Freight container

The technology of a carriage and a left side plate is applied in the direction of vehicles used for freight, vehicles with inclined bearing motion, and motor vehicles. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

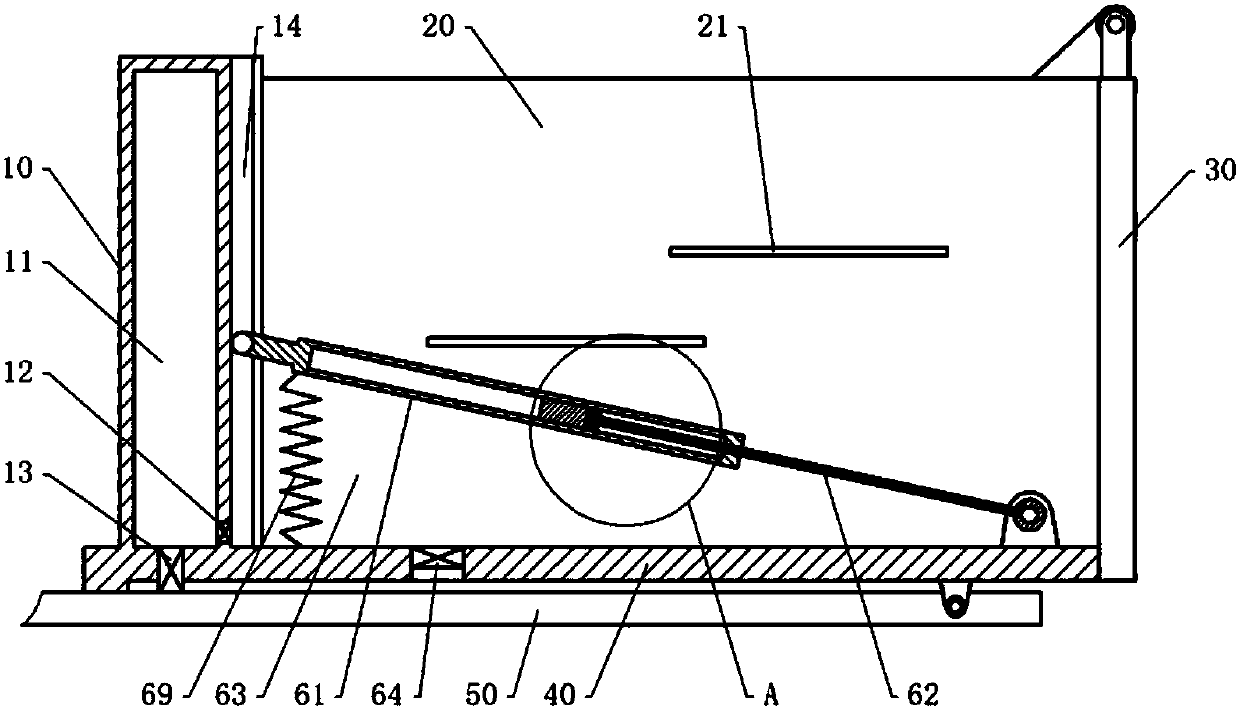

[0023] The present invention will be described in further detail below by means of specific embodiments:

