Patents

Literature

74 results about "Twin-turbo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Twin-turbo refers to a engine in which two turbochargers compress the intake fuel/air mixture (or intake air, in the case of a direct-injection engine). The most common layout features two identical turbochargers in parallel; other twin-turbo layouts include sequential and staged turbocharging.

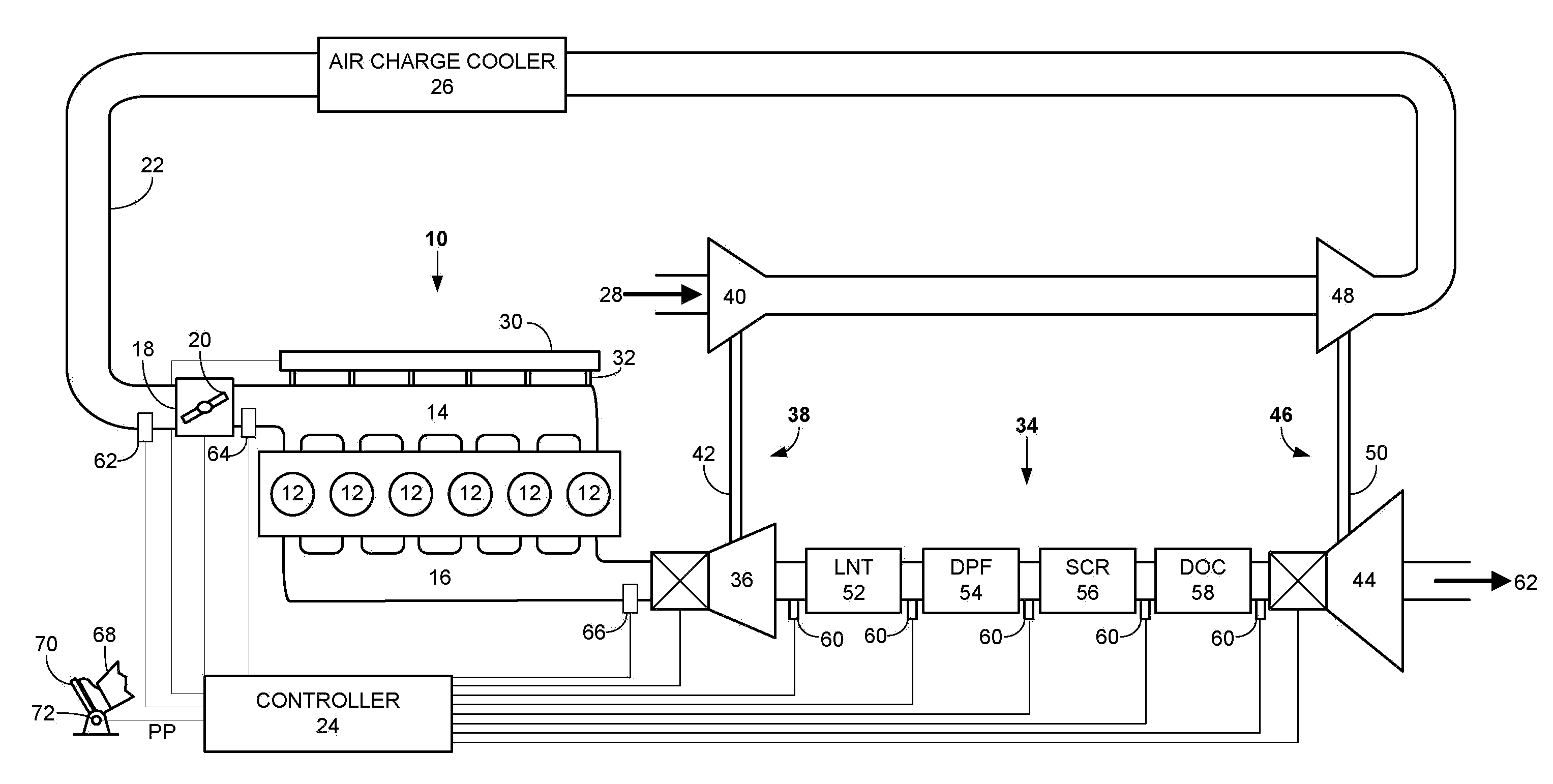

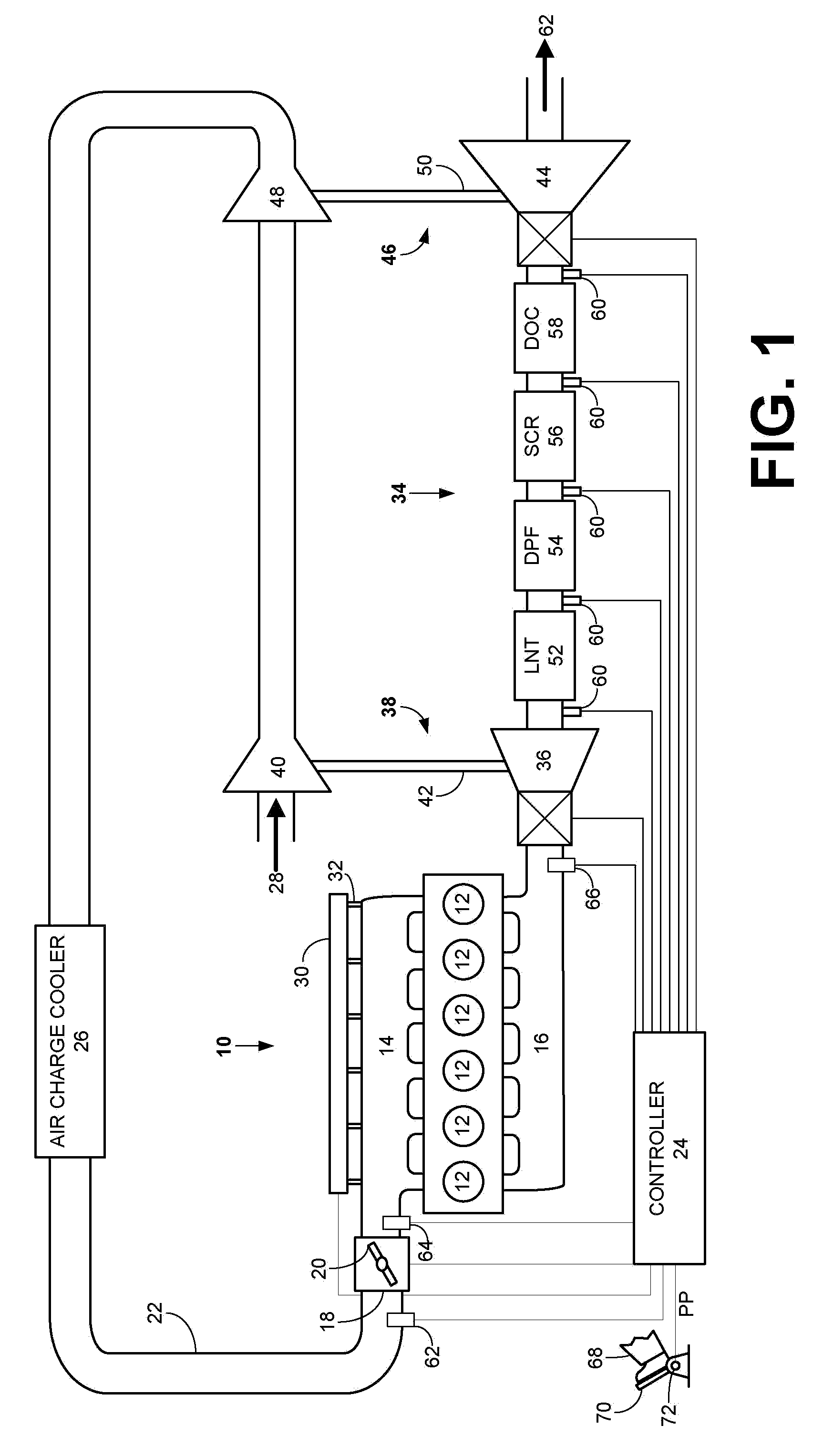

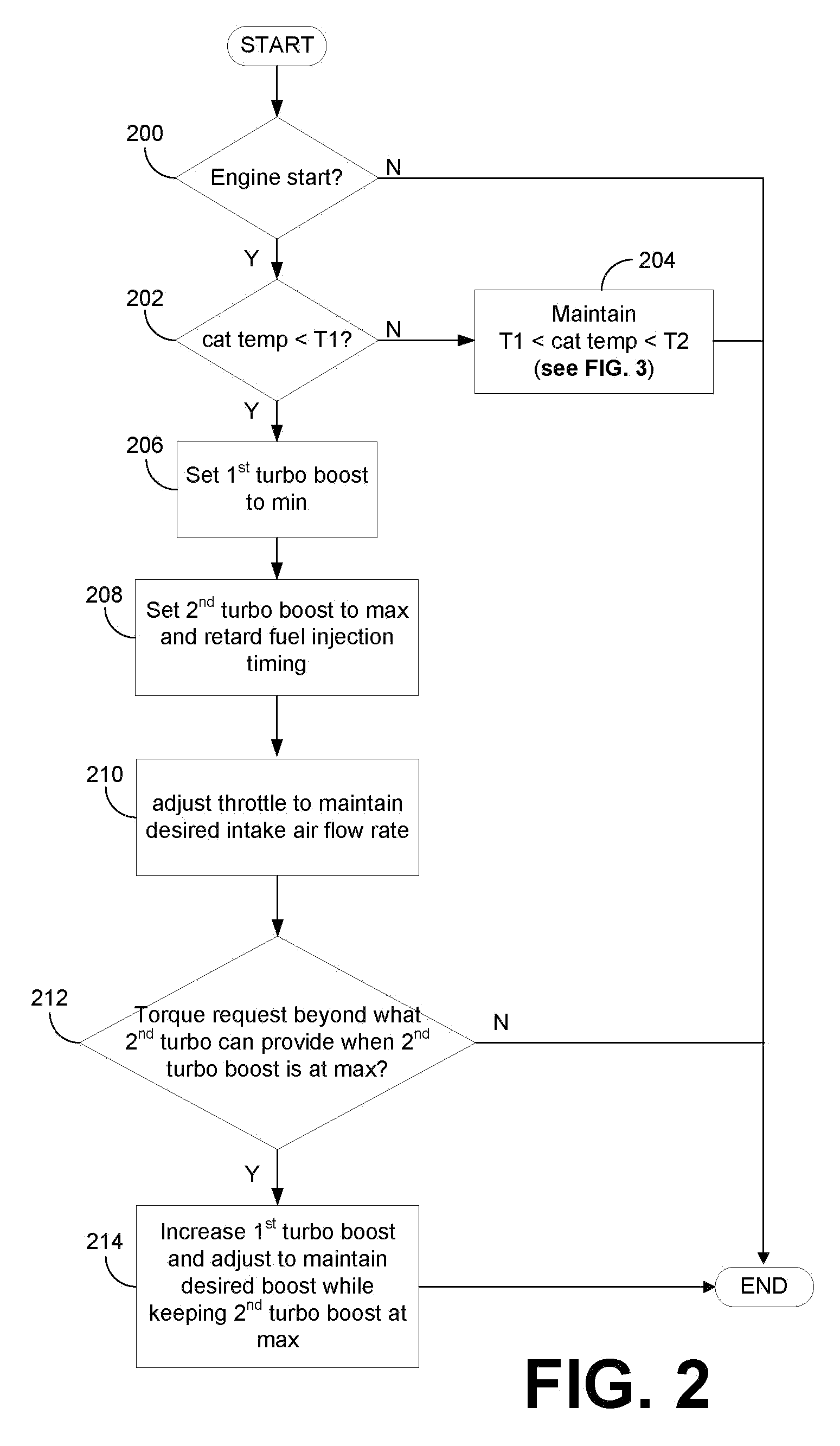

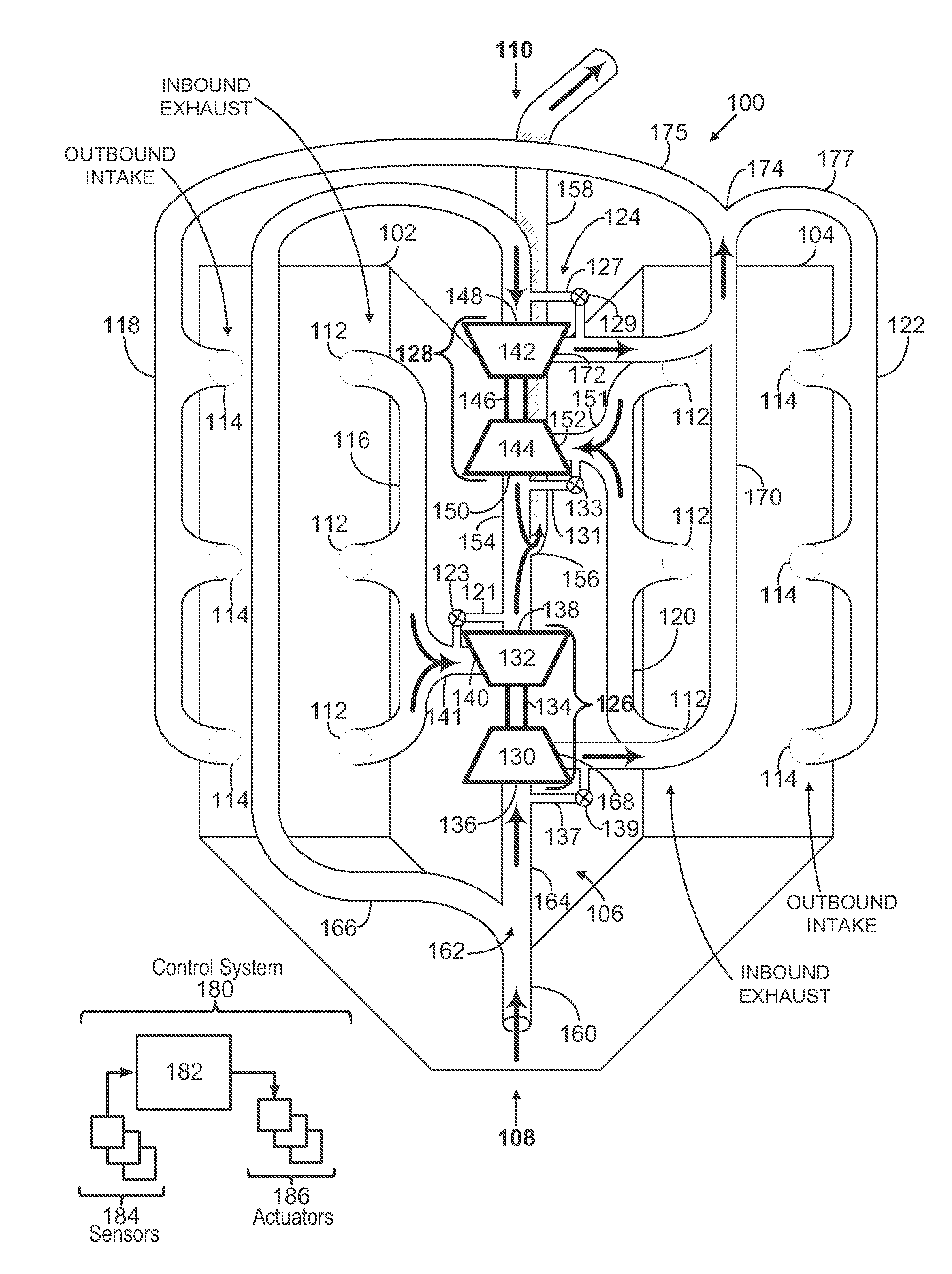

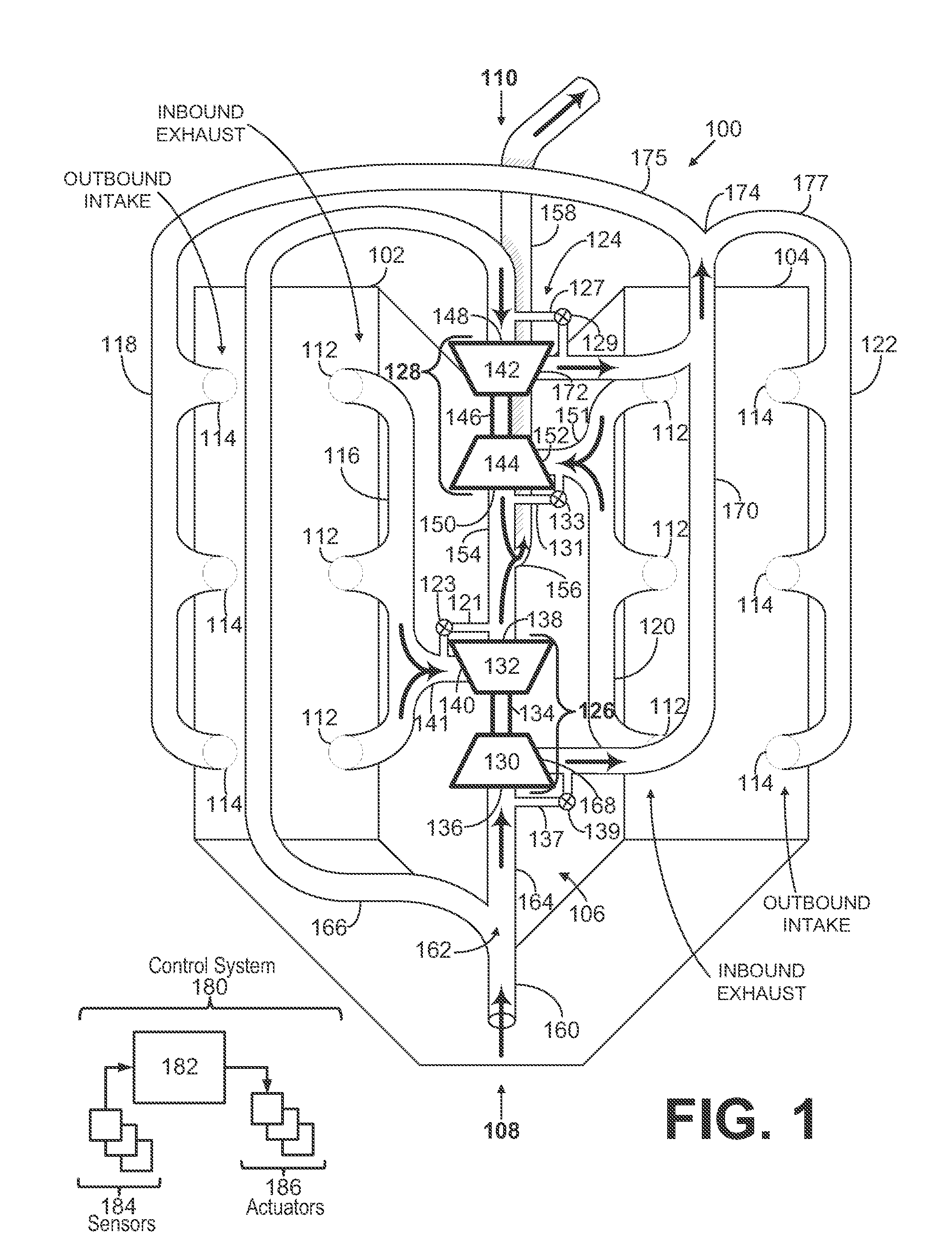

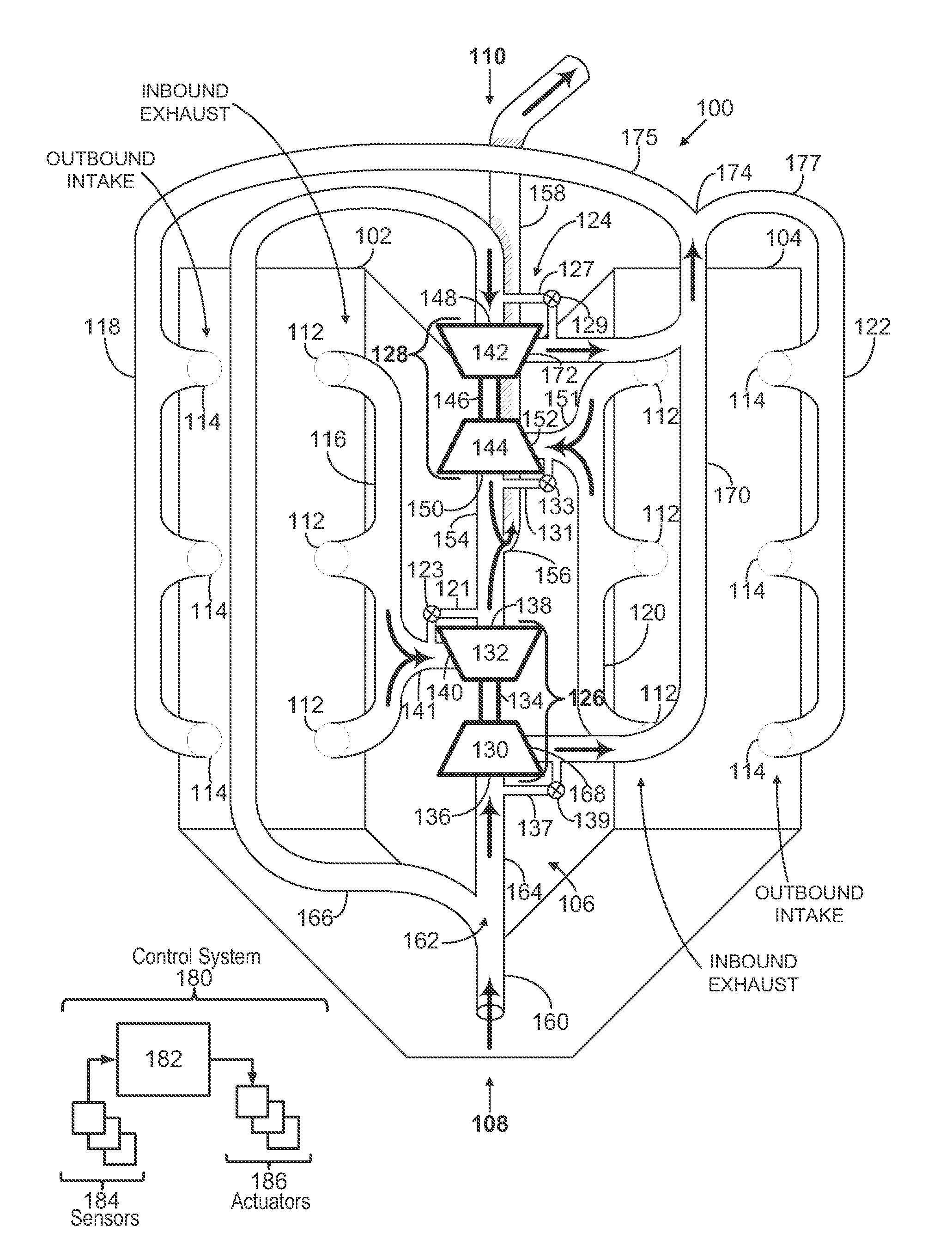

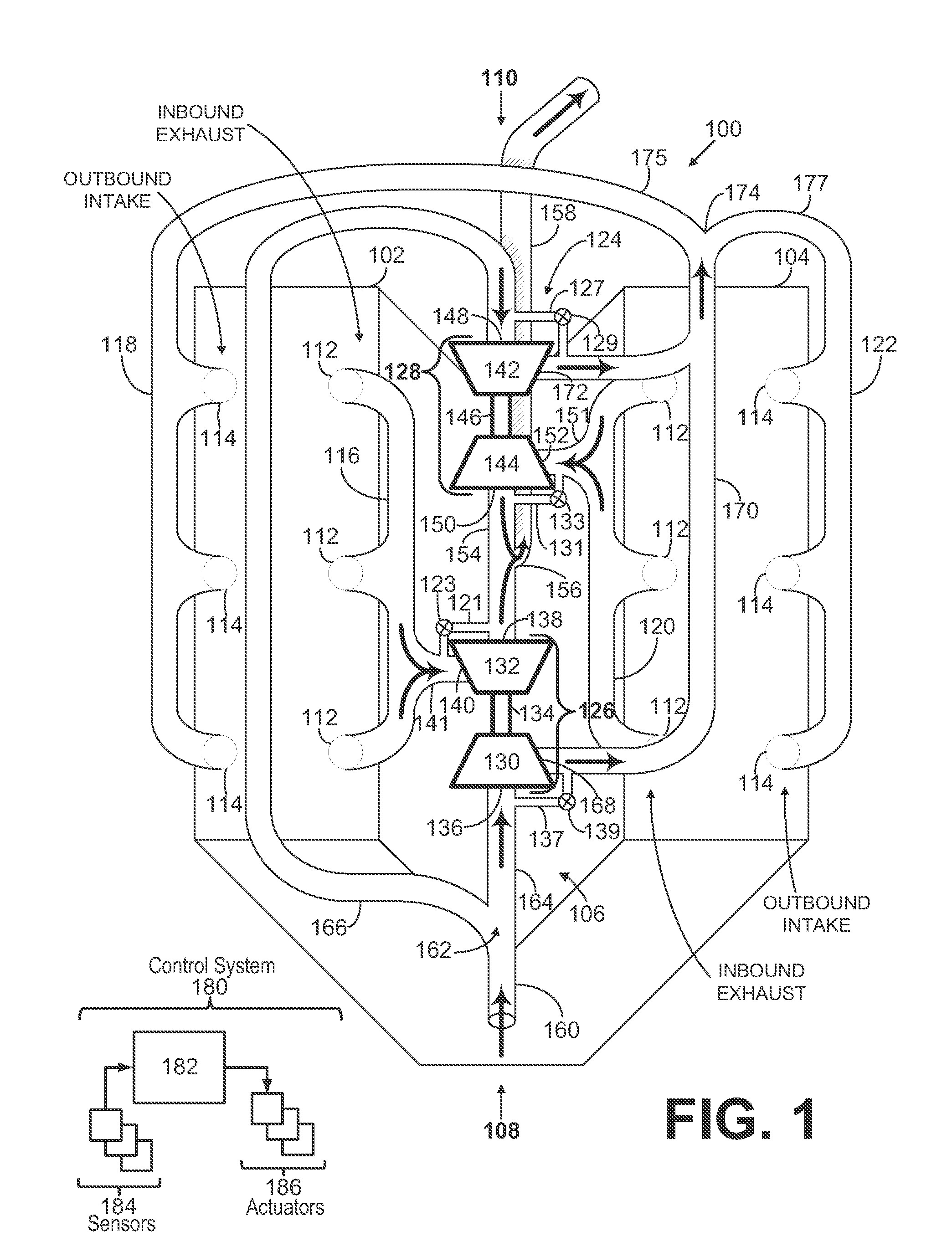

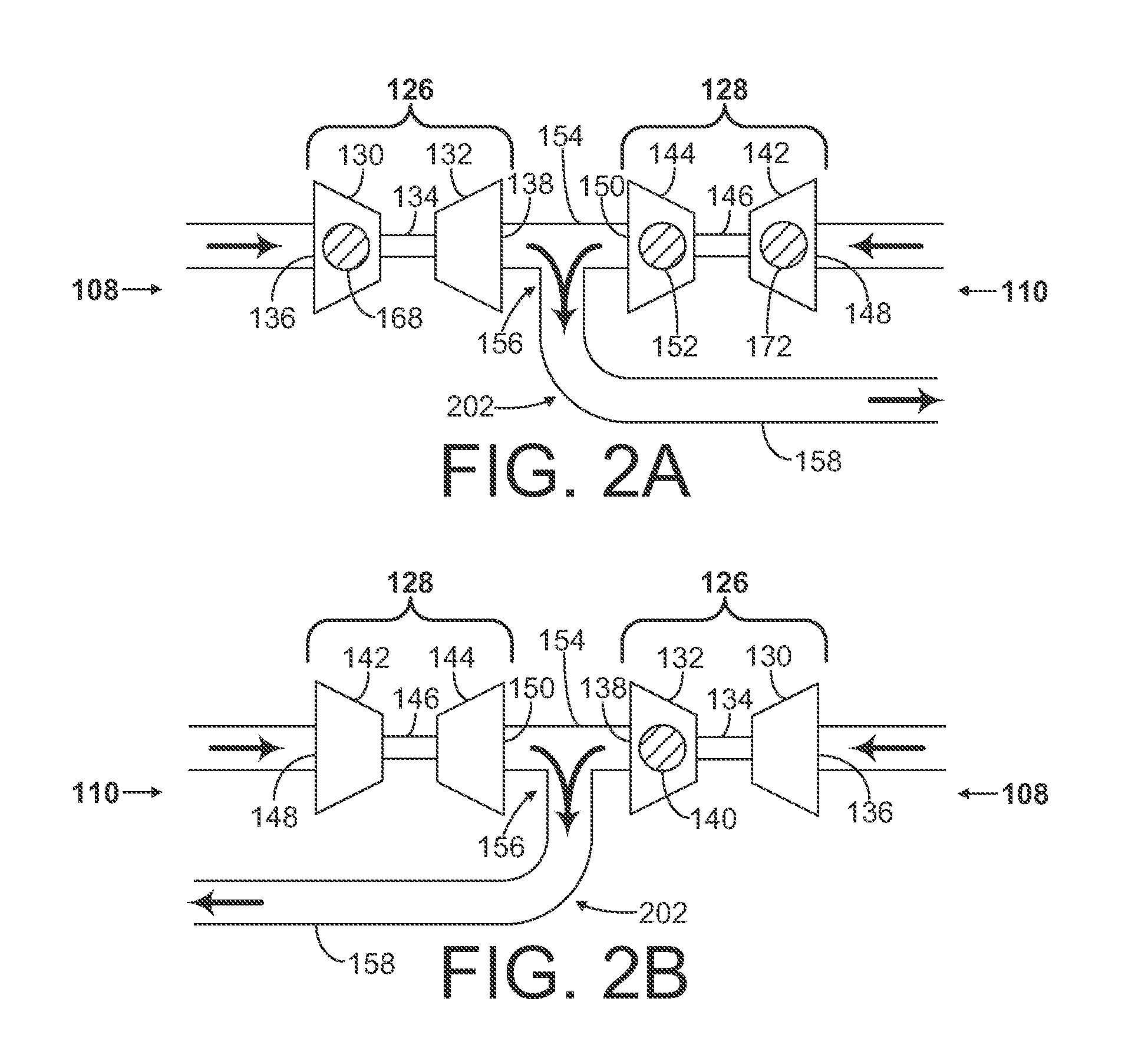

Twin turbo diesel aftertreatment system

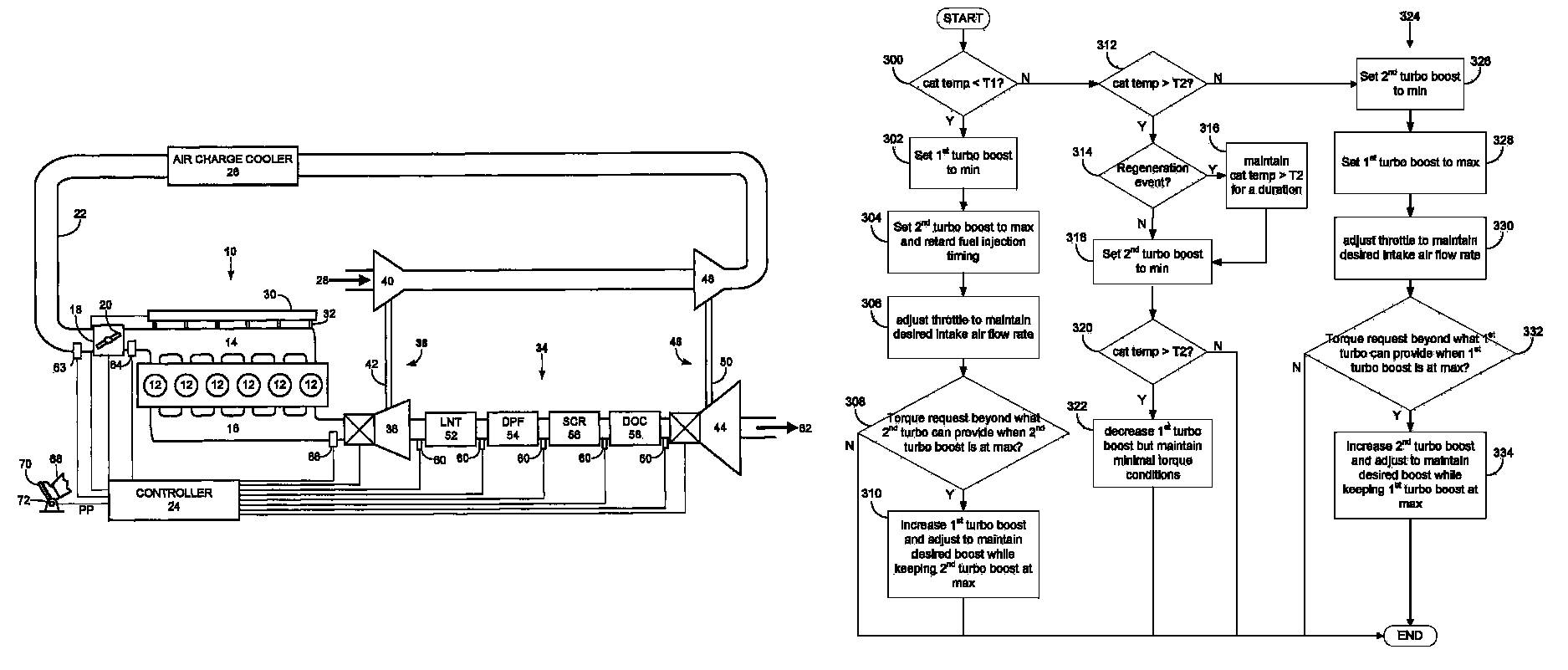

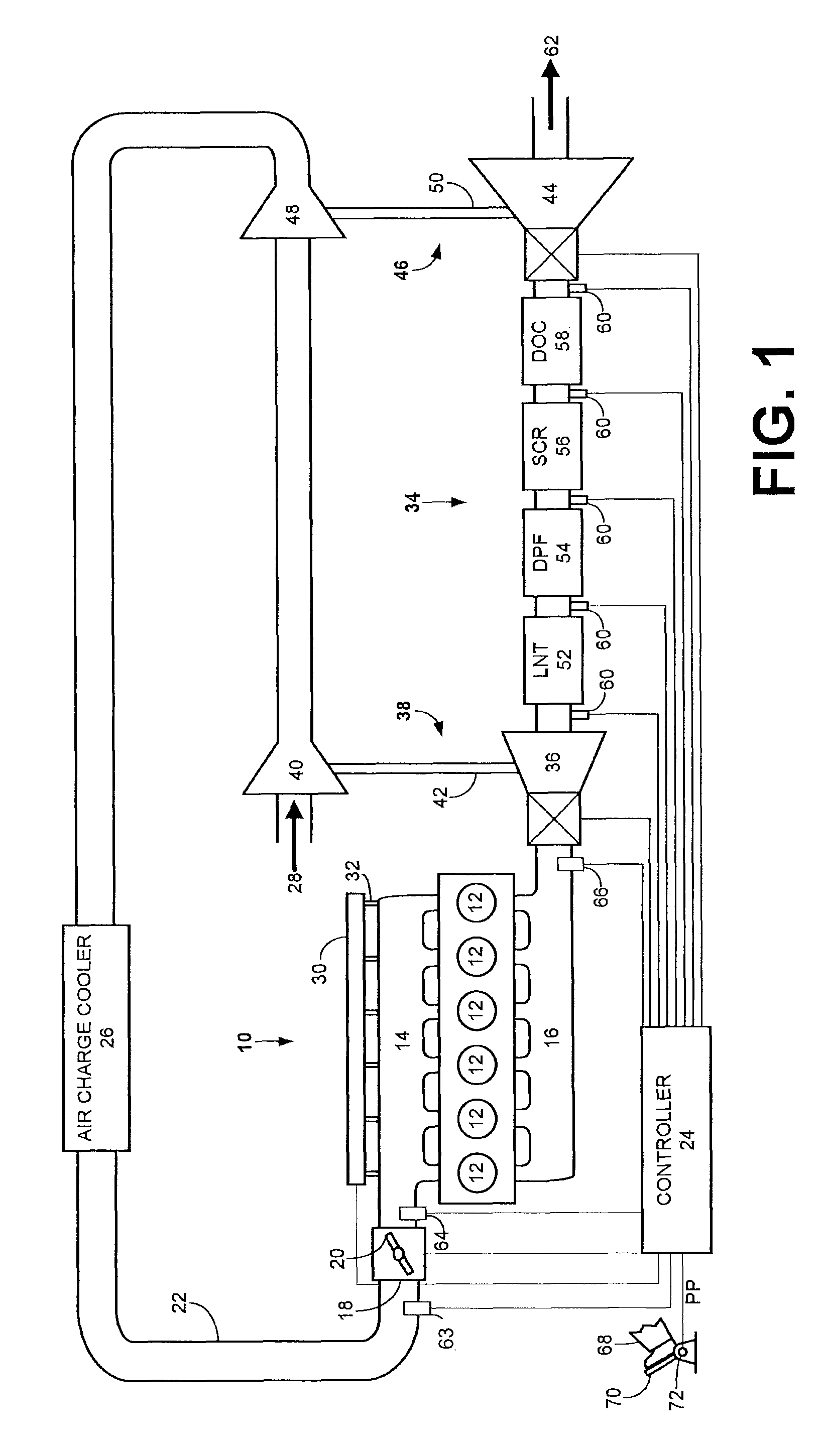

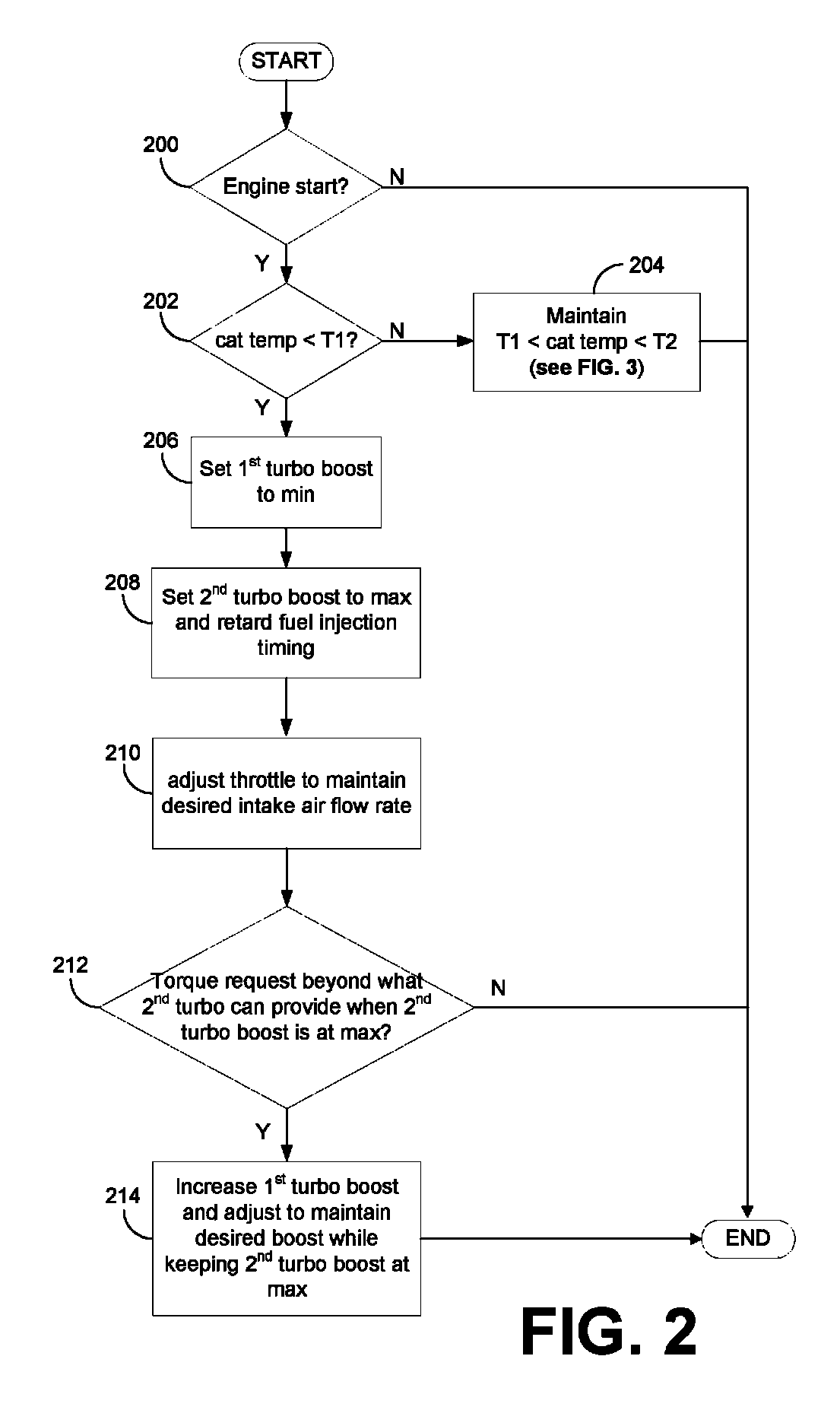

ActiveUS20110023480A1Improve NOx conversion efficiencyImprove fuel economyElectrical controlInternal combustion piston enginesCombustionInternal combustion engine

Exhaust temperatures in emission control devices may be directly controlled by an intake air throttle, fuel injection timing, and exhaust pressure when an emission control device is placed between