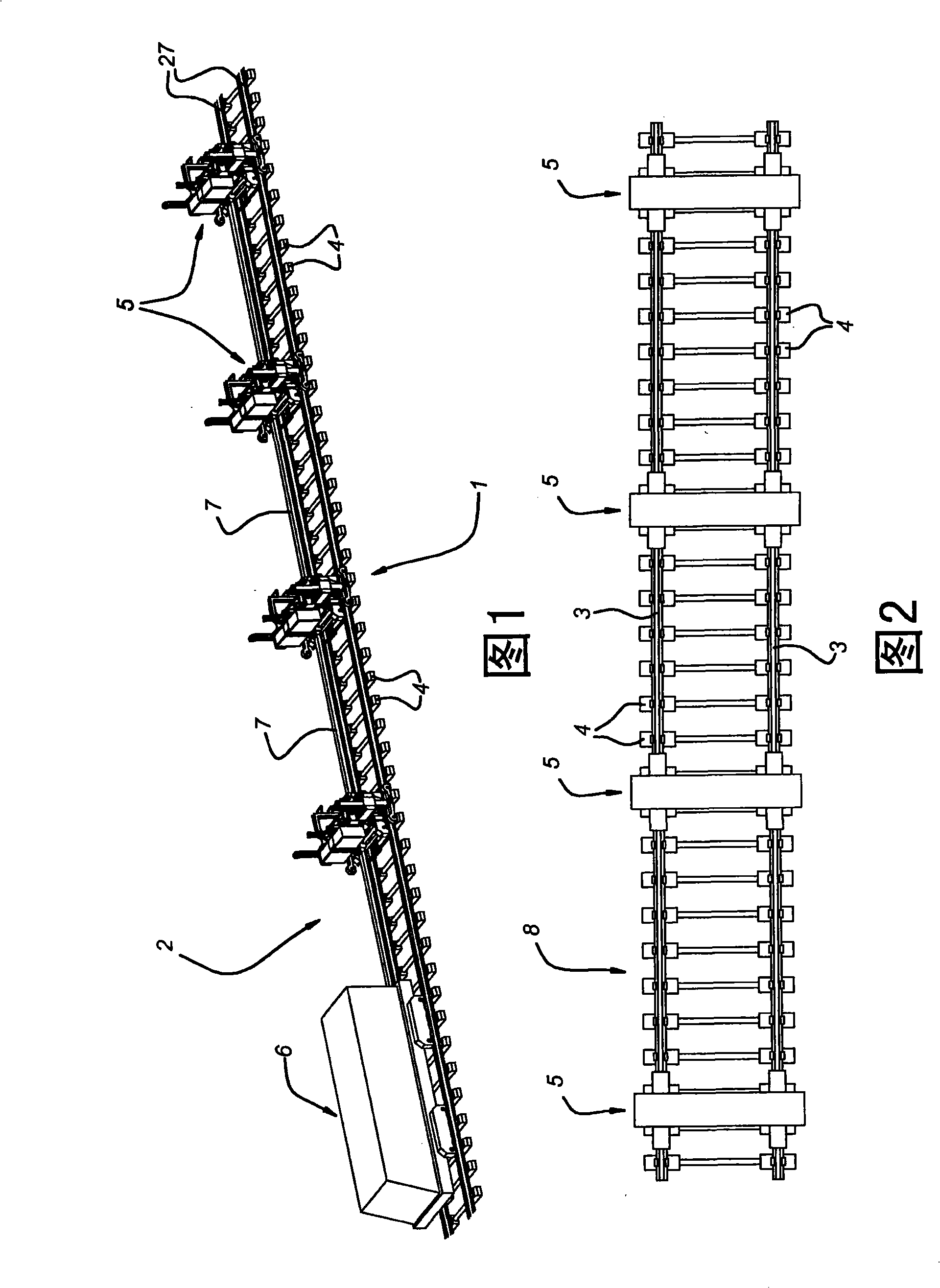

[0050] Fig. 1 shows a railway section 1 on which is shown an adjustment mechanism 2 (which is indicated in its entirety with 2) for carrying out the method according to the invention. The railway section 1 comprises crossties 4 which are connected to one another by means of rails 27 . In the shown example of embodiment, the adjustment mechanism 2 comprises four adjustment brackets 5 and a motorized stage 6 for moving the adjustment mechanism 2 . By means of connecting rods 7, the stand 6 and the adjustment bracket are connected to each other.

[0051] FIG. 1 shows the adjusting mechanism 2 on a ready-concreted railway section 1 . This means that permanent tracks can already be applied to the sleepers 4, but these could also be temporary tracks.

[0052] On the other hand, in the view from above in FIG. 2 , a system designated 8 is shown in its entirety, comprising thirty sleepers 4 connected to rails 3 . These rails 3 are not permanent rails as in FIG. 1 , but precisely for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com