Highway-railway dual-purpose six-wheel drive traction locomotive and traction method

A dual-purpose six-wheel drive, traction locomotive technology, which is applied to rail and road dual-purpose vehicles, motor vehicles, railway car body parts, etc. The complex structure of the frame can be reduced to reduce potential safety hazards, enhance the ability to get out of trouble, and have a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

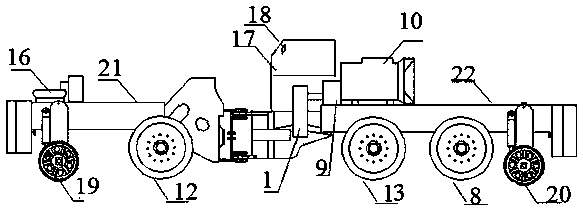

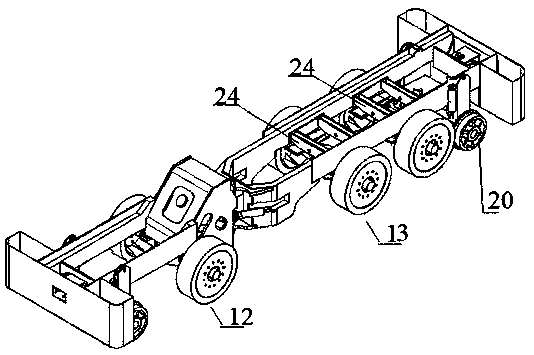

[0023] A road-rail dual-purpose six-wheel-drive traction locomotive, such as figure 1 and 2 As shown, including front frame 21, rear frame 22, transmission device, braking device, balance device, guide wheel lifting device and working video system, front frame 21 (length 3.9m) and rear frame 22 (length 5.6m) m) Hinged by the hinge pin.

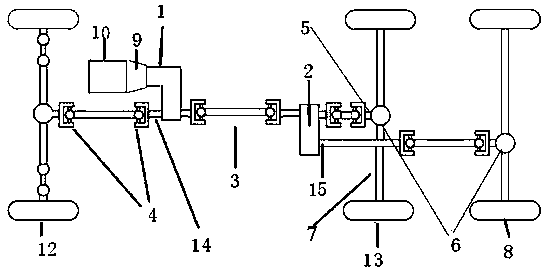

[0024] like image 3As shown, the transmission device includes an engine 10 (model Weichai WP10G240E341, power 178KW), a torque converter 9 (in the form of twin turbo four elements), a front drive shaft 14, a rear drive shaft 3, a transfer device, a half shaft 7, a differential device 6 (see Image 6 ), wheel reducer 23 (see Figure 7 ), the front wheel 12 , the middle wheel 13 and the rear wheel 8 , the middle wheel 13 and the rear wheel 8 are arranged on the rear frame 22 .

[0025] The transfer device is composed of a transfer device 1 1 and a transfer device 2 2. The transfer device 1 is a gearbox with the output shaft extending forwa...

Embodiment 2

[0034] The difference between the road-rail dual-purpose six-wheel-drive traction locomotive in the present embodiment and the embodiment 1 is:

[0035] The transfer device 1 is the transfer case, and the output shafts are the front drive shaft 14 and the rear drive shaft 3 respectively. Figure 16 shown;

[0036] The swing frame 24 also includes a pair of vertical plates (790 mm long, 240 mm high and 10 mm thick). The vertical plates are located at two ends of the horizontal plate 242 respectively. The vertical plates are perpendicular to the horizontal plate 242 and are fixedly connected. The vertical plates are closely attached to the rear frame 22 of the traction locomotive. The inner surface is fixedly connected with the rear frame 22;

[0037] The working video system also includes two laser ranging sensors, namely laser ranging sensor 1 and laser ranging sensor 2, which are installed on the front and rear ends of the locomotive, and are connected and communicated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com