two variable geometry turbocharger exhaust turbines and coupled to a combustion engine. Such an approach may substantially raise the temperature of the exhaust aftertreatment devices in an emission control device during non-warmed exhaust conditions, leading to faster catalytic light-off.

Owner:FORD GLOBAL TECH LLC

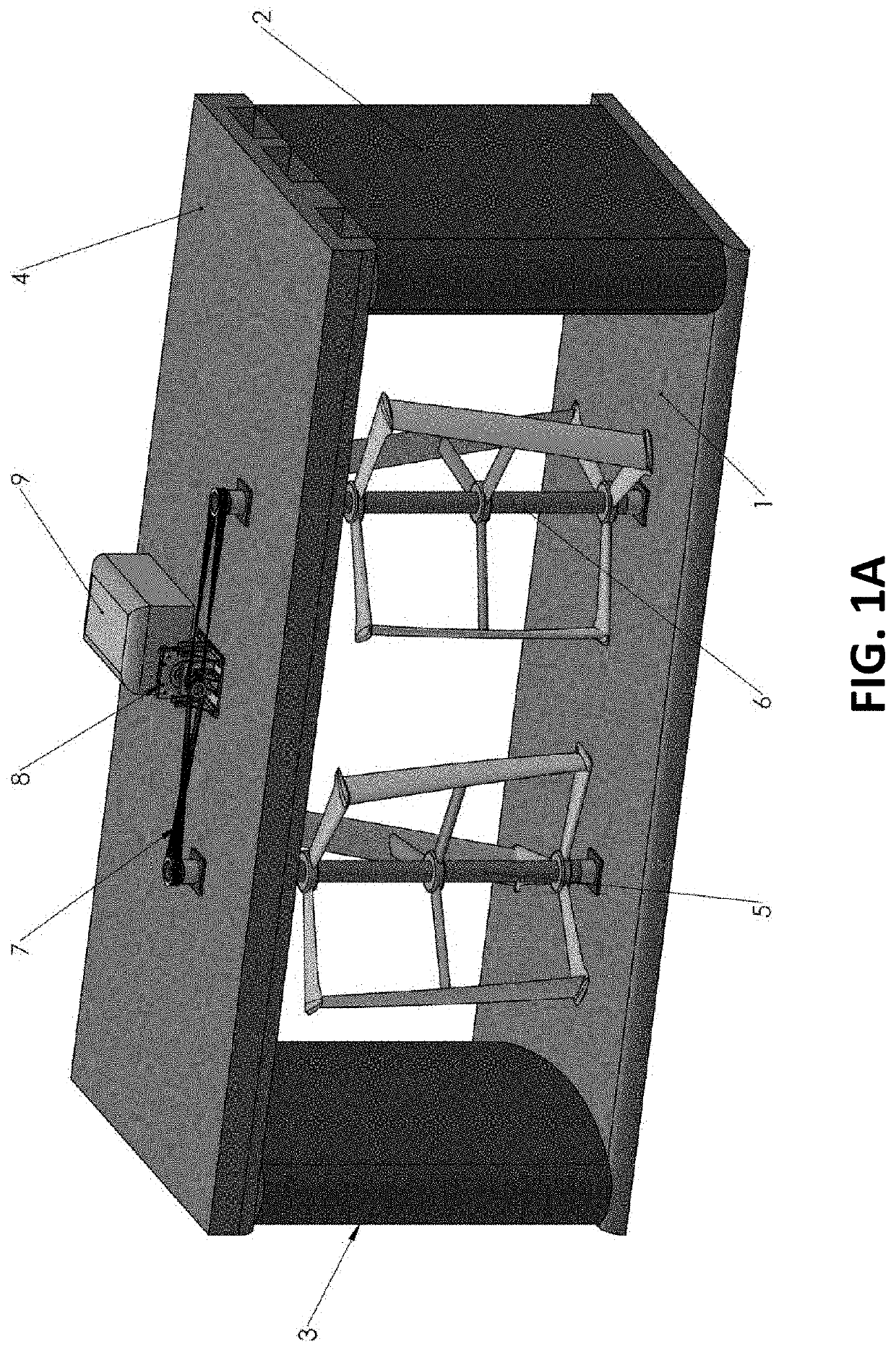

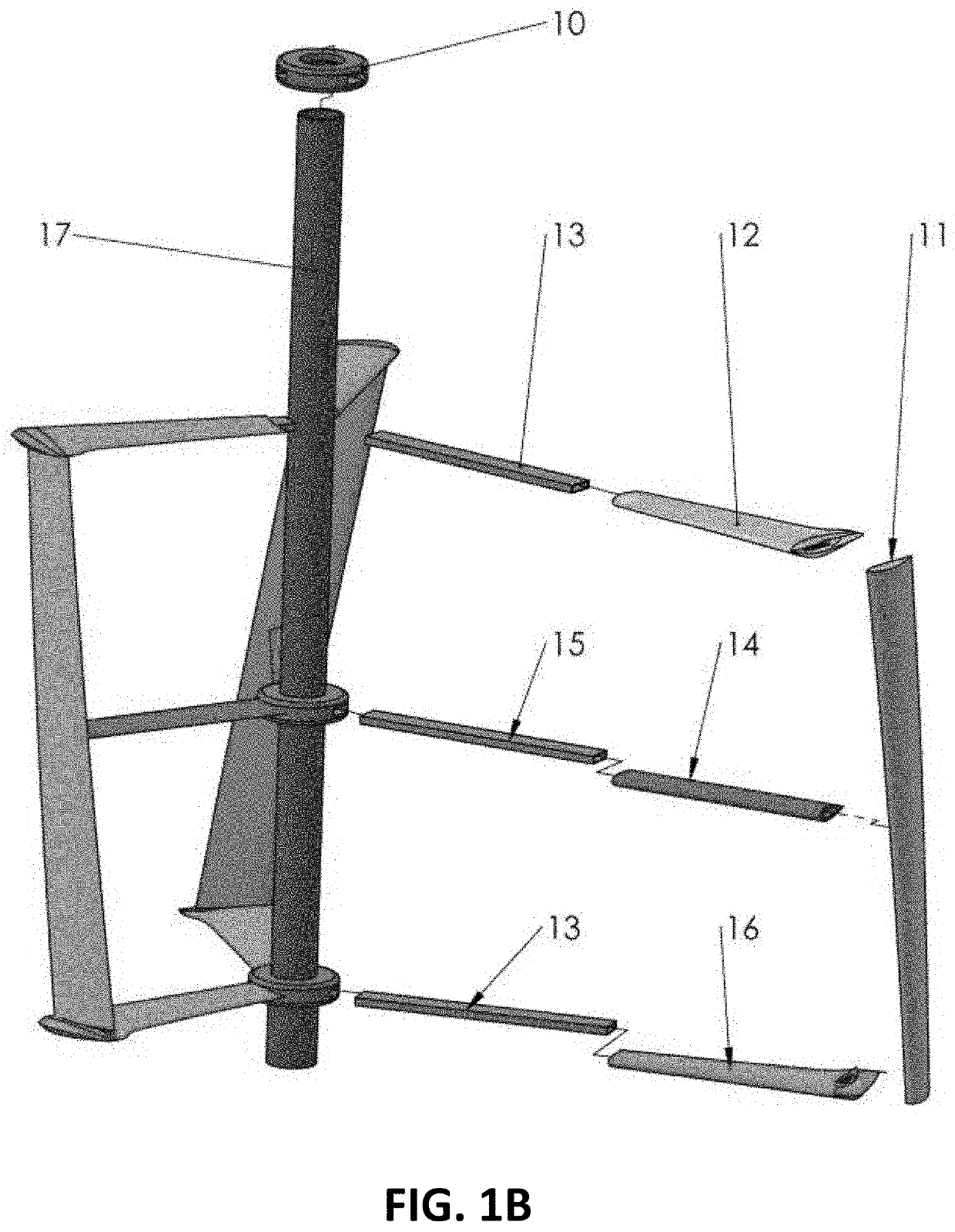

Shrouded vertical axis dual-turbine generator

InactiveUS20100213720A1Increase speedEliminate energy-robbing turbulenceWind motor controlWind motor combinationsLeading edgeWater flow

The Shrouded Vertical Axis Dual-Turbine Generator is a system consisting of a superstructure in the shape of a symmetrical foil, with a vertical axis turbine set into the camber of each side. The leading edge of the superstructure increases the speed of the water or air current passing around the generator. The trailing edge creates a slip stream which reduces turbulence. Shutters on each side of the superstructure control the amount of current in contact with the turbines by sliding forward or rearward to increase or decrease flow to the turbines. The turbines are modular in design and can be customized into longer or shorter turbines, depending on application.

