This resulted in the

reduced mass-to-

power ratio compared to piston engines (PE) at high

turbine rotor speeds limited predominantly by sound speed in the WM and strength of structural materials.

Having potentially higher energy coefficient compared to that of the ICE these engines as a whole have not surpassed them by

specific energy parameters due to structural complexity impeding achievement of maximum energy parameters and lack of optimal structural materials and precise mathematical models.

However, this is difficult to achieve since the above engines are characterized by lengthy sealing elements of working chambers (WC) and large area of walls thereof, thereby invalidating all advantages thereof in the majority of the structures over piston engines in implementing Otto, Diesel, Trinkler or Stirling cycles, as well as any cycle in which fuel or at least one of components thereof is pre-compressed in the engine WC.

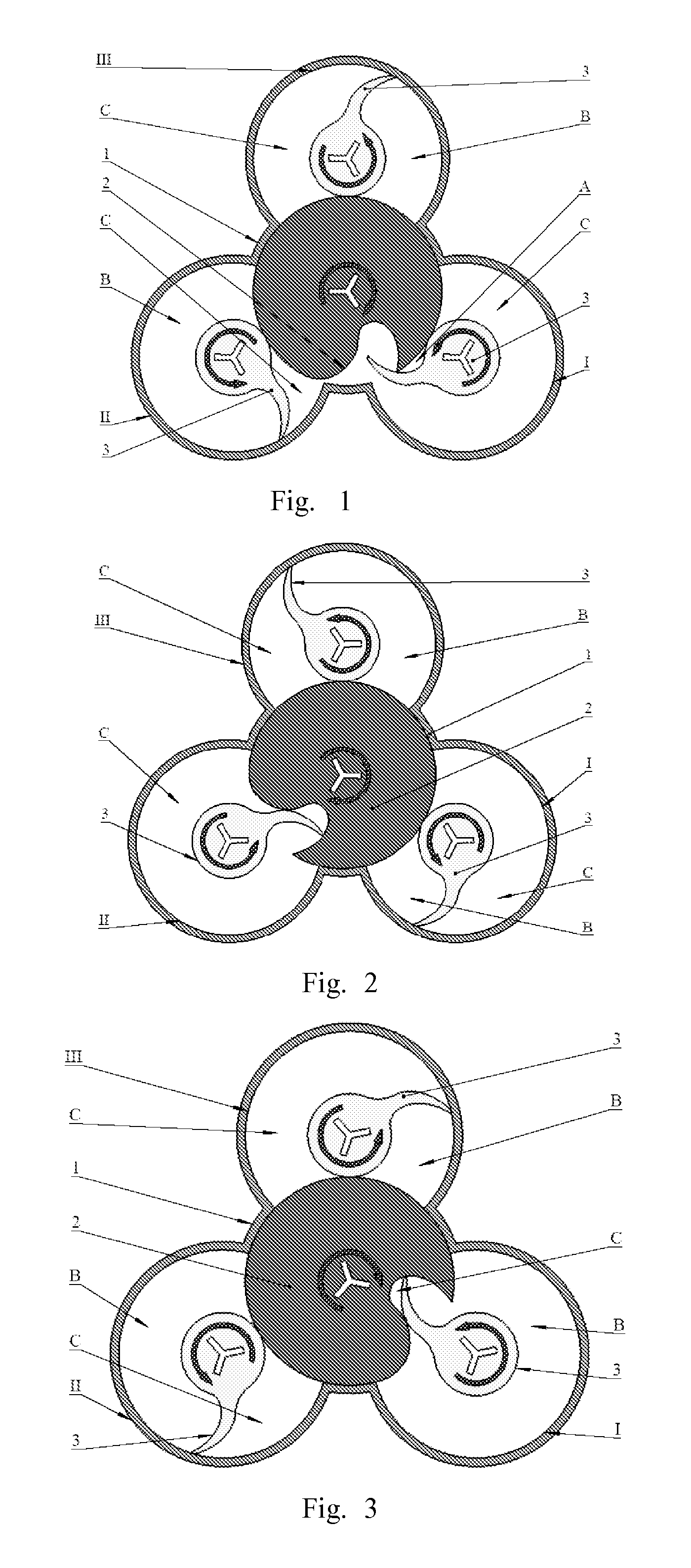

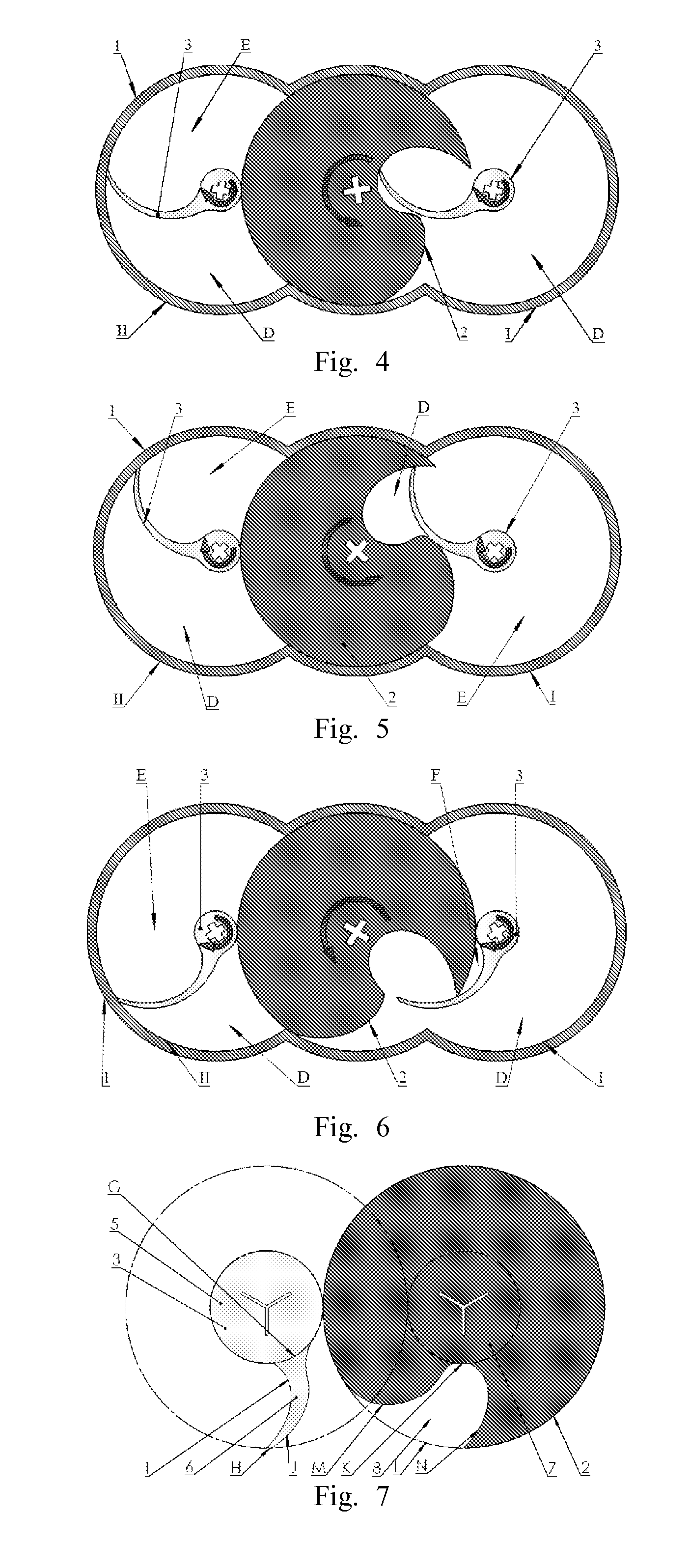

The structures allowing potentially higher efficiency to be achieved are characterized by relatively complex

manufacturing technology, for example, such as that of the

gerotor engine.

