A pneumatic magnetic pump

A technology of magnetic pump and pump body, applied in the direction of pump, pump device, non-variable-capacity pump, etc., can solve the problems of large shear rate and large flow pulse, avoid impact and corrosion, small pulse and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

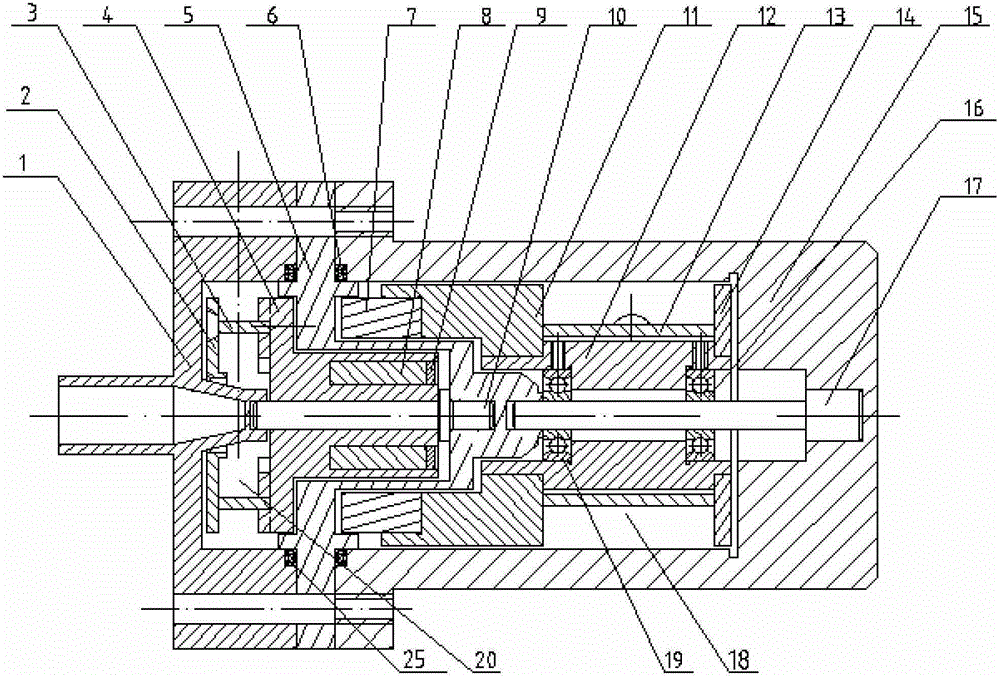

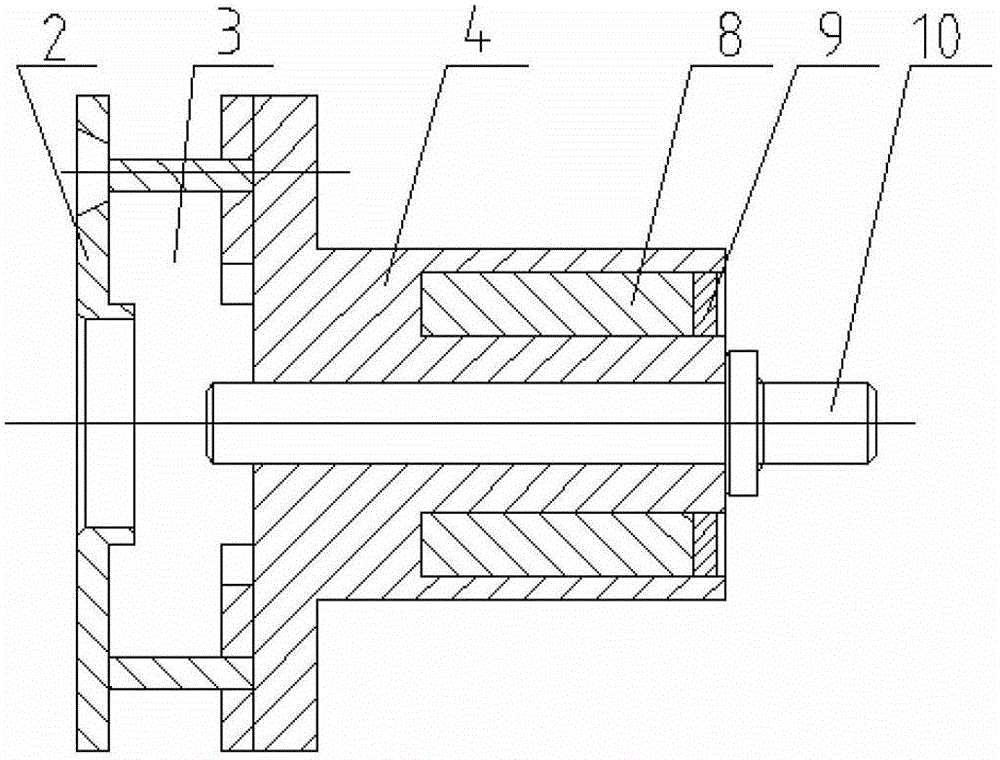

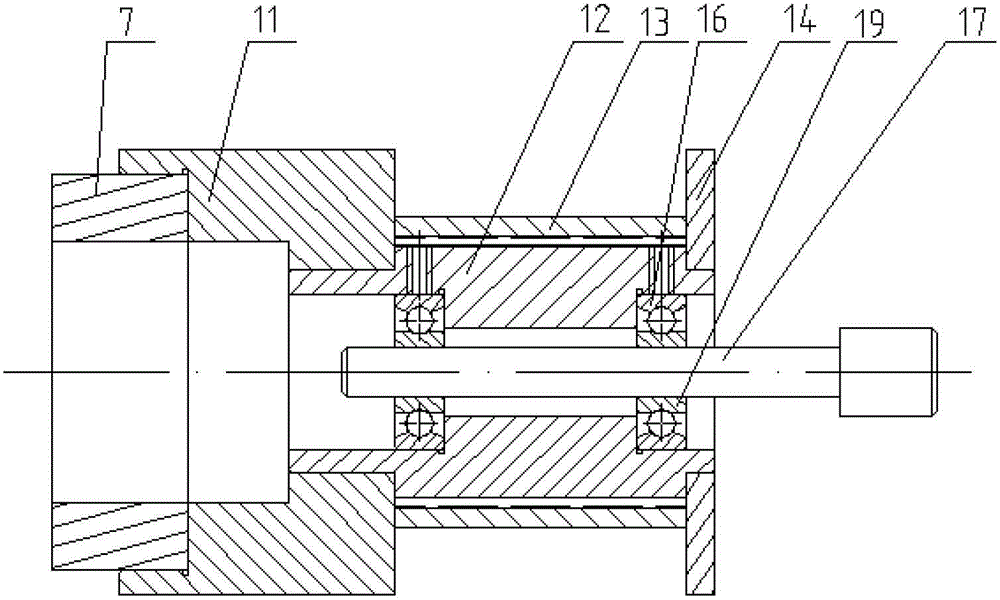

[0028] Such as Figure 1 to Figure 11 As shown, a pneumatic magnetic pump device includes a left pump body 1, a conveying part 20, a conveying impeller shaft 10, a sealing ring 6, a shielding sleeve 5, a driving part 18, a driving impeller shaft 17, a deep groove ball bearing I16, a deep groove Ball bearing II19, right pump body 15;

[0029] The left pump body 1, conveying part 20, conveying impeller shaft 10, shielding sleeve 5, driving part 18, driving impeller shaft 17, and right pump body 15 are connected in sequence; the conveying impeller shaft 10 is located between the left pump body 1 and the shielding sleeve 5 Between them, the conveying part 20 is set on the conveying impeller shaft 10; the conveying impeller shaft 10 is connected with the shielding sleeve 5 in the way of interference fit and shaft shoulder positioning, and adopts a clearance fit with the conveying part 20 and the left pump body 1; the driving impeller The wheel shaft 17 is located between the shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com