Owner:BAILEY LAURA J +1

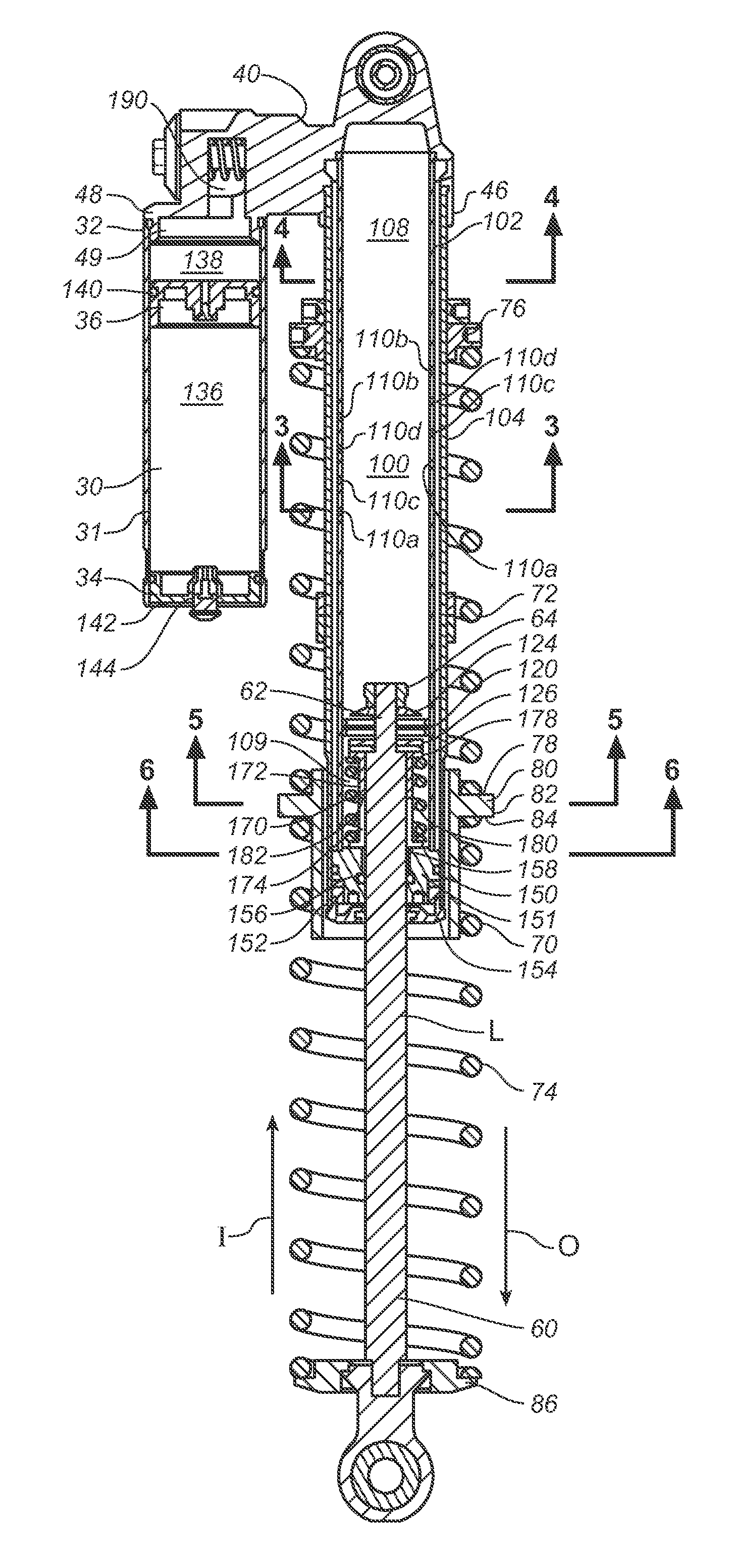

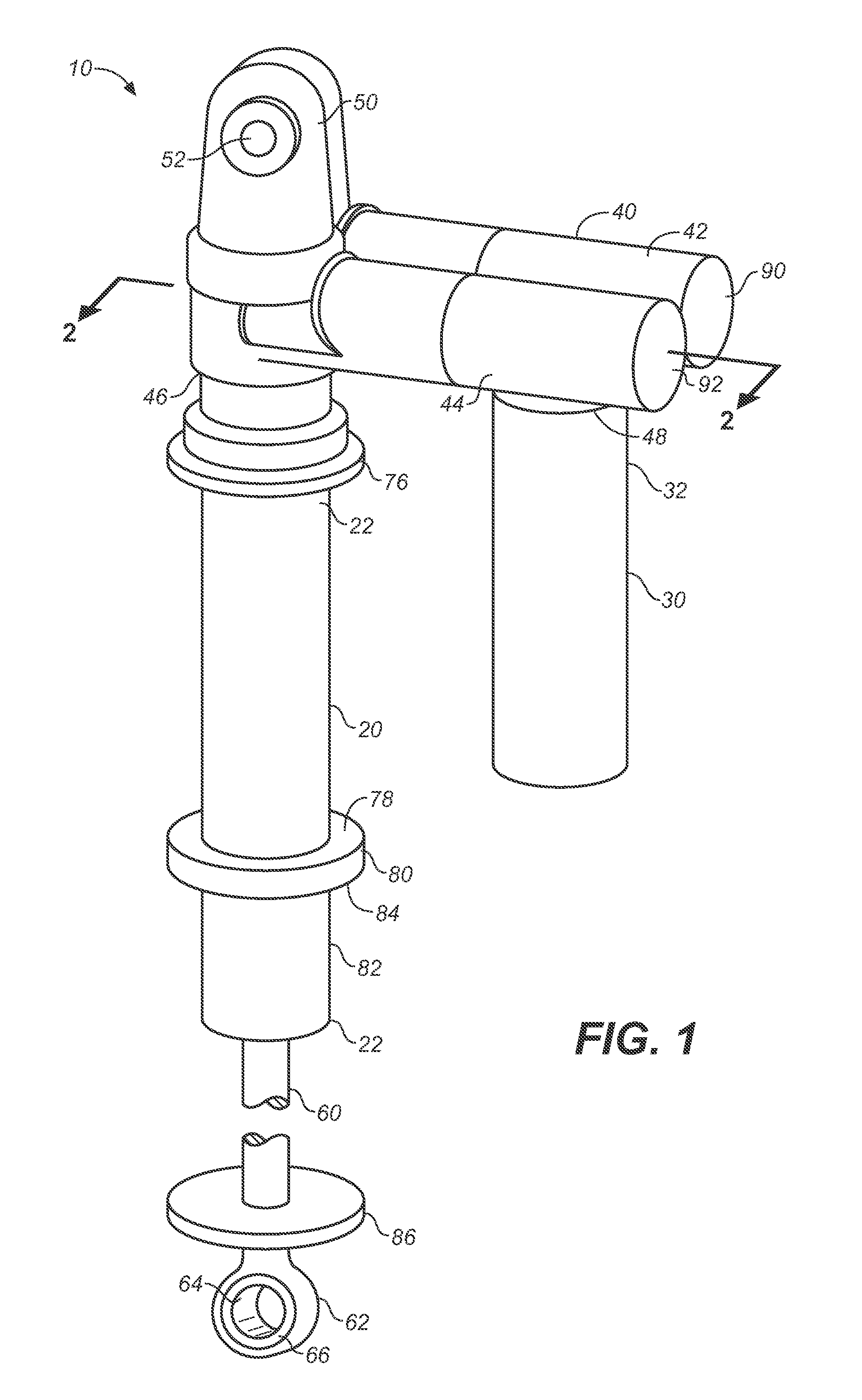

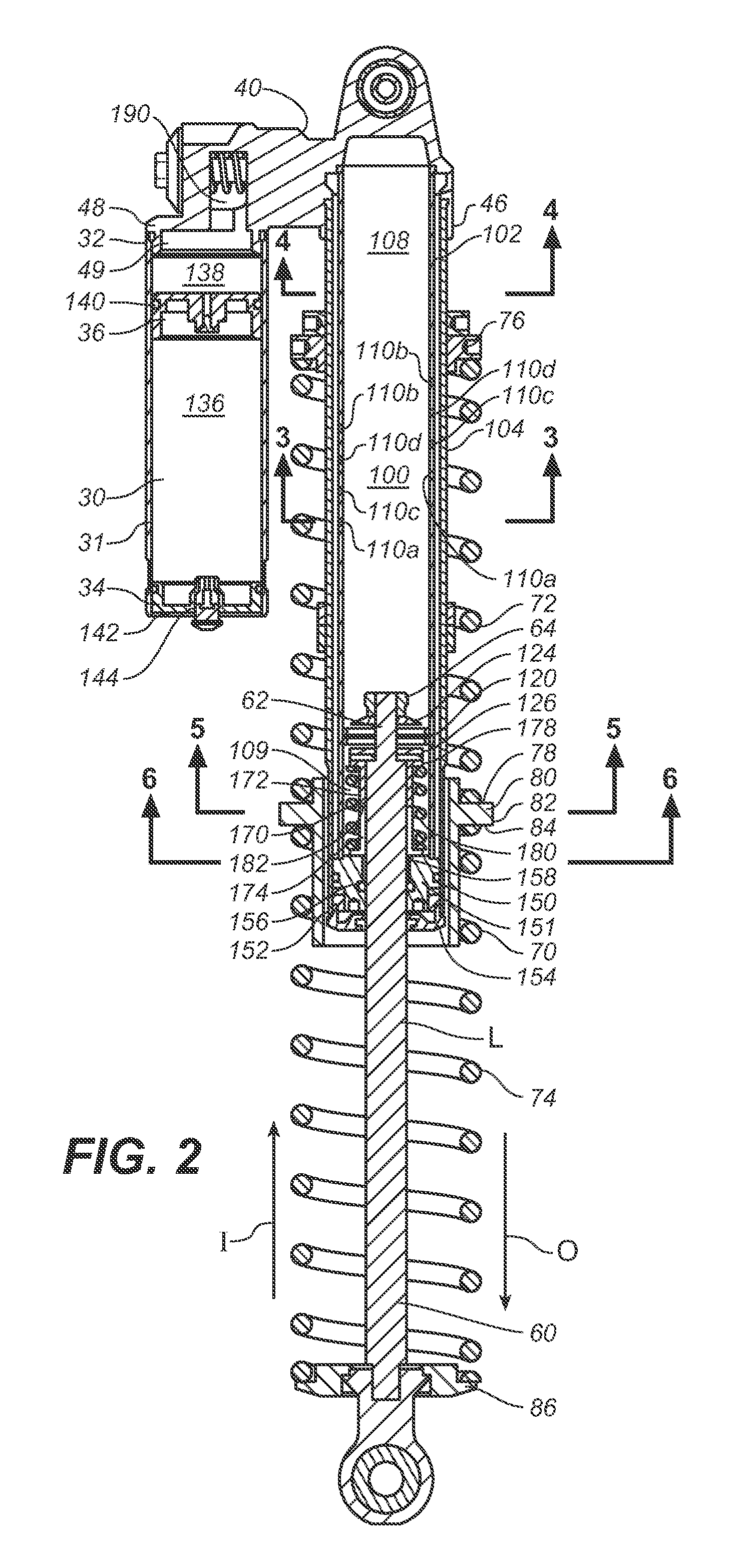

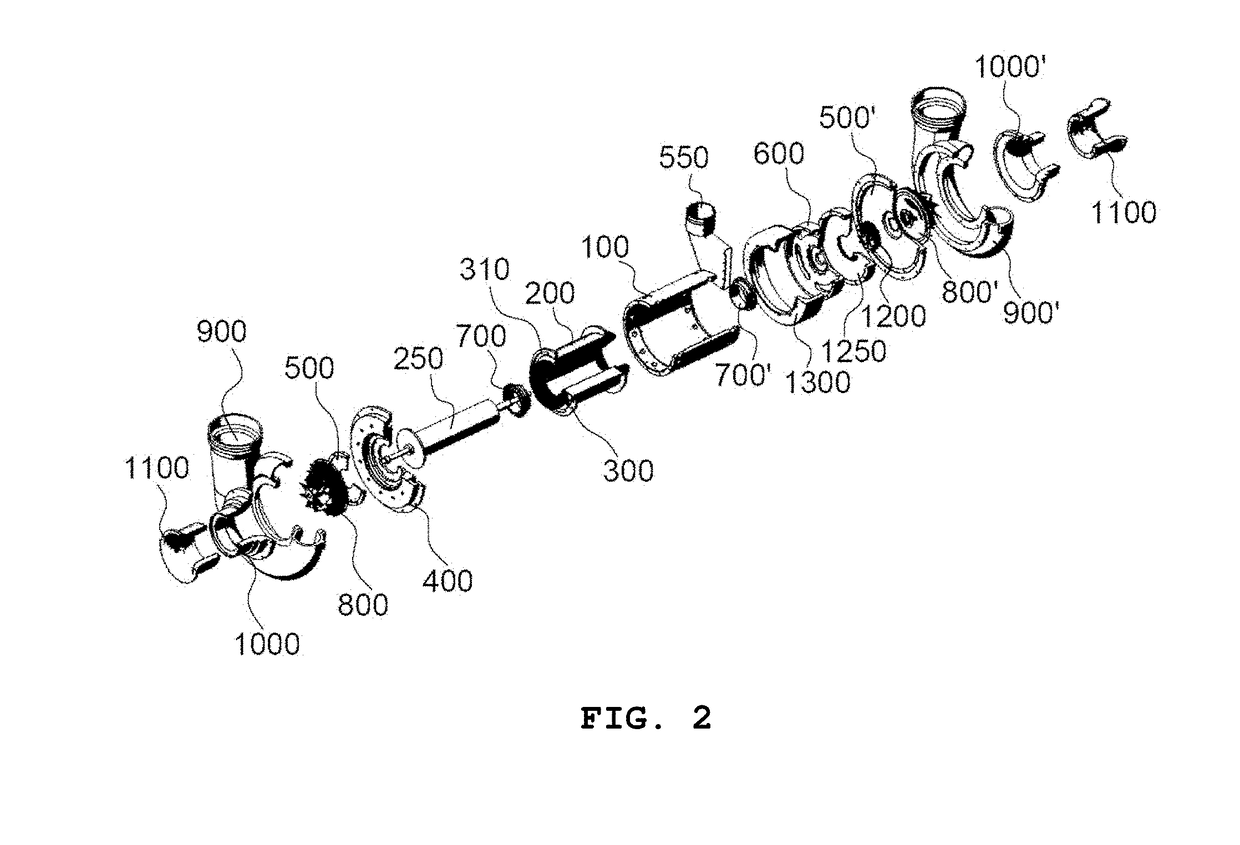

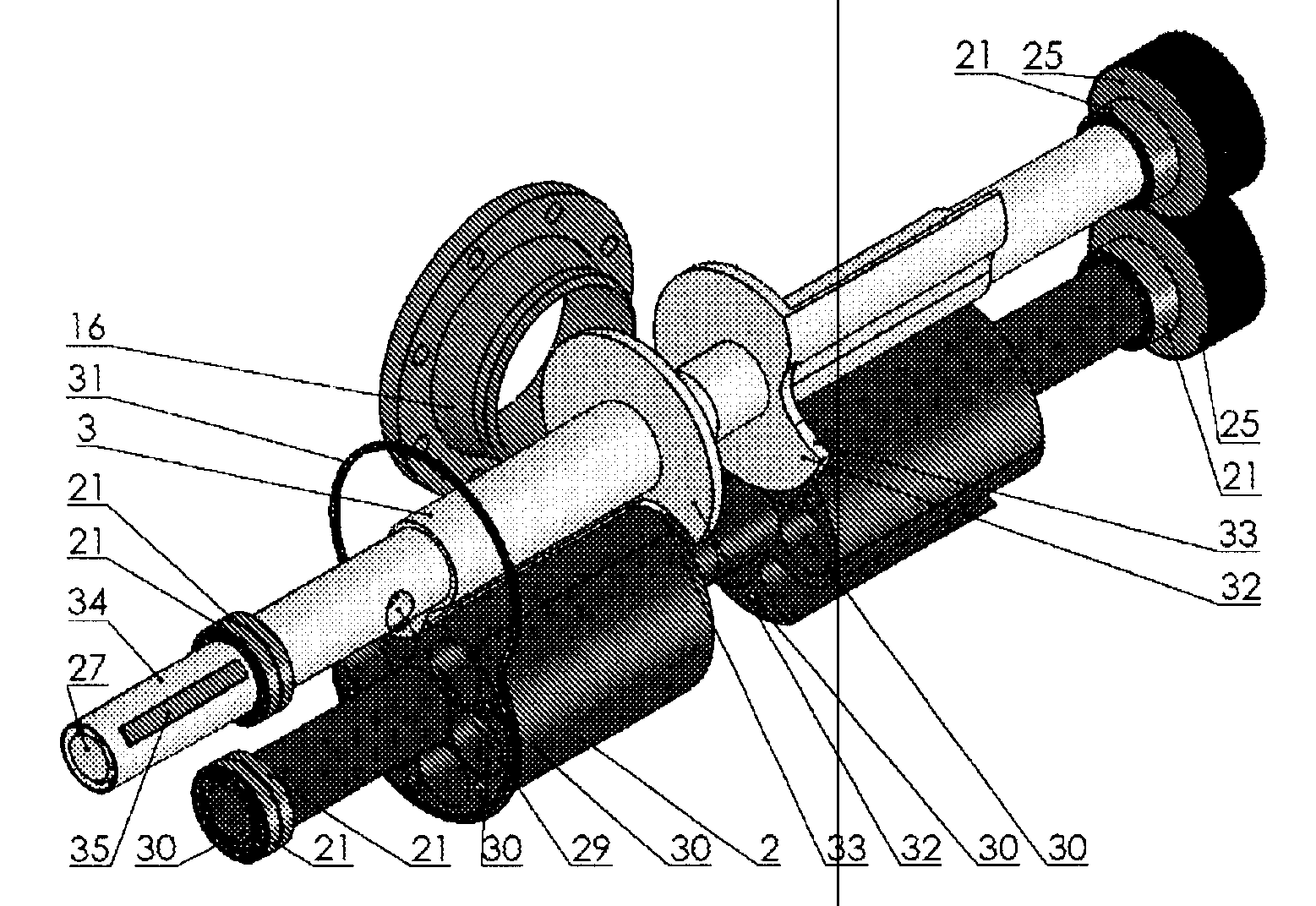

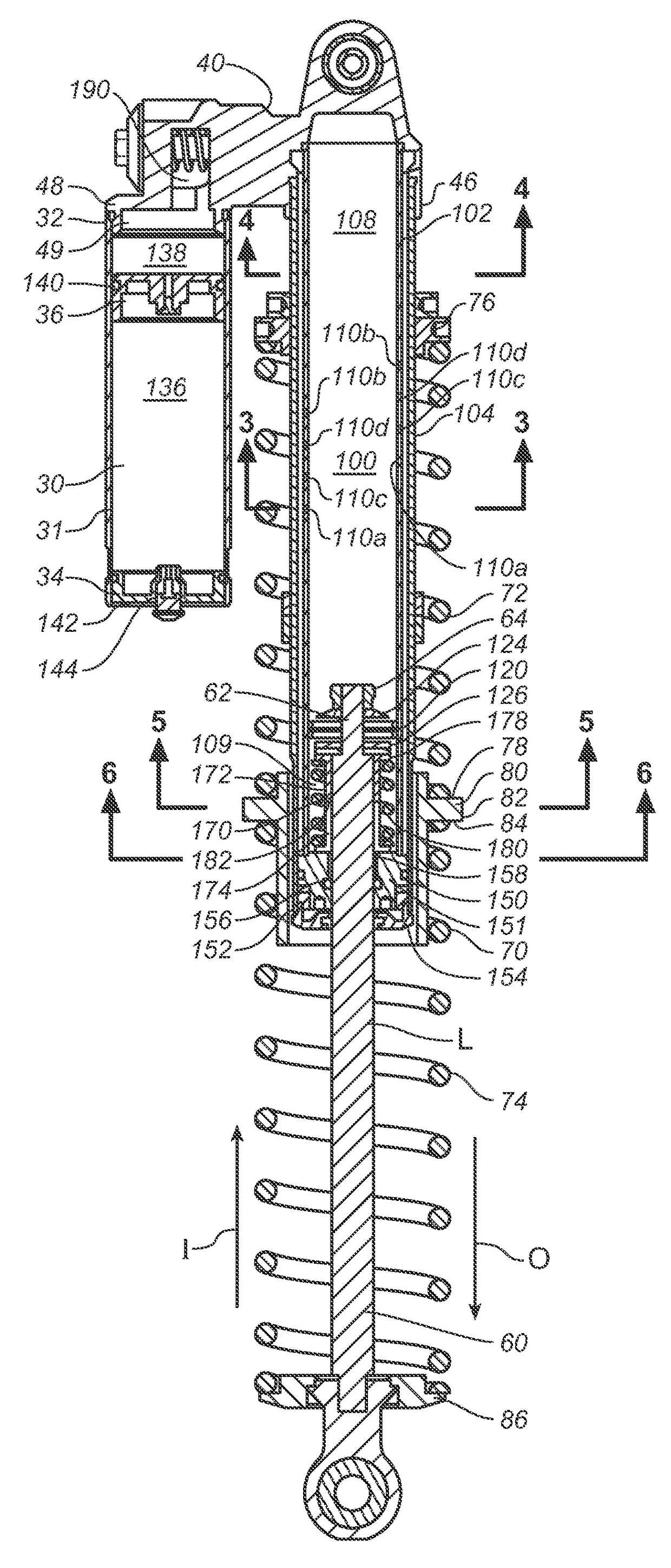

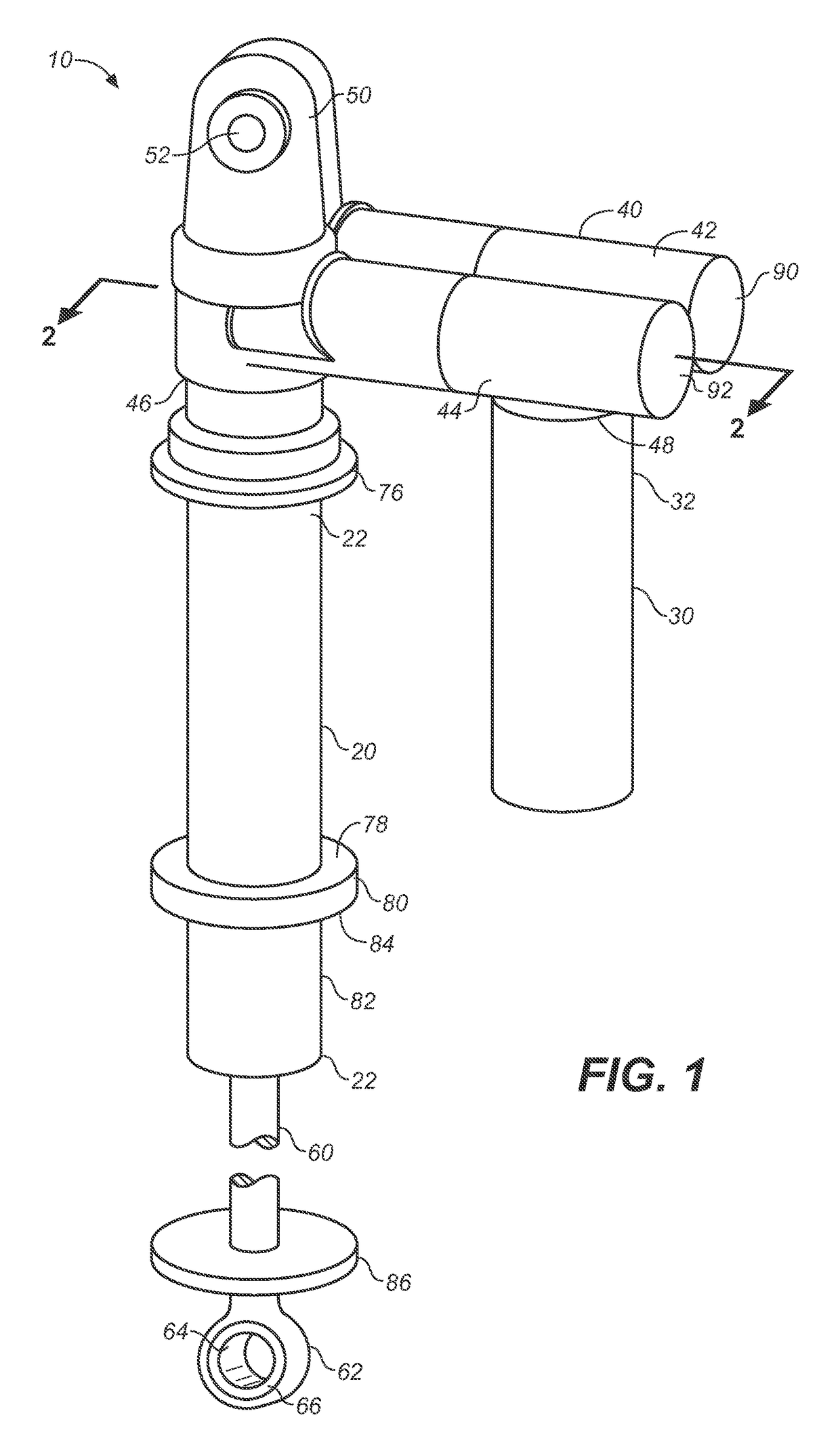

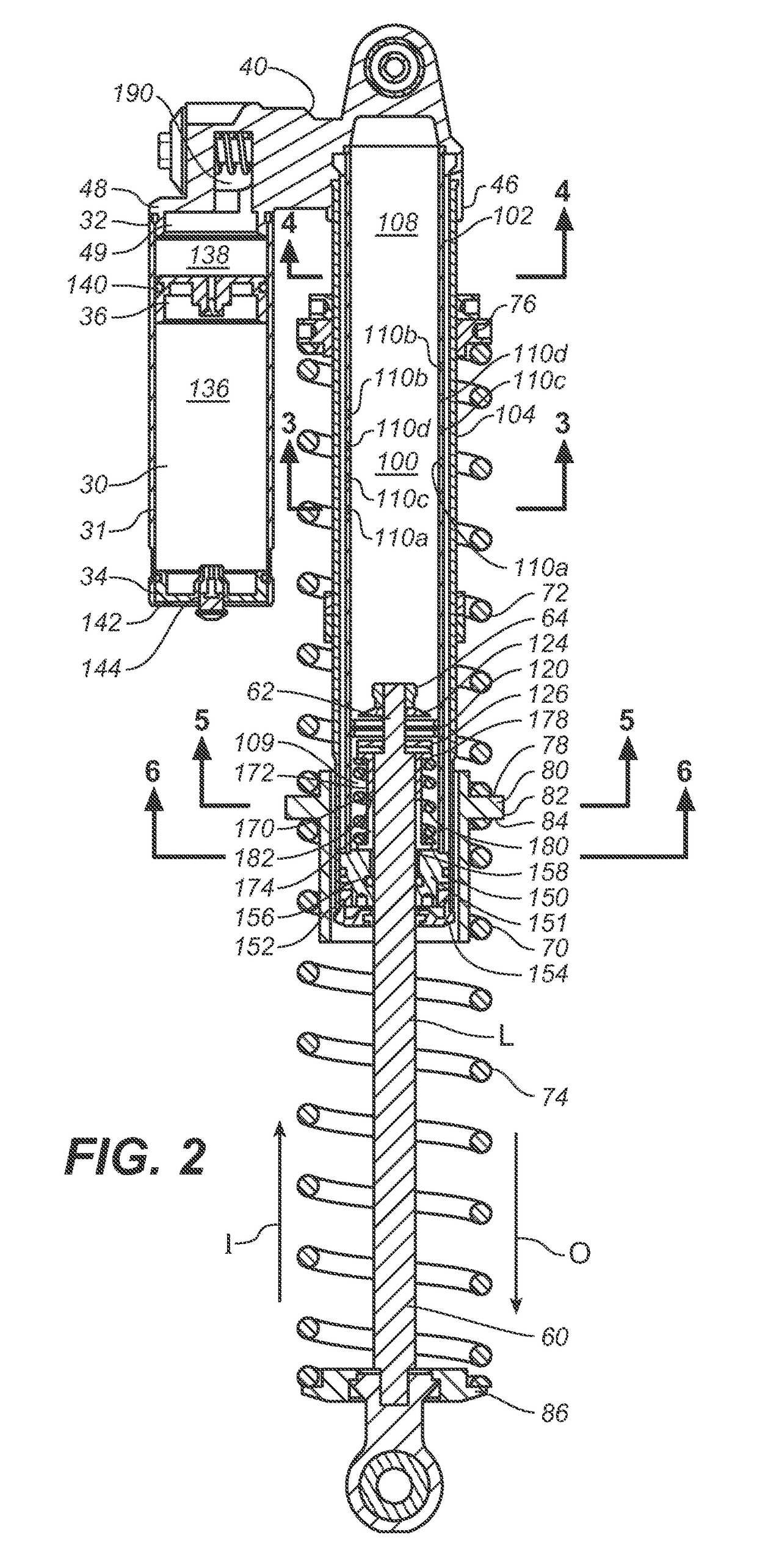

Twin tube damper with remote gas reservoir

A damper is provided having a twin tube construction interconnected to a gas reservoir. The connection of each of the inner and outer volumes of the twin tube to the gas reservoir is independently valved, and each of these valves are independently settable to change the differential pressure thereacross at which they open. The damper provides flow passages directly from the inner and outer volumes to enable flow form the compression to rebound sides thereof, as well as through the valved connections to the gas reservoir and at least one valved opening in the damper piston.

Owner:FOX FACTORY

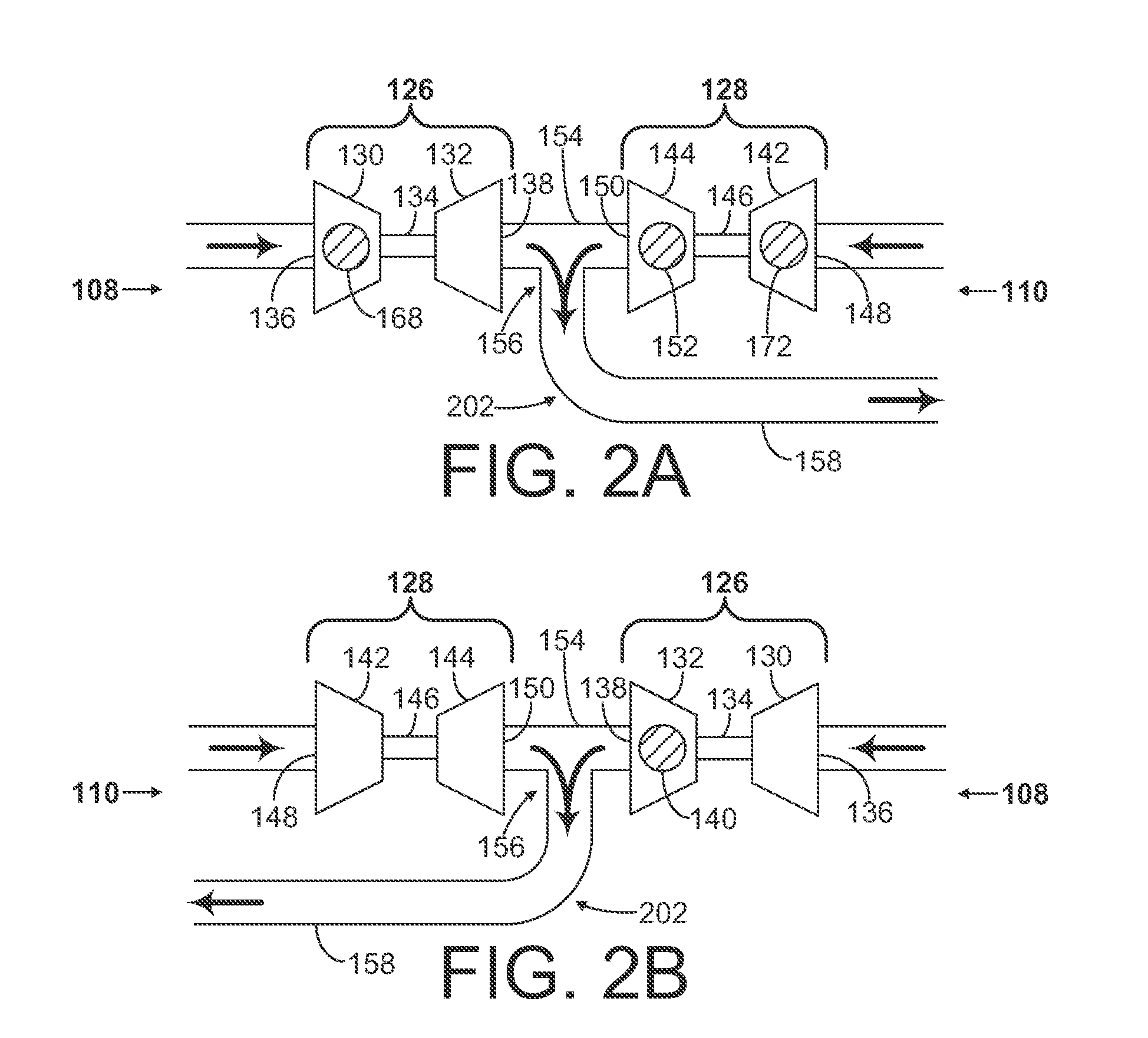

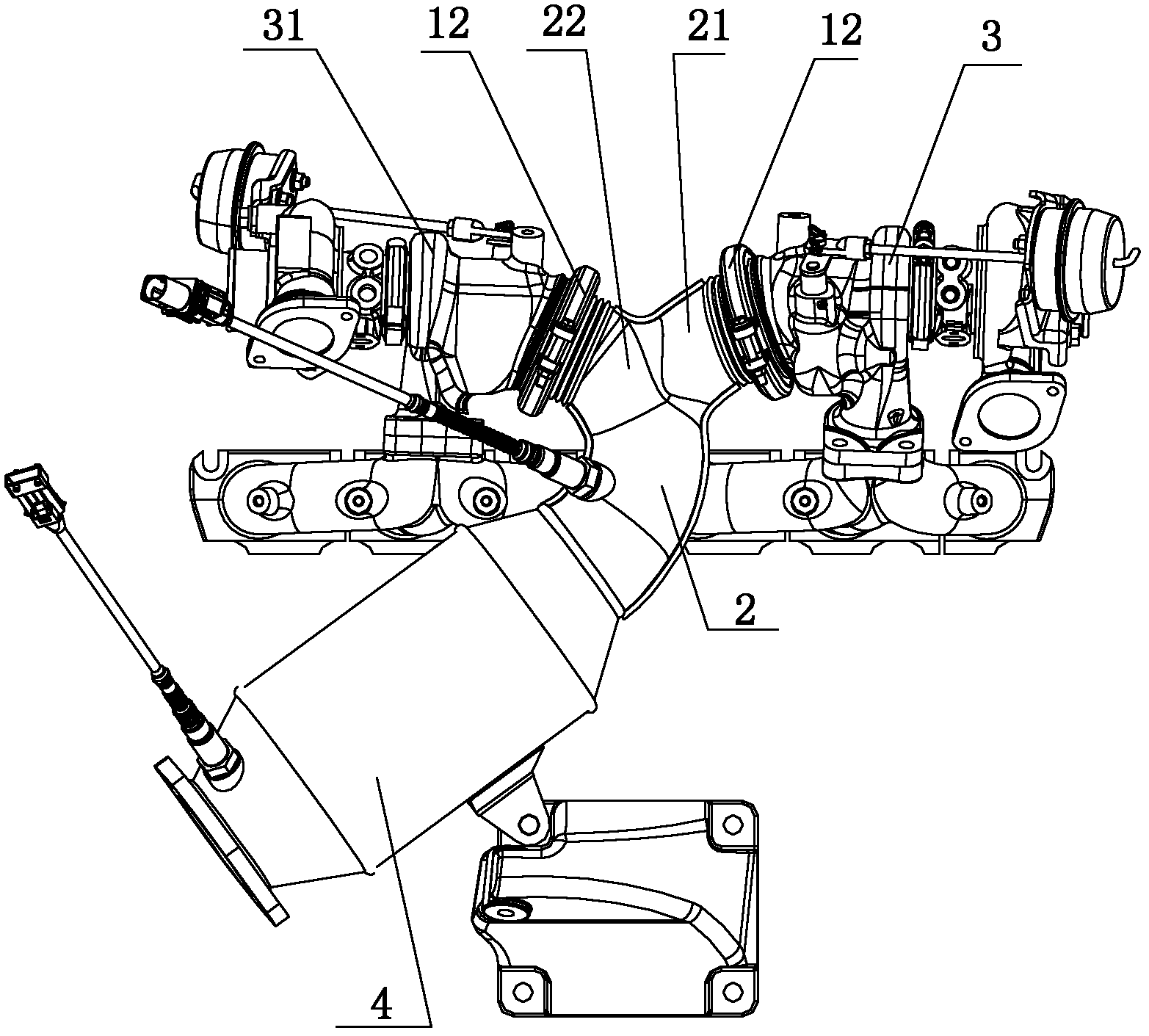

Central turbocharger mounting configuration for a twin-turbo engine

InactiveUS20110174247A1SpaceEfficient solutionInternal combustion piston enginesExhaust apparatusEngineeringTwin-turbo

The following description relates to a central turbocharger configuration in a V-engine with two turbochargers. In one example approach, A V-engine having a first and second bank forming a valley therebetween, comprises: first and second in-board exhaust manifolds on the first and second banks, respectively; first and second turbines coupled to the first and second manifolds, respectively; the first and second turbines between the first and second exhaust manifolds; a passage intermediate to and coupling outlets of the first and second turbines; and a junction branching from the passage downward into the valley.

