Snow tire

A technology for snow tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve problems such as poor wet skid resistance, insufficient handling, and insufficient snow safety, and achieve Effects of increasing grip, improving safety, improving adhesion and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

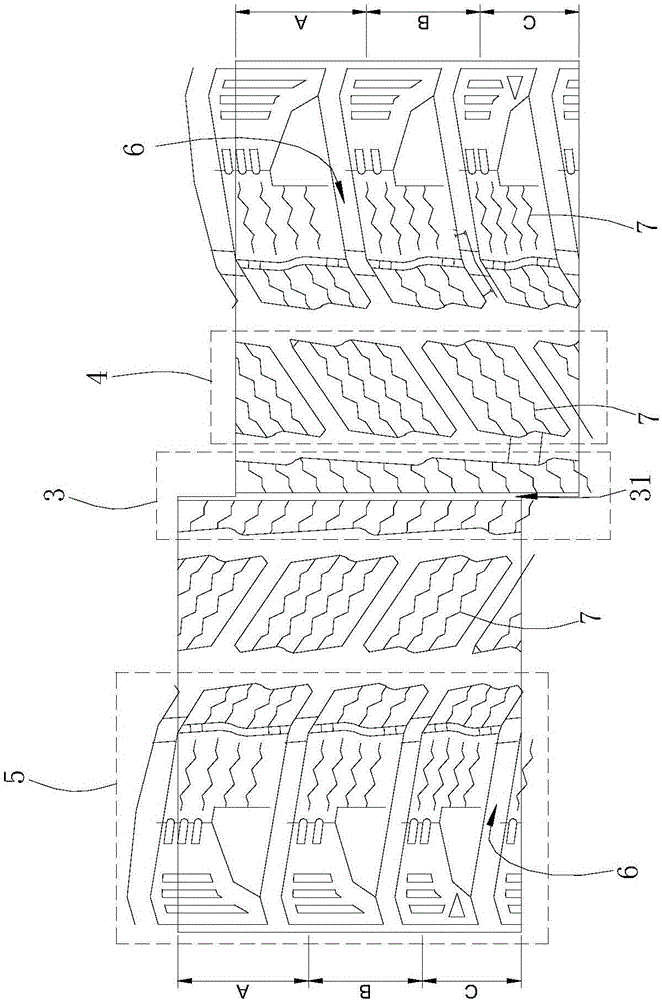

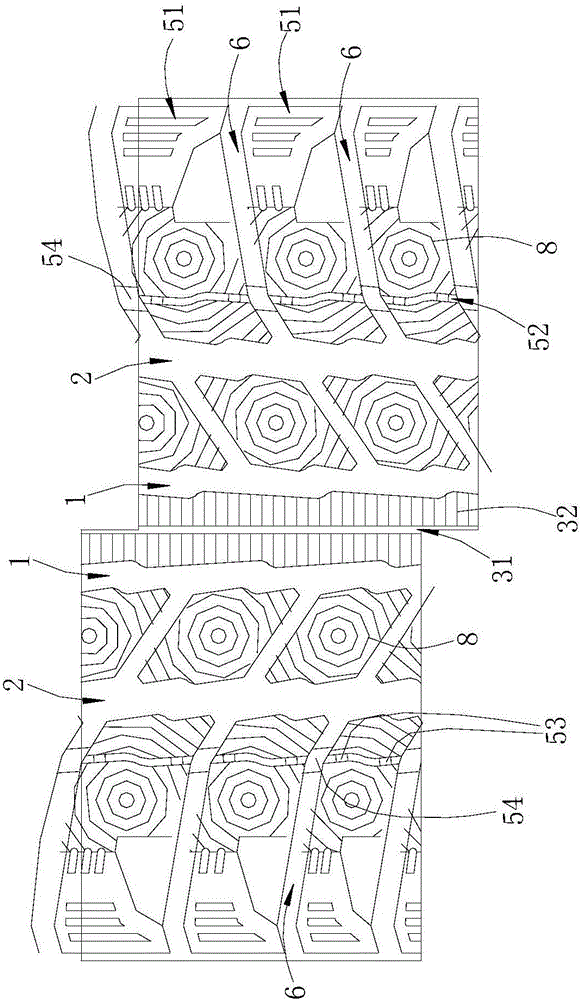

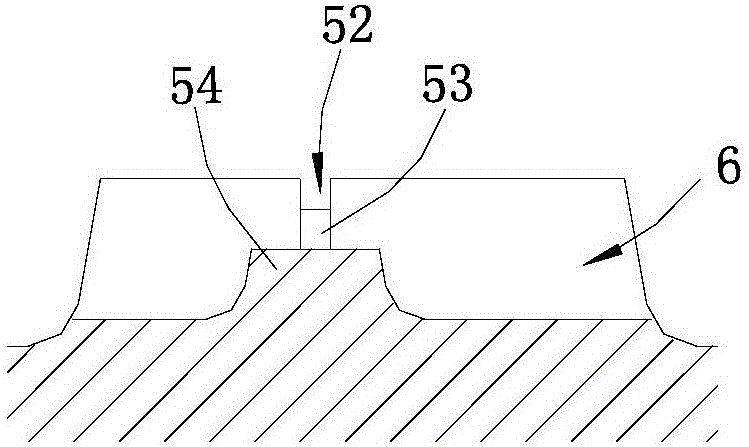

[0020] Such as Figures 1 to 3 As shown (for the sake of brevity and easy understanding of the view, figure 1 The horizontal fine lines 32 on the central land portion 3 and the concentric circular fine lines 8 on the pattern blocks of the secondary land portion 4 and the side land portion 5 are omitted in figure 2 The preset steel sheet 7) on the tire surface is omitted.

[0021] A pair of circumferential main grooves 1 and a pair of circumferential auxiliary grooves 2 are formed on the outer surface of the snow tire. The two circumferential auxiliary grooves 2 are located on both sides of the two circumferential main grooves 1. The sub-grooves 2 divide the tread into a central land portion 3 , two sub-side land portions 4 and two side land portions 5 .

[0022] The central land portion 3 is located between the two circumferential main grooves 1, the two auxiliary side land portions 4 are respectively located between the corresponding circumferential main grooves 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com