A textile product comprising metal cords and non-metallic fibers, and a semifinished sheet comprising such textile product

A technology of non-metallic fibers and textile products, applied in the field of textile products containing metal wires and non-metallic fibers and semi-finished boards containing such textile products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

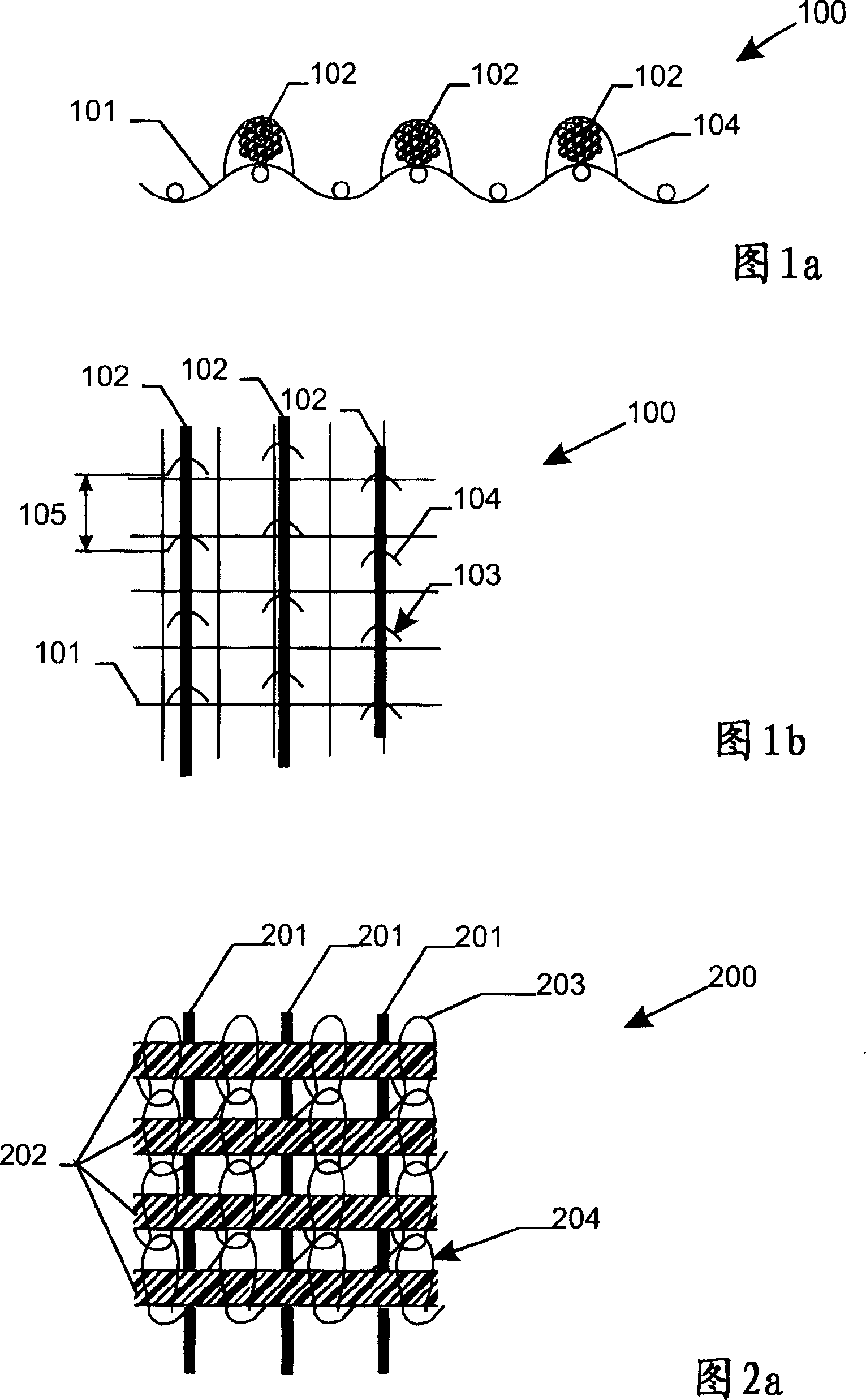

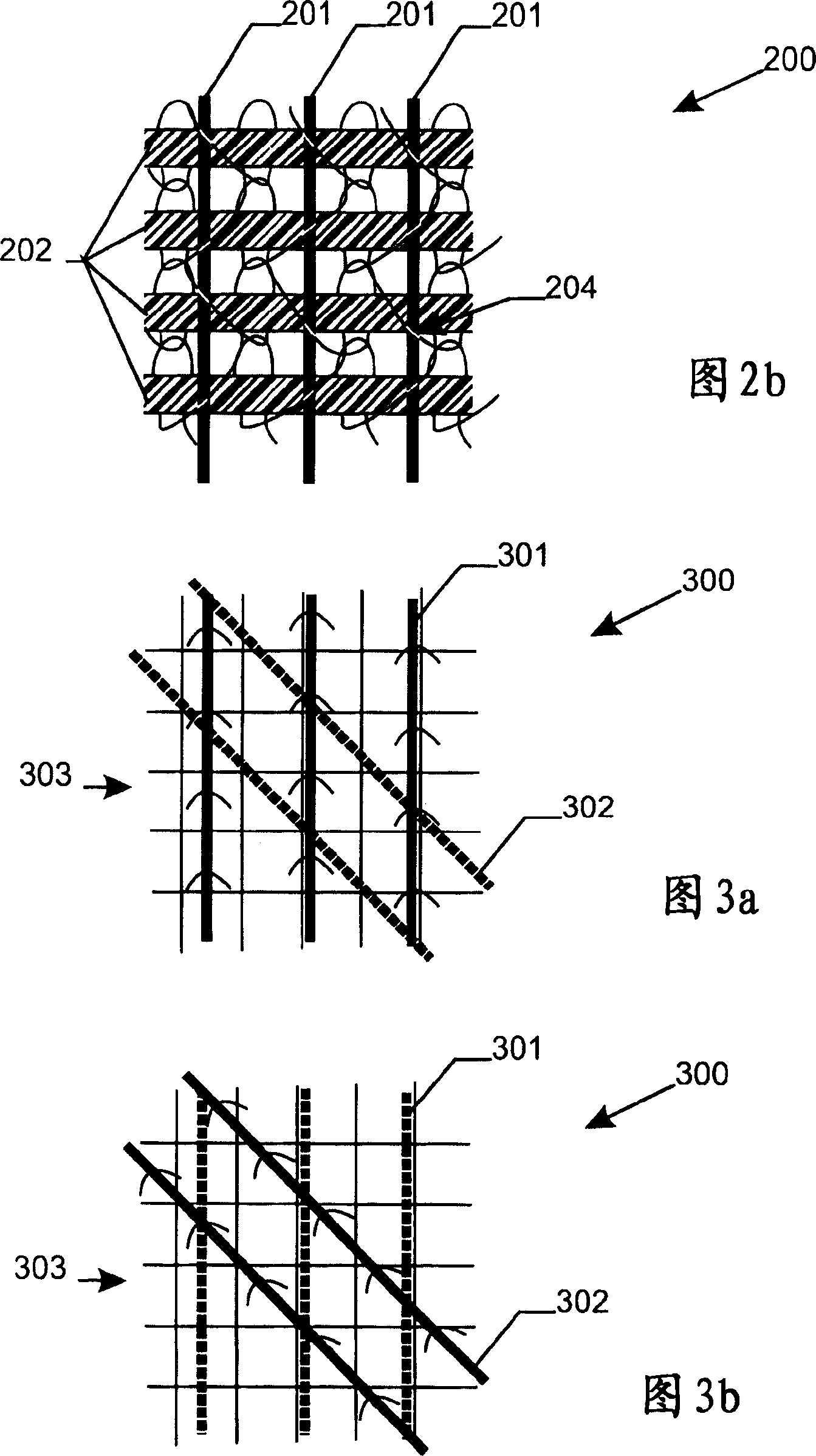

[0060] A first embodiment of a textile product 100 according to the invention is shown schematically in FIGS. 1 a and 1 b , which are a side view ( FIG. 1 a ) and a top view ( FIG. 1 b ) of the textile product 100 .

[0061] The non-metallic fiber layer 101 is a woven fabric made of glass fiber rovings of 1200 to 2400 tex, with a fiber diameter of 15 to 20 μm and a weight of 200 to 2000 g / m 2 between. PP compatible sizing can be used. Alternatively, the fiber rovings or yarns comprise PET or aramid fibers adjacent to the glass fibers of the woven fabric. This combination of different fibers can be provided in the woven fabric by using mixed fiber rovings or fiber rovings used separately from one another.

[0062] The textile article 100 also comprises a metal wire 102, which is a compact wire of the type 0.20+18×0.175, which is understood as a wire comprising a core wire with a diameter of 0.2 mm, around which 18 metal wires with a diameter of 0.175 mm are surrounded Twist ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com