Owner:FORD GLOBAL TECH LLC

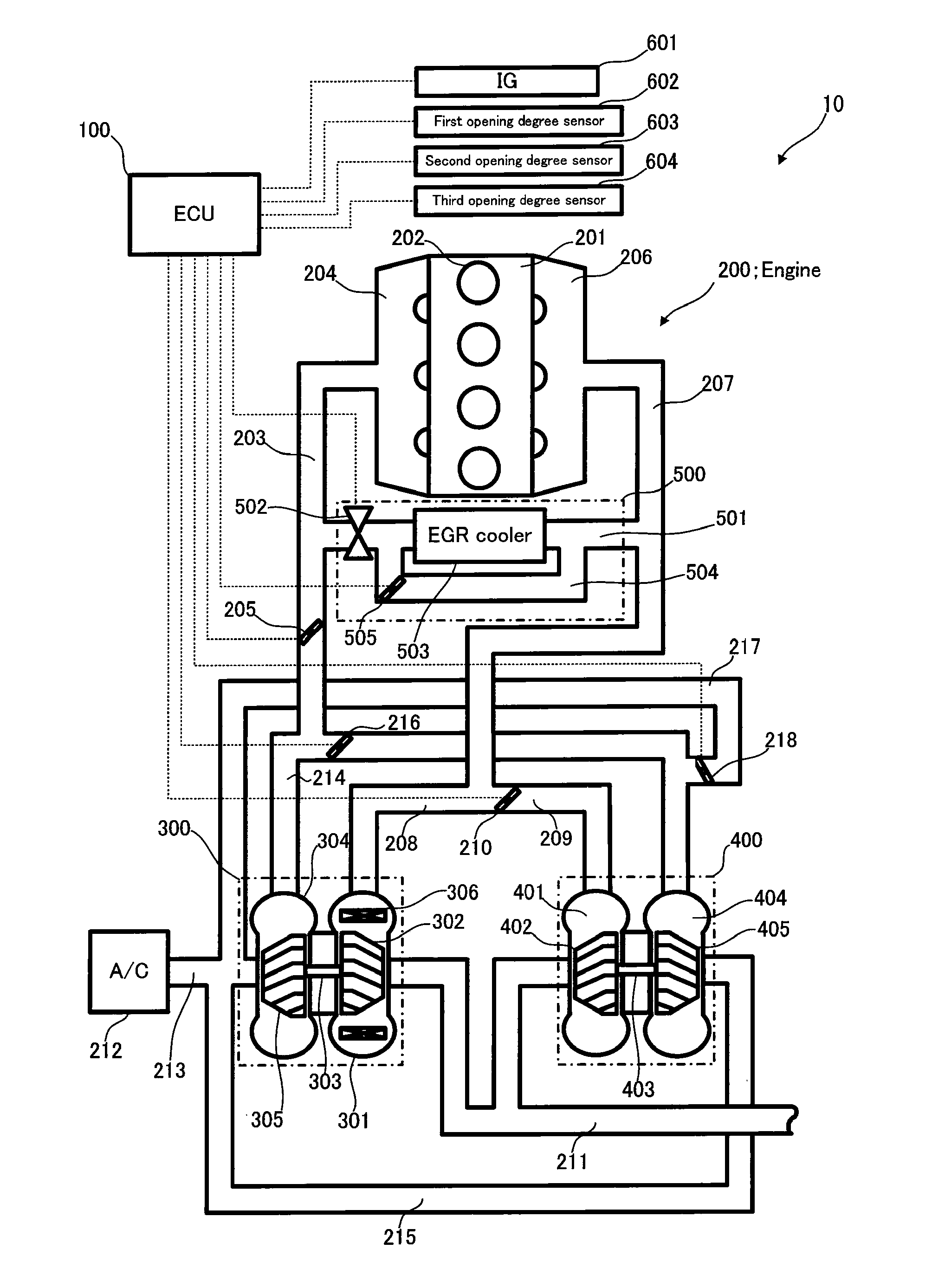

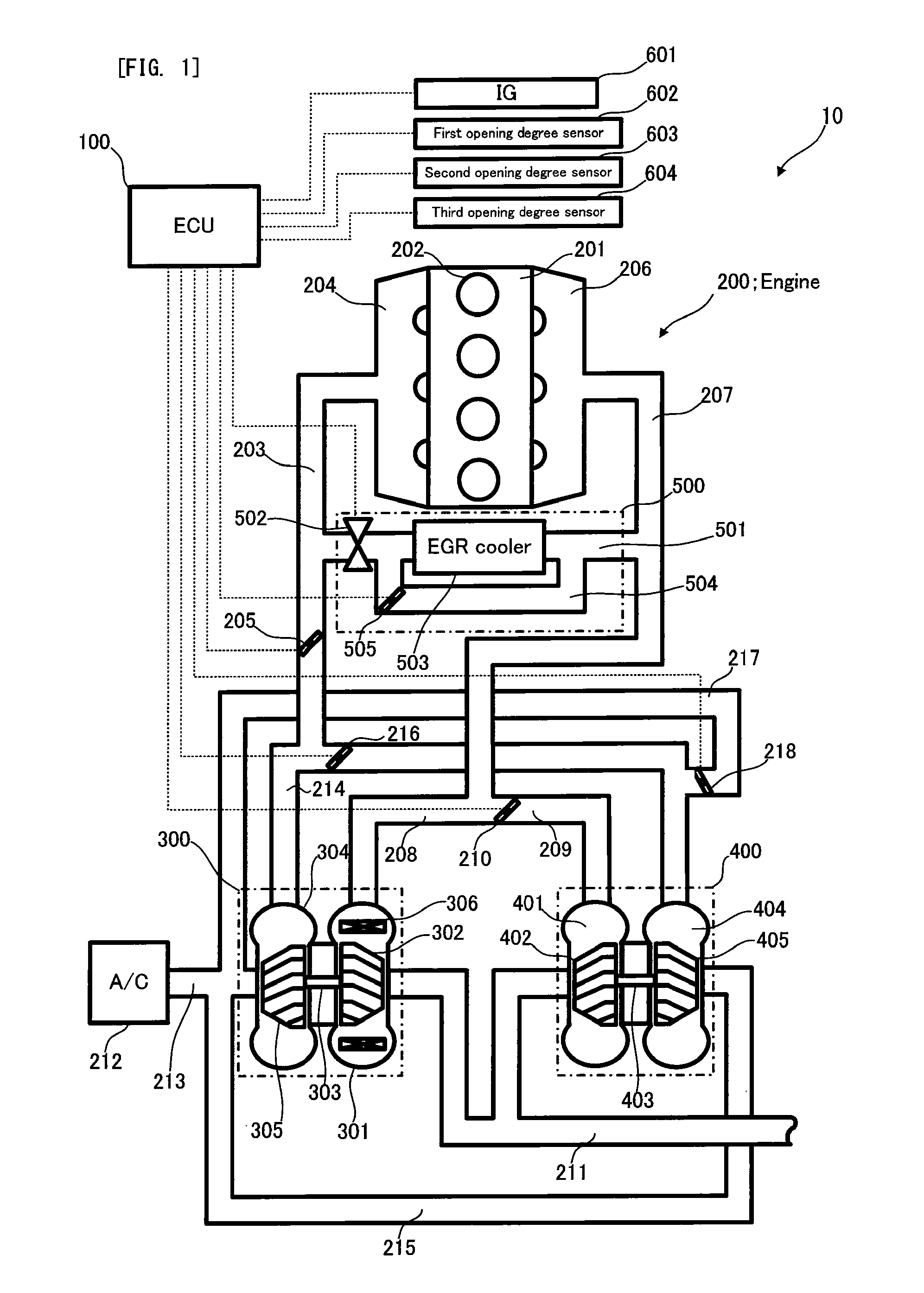

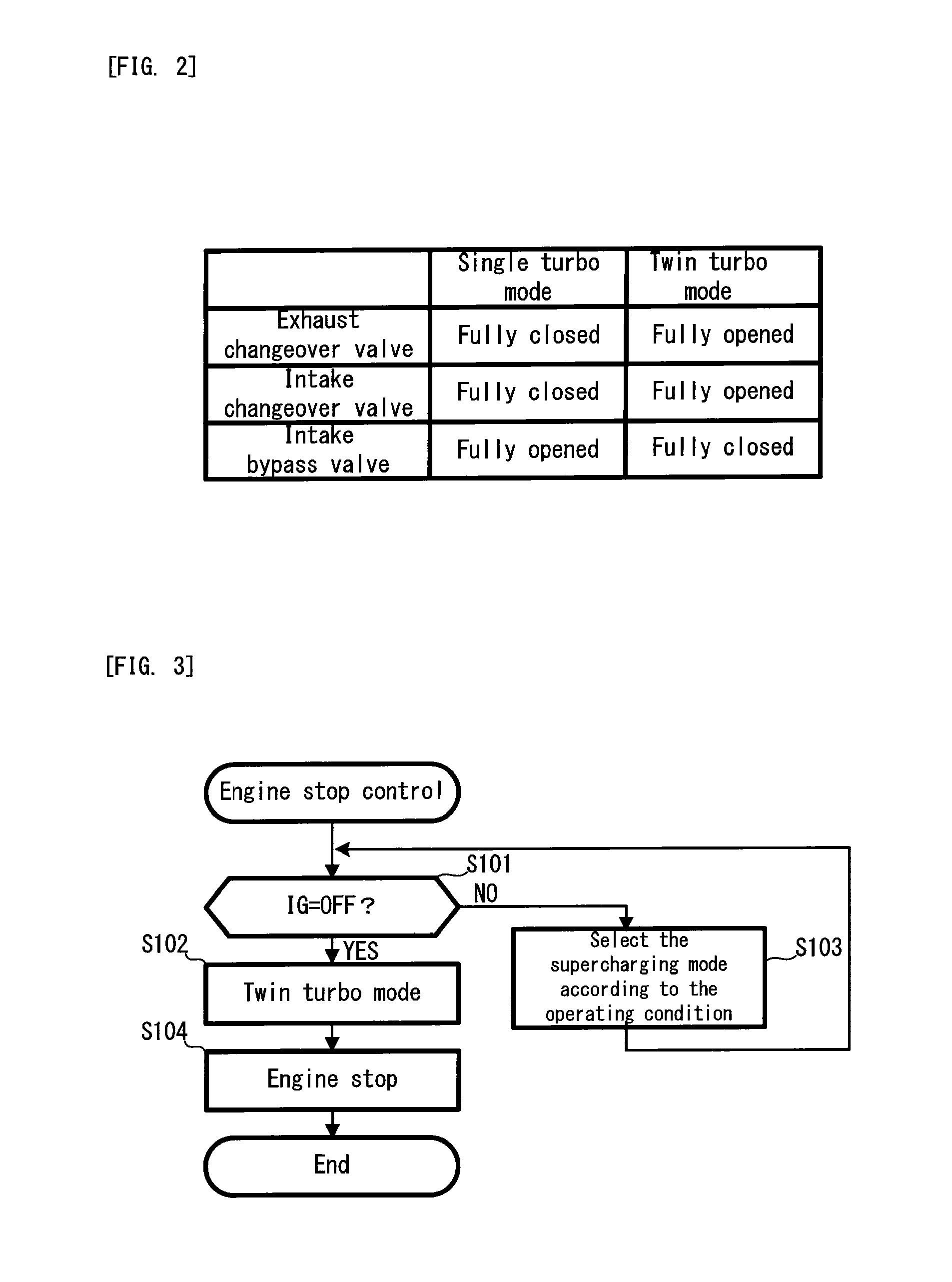

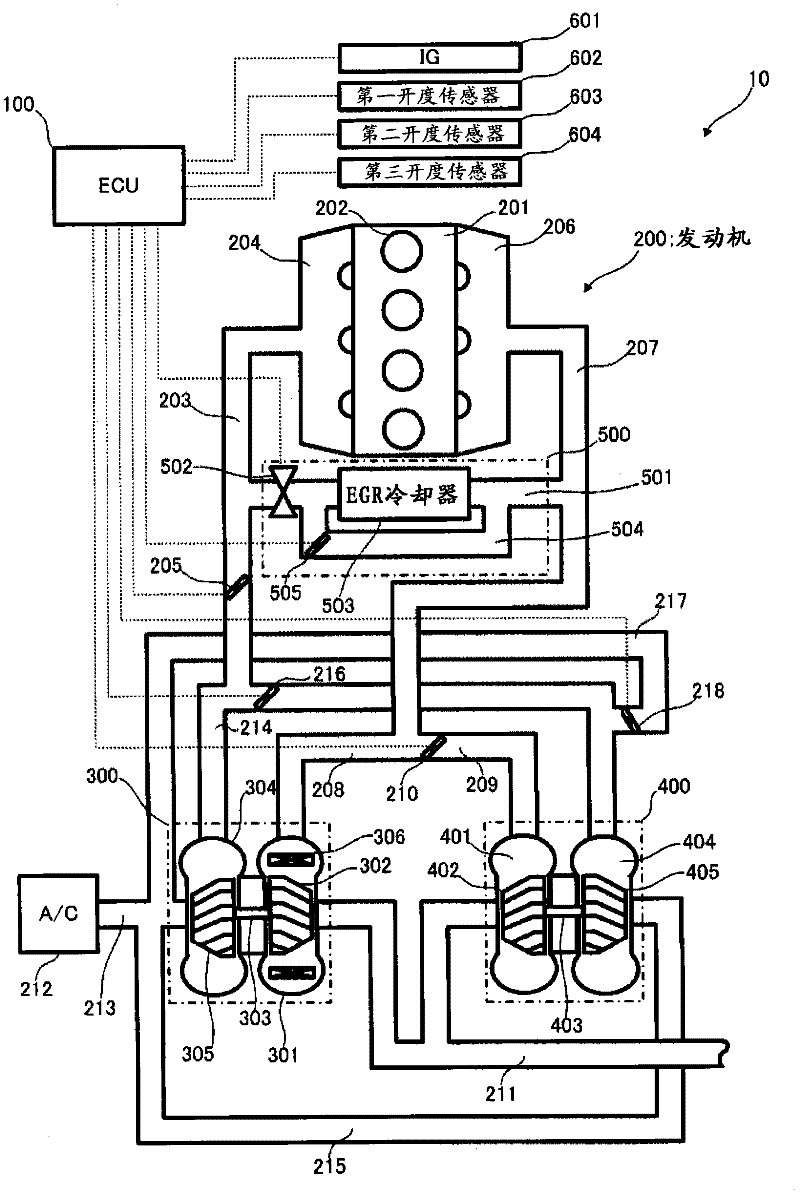

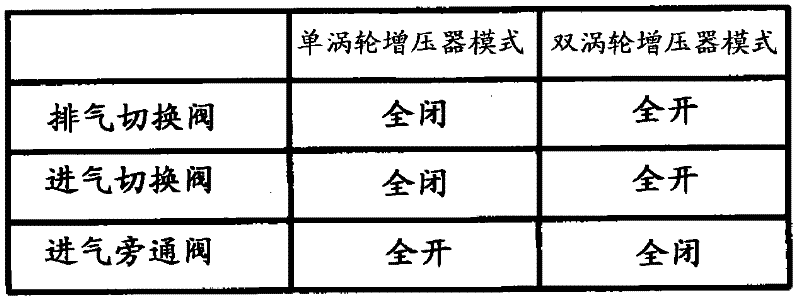

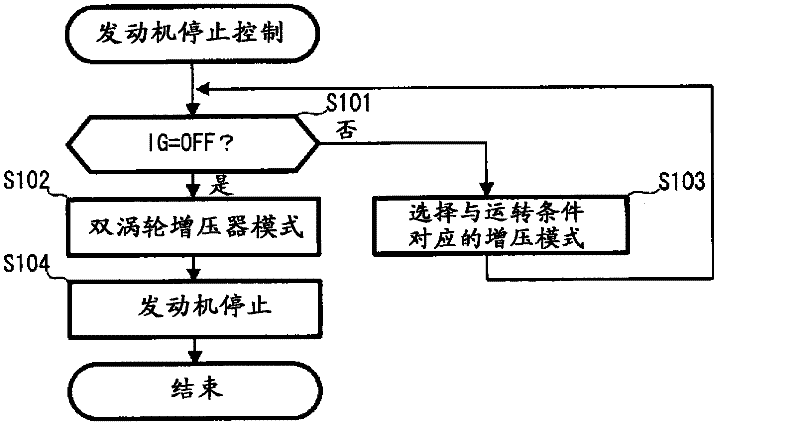

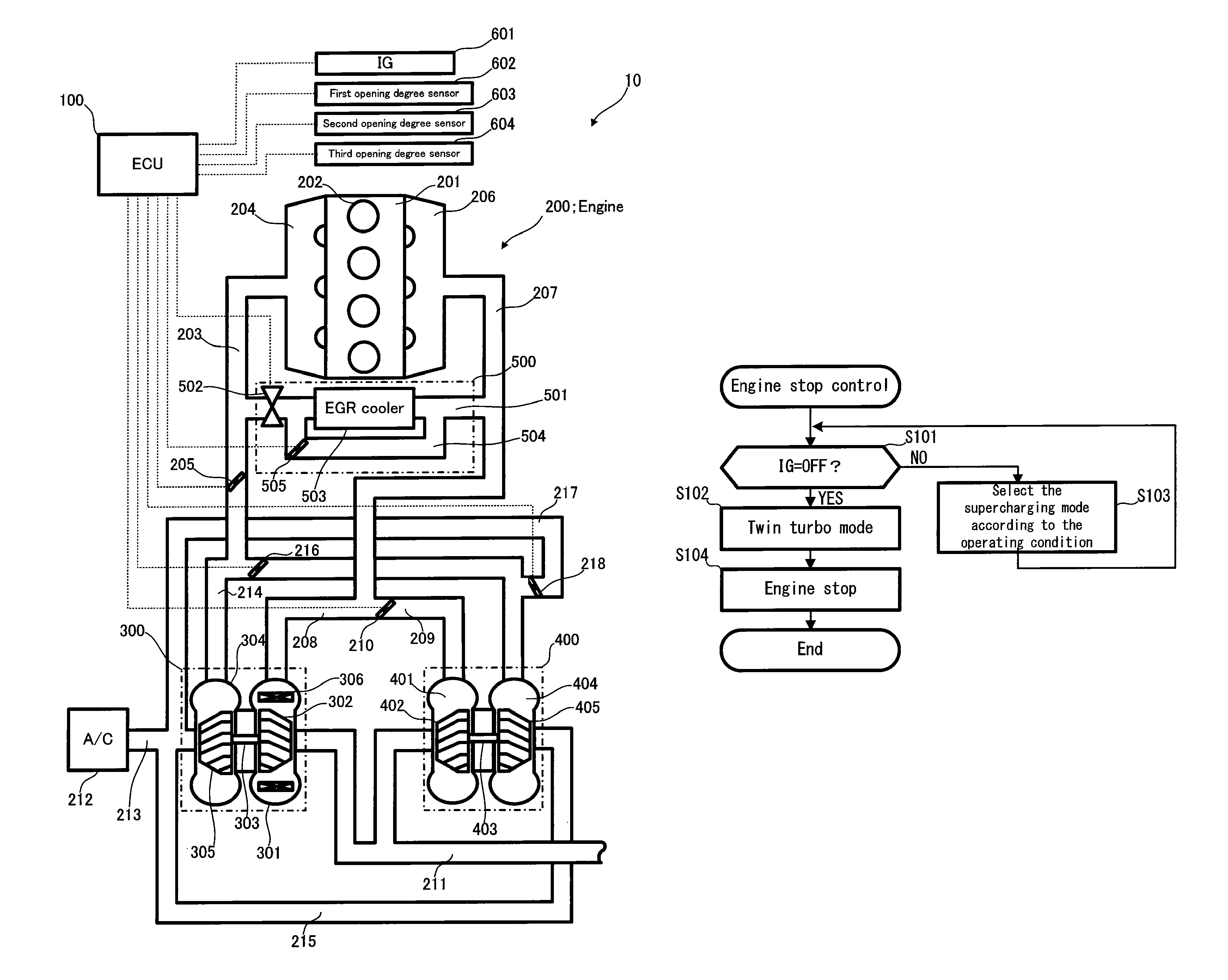

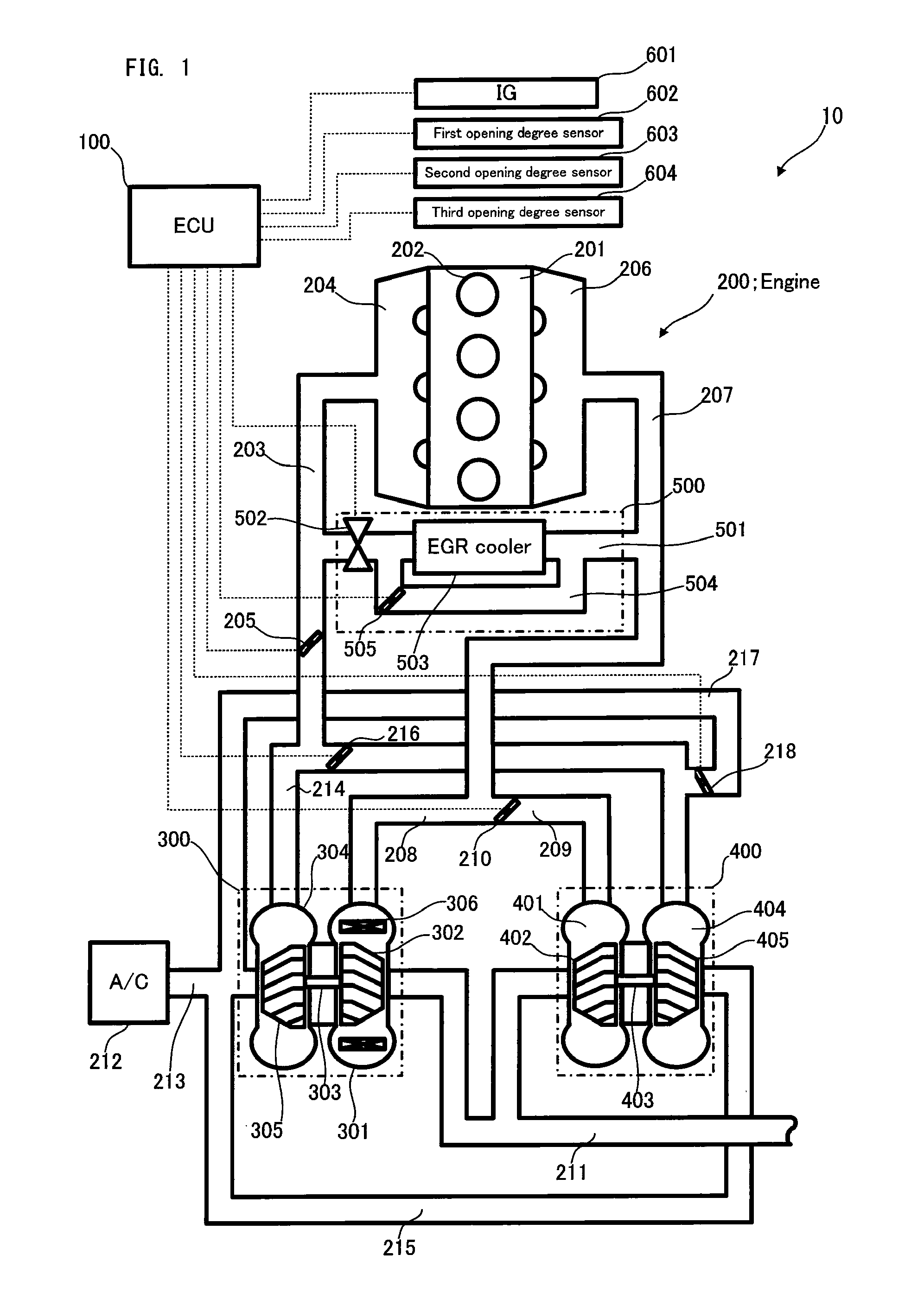

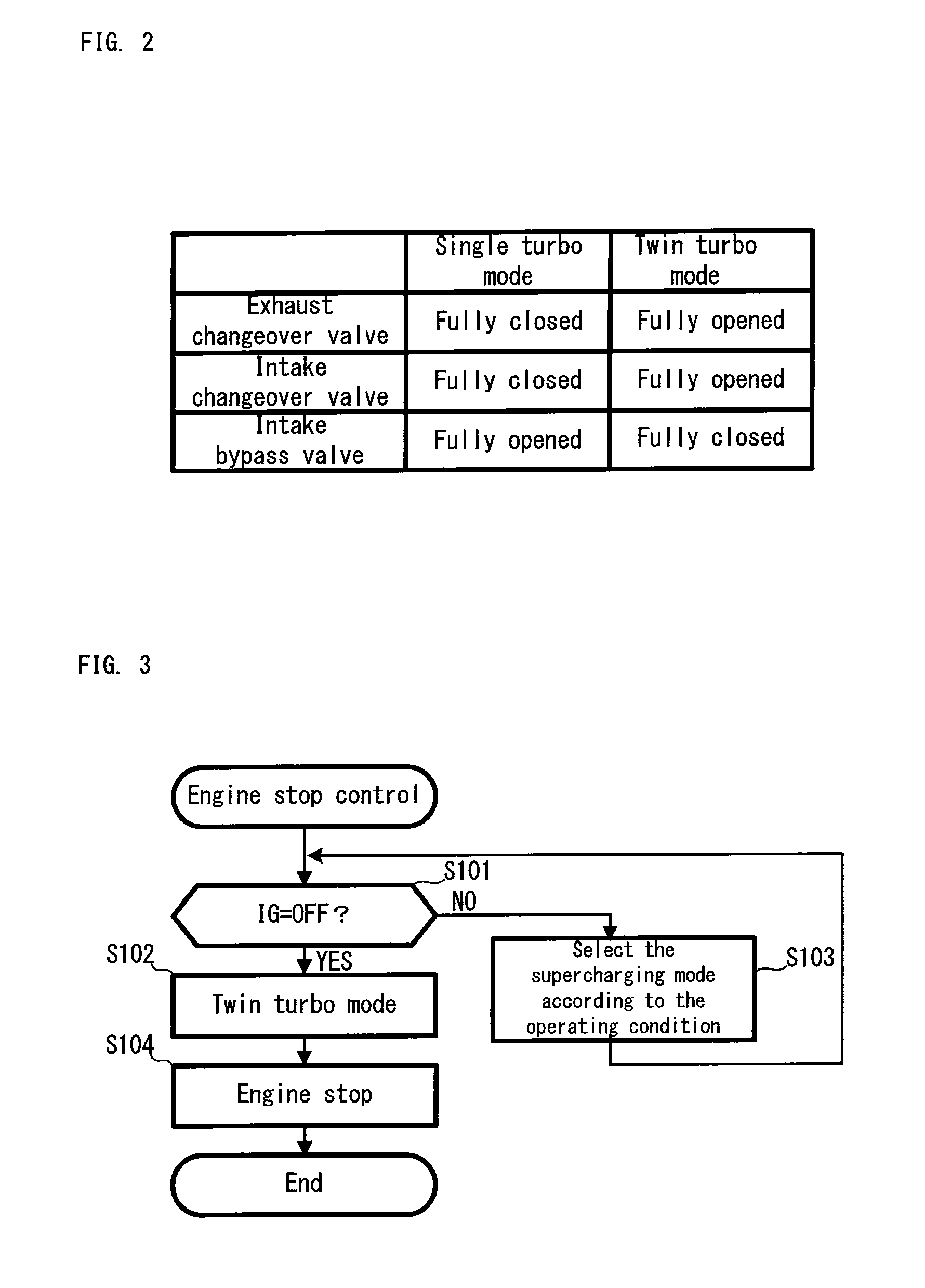

Control apparatus of vehicle

ActiveUS20110289919A1Easily and accurately judgedGood specificationElectrical controlInternal combustion piston enginesMechanical engineeringBypass valve

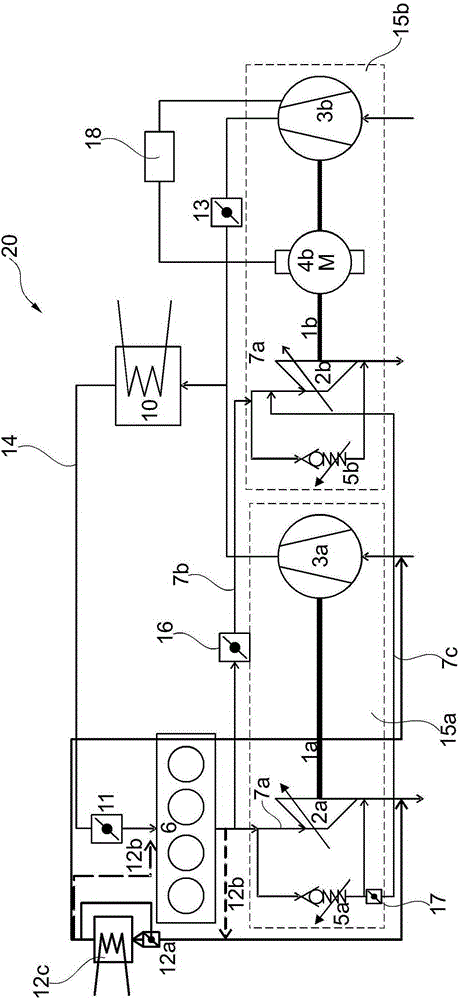

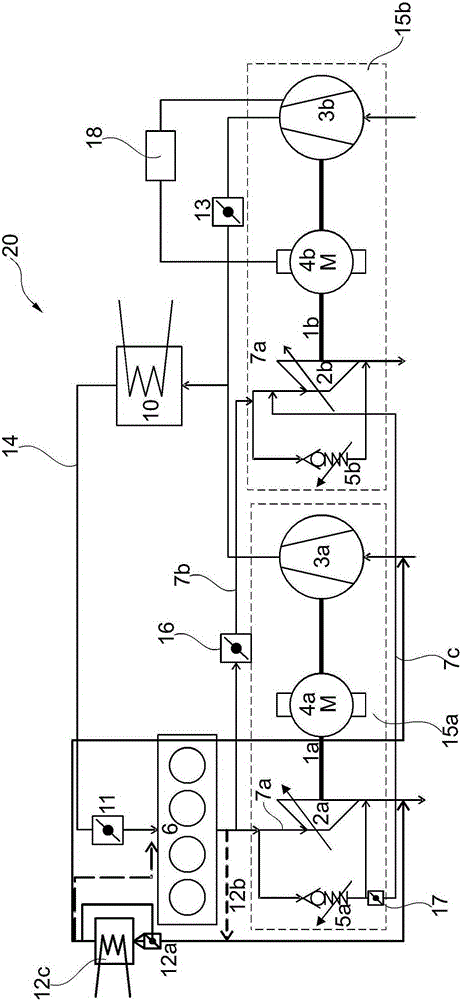

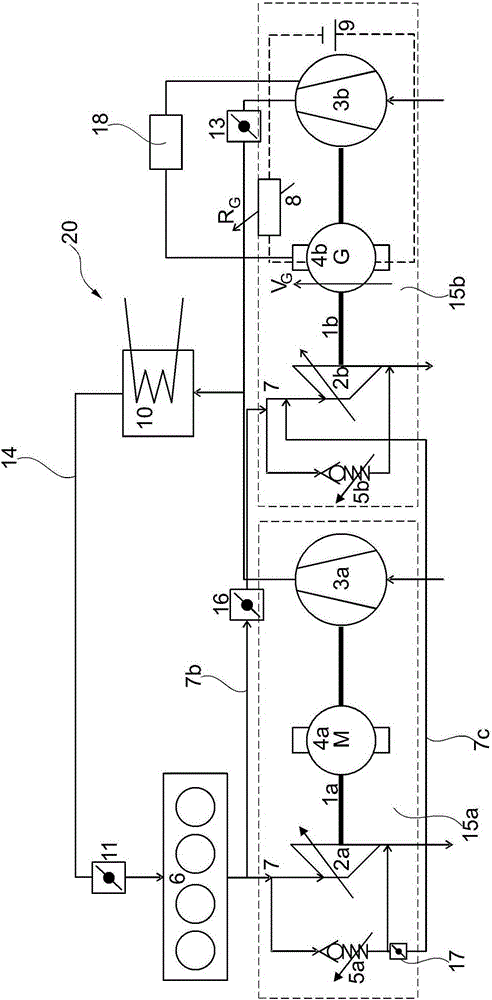

The subject is to efficiently detect the sticking of changeover valves for realizing a plurality of supercharging modes in a vehicle provided with a plurality of superchargers, and also to realize preferable fail-safe in cases where the sticking is detected. In a vehicle, which is provided with: a primary turbo and a secondary turbo, each of which is of an exhaust driven type; an exhaust changeover valve and an intake changeover valve, which are placed in a secondary exhaust passage and a secondary intake passage corresponding to the secondary turbo, respectively; and an intake bypass valve placed in an intake bypass passage, an ECU sets the opening / closing state of each changeover valve to an opening / closing state corresponding to a twin turbo mode at the time of engine stop, and it uses the drive control of each changeover valve which is necessitated in the transition to a single turbo mode at the engine start, thereby performing the sticking detection of the changeover valve at the same time.

Owner:TOYOTA JIDOSHA KK

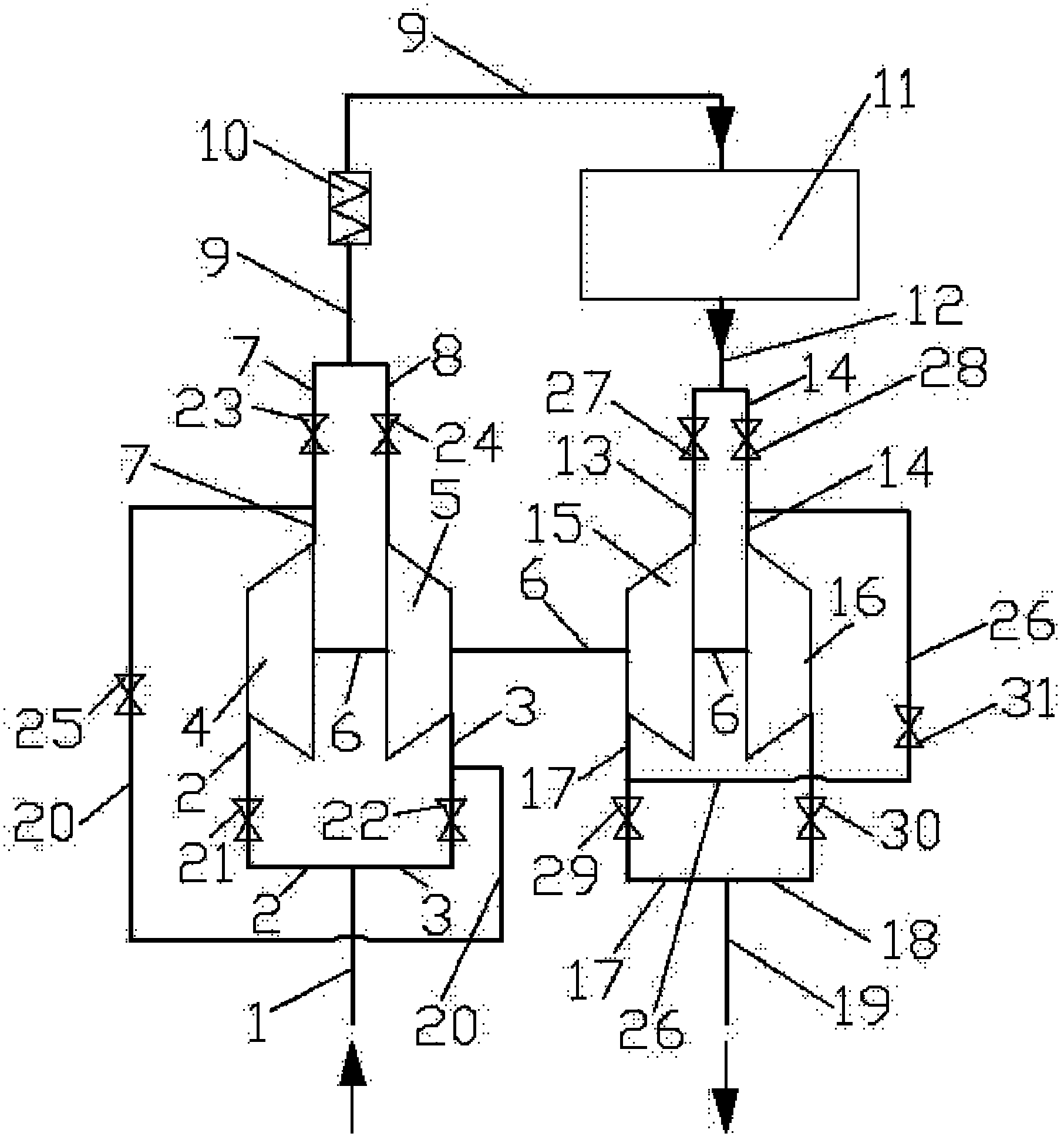

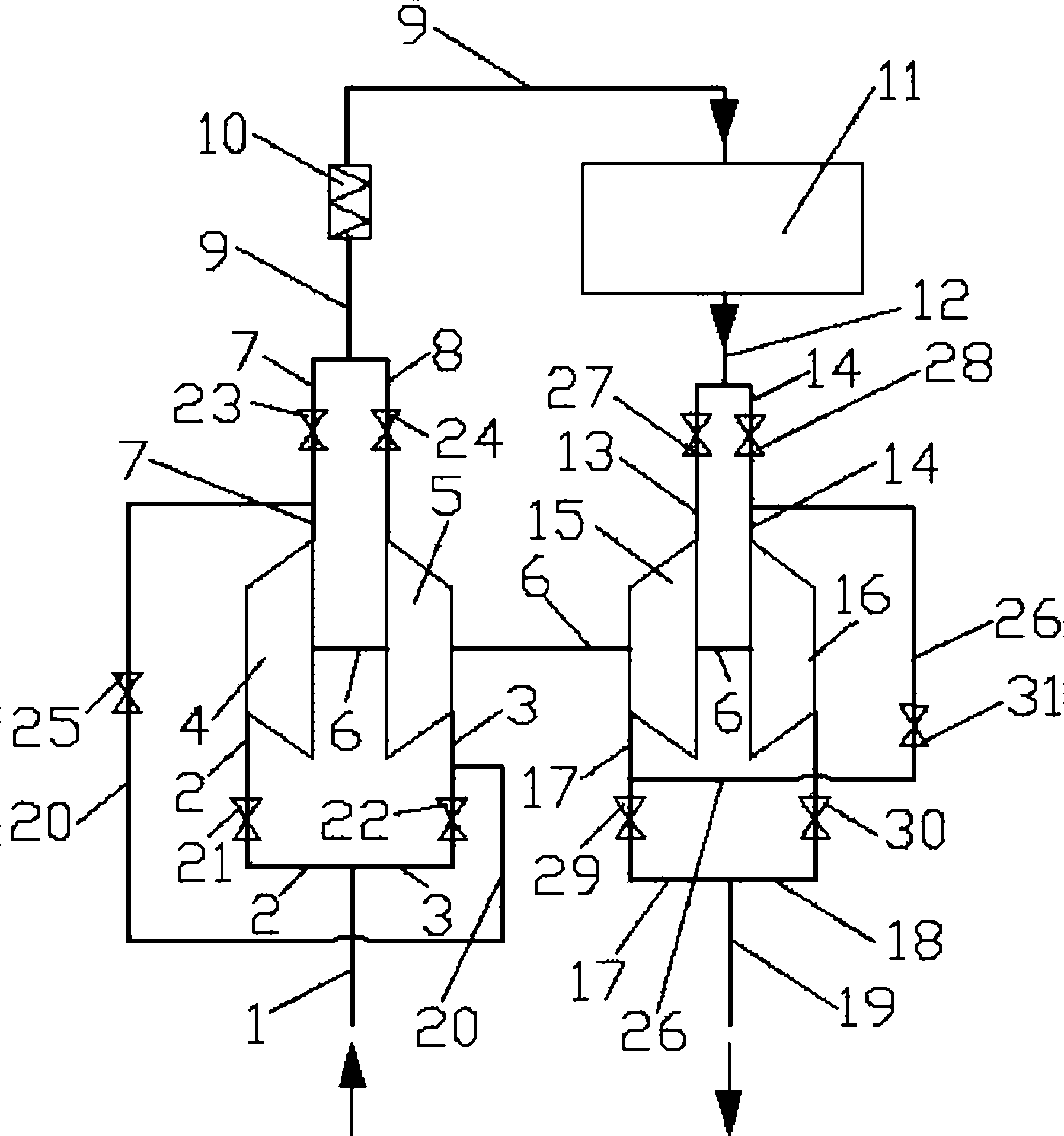

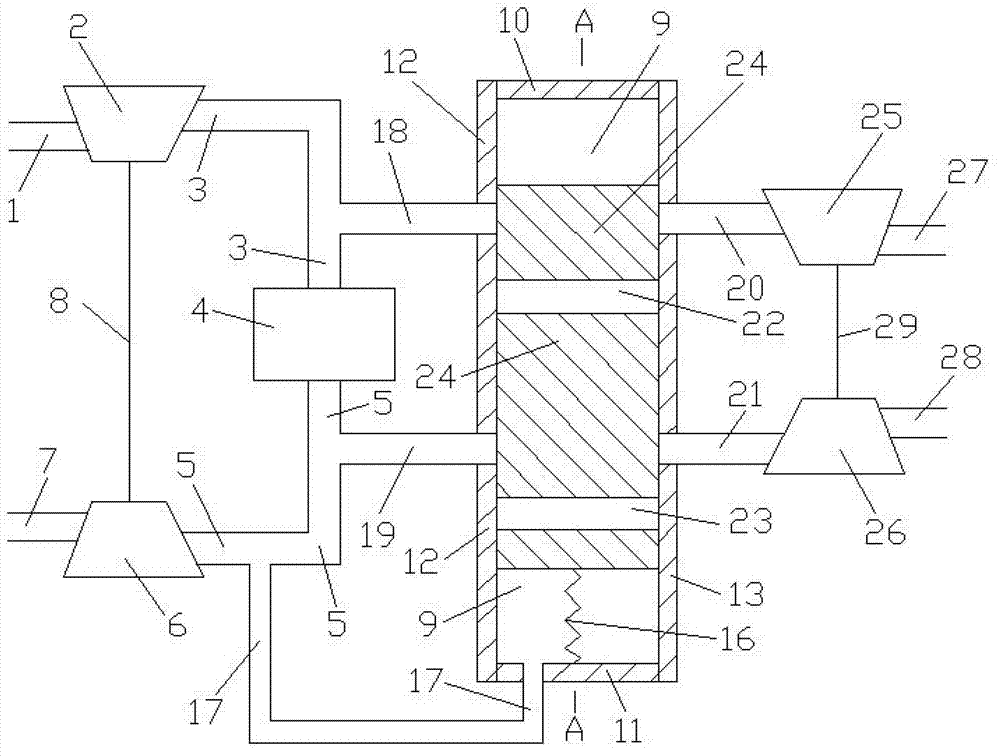

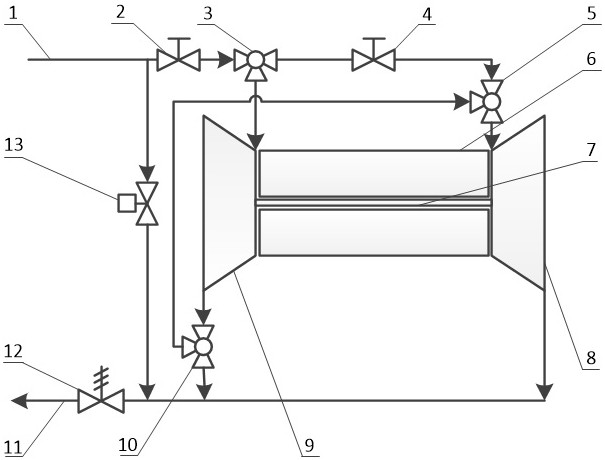

Double-turbine double-air-compressor turbocharging system

InactiveCN102434268ATo work aloneRealize parallel operationInternal combustion piston enginesCombustionTurbine blade

A double-turbine double-air-compressor turbocharging system belongs to the technical field of combustion engines and comprises an air inlet pipe, an air inlet main pipe, an engine, an air exhaust main pipe, an air exhaust pipe, a first air compressor, a second air compressor, a first turbine, a second turbine, connection shafts, a connection pipe and control valves. The first air compressor, the second air compressor, the first turbine and the second turbine are in coaxial connection through the connection shafts. The control valves are respectively arranged on an air compressor air inlet pipe, an air compressor air outlet pipe, an air compressor connection pipe, a turbine air inlet pipe, a turbine air outlet pipe and a turbine connection pipe. By adjusting opening and closing of different control valves, three working modes of the air compressors, namely a single air compressor, double air compressors in parallel and double air compressors in series can be achieved; and three working modes of the turbines, namely a single turbine, double turbines in parallel and double turbines in series can be achieved. The double-turbine double-air-compressor turbocharging system is reasonable in design, simple in control strategy and suitable for turbocharging systems with various cylinder numbers.

Owner:SHANGHAI JIAO TONG UNIV

Twin turbo diesel aftertreatment system

ActiveUS8371108B2Improve NOx conversion efficiencyImprove fuel economyElectrical controlInternal combustion piston enginesCombustionInternal combustion engine

Exhaust temperatures in emission control devices may be directly controlled by an intake air throttle, fuel injection timing, and exhaust pressure when an emission control device is placed between two variable geometry turbocharger exhaust turbines and coupled to a combustion engine. Such an approach may substantially raise the temperature of the exhaust aftertreatment devices in an emission control device during non-warmed exhaust conditions, leading to faster catalytic light-off.

