Reciprocating compressor

A compressor and reciprocating technology, applied in the direction of liquid variable displacement machinery, mechanical equipment, engine components, etc., can solve the problems of exhaust valve system damage, increase valve chamber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

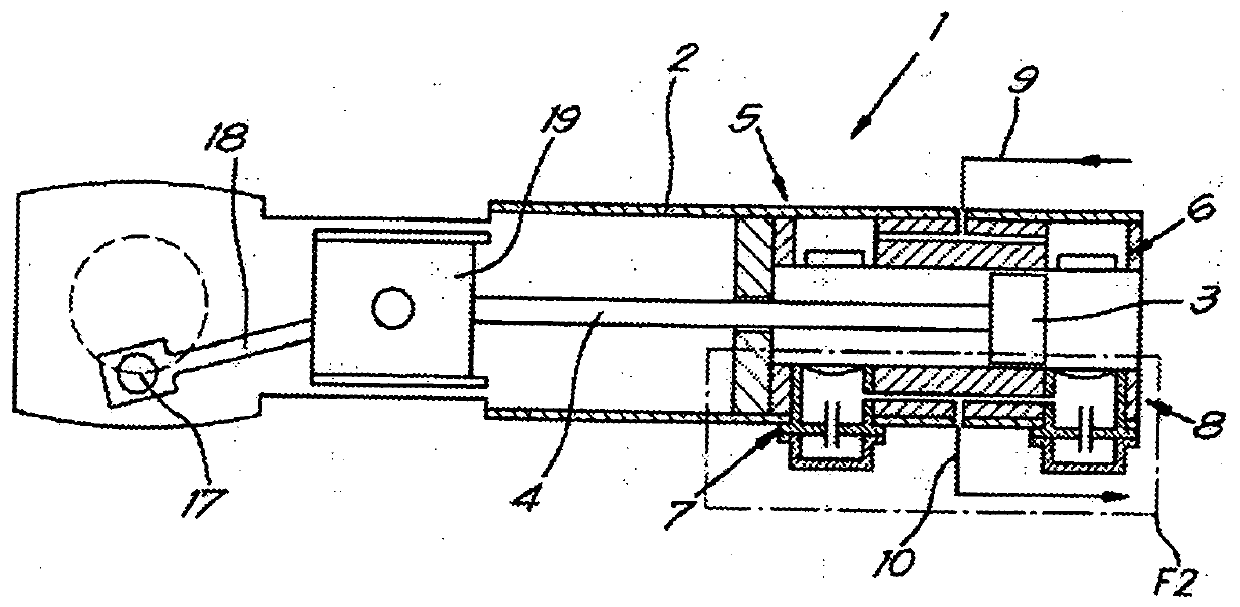

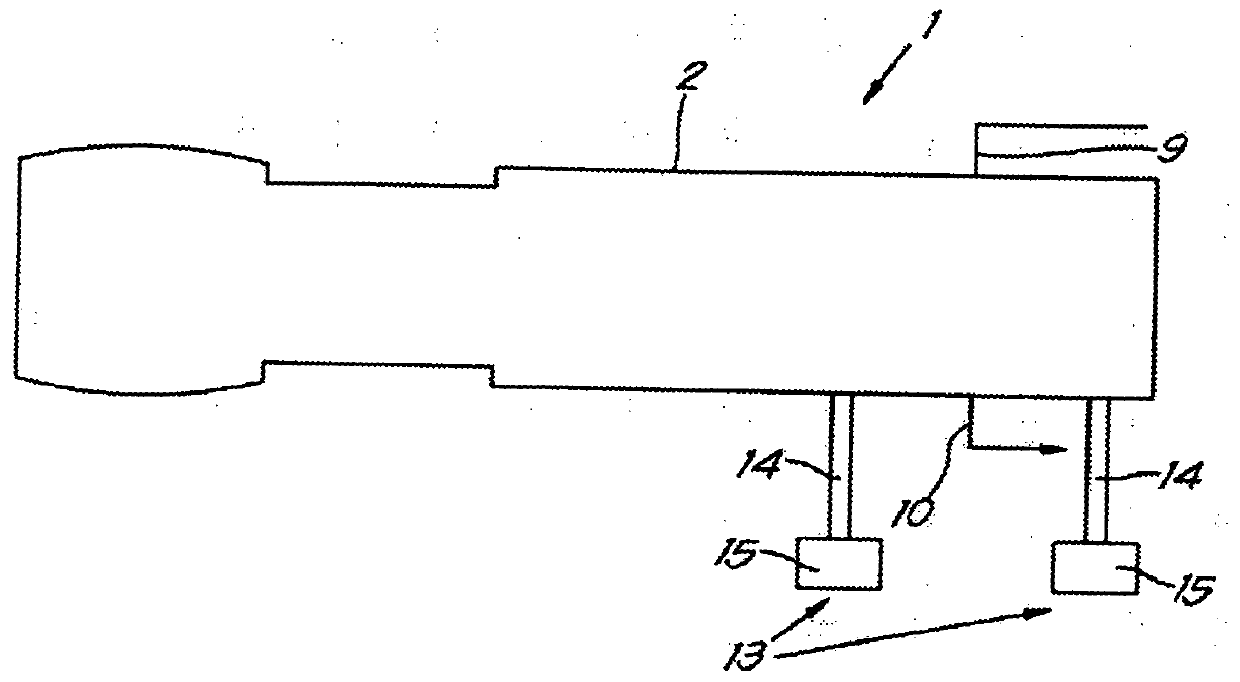

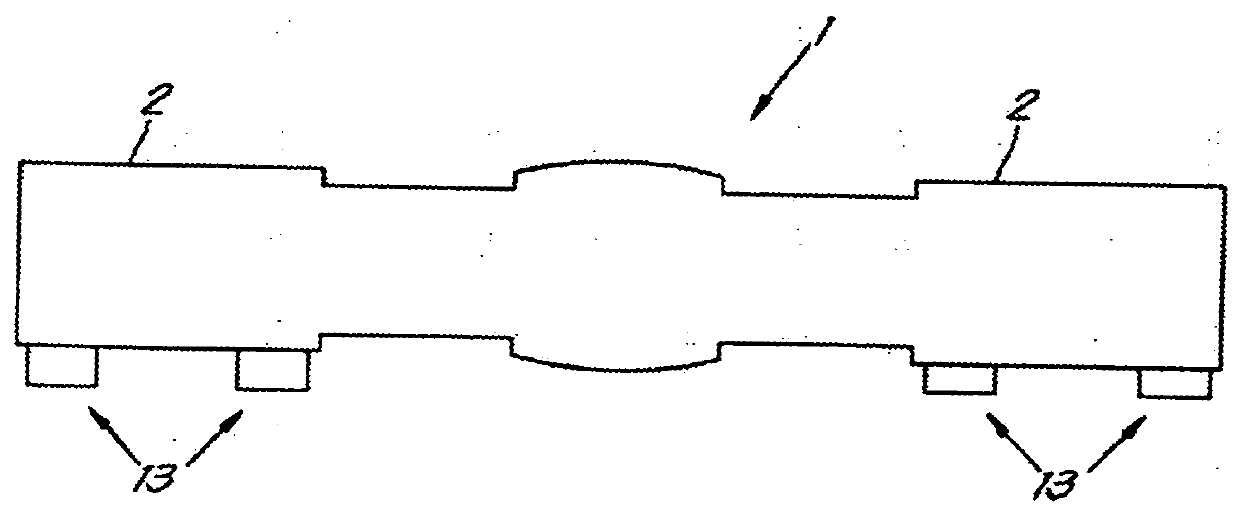

[0018] exist figure 1 with 2 In , a reciprocating compressor 1 according to the invention is shown. Said compressor 1 comprises a cylinder 2 comprising an internal cylindrical cavity in which a piston 3 will be housed. Said piston 3 movable inside said cavity forms part of a device capable of reciprocating movement, which also includes a piston rod 4 .

[0019] The compressor 1 also includes drive means configured to move said device in reciprocating motion, said drive means optionally including a crankshaft.

[0020] Said piston 3 divides said cavity into a first chamber and a second chamber, denoted by the terms "head side end chamber" and "crankshaft side end chamber" respectively , each of the first and second chambers is connected to a respective suction duct 9 and exhaust duct 10 via a respective suction valve system 5 or 6 and an exhaust valve system 7 or 8 .

[0021] Said suction valve systems 5 and 6 and said discharge valve systems 7 and 8 each comprise a valve h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com