Twin turbo engine

A turbocharger and turbocharger technology, applied in engine components, combustion engines, machines/engines, etc., to solve problems such as difficulty in controlling exhaust gas return, expensive exhaust flap valves, and unused exhaust energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

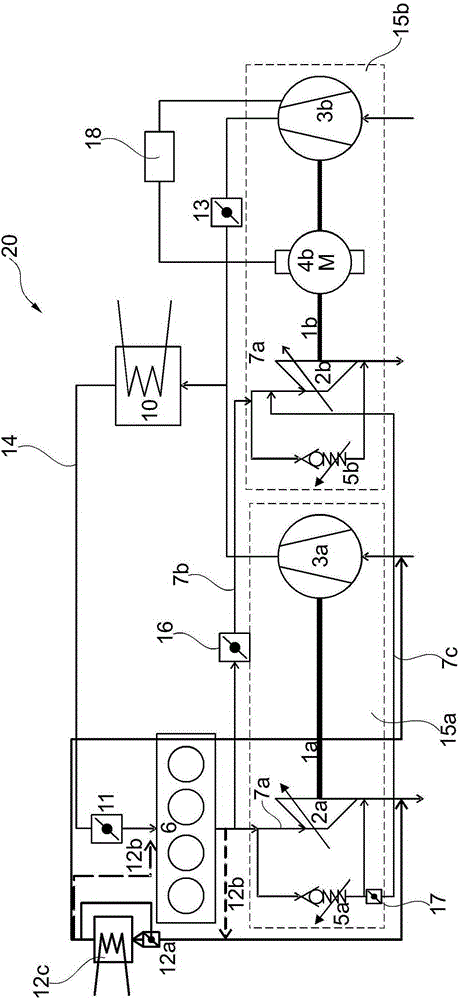

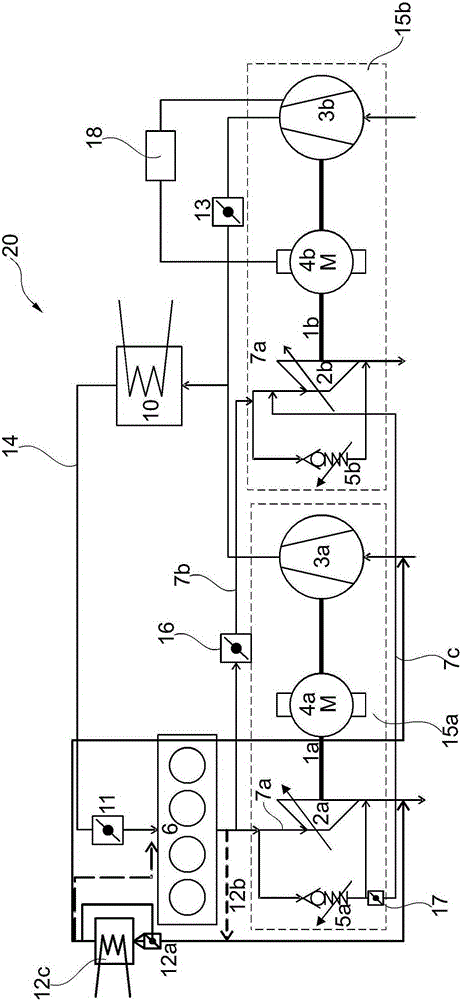

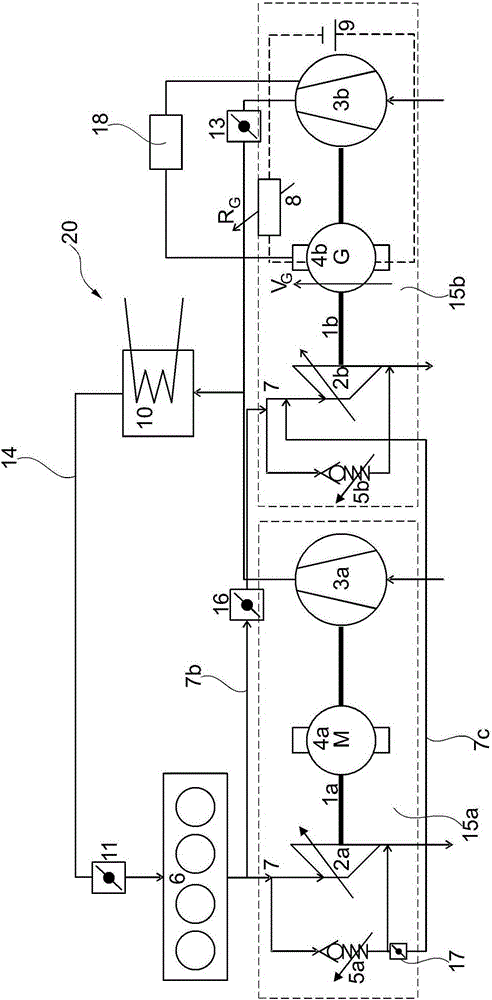

[0016] like figure 1 As shown, the invention relates to an arrangement of an internal combustion engine having a first turbocharger and a second turbocharger, wherein at least the second turbocharger additionally has an electrical energy converter. like Figure 2 to Figure 4 As shown, the first turbocharger may also include a separate electric energy converter, wherein the separate electric energy converter can be operated in a motor mode or a generator mode. exist Figure 5 A method of operating these power converters based on exhaust gas flow and / or battery state of charge is shown in .

[0017] In a first embodiment, an internal combustion engine for a motor vehicle may include a first turbocharger and a second turbocharger, the first turbocharger including at least a first turbine and at least a first compressor , the second turbocharger has at least a second turbine and at least a second compressor. The first turbocharger and the second turbocharger may be arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com