Owner:FORD GLOBAL TECH LLC

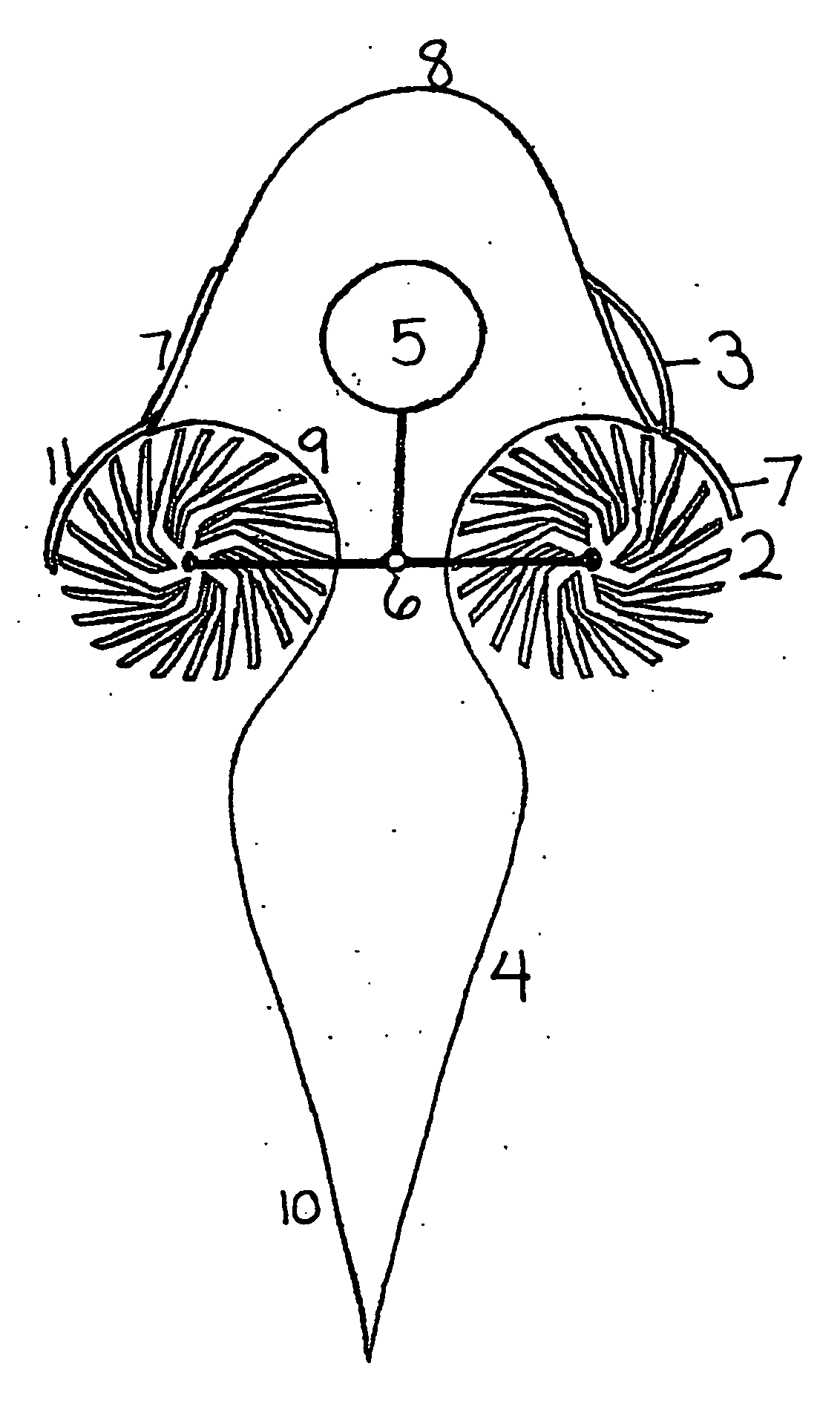

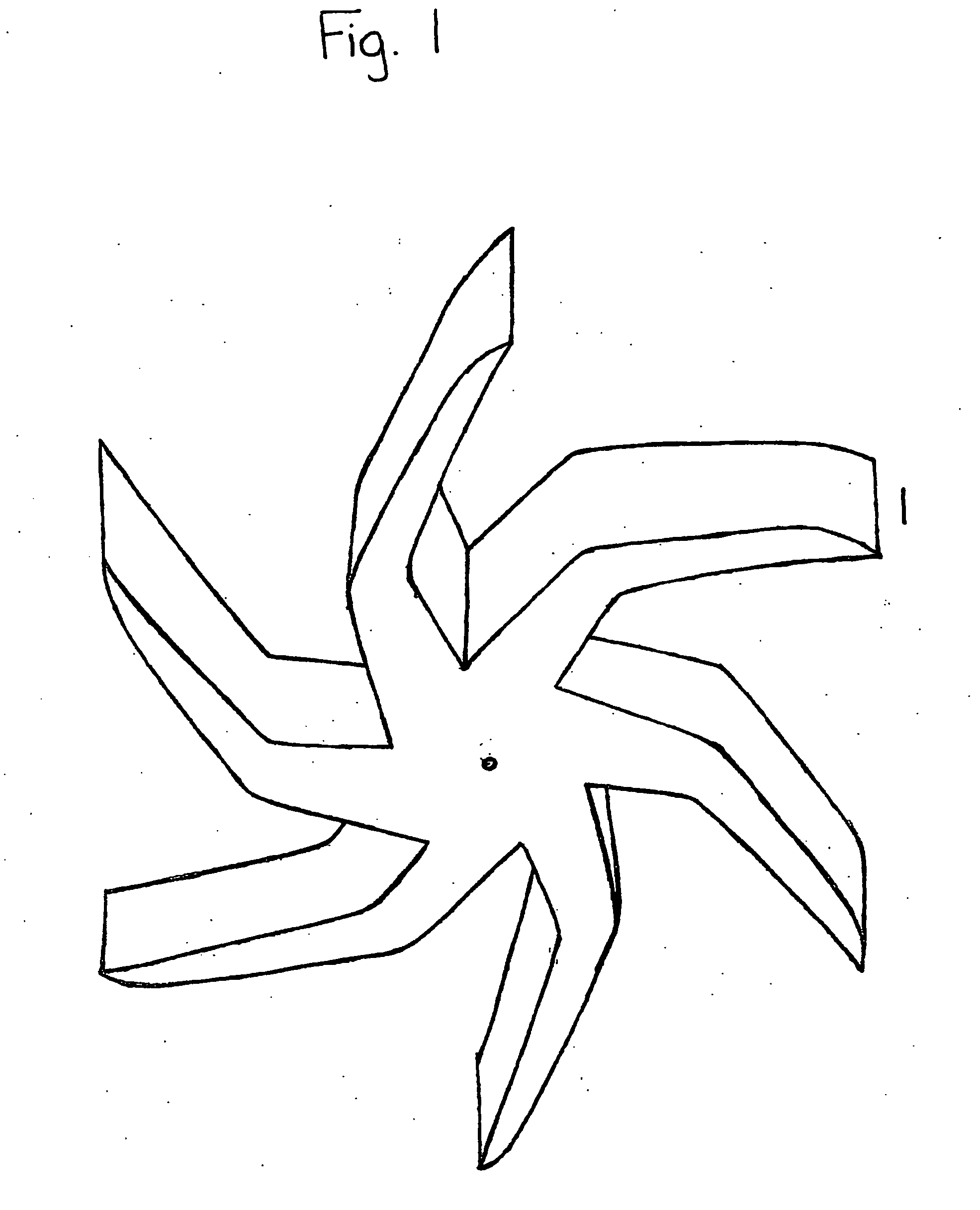

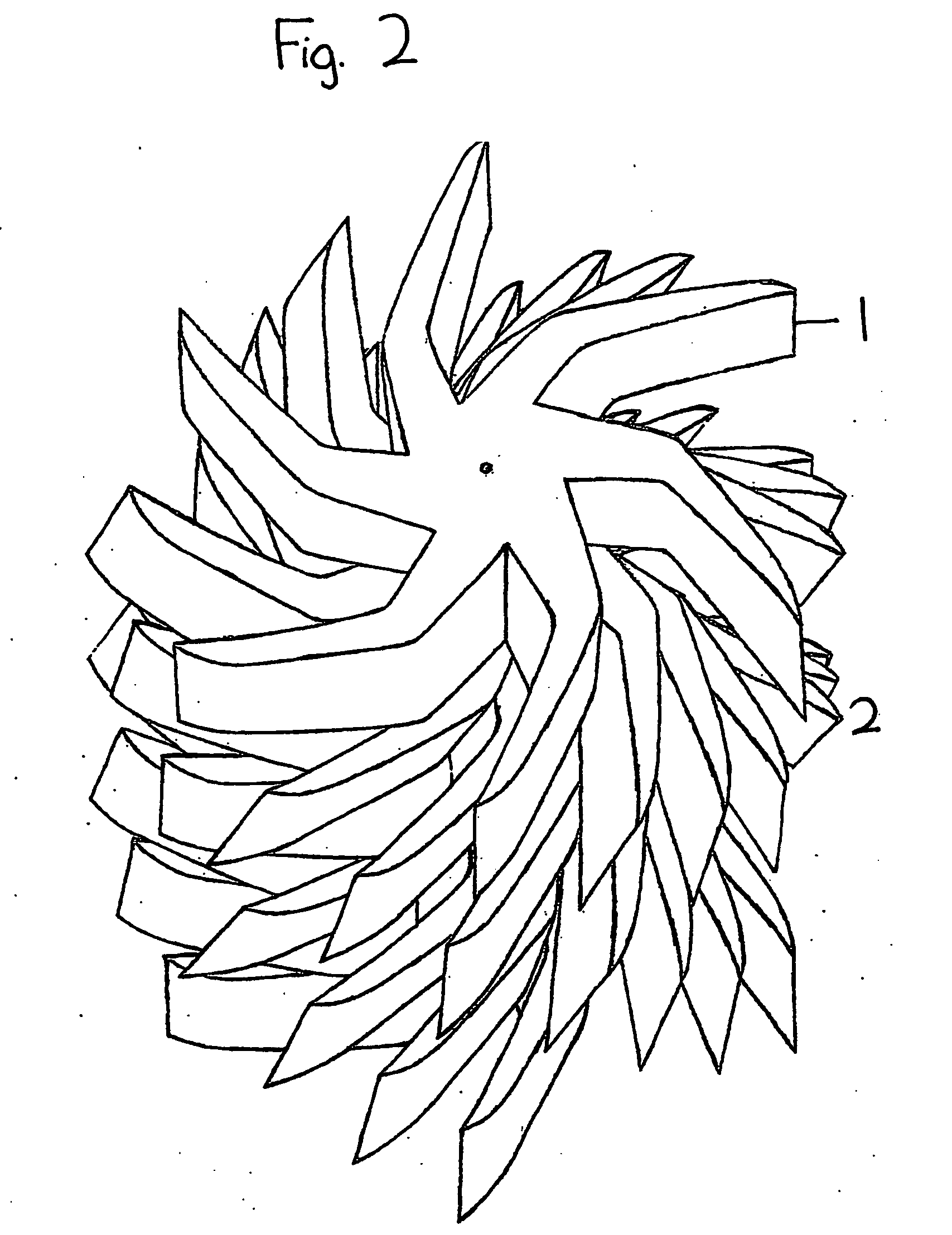

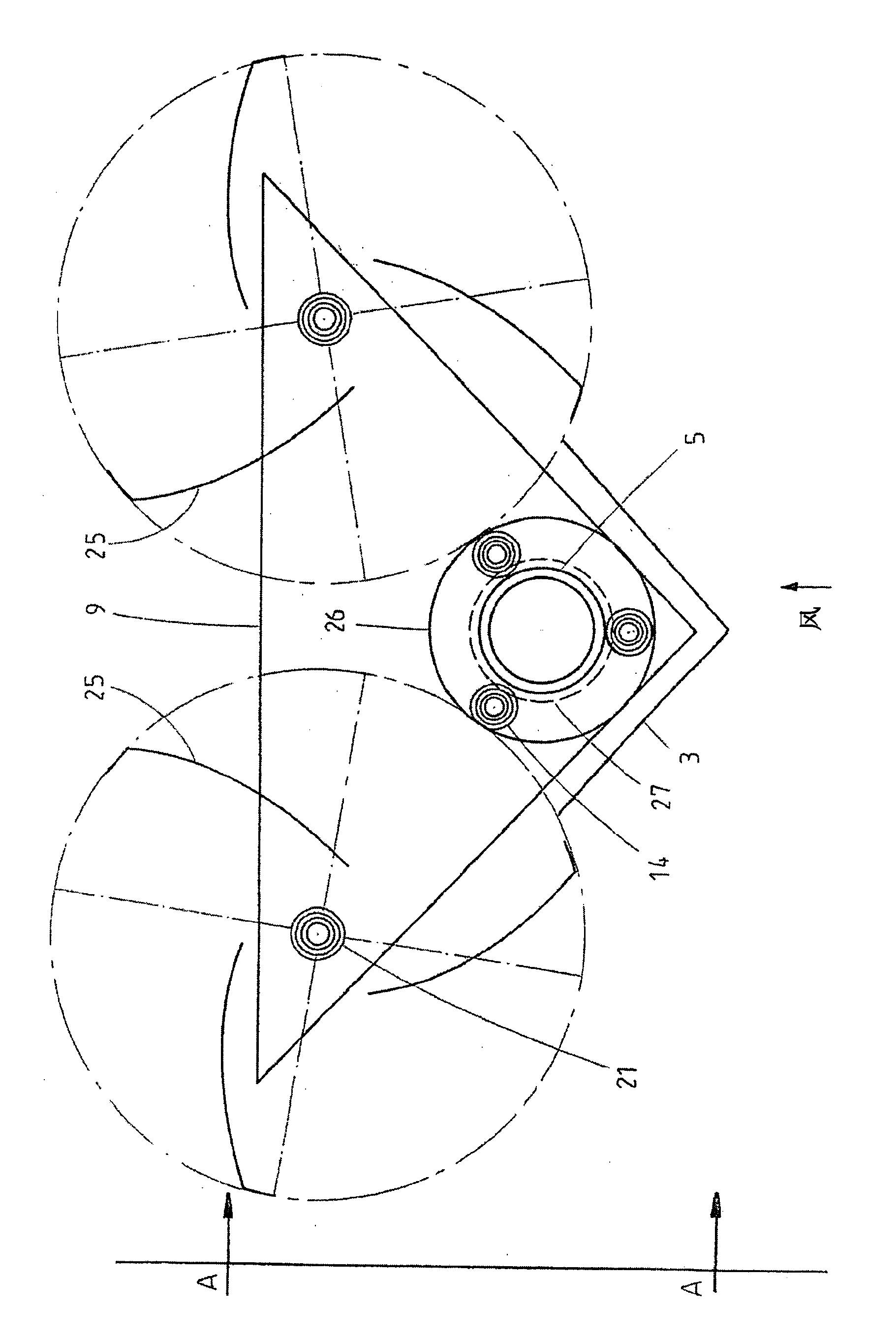

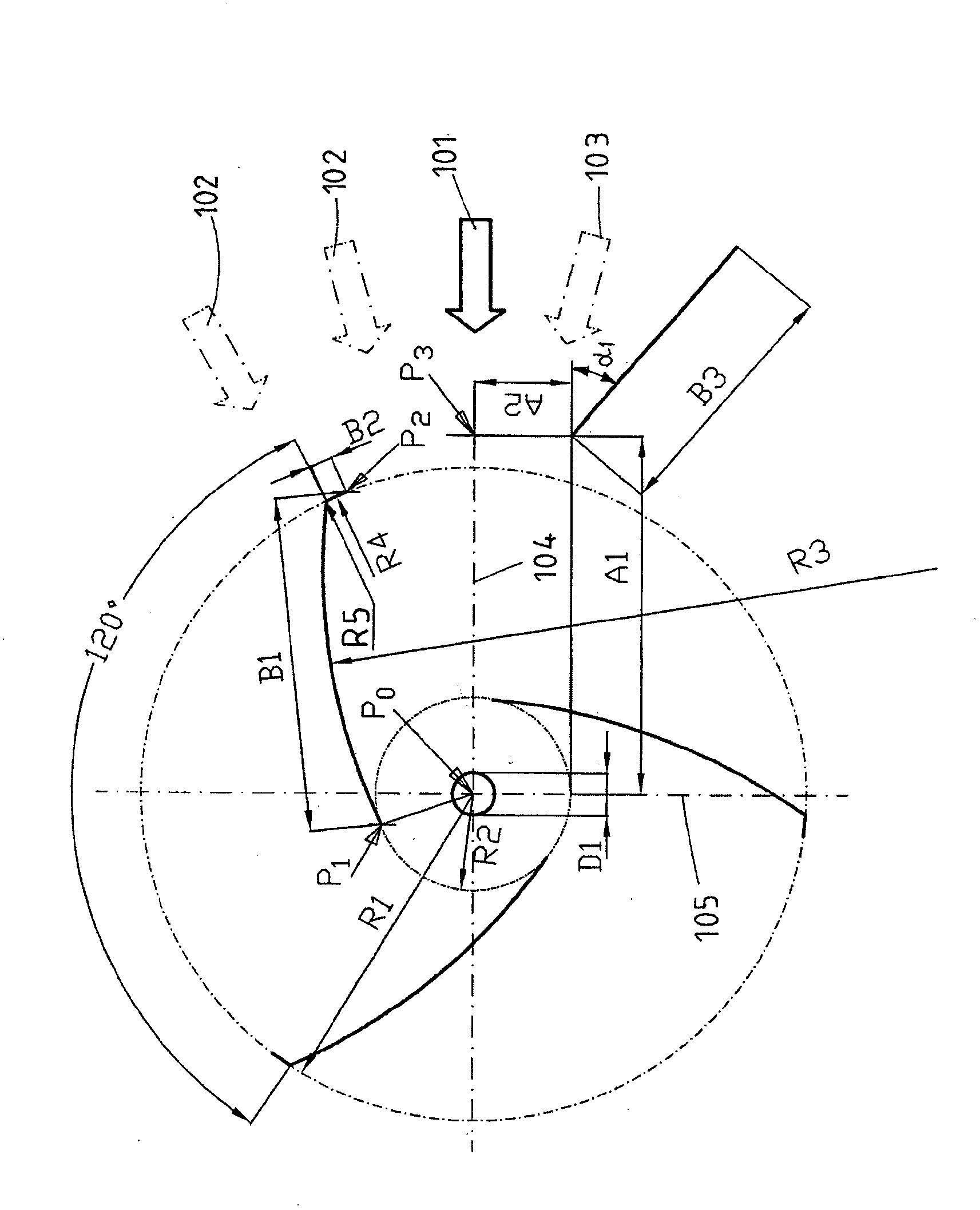

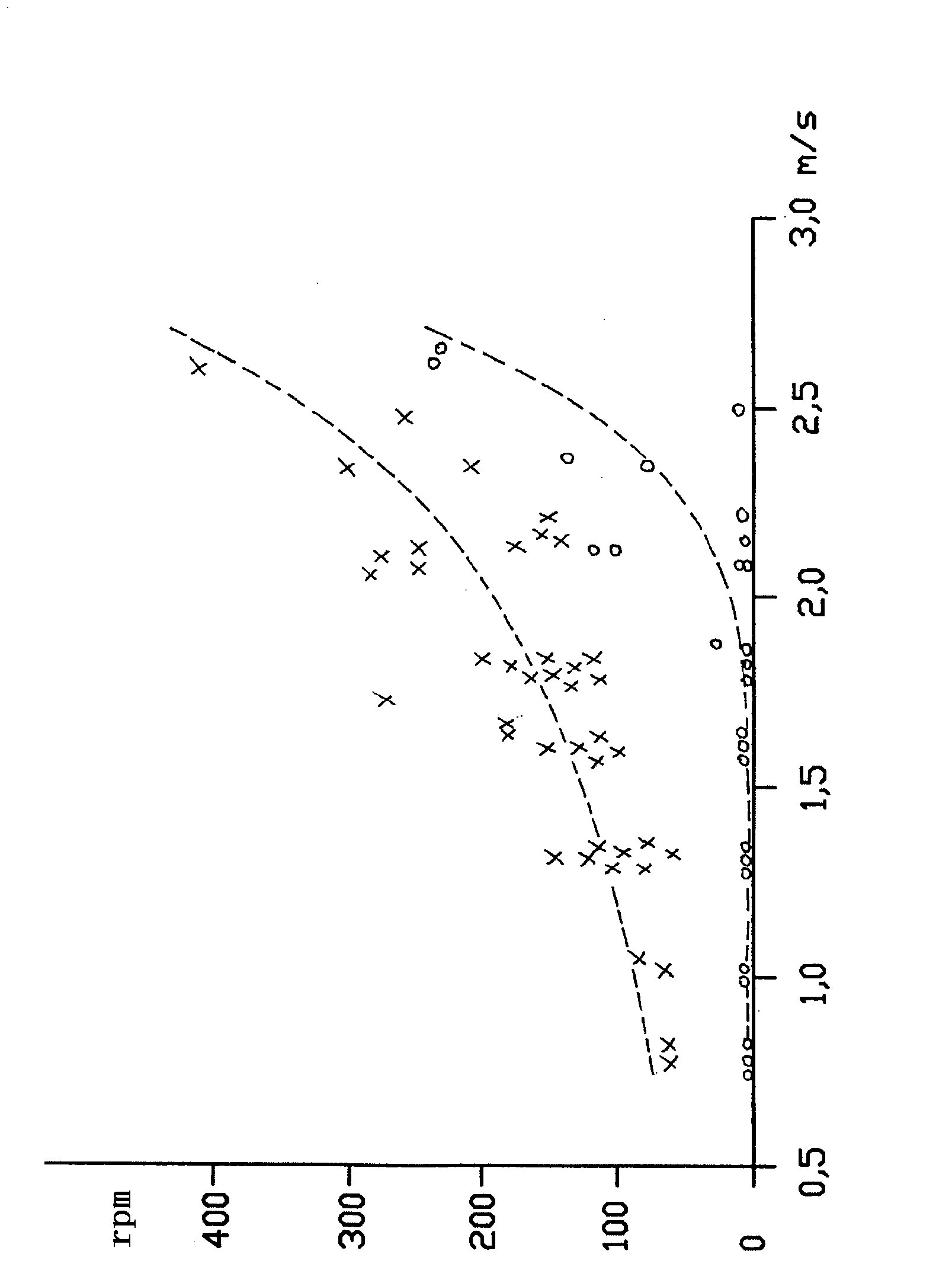

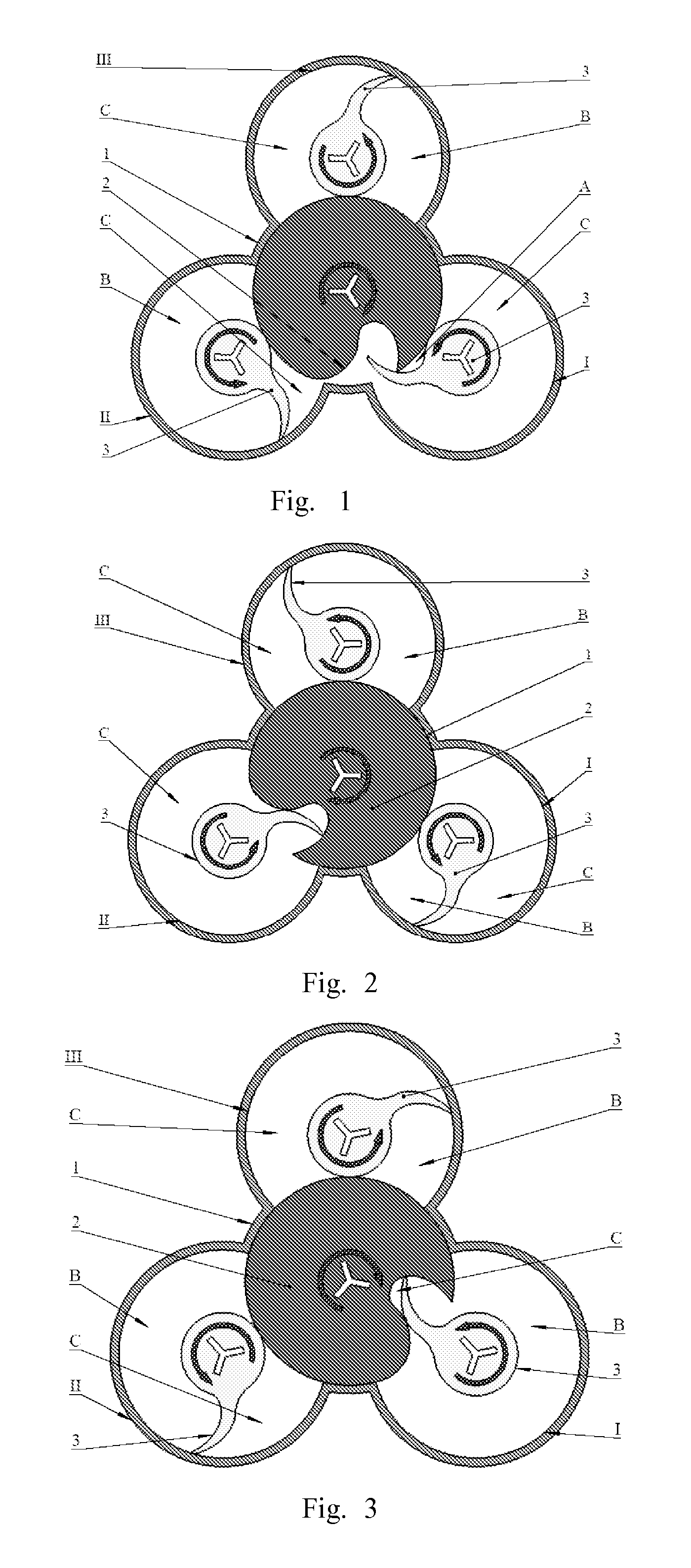

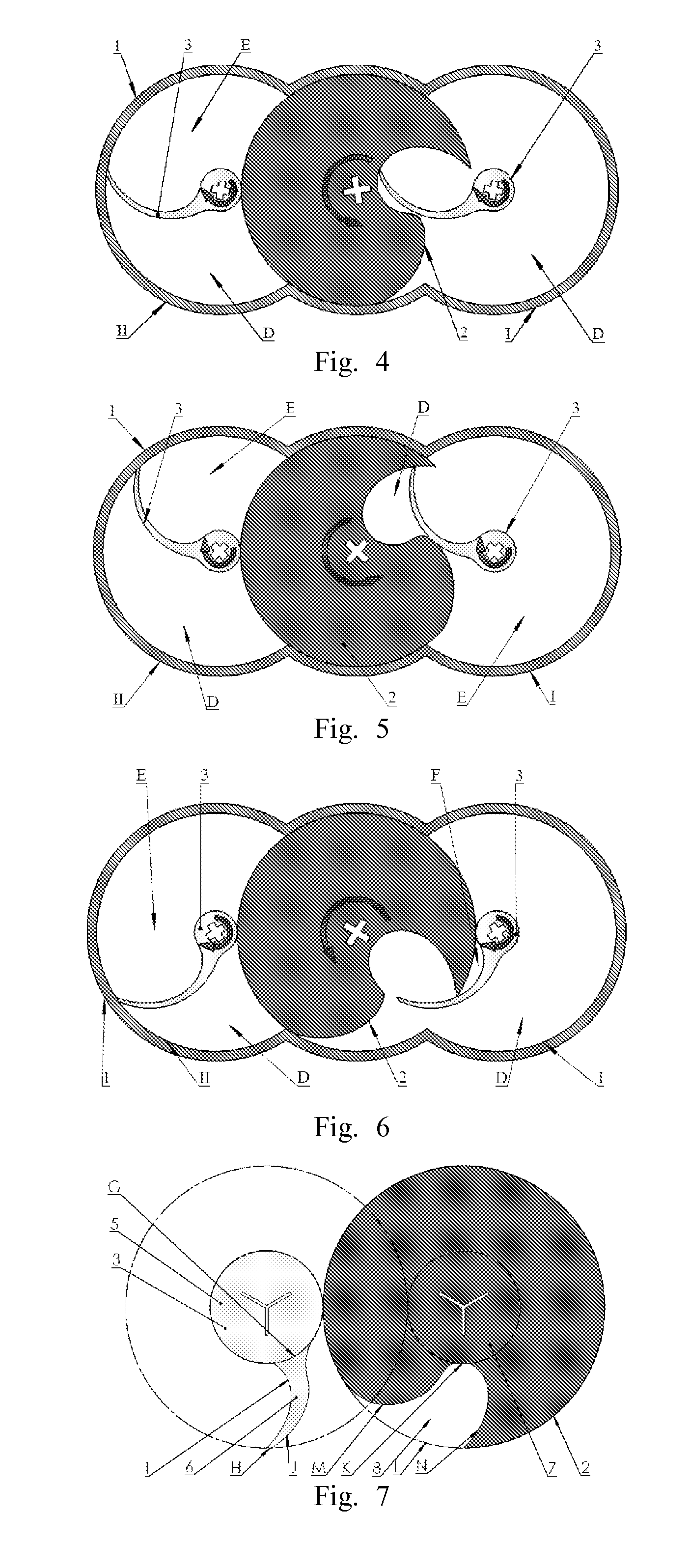

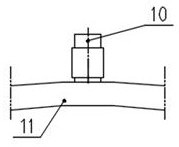

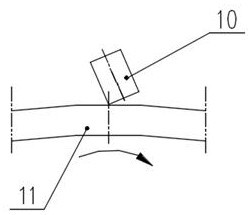

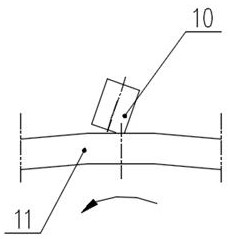

Twin turbine system which follows the wind/water (windtracker) for wind and/or water power, with optimized blade shape

ActiveCN103221684AImprove performanceLow efficiencyMachines/enginesWind motor combinationsTurbine bladeClassical mechanics

The turbine system for wind and / or water power, wherein the radial turbines have a rotor which can rotate about an axis and comprises one or more turbine blades, wherein the turbine blades are aligned parallel to the rotor, wherein the turbine blades are arranged within a cylindrical shell, which is arranged concentrically around the axis and has an outer radius R1 and an inner radius R2, is characterized in that the turbine blades have a specific geometry and in that two radial turbines (1, 2) which are aligned alongside one another and parallel are arranged, which radial turbines (1, 2) are connected to one another and can pivot about a pivoting axis (15) parallel to the turbine axes (18), wherein the pivoting axis and the guide surfaces (3, 4) are not located on the connecting line between the turbine axes, and are both located on the same side of the connecting line. It is proposed that the abstract be published without any drawing.

Owner:ウインドクワイエット テクノロジーズ インコーポレーテッド

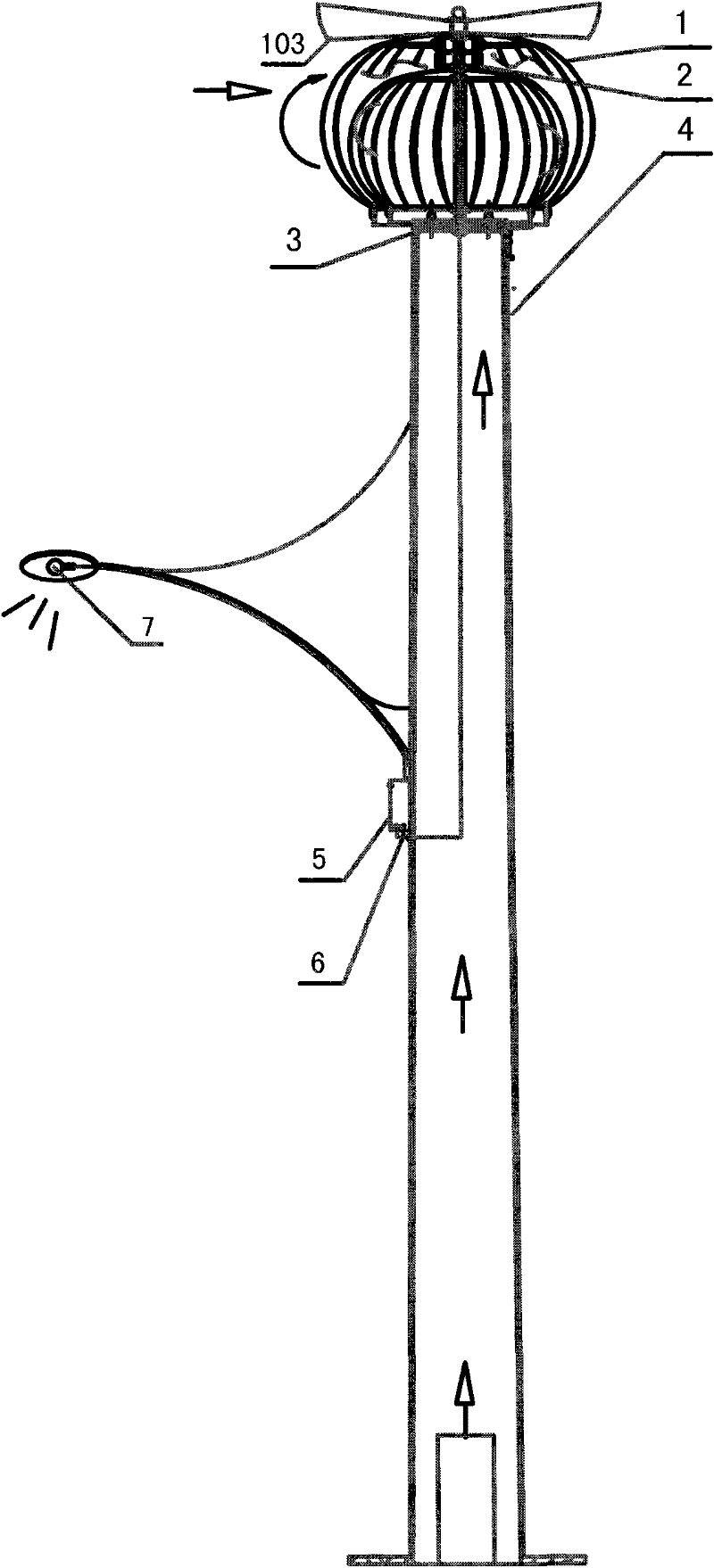

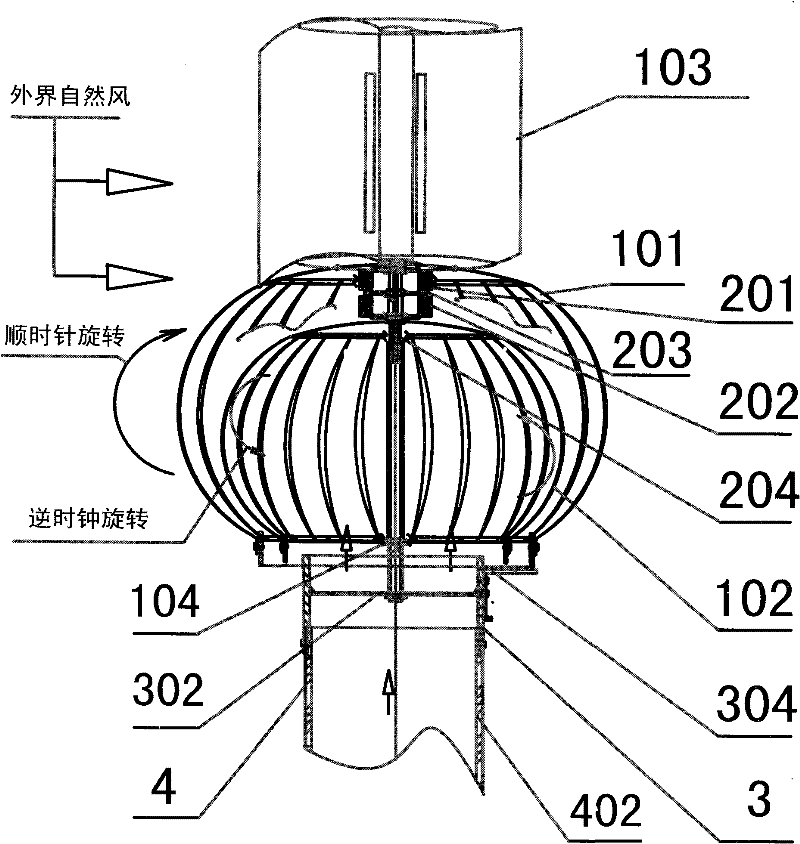

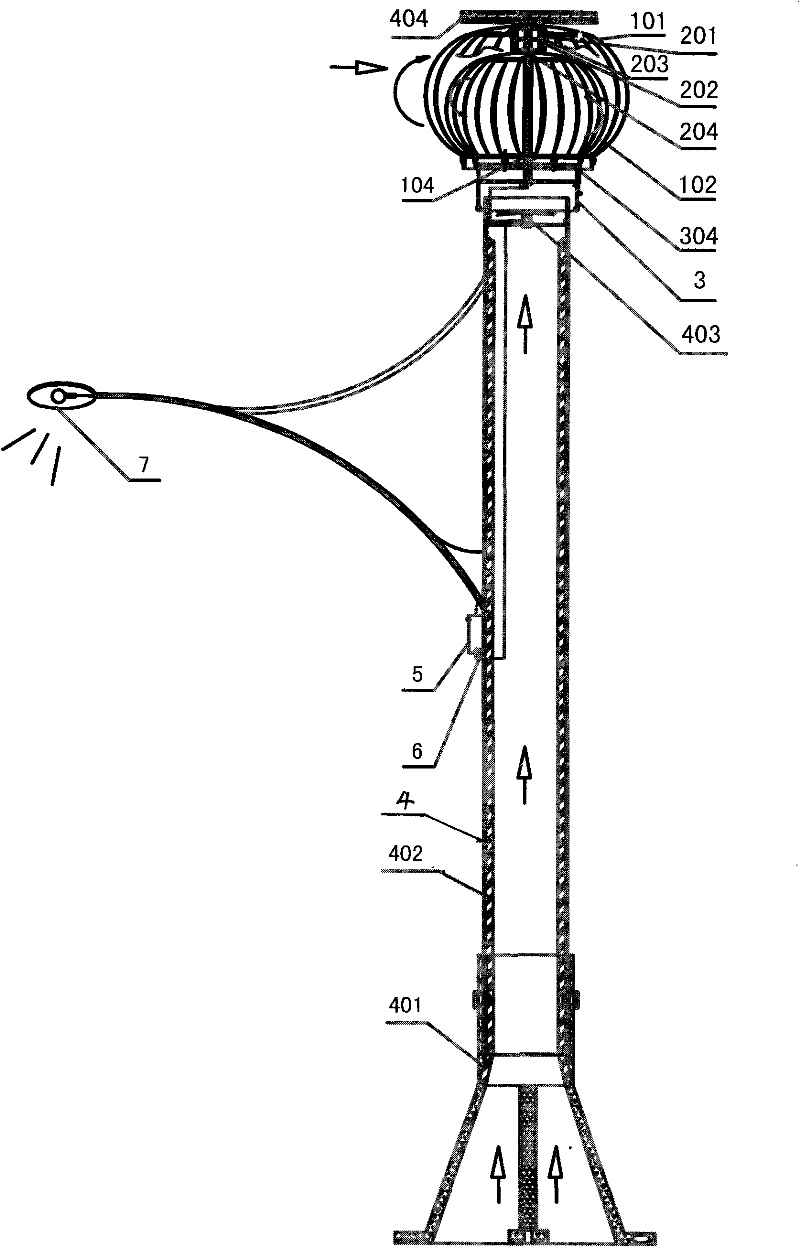

Twin Turbine Interactive Wind Power Lamp

ActiveCN102287743AIncrease output powerReduce volumeLighting support devicesOutdoor lightingLinear motionNew energy

The invention relates to a dual-turbo interactive wind power generation streetlamp, and belongs to the technical field of new energy resources. Two turbo type spherical wind wheels are respectively arranged on two outer rotors of a coaxial motor; a main shaft is fixed in a rack; a guide line is respectively connected with a generator, a control box, a lamp, a photovoltaic cell and an air induction fan; the streetlamp is characterized in that: a second wind wheel is arranged in a first wind wheel; the inner wall of a lamp post is provided with a spiral air channel and the air induction fan, soair flow ascends from linear motion to spiral rotation, strong spiral type rotation torque is generated to drive the second wind wheel to rotate counterclockwise, the air flow is exhausted from gaps of a plurality of arc blades to drive the first wind wheel to rotate clockwise, and the two wind wheels produce motion supporting action to drive the two outer rotors to rotate and generate power along different directions; and the exhaust direction of the air flow is changed and isolated, and the defect that two air flows are mutually offset when outside wind power is greater than airflow in the post is overcome, so the efficiency of the generator is improved by more than one time, and the generator can rotate and generate power around the clock under the normal conditions of breeze and ash breeze.