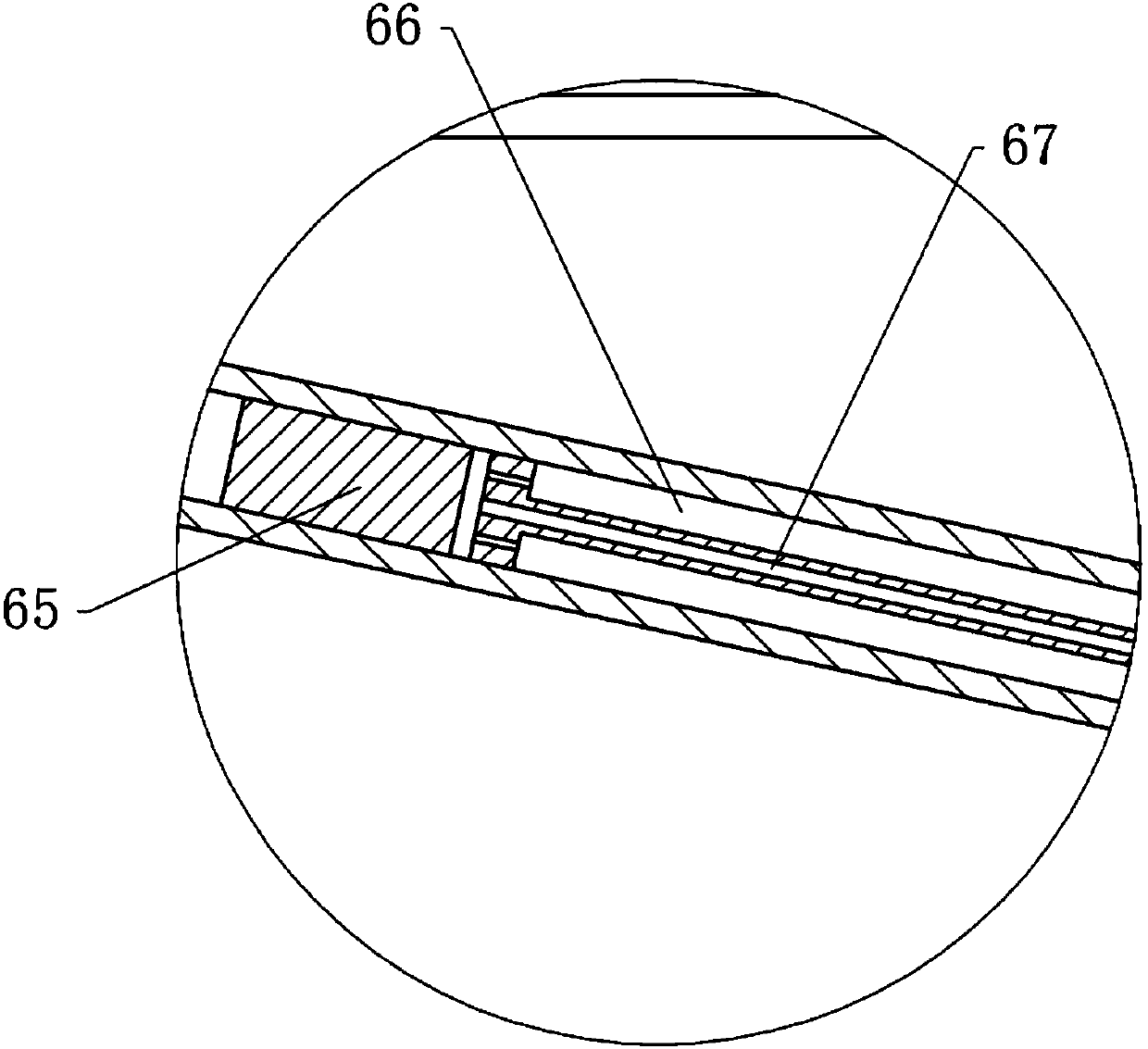

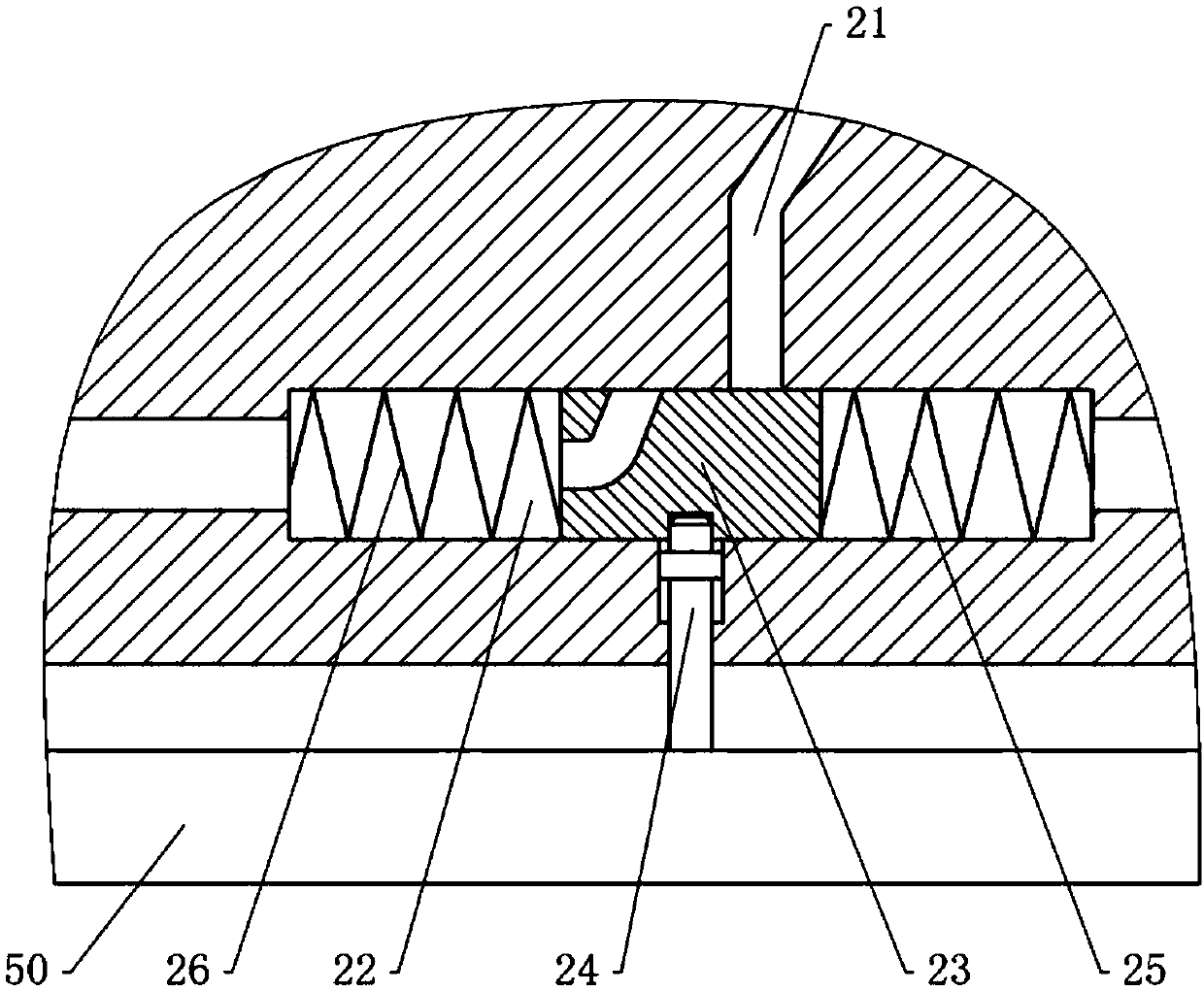

[0024] The reference signs in the drawings of the description include: front plate 10, air collection chamber 11, first one-way valve 12, press valve 13, chute 14, right side plate 20, exhaust port 21, slideway 22, slider 23. Locating pin 24, first spring 25, second spring 26, rear plate 30, bottom plate 40, frame 50, first plate 61, second plate 62, compression chamber 63, second one-way valve 64, piston 65 , inner cavity 66, air flow channel 67, return spring 69,

[0025] The embodiment is basically as figure 1 , figure 2 Shown:

[0026] The cargo compartment of the present embodiment comprises a base plate 40, a front plate 10, a left side plate, a right side plate 20 and a rear plate 30, and the two ends of the top of the rear plate 30 are respectively hinged on the left side plate and the right side plate 20, and the base plate 40 , front plate 10, left side pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com