Both internal and external combustion PEs and also piston expanders are characterized by limited power-to-weight ratio and / or E because of lower piston or cross head speeds compared to the speed of the

turbine's working members.

Disadvantages of turbines reside in high sensitivity of the first stages to high WM temperatures due to high loads on the material of working members, which results in the need of introducing additional quantity of air into the cycle to be mixed with the GCP exhausting from the CC before it is fed to the GT first stage.

However, high-power

ceramic turbines are still difficult to manufacture, while turbines with steam-cooled blades are characterized by high aggregate power and imply the use of the gas-steam cycle which is preferable to be used at powerful power industry's facilities.

It is worth noting that the turbine is not capable of operating in principle at high pressures, therefore, it is unreasonable to further increase pressures and hope for a substantially higher E, since the E of high-pressure cylinders of the state-of-the-art turbines is extremely low and the total E, in particular, of supercritical STP is not higher than the E of SE of the first quarter of the twentieth century.

Existing ring ICEs and non-

trunk or non-

crosshead ICEs are provided with a WC combined with a CC of a noncircular or variable shape, thereby leading to non-optimal fuel

combustion process and to less environment-friendly exhaust than those of classic PICE.

STPs using steam, binary WM, for example,

ammonia-water mixture or two-phase WM, for example,

wet steam, are characterized by a reduced life if droplets are available in the WM that results in underutilization of a portion of energy in the backpressure or condensing cycle or requires intermediate WM heating with different methods, thereby complicating the structure and / or reducing flexibility thereof.

Piston SEs are free from this

disadvantage, but they are characterized by high unit weight and are not capable of achieving economically efficient thousands-fold expansion ratios when the WM of supercritical parameters is fed, for example, similar to STP.

A specific feature of the majority of synthetic and composite fuels is an unstable composition, availability of large quantity of hazardous impurities and

hydrocarbon mist, variable

ignition delay and relatively lengthy period of combustion time which leads to deposits on the ICE WC and causes premature engine failure.

Low-

calorie fuels require a relatively large clearance space in the PICE which inevitable results in the reduced efficiency.

The above problems of burning low-

calorie gases in the PICEs resulted in widespread utilization thereof in the GTP.

However, in the majority of cases, non-standard gases are characterized by relatively low output and unstable parameters, for example, the caloric content of the synthesis gas fluctuates within an extensive range depending on the composition of a gasifiable fuel, for example,

municipal solid waste (MSW).

Moreover, it is undesirable to filtrate the above high-molecular compounds being predominantly hydrocarbons because this may lead to significant reduction in the caloric content of the fuel and poses problems of utilizing these compounds, which, nevertheless, are valuable chemical raw materials in large quantities, although they are potent carcinogens.

In operating

gas turbines, which are more sensitive to the above impurities than the PICE, the cost of gas purification systems is comparable to that of power-generating equipment, therefore, it is unreasonable to fire certain types and / or quantities of gas in

gas turbines and, as a result, MSW gasification products, for example, are not used in GTP.

Using STPs is not effective at such efficiency level.

However, using the GTP as a CR leads to rapid failure of working members thereof because of high aggressiveness of

chemical weapon), in particular,

chlorine-containing compounds.

Availability of a clearance space accounting for not less than 2% of the

working space is the

disadvantage of positive displacement superchargers, for example, piston superchargers, in particular, piston engines.

For example, the

disadvantage of screw or similar superchargers is a relatively low degree of

pressure increase in the stage at an optimal efficiency.

Disadvantages of dynamic type superchargers, in particular, turbines include sensitivity of working members to the WM composition and parameters and also substantial dependence of the efficiency on supercharger load percentage.

High

working space-total volume ratio of the supercharger is characteristic of

cam-driven vacuum pumps of different designs, however, all of them have very large clearance space and, thus, they are not suitable to be converted into compressors and engines with specifications substantially exceeding those of the similar equipment based on classical solutions.

Login to View More

Login to View More  Login to View More

Login to View More