Owner:天津滨海新区嘉和祥宇科技发展有限公司

vehicle controls

InactiveCN102292529AObvious excellenceElectrical controlNon-fuel substance addition to fuelEngineeringFail-safe

The subject is to efficiently detect the sticking of changeover valves for realizing a plurality of supercharging modes in a vehicle provided with a plurality of superchargers, and also to realize preferable fail-safe in cases where the sticking is detected. In a vehicle, which is provided with: a primary turbo 300 and a secondary turbo 400, each of which is of an exhaust driven type; an exhaust changeover valve 210 and an intake changeover valve 21G, which are placed in a secondary exhaust passage 209 and a secondary intake passage 215 corresponding to the secondary turbo 400, respectively; and an intake bypass valve 218 placed in an intake bypass passage 217, an ECU 100 sets the opening / closing state of each changeover valve to an opening / closing state corresponding to a twin turbo mode at the time of engine stop, and it uses the drive control of each changeover valve which is necessitated in the transition to a single turbo mode at the engine start, thereby performing the sticking detection of the changeover valve at the same time.

Owner:TOYOTA JIDOSHA KK

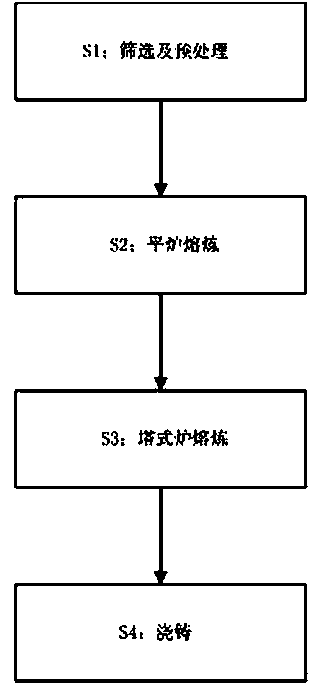

Application method of aluminium scraps in aluminium alloy cylinder cover casting

The invention discloses an application method of aluminium scraps in aluminium alloy cylinder cover casting. The method comprises the following four steps of screening and preprocessing; open-hearth furnace smelting; tower-type furnace smelting; and casting; by virtue of arrangement of a preprocessing system, the aluminium scraps are put in the preprocessing system to be dewatered, deoiled and dried; in the tower-type furnace smelting step, the aluminium scraps are directly immersed into molten aluminum when added by virtue of rotation of a twin turbo so as to reduce the burning loss. Proved by production practices, the aluminium scrap using amount of aluminium alloy cylinder cover castings can be up to 50% at present and the castings can completely meet the requirements of salt spray tests and metallographic tests, so that the production cost is effectively reduced and the product benefit is increased.

Owner:WUHU YONGDA TECH

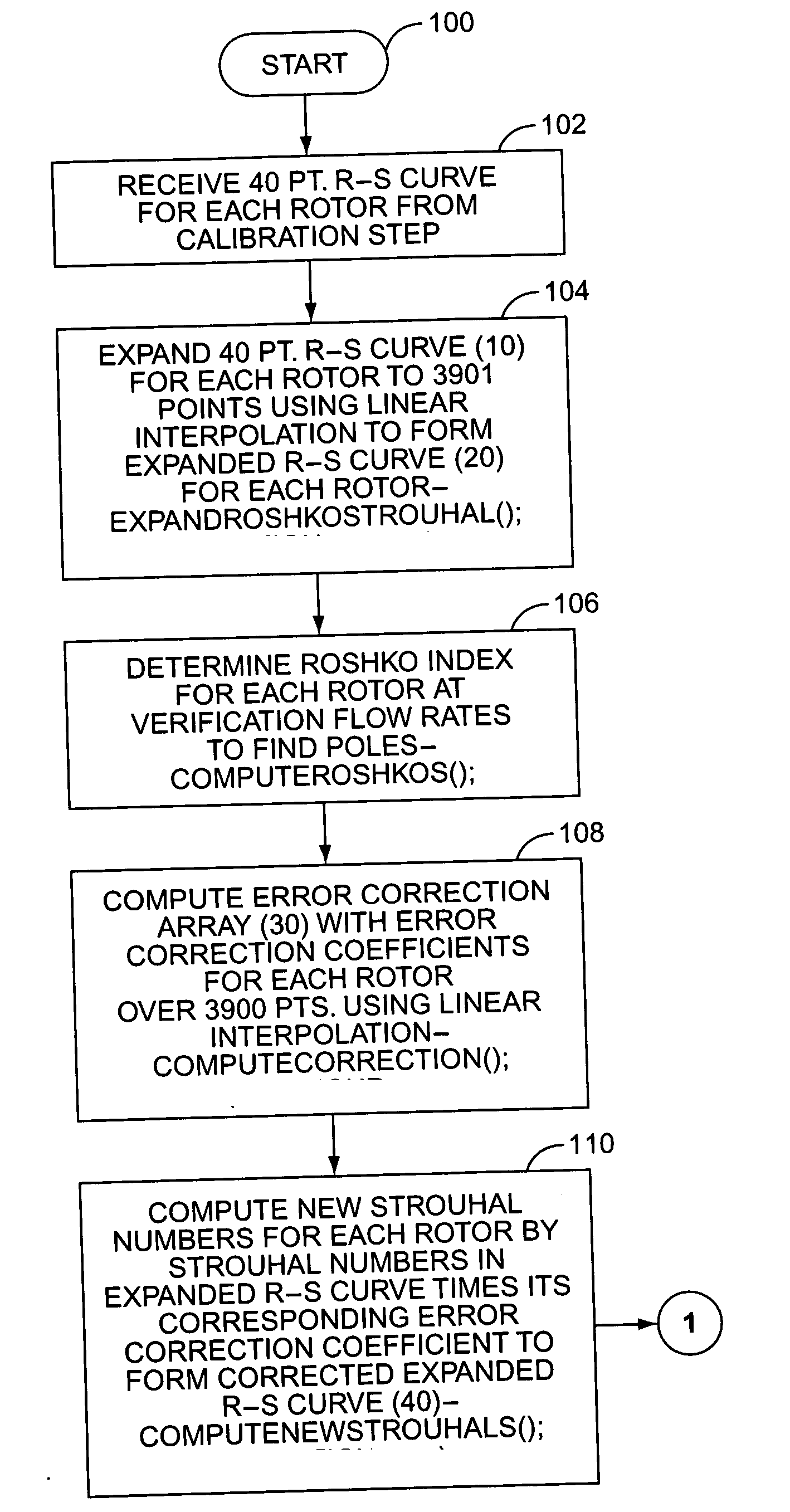

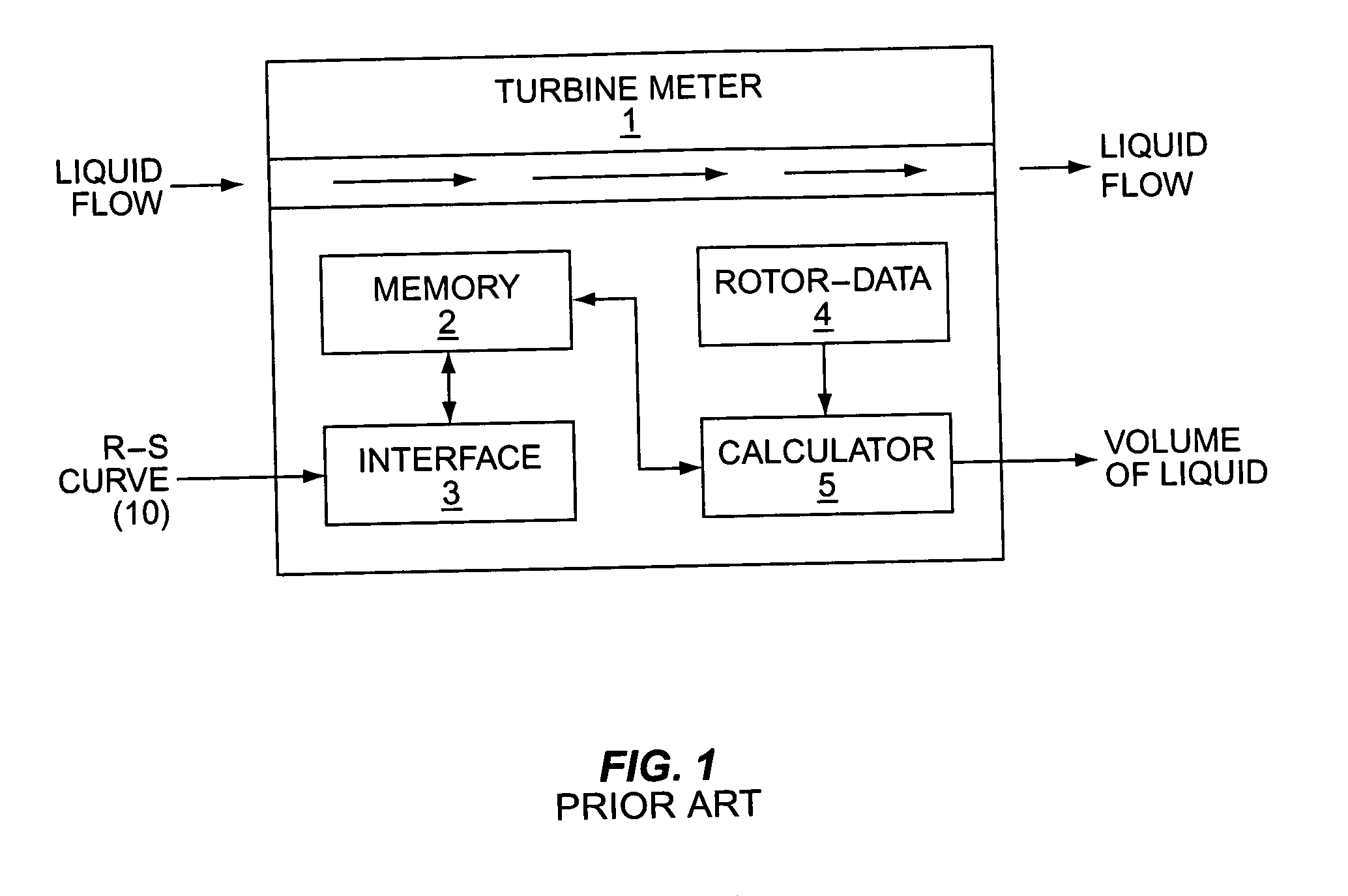

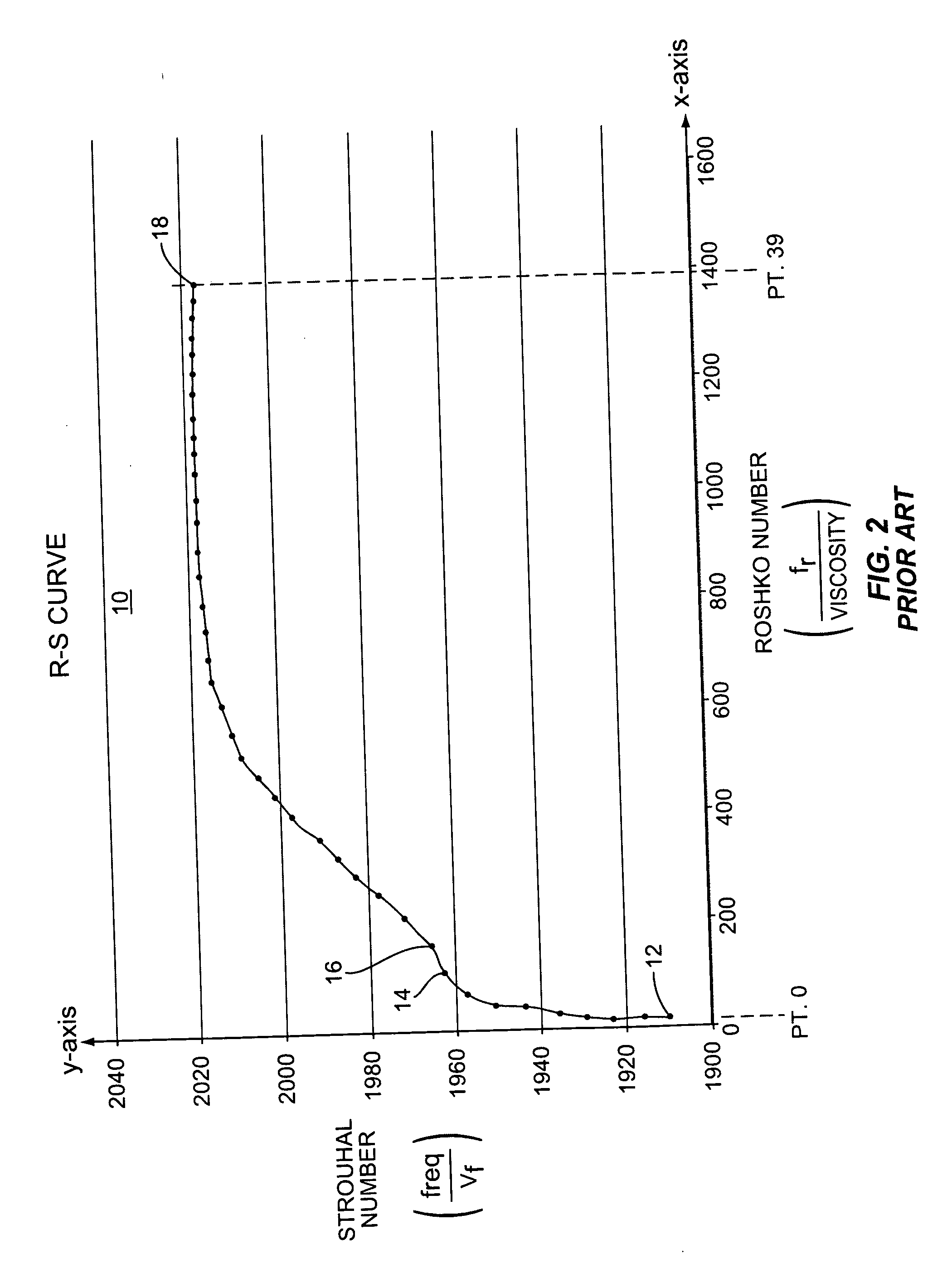

Nullification of measurement error, particularly within a dual turbine flow meter used in a fuel dispenser

InactiveUS20050283329A1Fluid pressure measurementLiquid transferring devicesEngineeringCalibration curve

A system and method for correcting a meter calibration curve in a fuel dispenser. The meter may be a turbine flow meter. A meter calibration curve is expressed in a finite number of data points. The meter calibration curve is used to determine the volume and / or flow rate of liquid flowing through the meter. Since the meter calibration curve may contain errors, the meter calibration curve is corrected by determining poles in the meter calibration curve for given known flow rates and / or volumes of liquid passing through the meter, determining an error correction at each of the poles in the meter calibration curve, correcting the expanded meter calibration curve at each of the poles, using linear interpolation to correct points in the meter calibration curve adjacent to the poles.

Owner:GILBARCO

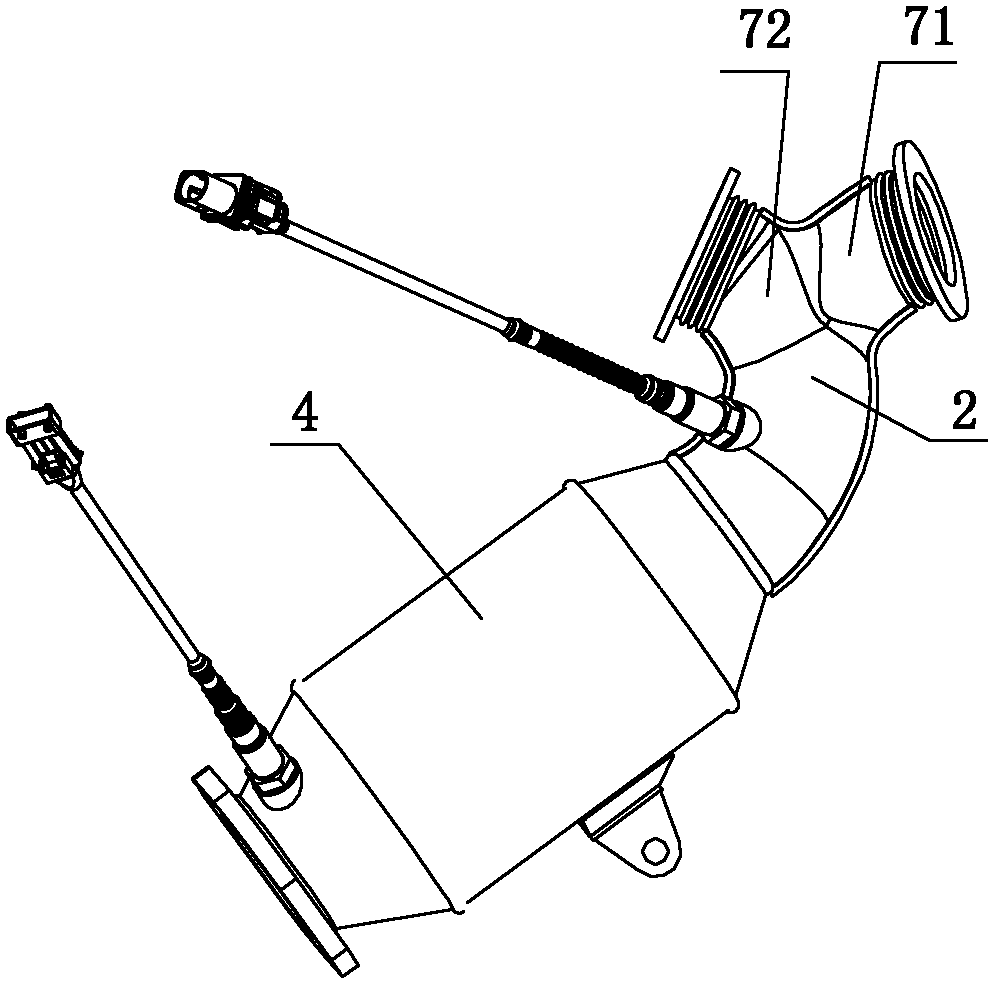

Waste gas post-processing system of twin-turbo supercharged engine

InactiveCN102588051AReduce temperature and pressurePass smoothlyInternal combustion piston enginesExhaust apparatusProcess engineeringTwin-turbo

The invention discloses a waste gas post-processing system of a twin-turbo supercharged engine, which belongs to the technical field of engines and is aiming at solving the problem that the three-way catalytic conversion efficiency is low in the prior art. The waste gas post-processing system of a twin-turbo supercharged engine comprises a first gas exhaust manifold and a second gas exhaust manifold, wherein a gas inlet of the first gas exhaust manifold is connected to a waste gas outlet of a first turbo supercharger; a gas inlet of the second gas exhaust manifold is connected to a waste gas outlet of a second turbo supercharger; the gas outlet of the first gas exhaust manifold and the gas outlet of the second gas exhaust manifold are connected to a three-way catalyst; a meeting chamber is arranged among the gas outlet of the first gas exhaust manifold and the gas outlet of the second gas exhaust manifold and the three-way catalyst; the gas outlets of the first gas exhaust manifold and the second gas exhaust manifold are connected to the meeting chamber after being converged; and the meeting chamber is connected to the catalyst. The waste gas post-processing system of a twin-turbo supercharged engine disclosed by the invention is used for processing the waste gas produced by an engine.

Owner:GREAT WALL MOTOR CO LTD

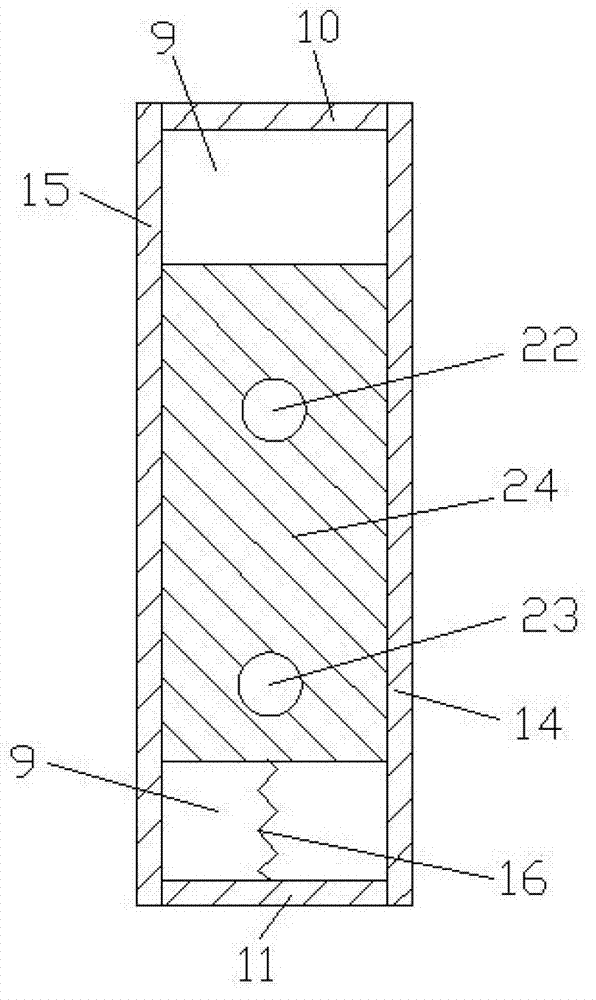

Parallel system of twin-turbo supercharger

InactiveCN102817700AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesLow speedCombustion

The invention provides a parallel system of a twin-turbo supercharger, relating to the technical fired of combustion motors, and comprising air compressors, an air inlet pipe, an engine, an air exhaust pipe, turbos, a volume chamber, connection pipes, a moving body, a spring and penetration pipes, wherein the moving body is installed in the volume chamber and further contacts with the inner wall face of the volume chamber in a sealing way; the first penetration pipe and the second penetration pipe penetrate through the left wall face and the right wall face of the moving body; and the lower wall face of the moving body is connected with the lower wall face of the volume chamber through the spring. When the engine is located under the low speed working condition, the moving body moves downward; only the first air compressor and the first turbo work; the pulse energy is fully utilized; the air inlet pressure of the engine is higher; and the overall performance of the engine is better. When the engine is located in the high speed working condition, the moving body moves upward; the first air compressor, the second air compressor, the first turbo and the second turbo simultaneously work; the pumping loss of the engine is less; and the overall performance of the engine is better. The parallel system of the twin-turbo supercharger is rational in design, simple in structure and applicable for a turbo charging system with two turbo superchargers.

