Heavy truck cab hydraulic hoisting radial plunger pump

A cab and radial column technology, which is applied in the field of hydraulic lifting of heavy-duty truck cabs, can solve the problems of high manufacturing cost, large pulse, and high labor intensity, and achieve the effect of low manufacturing cost, small pulse, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

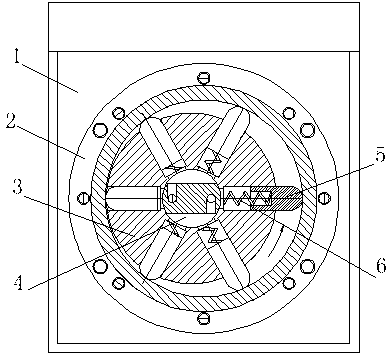

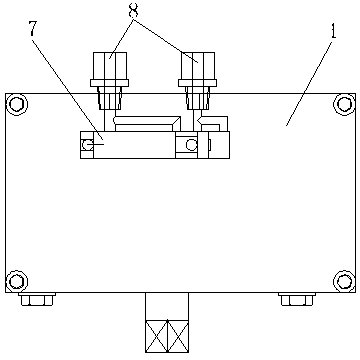

[0010] attached figure 1 It is the front view of the embodiment of the heavy-duty truck cab hydraulic lift radial plunger pump with five sets of plunger units, attached figure 2 It is a top view of an embodiment of the heavy-duty truck cab hydraulic lift radial piston pump with five sets of plunger units in the present invention. In the figure, 1 is the pump body, 2 is the stator, 3 is the rotor, 4 is the oil distribution plate, and 5 is the Plunger, 6 is a spring, 7 is a reversing valve, and 8 is an external pipeline. As can be seen from the figure, the heavy-duty truck cab hydraulic lift radial piston pump of the present invention includes a pump body 1, a stator 2, a rotor 3, an oil distribution plate 4 and a reversing valve 7; The plug unit; the stator 2 and the rotor 3 are arranged eccentrically; the oil distribution plate 4 is arranged in the center of the rotor 3, and is provided with an oil inlet channel and an oil outlet channel and respectively connected to the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com