Bogie air spring assembling tool and method for assembling air spring by utilizing same

A technology for air springs and assembling tooling, which is applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of low quality of air springs, and achieve the effect of improving production efficiency, good effect and reducing human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

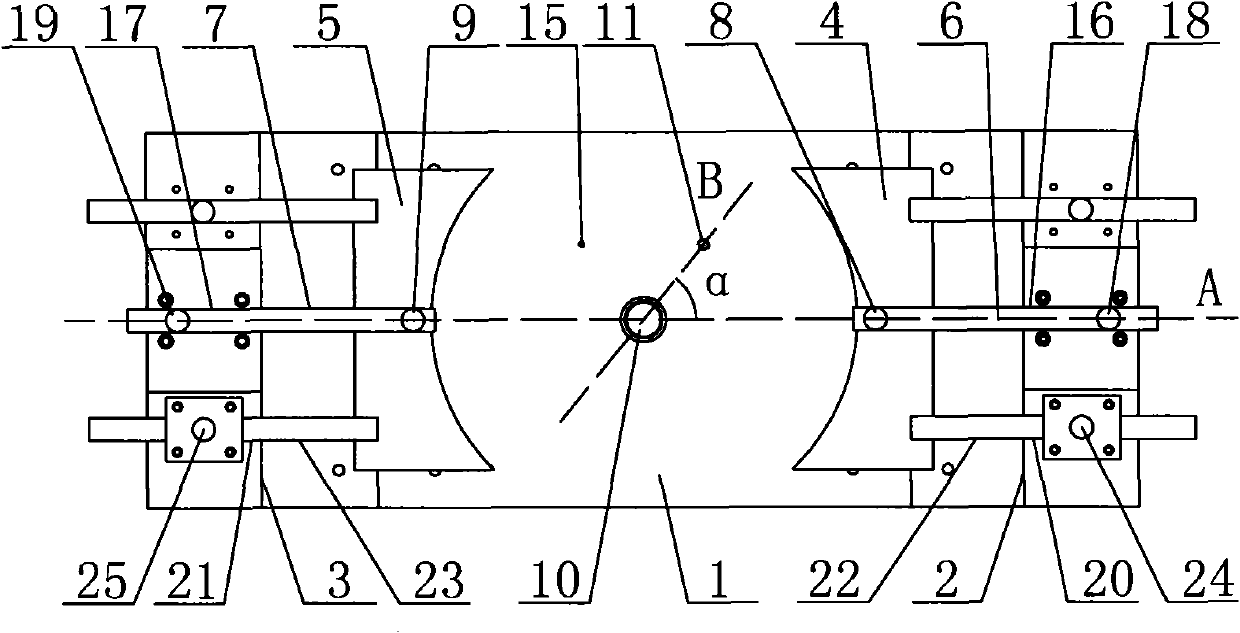

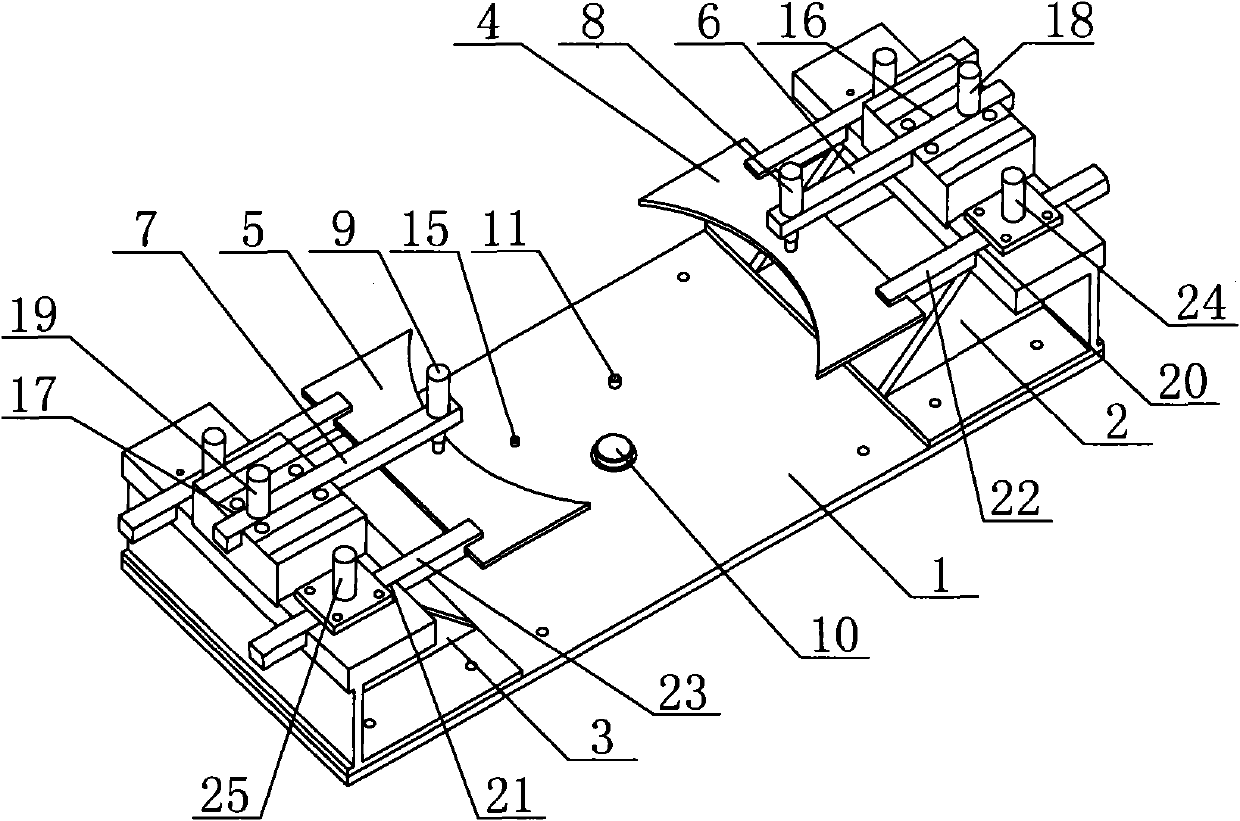

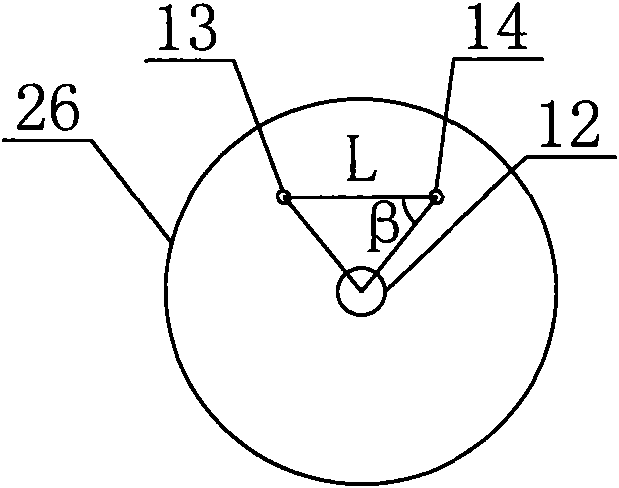

[0022] The bogie air spring assembly tool of the present embodiment, such as figure 1 As shown, it includes: a base plate 1, two brackets 2, 3 located on the left and right sides of the base plate 1, and the two brackets 2, 3 are provided with mutually coplanar surfaces for holding the air spring buckle 28 that can slide toward each other. And support plates 4,5 parallel to the base plate, and slide bars 6,7 that can slide towards each other, the front ends of slide bars 6,7 have vertical through holes, and the vertical through holes are inserted with 28 screw holes with the air spring buckle. Cooperating buckle positioning pins 8, 9 (the buckle positioning pin blocks the vertical through hole, so the vertical through hole is not marked in the figure), the bottom plate 1 has a center hole positioning pin that matches the center hole 12 of the air spring base 26 10. And a screw hole locating pin 11 matched with the screw hole 13 of the first air spring base 26. The center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com