Owner:SHANGHAI JIAO TONG UNIV

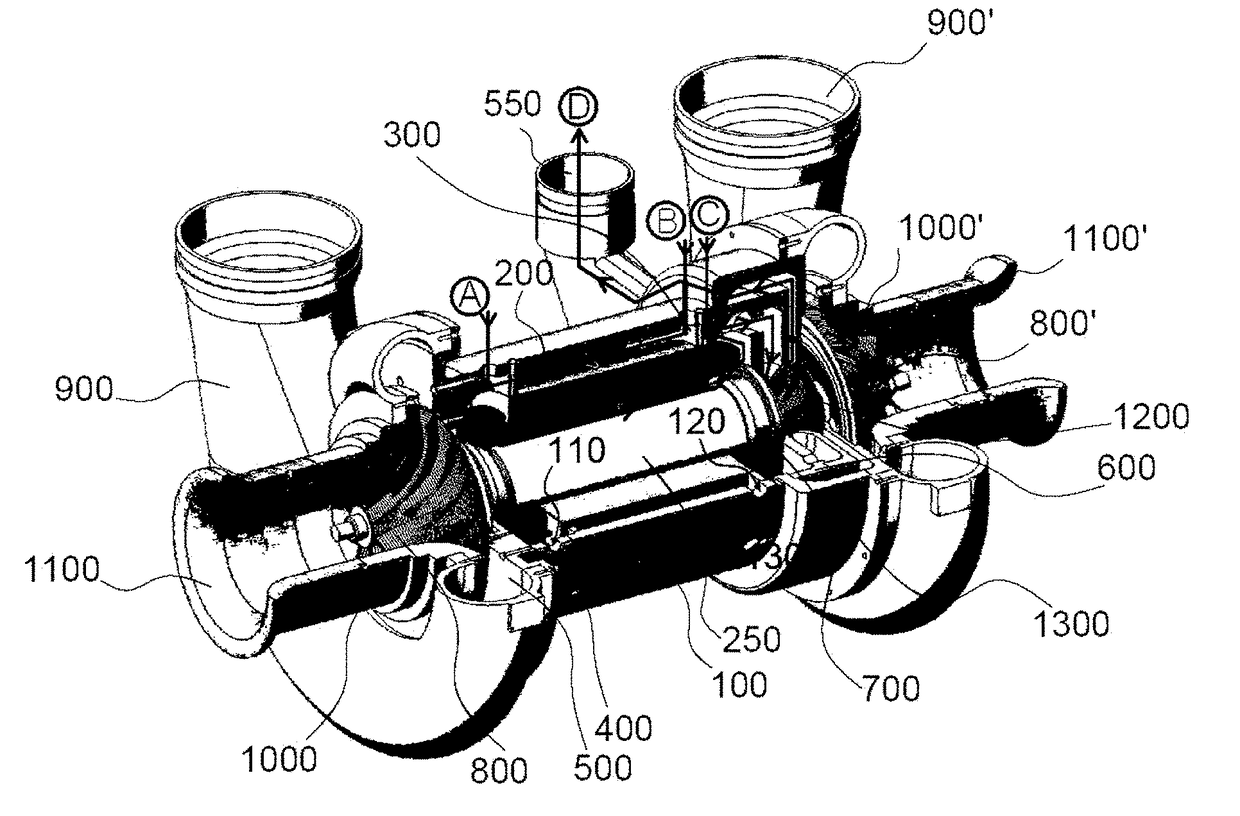

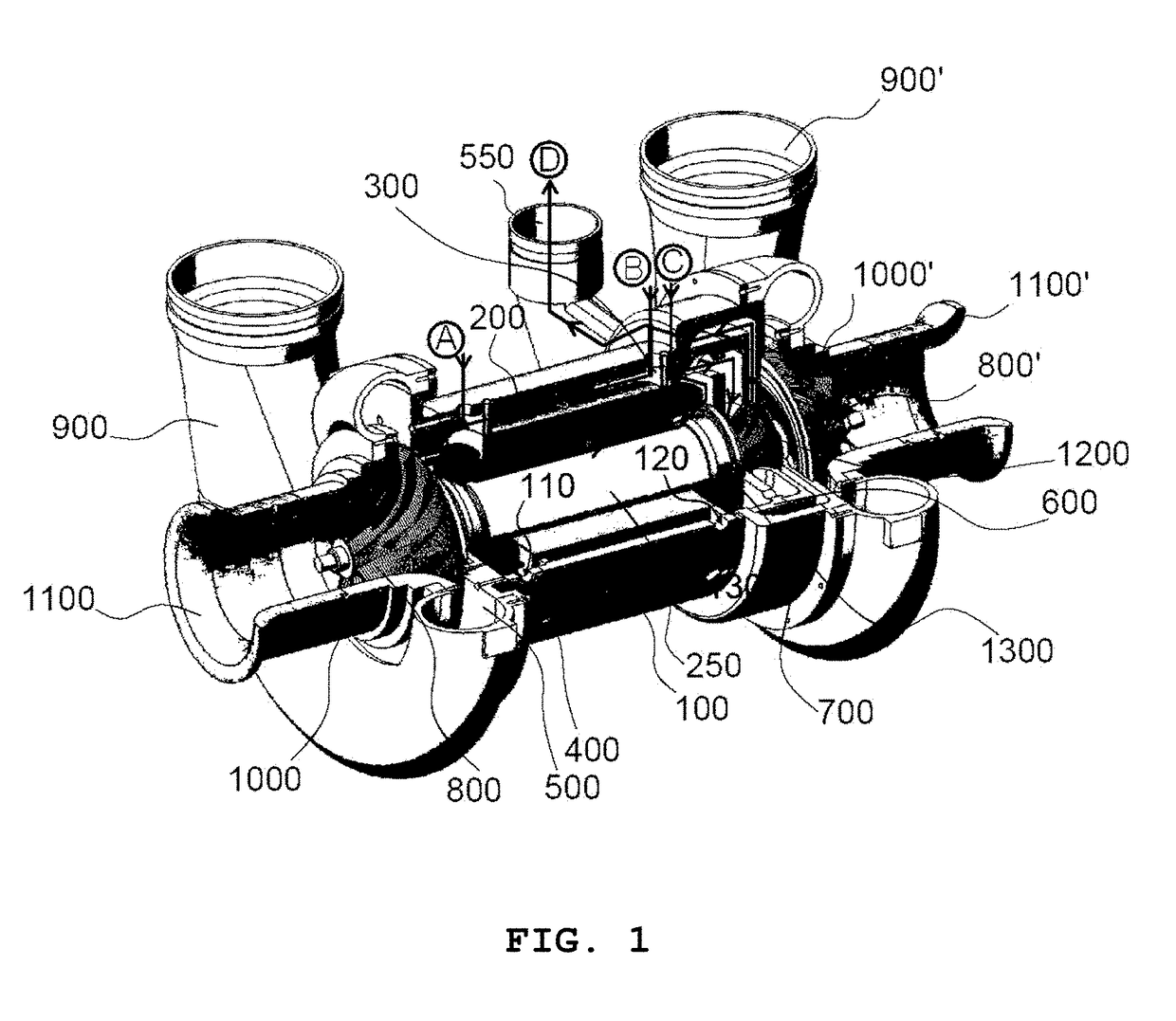

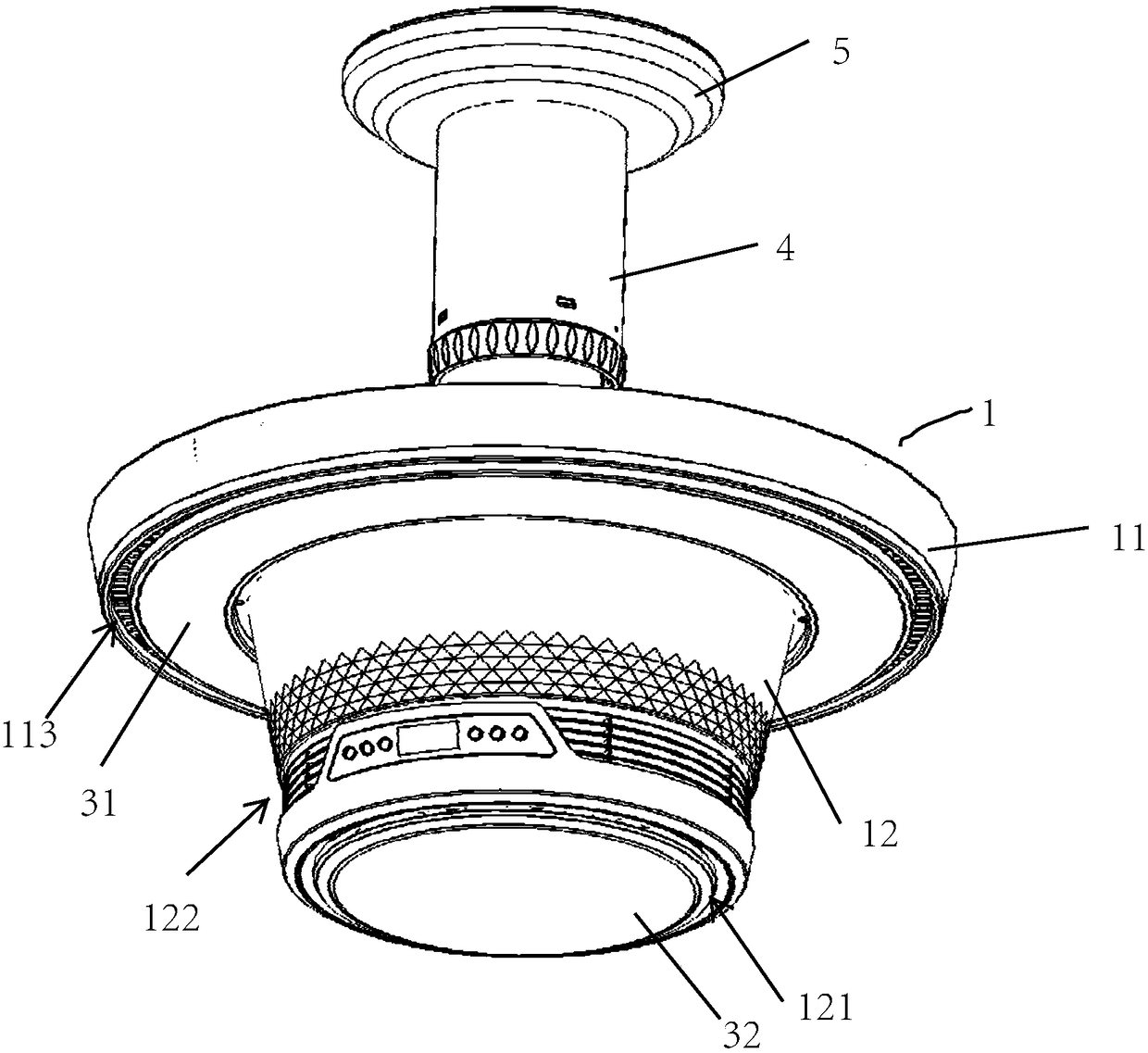

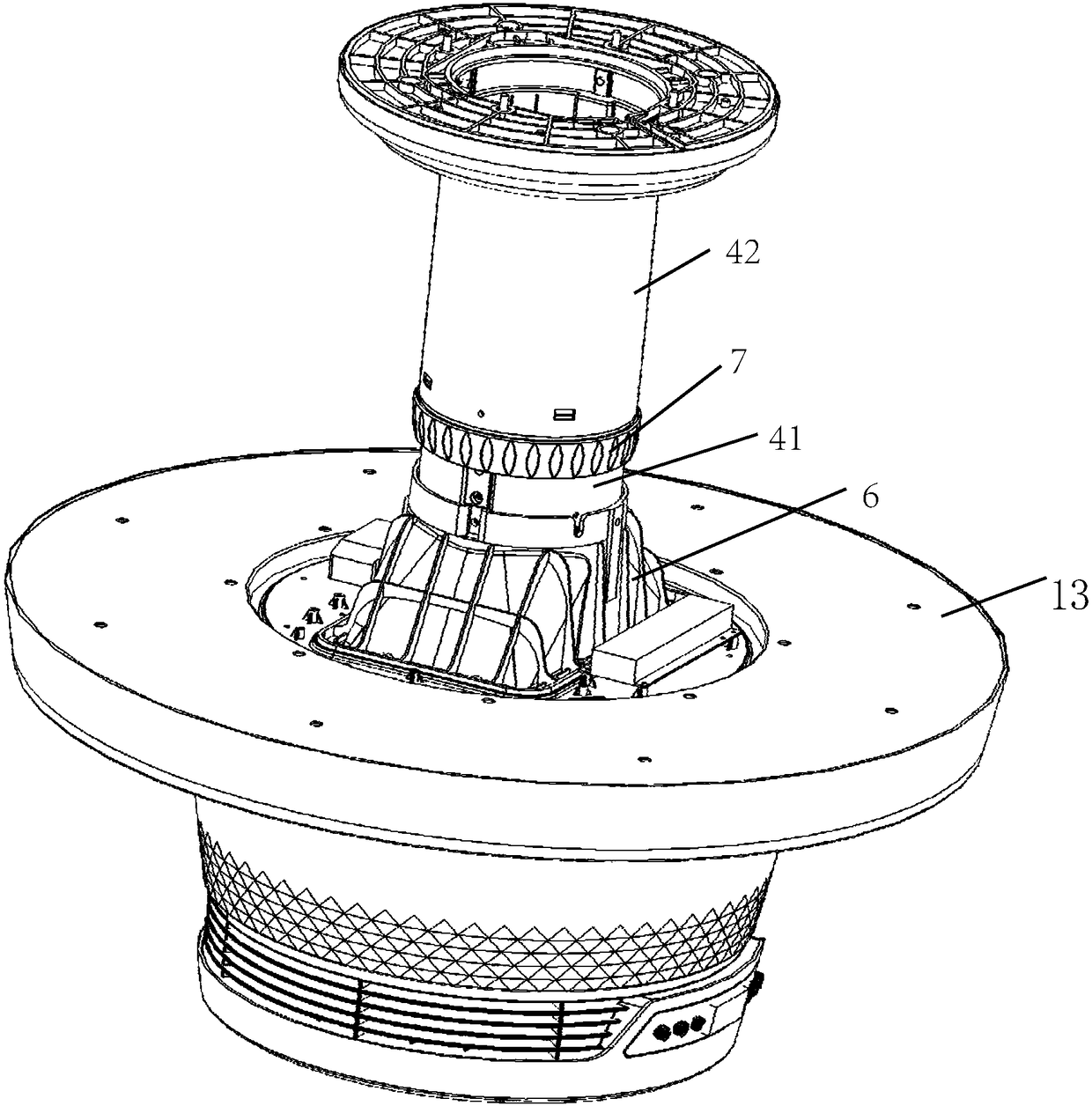

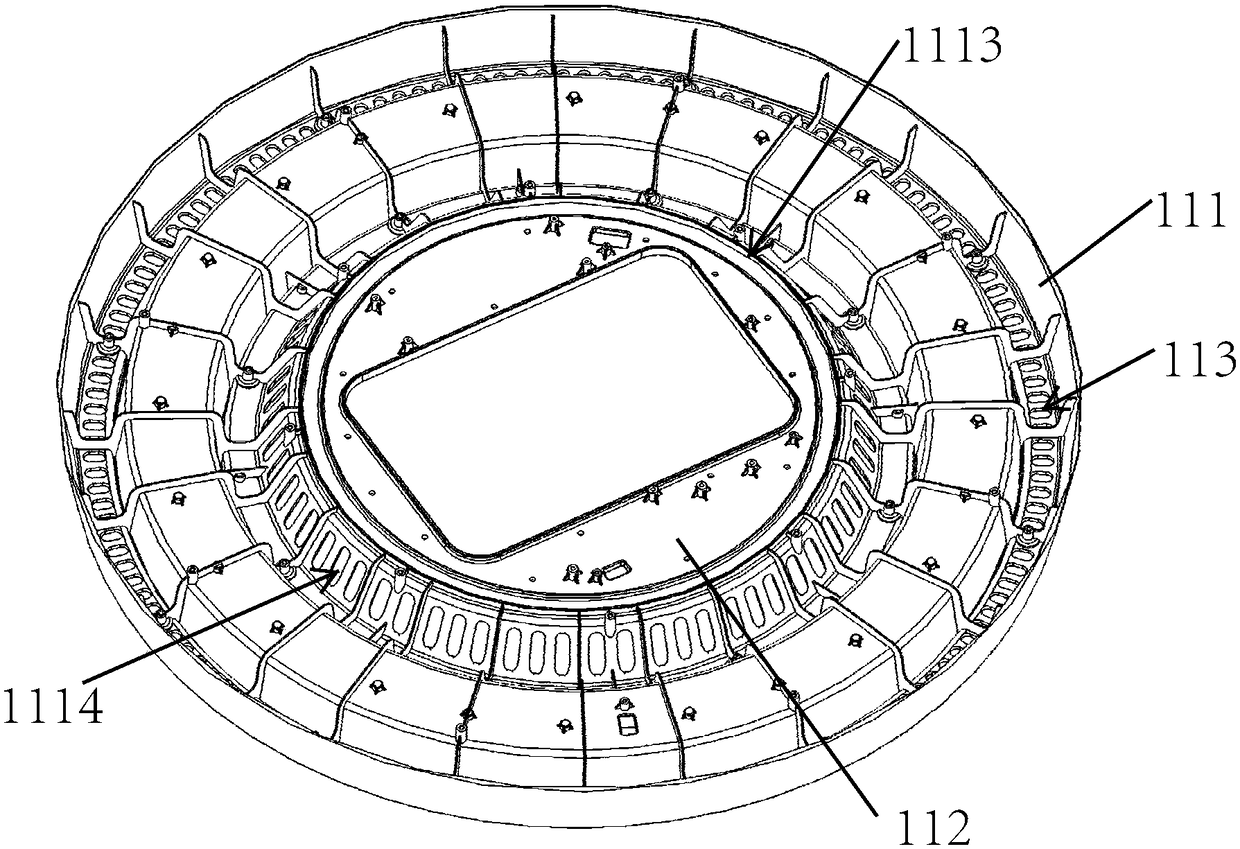

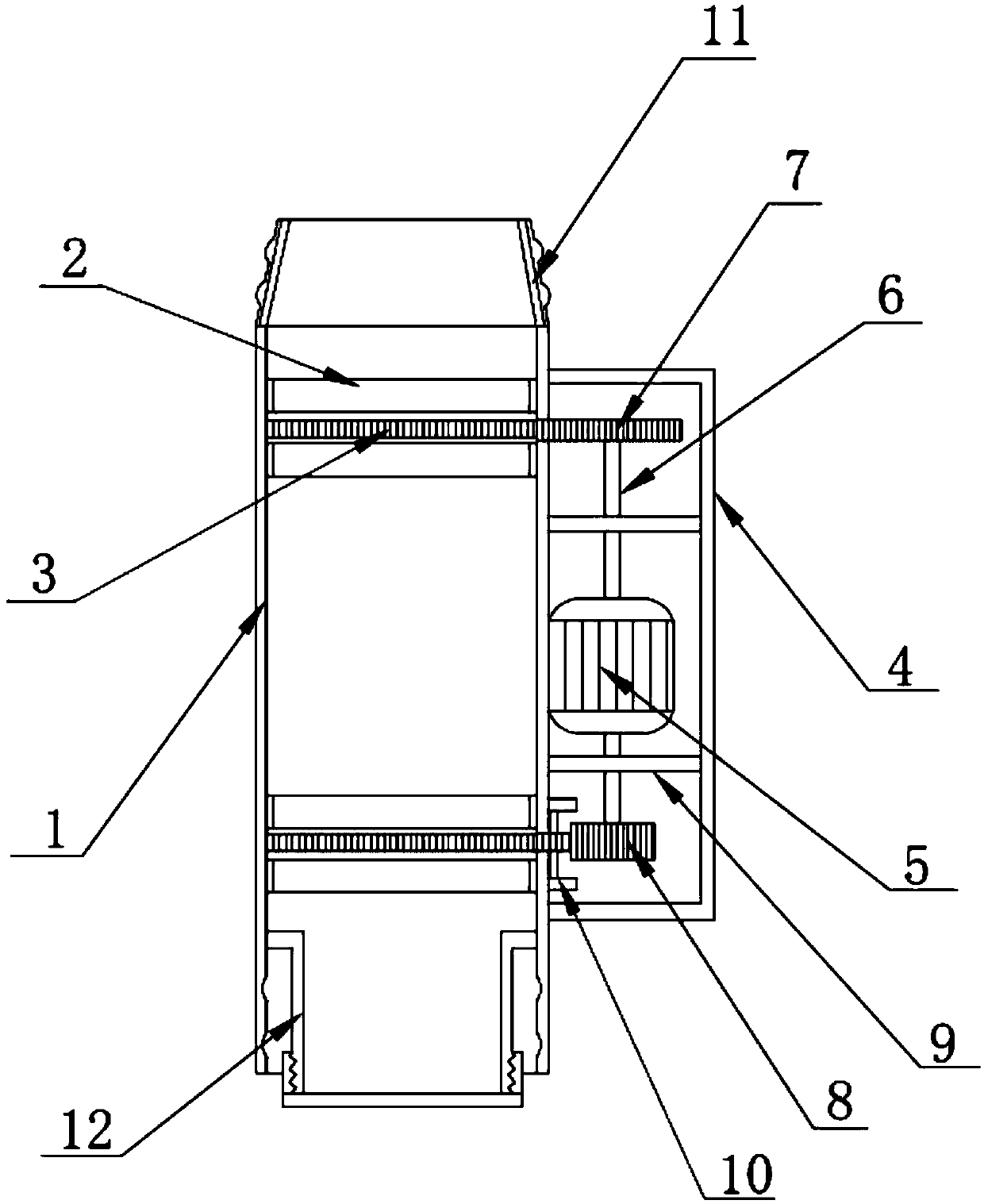

Direct drive type dual turbo blower cooling structure

ActiveUS20180238347A1Increase flow rateImprove cooling efficiencyPump componentsMagnetic circuit stationary partsImpellerElectric machine

The present invention relates to a direct drive type dual turbo blower cooling structure and, more particularly, to a direct drive type dual turbo blower cooling structure in which a plurality of hole portions for cooling a stator and a plurality of hole portions for cooling a coil portion, a bearing housing, and a rotor are formed along the inner diameter of a motor casing; impellers are disposed on both sides thereof, such that a flow rate is doubled; and an air cooling system capable of achieving thermal balance through the plurality of hole portions is implemented at the time of operation of a cooling fan which provides an air cooling system instead of a conventional water cooling system. As such, it is possible to simplify the mechanical structure and reduce manufacturing time and costs because the pump, heat exchanger, water tank, pipes, etc. required for a water cooling system are unnecessary.

Owner:TURBOWIN

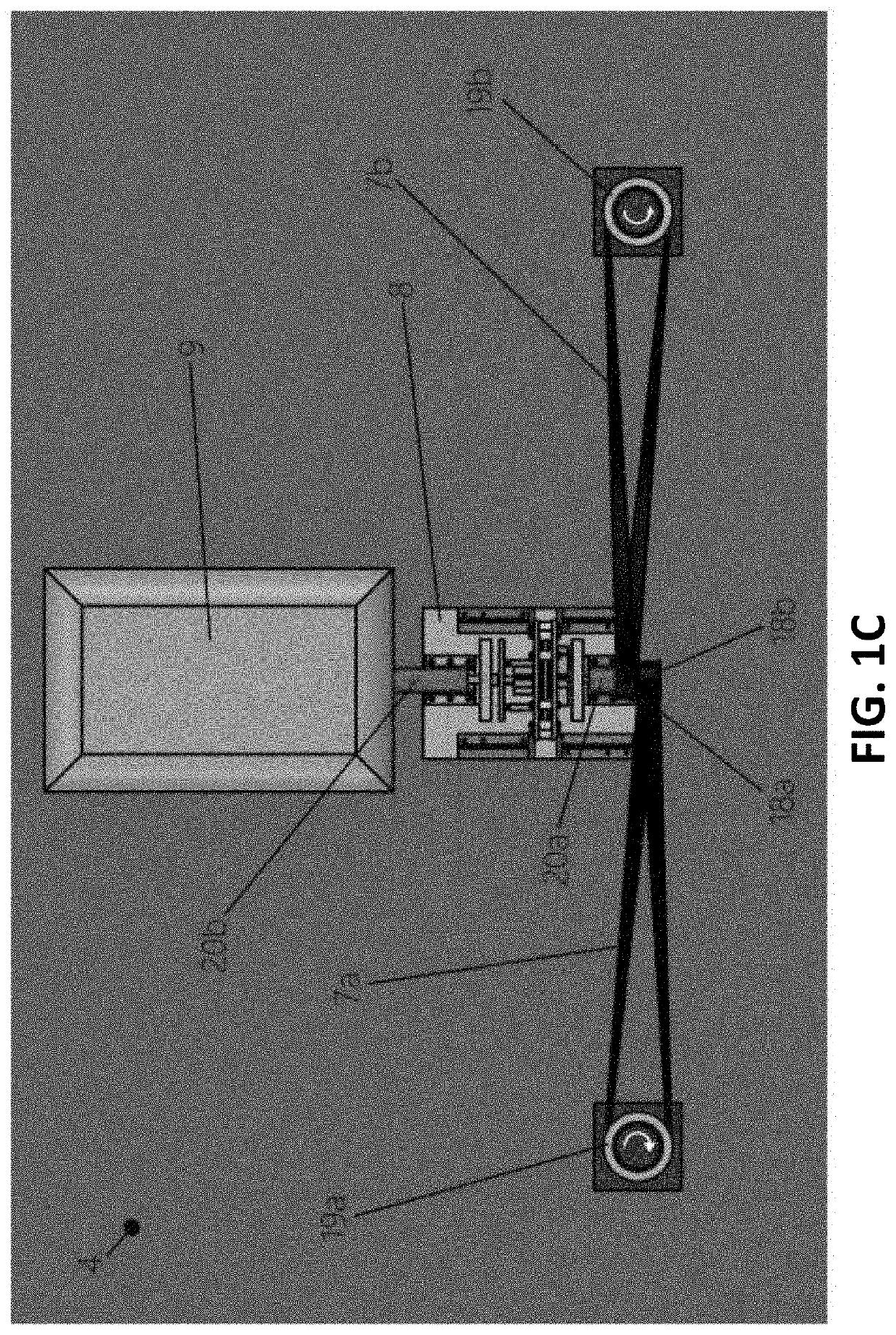

Hydrokinetic turbine system

PendingUS20200088159A1Without sacrificing performanceAvoid excessive wearEngine fuctionsDynamo-electric gearsEngineeringTurbine

Hydrokinetic fluid turbines utilize a flowing body of liquid to translate the kinetic energy of the fluid into electric power or other useful energy. The available kinetic energy is proportional to the squared fluid velocity in an open channel with a fixed cross-sectional area. The proposed twin turbine system coupled with a cycloidal magnetic gear exploits the hydrokinetic energy existing in open-channels.

Owner:EMRGY INC

Twin turbo engine

Owner:FORD GLOBAL TECH LLC

Ring turbo-piston engine and ring turbo-piston supercharger

InactiveUS20090028739A1Increase heightLow powerOscillating piston enginesEngine of counter-engagement typeCombustionSwing-piston engine

The inventive turbo-piston machine is embodied in the form of a turbo-piston expander and / or a turbo-piston supercharger and / or internal combustion engine comprising two mating working members i.e. a rotor and a valve. The rotor is provided with a piston embodied thereon and the valve is provided with a groove. The working members are arranged in the body of the turbo-piston machine, wherein the rotor is placed in at least one cylinder formed by the body walls and, for example, by the sidewalls. The operating process is carried out in at least two working chambers formed by the division of the cylinder space. A working medium is injected into one of the working chambers of the turbo-piston expander and is pumped into the other working chamber. The combination of the turbo-piston supercharger and the turbo-piston expander in one turbo-piston machine makes it possible to develop the internal combustion engines which can operate according to any known cycles, for example according to the Otto, Diesel, Trinkler, Atkinson, Miller, Brayton, Ericsson-Joule, Humphrey, Lenoir, Rankine and Stirling cycles.

Owner:VELITSKO VLADISLAV VLADIMIROVICH

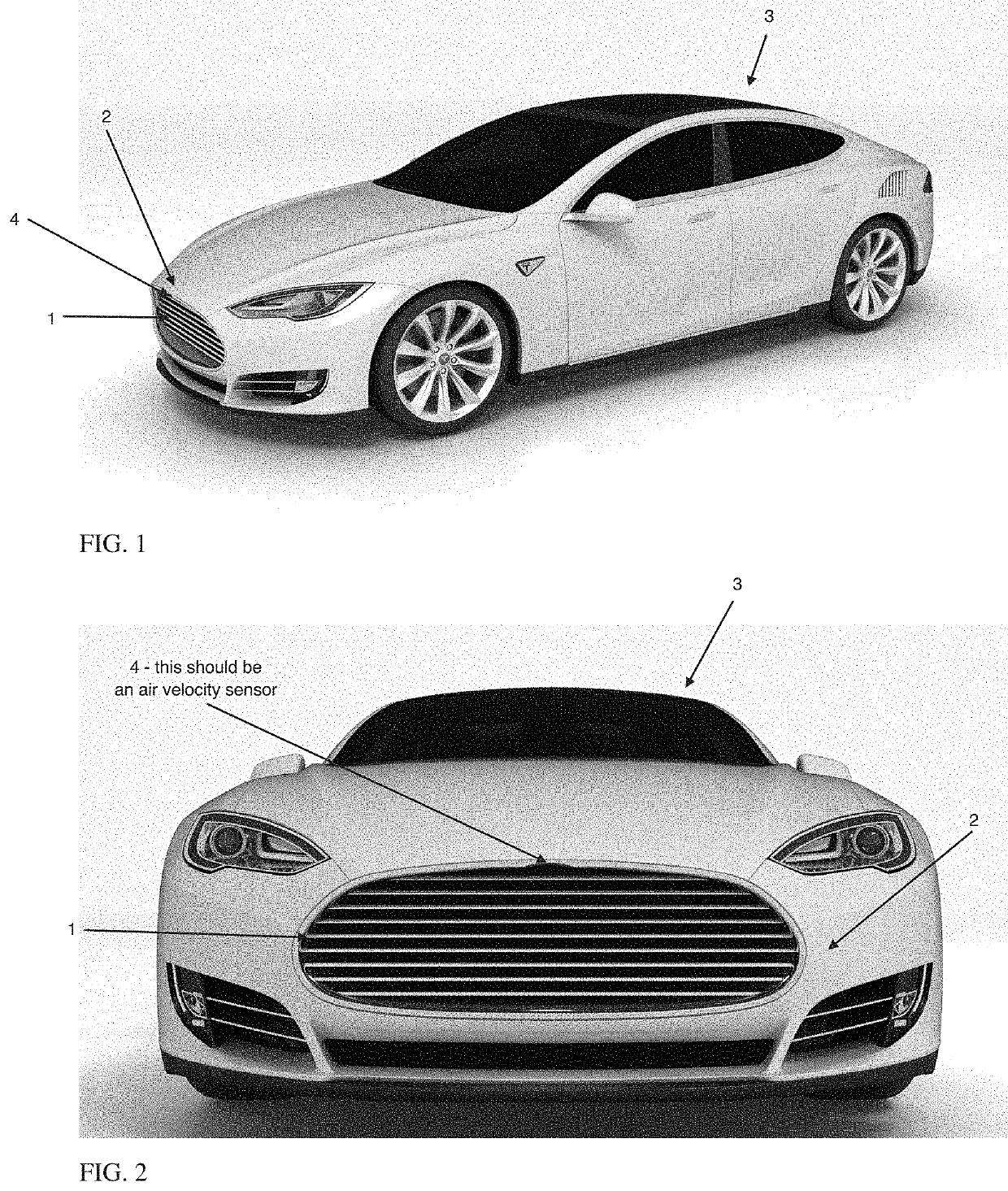

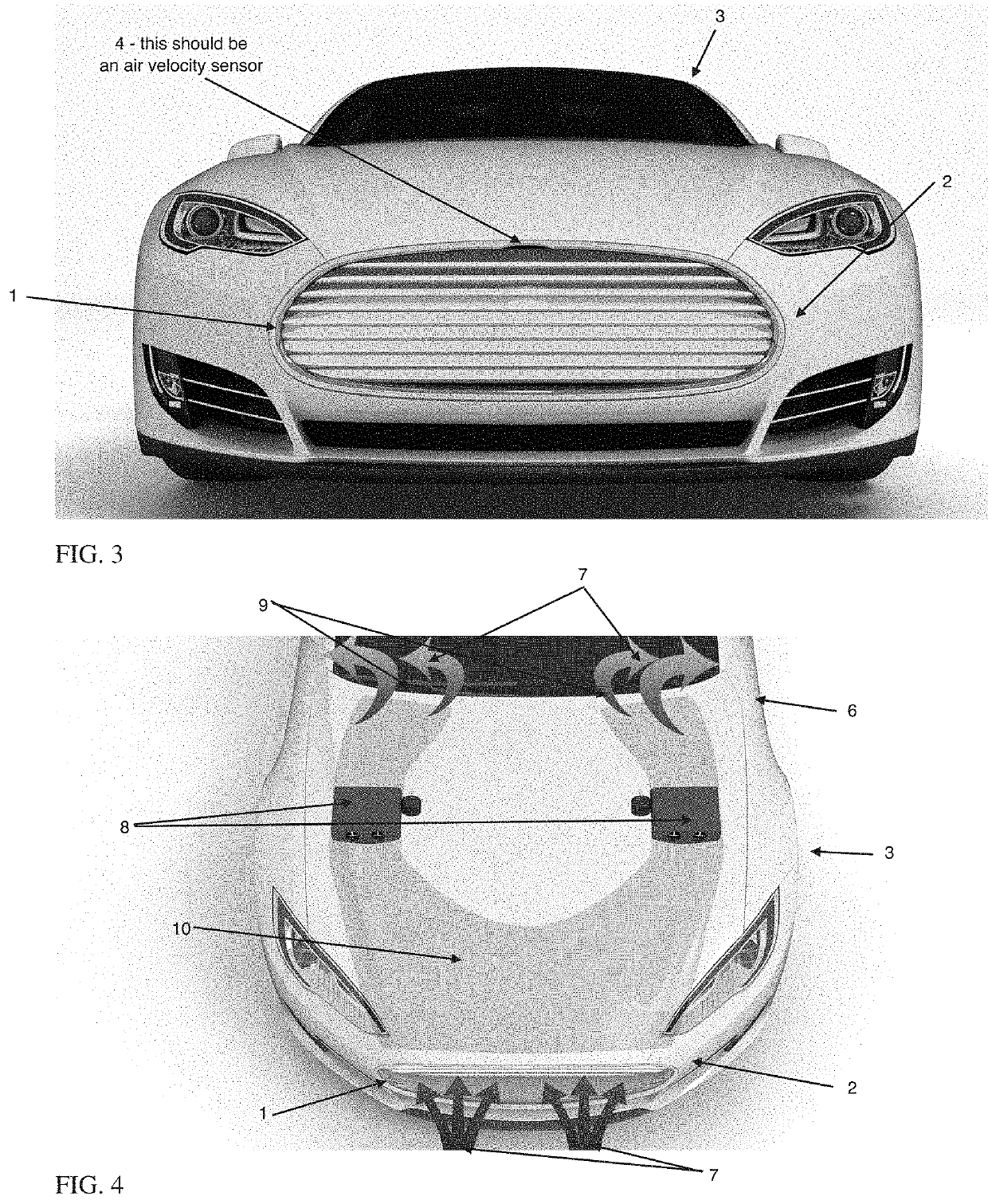

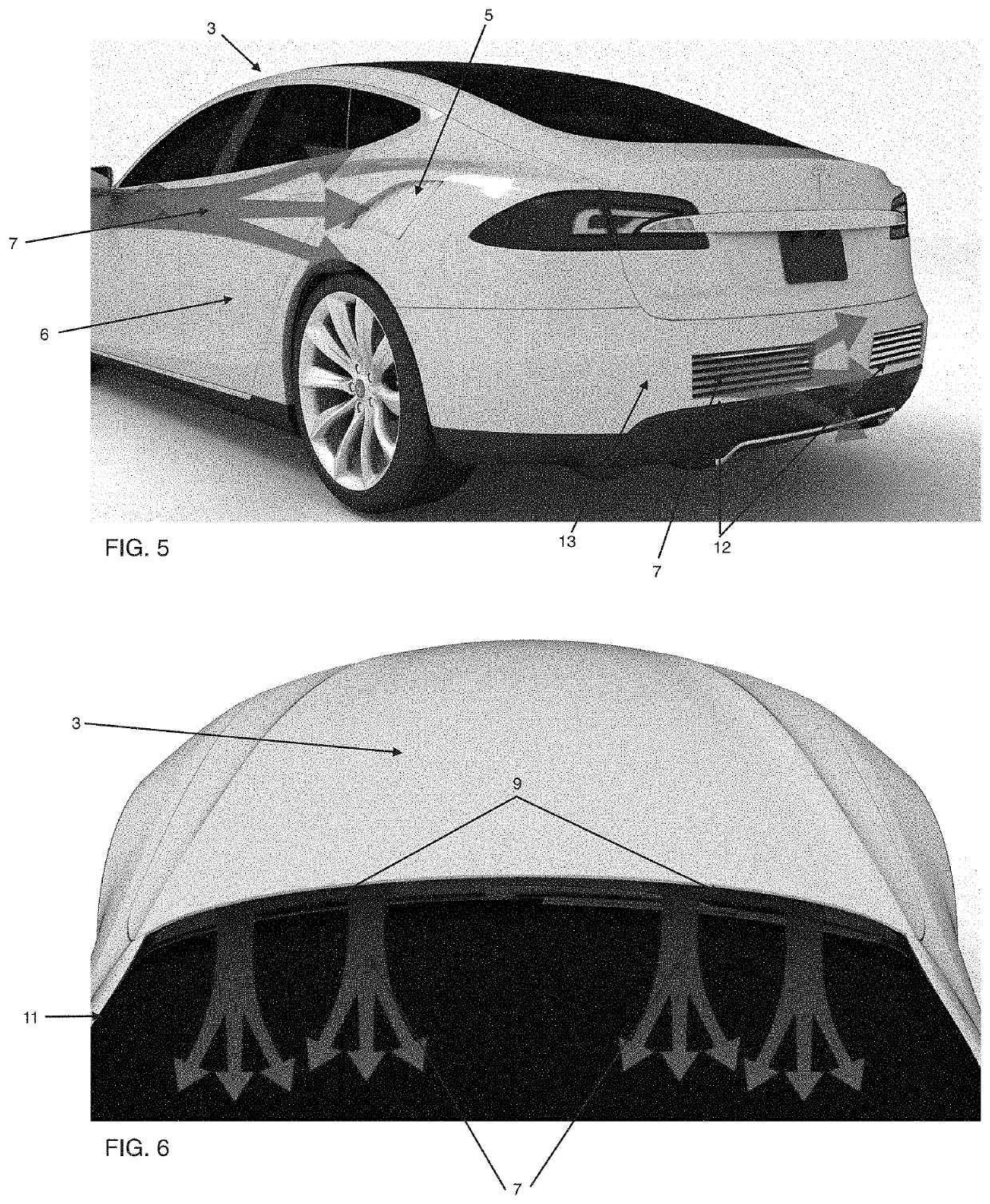

Wind-powered electric vehicle power regeneration system

InactiveUS20200189397A1Increase rangeReduce power lossAuxillary drivesAir-treating devicesSuction forceElectrical battery

A wind-powered electric vehicle power regeneration system for increasing the range of electric vehicles. The system includes a twin turbine system with at least one fan on each turbine, and may include a vacuum-assisted turbine and gearbox. The twin turbine system preferably has three fans on each turbine. The fans may be of various sizes. The first and largest fan may be directly powered via the electric vehicle motor, which may create a vacuum. The second fan may partially be powered by the EV motor, while also being moved by the vacuums suction and the air that enters the compartment. The third fan may rotate via force of air entering the compartment. All of the fans may be connected to a central gearbox located beneath them. The gearbox may be connected to a generator that may be connected to a capacitor that charges an electric vehicle's battery.

Owner:MANGUM XAVIER

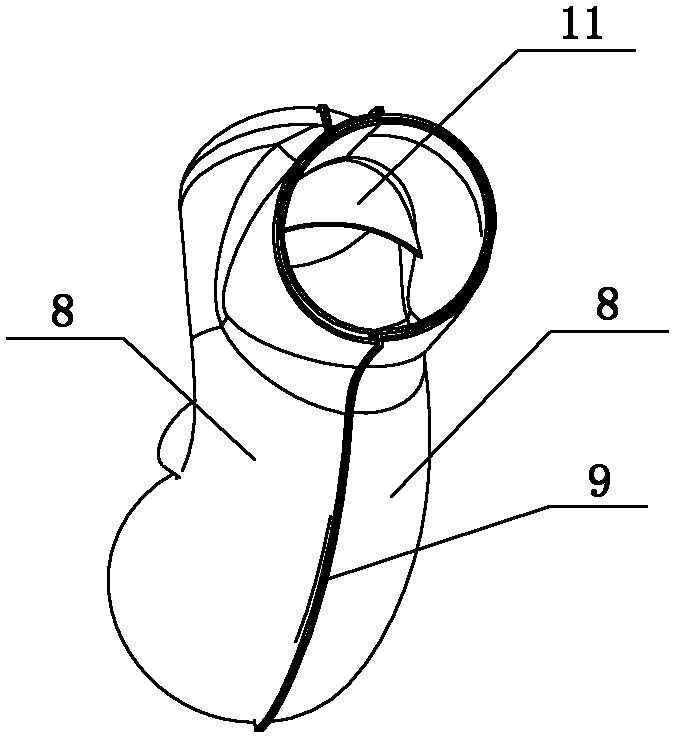

Central turbocharger mounting configuration for a twin-turbo engine

InactiveUS8459026B2SpaceReduce complexityInternal combustion piston enginesExhaust apparatusEngineeringTwin-turbo

A central turbocharger configuration in a V-engine with two turbochargers is described. In one example approach, a V-engine includes first and second in-board exhaust manifolds; first and second turbines coupled to the first and second manifolds, respectively; and a passage intermediate to and coupling outlets of the first and second turbines; and a junction branching from the passage downward into the valley.

Owner:FORD GLOBAL TECH LLC

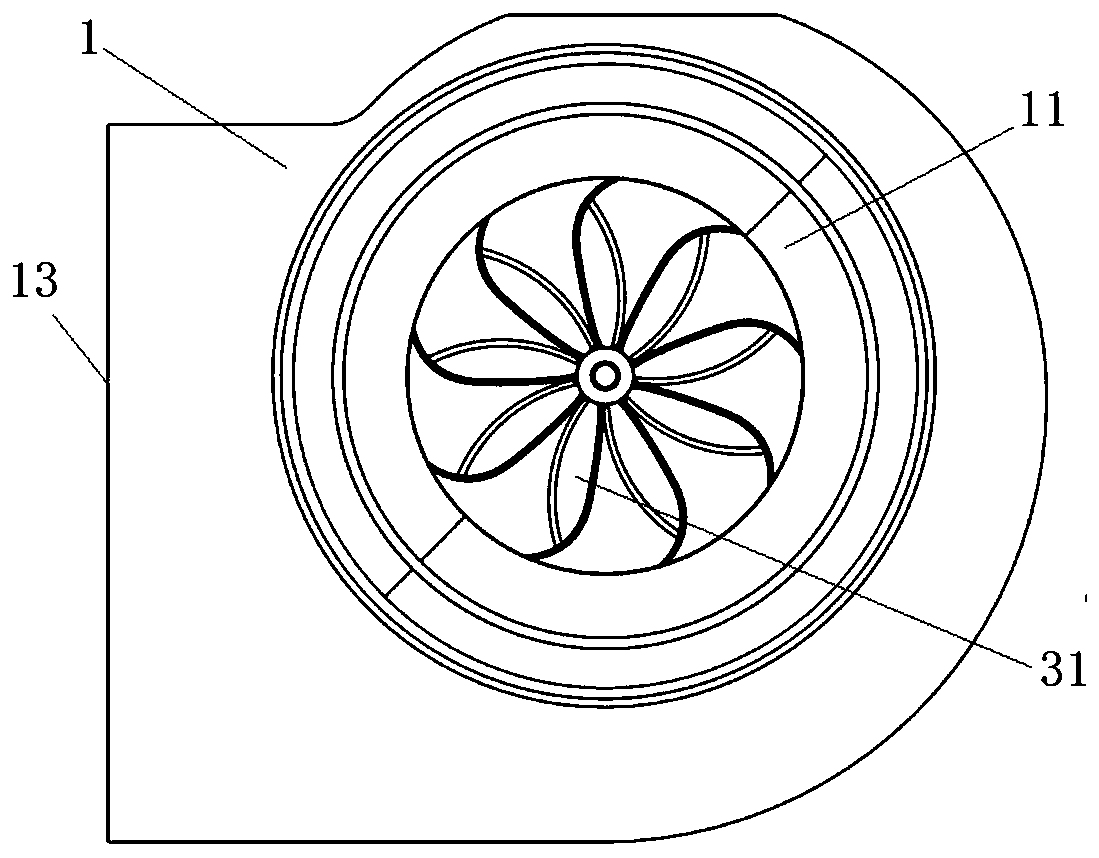

Smoke eliminator and dual turbine fan thereof

The invention discloses a smoke eliminator and a dual turbine fan thereof. The dual turbine fan comprises a volute and two centrifugal impellers driven by a motor to reversely rotate. The smoke eliminator comprises a smoke eliminator body, an exhaust pipe and a fixing seat, wherein the exhaust pipe and the fixing seat are used for fixing the smoke eliminator body. The smoke eliminator body comprises a shell and a fan arranged in the shell, and the fan is the dual turbine fan. The two centrifugal impellers in the dual turbine fan rotate synchronously and reversely, two air flues are used for air exhausting, and the air exhausting amount can be effectively increased.

Owner:浙江承驰科技有限公司

Twin tube damper with remote gas reservoir

A damper is provided having a twin tube construction interconnected to a gas reservoir. The connection of each of the inner and outer volumes of the twin tube to the gas reservoir is independently valved, and each of these valves are independently settable to change the differential pressure thereacross at which they open. The damper provides flow passages directly from the inner and outer volumes to enable flow form the compression to rebound sides thereof, as well as through the valved connections to the gas reservoir and at least one valved opening in the damper piston.

Owner:FOX FACTORY

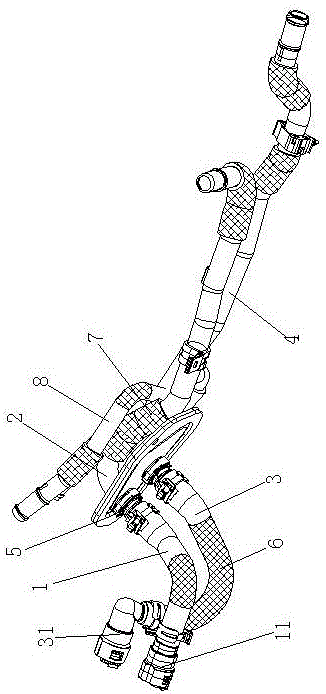

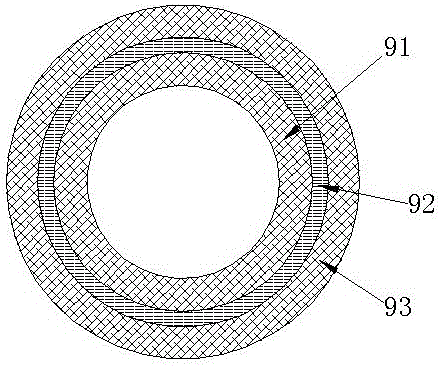

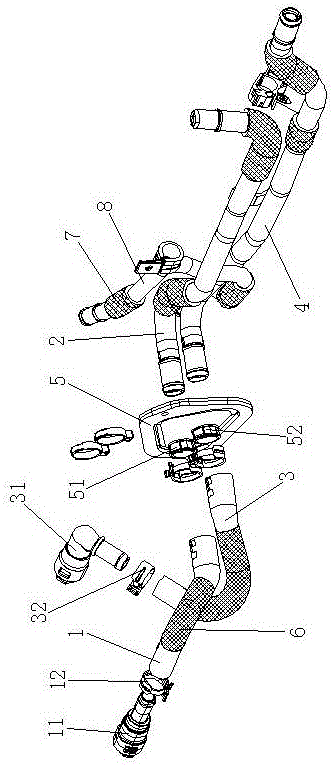

Cooling pipeline of double-turbine pressurizing plug-in type hybrid power system and manufacturing technology of cooling pipeline

InactiveCN105804855AExtended service lifeShorten vulcanization timeMachines/enginesEngine cooling apparatusEngineeringPressure resistance

The invention relates to a cooling pipeline of a double-turbine pressurizing plug-in type hybrid power system and a manufacturing technology. The cooling pipeline comprises a first cooling pipe and a second cooling pipe, the first cooling pipe is formed through connection of a first rubber pipe and a first aluminum pipe, the second cooling pipe is formed through connection of a second rubber pipe and a second aluminum pipe, the rubber pipes are arranged on one side of a datum plate, and the aluminum pipes are arranged on the other side of the datum plate; the bending positions of the rubber pipes are sleeved with woven protecting bushes, the bending positions of the aluminum pipes are sleeved with sponge protecting bushes, and branch pipes are arranged on the aluminum pipes; and the cooling pipeline has the beneficial effects that the cooling pipes are formed through connection of the rubber pipes and the aluminum pipes and formed through connection of different pipe materials, the characteristics of different materials are used for ensuring pressure resistance and heat resistance properties of a connecting pipe, and the service life of the cooling pipeline can be prolonged; through the protecting bushes, the weakest bending positions are protected, and the service life of the cooling pipeline can be further prolonged; and a peroxide vulcanization system is adopted, the heat resistance performance is improved, and the vulcanization time is shortened.

Owner:ZHEJIANG JUNHE RUBBER TECH

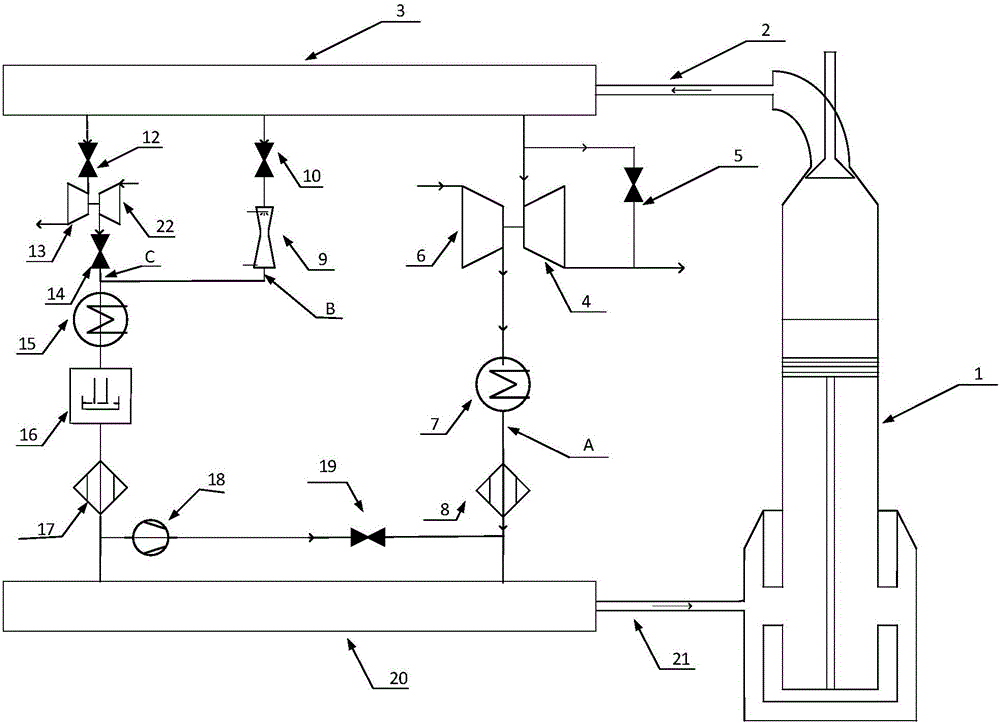

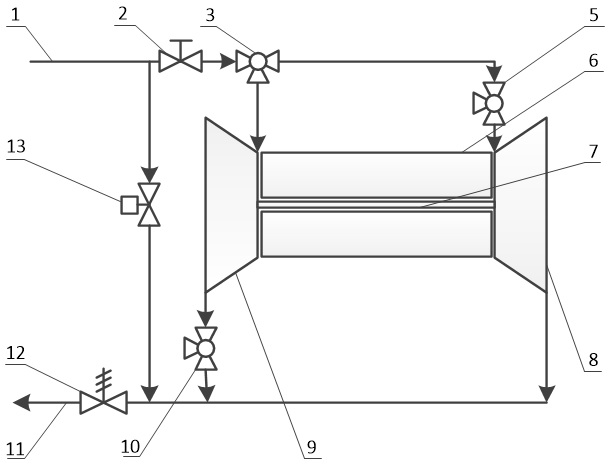

Twin-turbo EGR system and method for ship two-stroke diesel engine

InactiveCN105781809ASave spaceReduce volumeInternal combustion piston enginesExhaust gas recirculationTwo-stroke diesel engineExhaust pipe

The invention aims at providing a twin-turbo EGR system and method for a ship two-stroke diesel engine. The twin-turbo EGR system comprises the diesel engine, an exhaust header, a scavenging header, a large turbocharger and a small turbocharger. The exhaust header communicates with an exhaust pipe of the diesel engine, and the scavenging header communicates with a gas inlet pipe of the diesel engine. A large turbine communicates with the exhaust header through a large turbine inlet pipeline. An outlet of the large turbine communicates with the air and meanwhile is connected with the large turbine inlet pipeline through a first bypass pipeline. A large gas compressor communicates with the scavenging header through a large gas compressor outlet pipeline. A small turbine communicates with the exhaust header through a small turbine inlet pipeline. A small gas compressor communicates with the scavenging header through a small gas compressor outlet pipeline. The small gas compressor outlet pipeline communicates with the exhaust header through a second bypass pipeline. Compared with an SCR system, a large quantity of reducing agent is saved, the output power of the large turbine cannot be influenced by switching the large turbine and the small turbine, and scavenging flow can keep stable to a certain degree.

Owner:HARBIN ENG UNIV

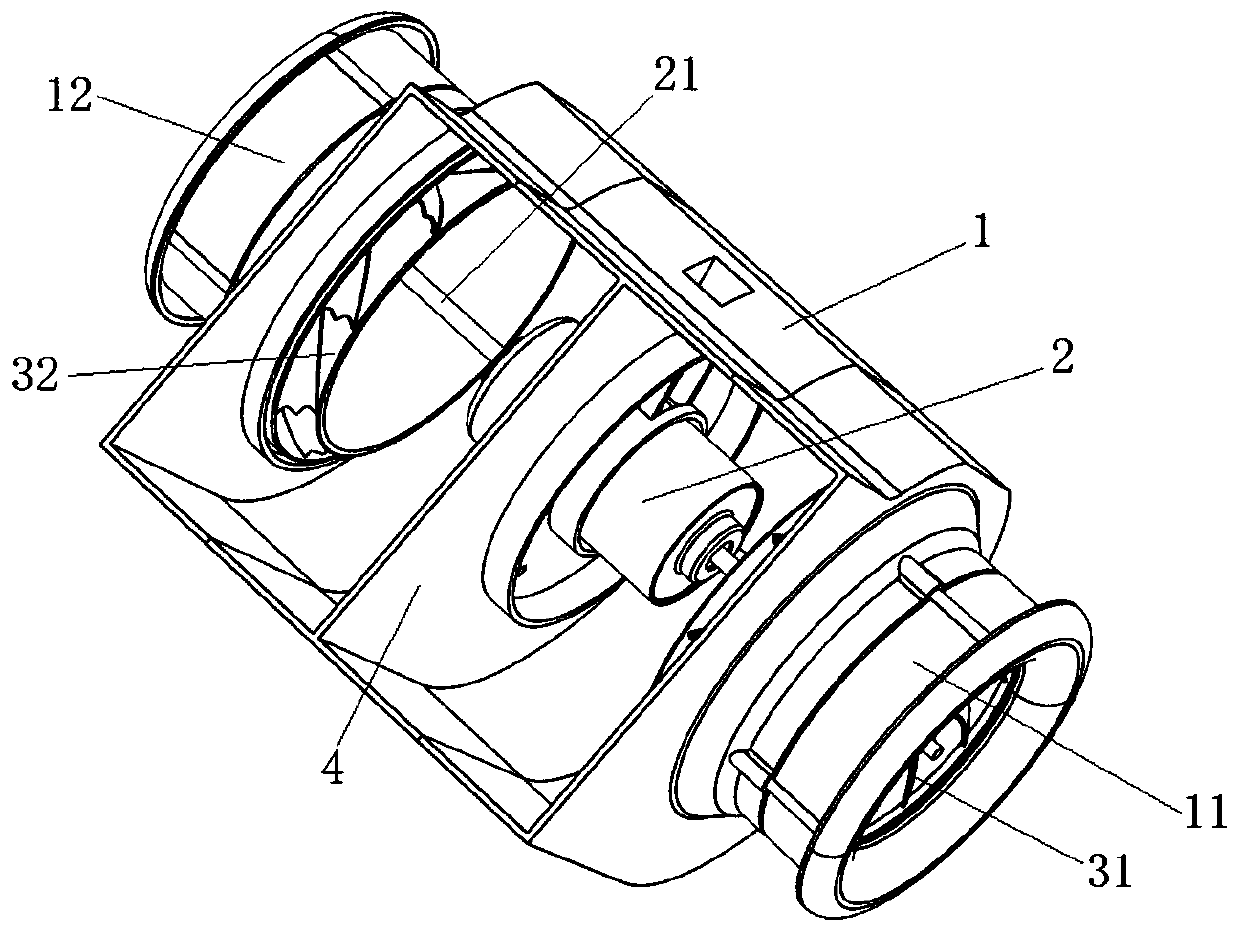

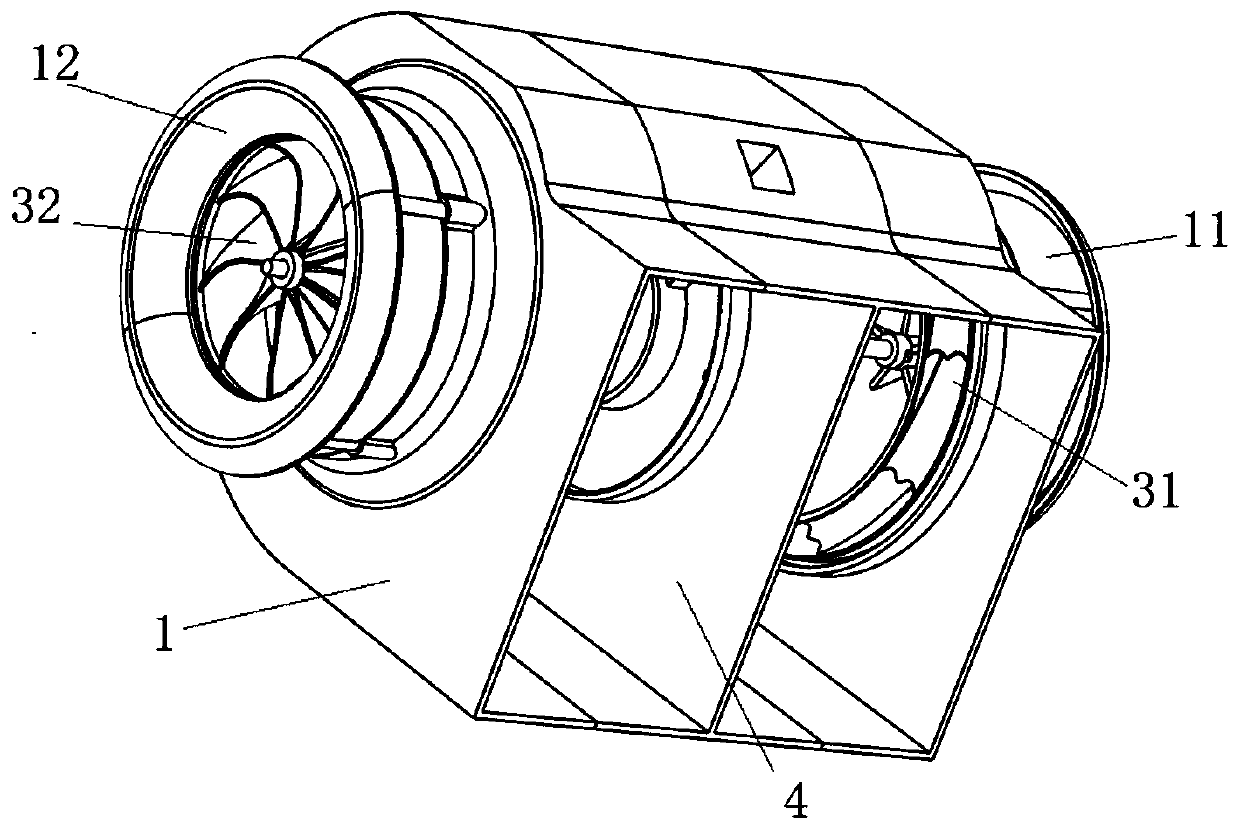

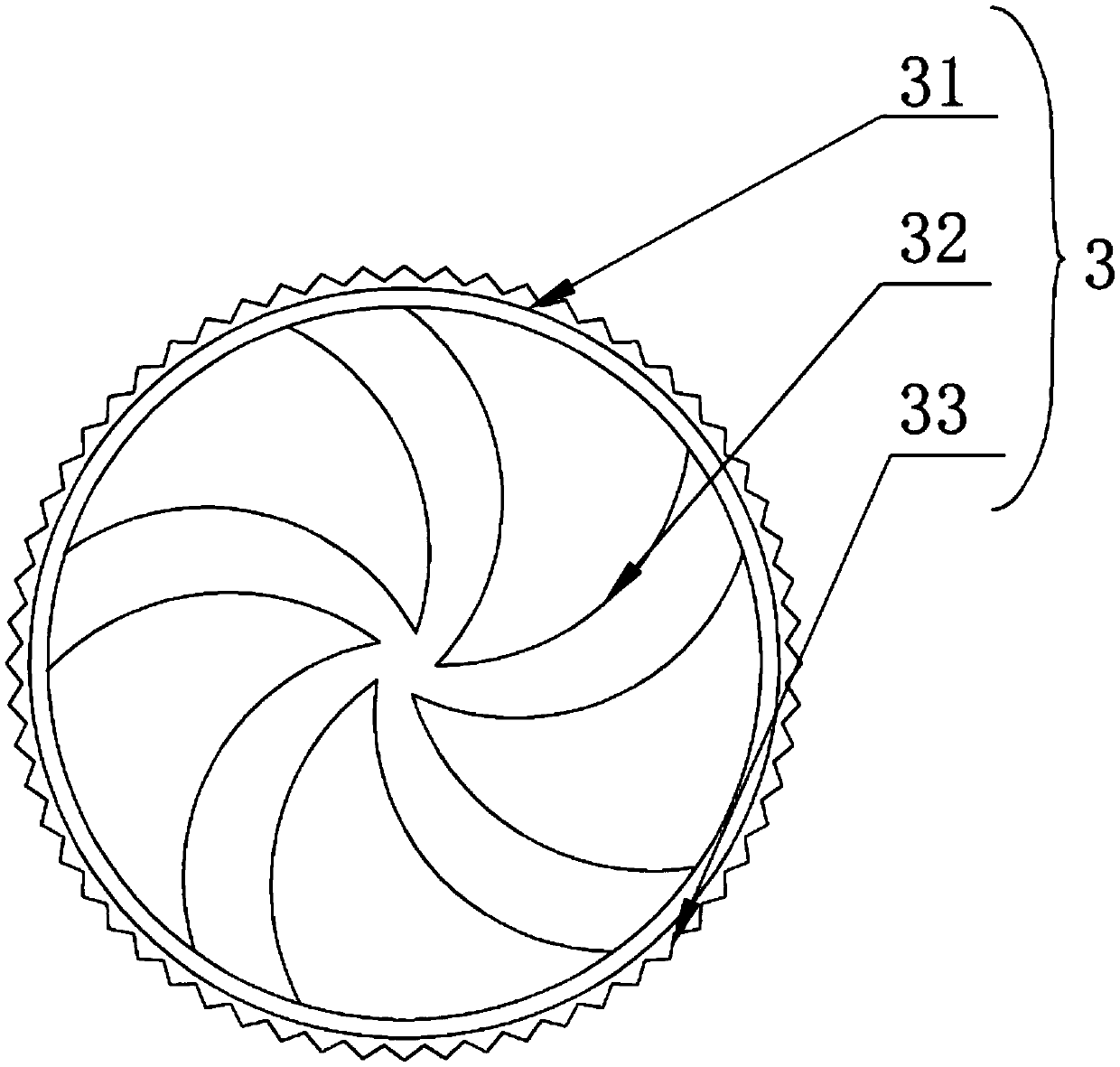

Radial dual turbosupercharging fan and air pipe machine

PendingCN110657119AAchieve a supercharged effectIncrease weightPump componentsAir heatersImpellerElectric machinery

The invention provides a radial dual turbosupercharging fan and an air pipe machine. The fan comprises a shell, a drive motor, a first spiral impeller and a second spiral impeller. A first shell air inlet and a second shell air inlet are oppositely arranged on the shell, and the shell is further provided with a fan air outlet. The drive motor is arranged in the shell and is provided with a drive rotating shaft penetrating through the drive motor. The two ends of the drive rotating shaft correspond to the first shell air inlet and the second shell air inlet. The first spiral impeller is mountedin the first shell air inlet through the drive rotating shaft, the second spiral impeller is mounted on the second shell air inlet through the drive rotating shaft, and the impeller spiral directionsof the first spiral impeller and the second spiral impeller are opposite. Through the arrangement of the bidirectional spiral impellers, the spiral directions of the first spiral impeller and the second spiral impeller are opposite, and the aim of one motor and two impellers is achieved; and the effect of dual turbosupercharging is achieved.

Owner:朱利新

Control apparatus of vehicle

ActiveUS8763396B2Efficient detectionPreferable fail-safeElectrical controlInternal combustion piston enginesBypass valveTwin-turbo

In a vehicle, which is provided with: a primary turbo and a secondary turbo, each of which is of an exhaust driven type; an exhaust changeover valve and an intake changeover valve, which are placed in a secondary exhaust passage and a secondary intake passage corresponding to the secondary turbo, respectively; and an intake bypass valve placed in an intake bypass passage, an ECU sets the opening / closing state of each changeover valve to an opening / closing state corresponding to a twin turbo mode at the time of engine stop, and it uses the drive control of each changeover valve which is necessitated in the transition to a single turbo mode at the engine start, thereby performing the sticking detection of the changeover valve at the same time.

Owner:TOYOTA JIDOSHA KK

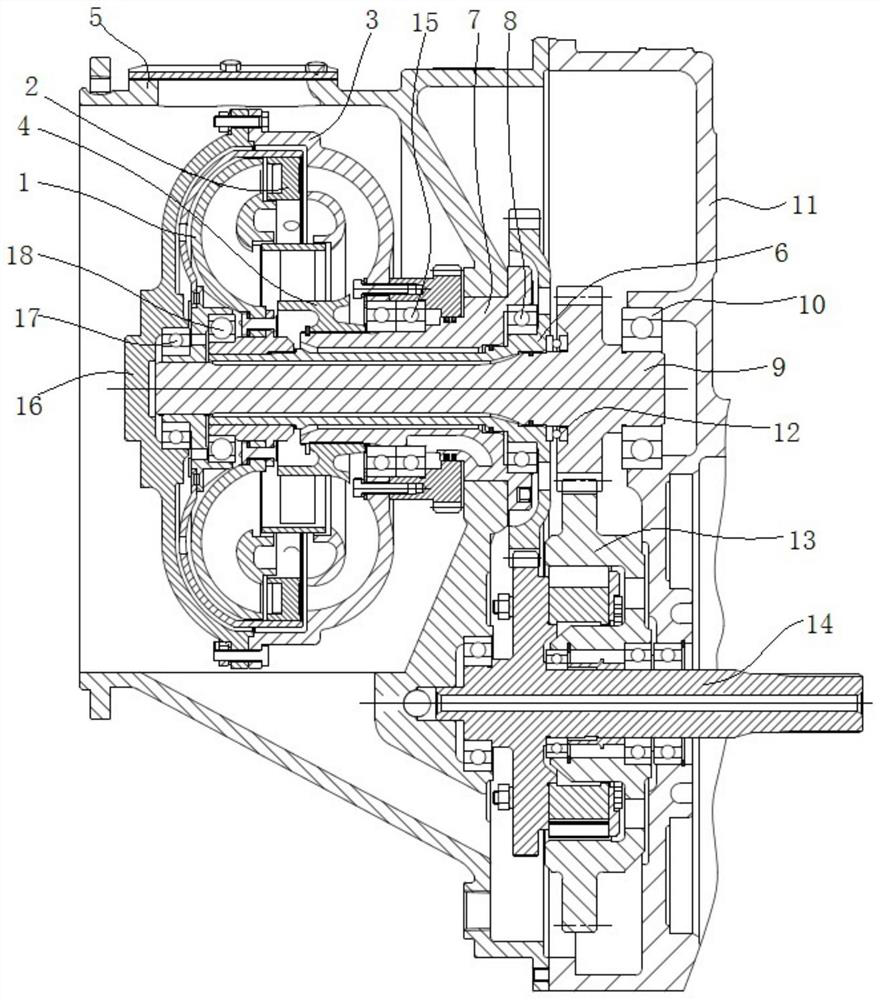

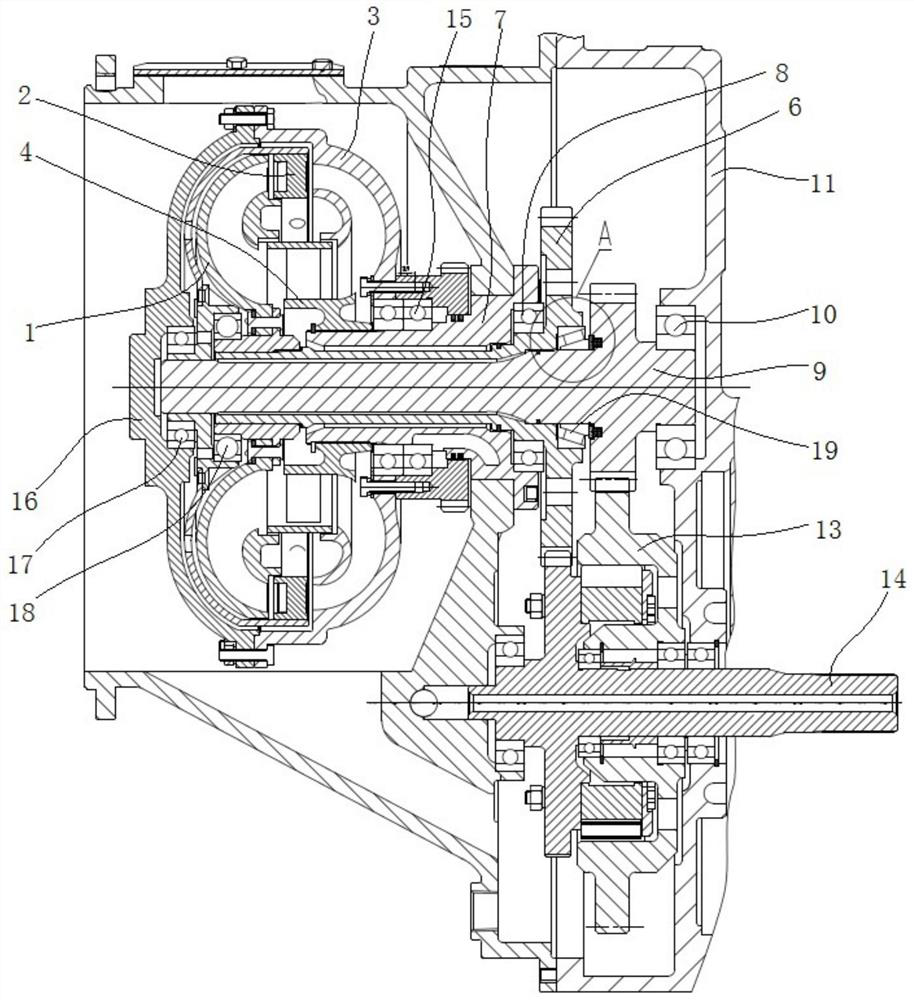

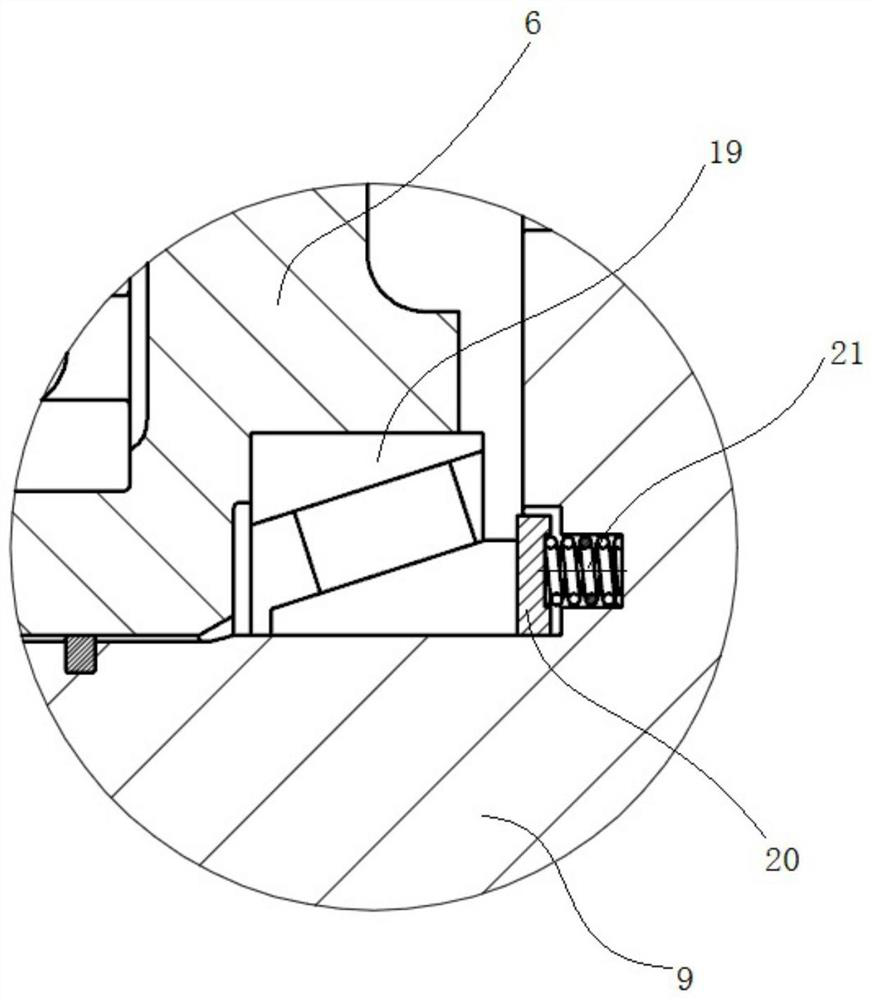

Double-turbine structure of pumped storage water-turbine generator set

InactiveCN111794893AAchieve co-rotationAvoid adjusting the direction of rotationHydro energy generationReaction enginesElectric machineTurbine blade

The invention discloses a double-turbine structure of a pumped storage water-turbine generator set. The double-turbine structure comprises a motor and a rotating shaft, the motor is arranged at the top end of the rotating shaft, a fixed stator and a fixed rotor are arranged in the motor, the rotor is arranged at the upper end of the rotating shaft and rotates along with the rotating shaft; a slipring chamber is arranged on the motor in a matched manner; a first turbine and a second turbine are axially arranged on the rotating shaft at an interval, the directions of turbine blades of the firstturbine and the second turbine are opposite, one turbine blade is arranged in the forward direction, the other turbine blade is arranged in the reverse direction; and the first turbine is provided with a first water guide mechanism in a cooperating mode, introduced water makes contact with the turbine blades of the first turbine, the second turbine is provided with a second water guide mechanismin a cooperating mode, and the introduced water makes contact with the turbine blades of the second turbine. According to the double-turbine structure of the pumped storage water-turbine generator set, the motor and the rotating shaft rotate in the same direction during power generation and water pumping, so that the rotating direction of the motor is prevented from being adjusted; power generation and water pumping can be carried out on the same equipment at the same time or in a time-sharing manner; angle deviation of a slip ring and a carbon brush is prevented, the fact that the contact area of the carbon brush and the slip ring is reduced is prevented, and the contact area of the carbon brush and a collector ring is ensured to be within a reasonable range.

Owner:重庆华能水电设备制造有限公司

Reverse double-turbine high-pressure axial flow pump

InactiveCN111520327AReduce resistanceImprove efficiencyPump componentsPump installationsAxial-flow pumpRotational axis

The invention discloses a reverse double-turbine high-pressure axial flow pump, and relates to the technical field of axial flow pumps. The reverse double-turbine high-pressure axial flow pump comprises a water conveying pipe, two rotary bearings with same structures are arranged at the positions, close to the upper position and the lower position, of an inner cavity of the water conveying pipe, and turbofans are arranged on the inner walls of every two rotary bearings. A sealing shell is arranged on the right side of the water conveying pipe, a motor is arranged on the right side of the waterconveying pipe, a rotary shaft is arranged in an inner cavity of the motor, the rotary shaft penetrates through the surface of the motor, an upper gear is arranged at the bottom of the rotary shaft,a lower gear is arranged at the bottom of the rotary shaft, and the surface of the upper gear is clamped with the surface of the turbofan at the upper end. Two installation blocks with same structuresare arranged on the right side of the water conveying pipe, a rotating shaft is arranged between the two installation blocks with the same structures, a transmission gear is arranged on the surface of the rotating shaft, and the left side of the transmission gear is clamped with surface of the turbofan at the lower end. According to the reverse double-turbine high-pressure axial flow pump, the resistance of the flow is reduced, no gap exists between the turbofans and the inner wall of the water conveying pipe, the loss of pressure is avoided, and the efficiency of a water pump is improved.

Owner:GAOYOU HUAN LIU PUMP IND CO LTD

Double-turbine hydraulic torque converter

The invention relates to a double-turbine hydraulic torque converter. The double-turbine hydraulic torque converter aims to solve the problem that in an existing double-turbine hydraulic torque converter, a first-stage input gear shaft and a second-stage input gear shaft are of cantilever structures, so that the service life of bearings is affected, and the stability and reliability of gear transmission are affected. The double-turbine hydraulic torque converter is characterized in that a fifth bearing capable of bearing radial loads and axial loads at the same time is arranged between a second-stage input gear and a first-stage input gear, and the fifth bearing is located at the right end of the second-stage input gear. According to the double-turbine hydraulic torque converter, the first-stage input gear and the second-stage input gear are of double-point-supported simply supported beam structures, so that the stress on the first-stage input gear, the second-stage input gear, a firstbearing and a second bearing is improved, the service life of the bearings and the gears is prolonged, and the rotation stability and reliability are higher.

Owner:柳工柳州传动件有限公司 +1

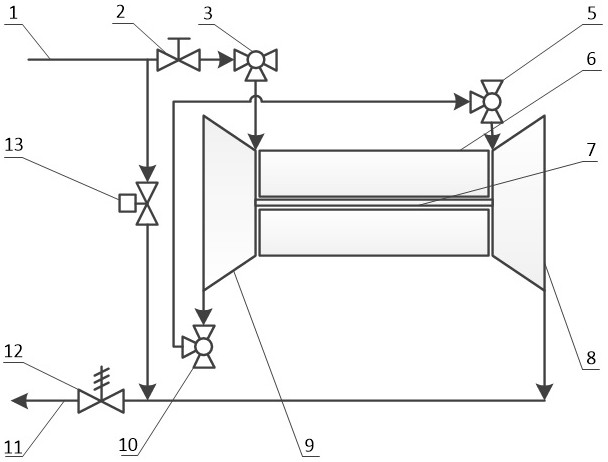

Symmetrically-arranged high-speed double-turbine distributed excess pressure power generation system

PendingCN112282871ABalance axial forceLarge flowCombination enginesSteam useIsolation valveElectric machine

The invention discloses a symmetrically-arranged high-speed double-turbine distributed excess pressure power generation system, and belongs to the field of distributed excess pressure power generation. The excess pressure power generation system comprises a first isolation valve, a flow distribution valve, a second isolation valve, a second three-way switching valve, a high-speed permanent magnetmotor, a second turbo-expander, a first turbo-expander, a first three-way switching valve, a safety valve and a bypass isolation valve, the first turbo-expander and the second turbo-expander are oppositely and symmetrically arranged, and the high-speed permanent magnet motor is arranged between the first turbo-expander and the second turbo-expander. Through the symmetrically arranged double-turbine structure, the balance of the axial force of a high-speed bearing is realized, the flux of a working medium is increased, and the power output of the system is improved; and through switching of theisolation valve and the three-way switching valve, series operation and parallel operation of the double turbo-expanders are achieved, and the system has better adaptability to scenes with high steamquality and large pressure difference.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com