Patents

Literature

31results about How to "Reduce temperature and pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

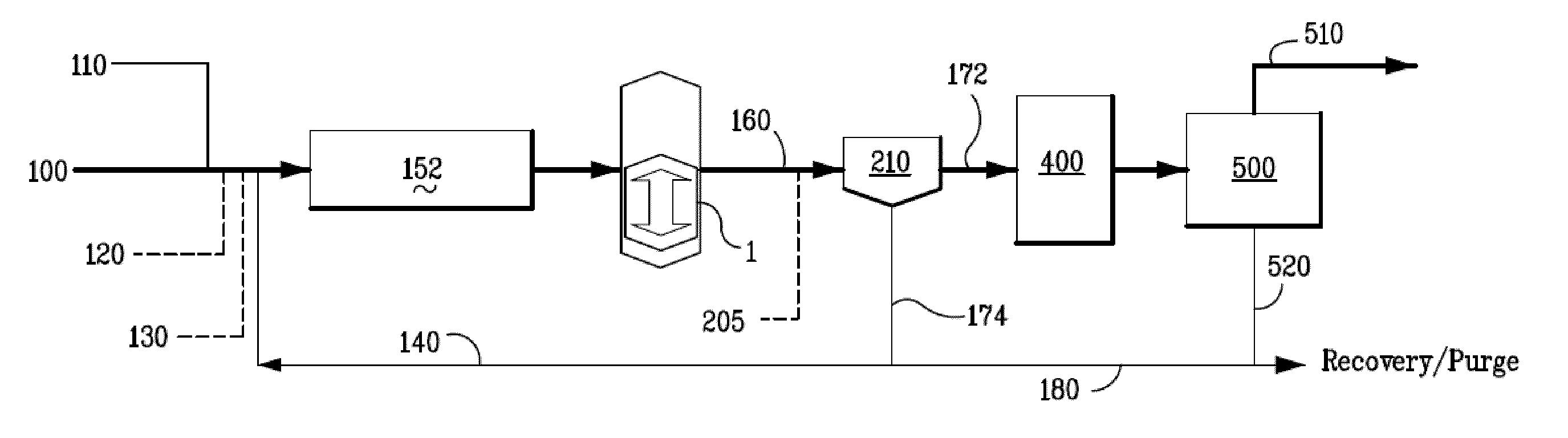

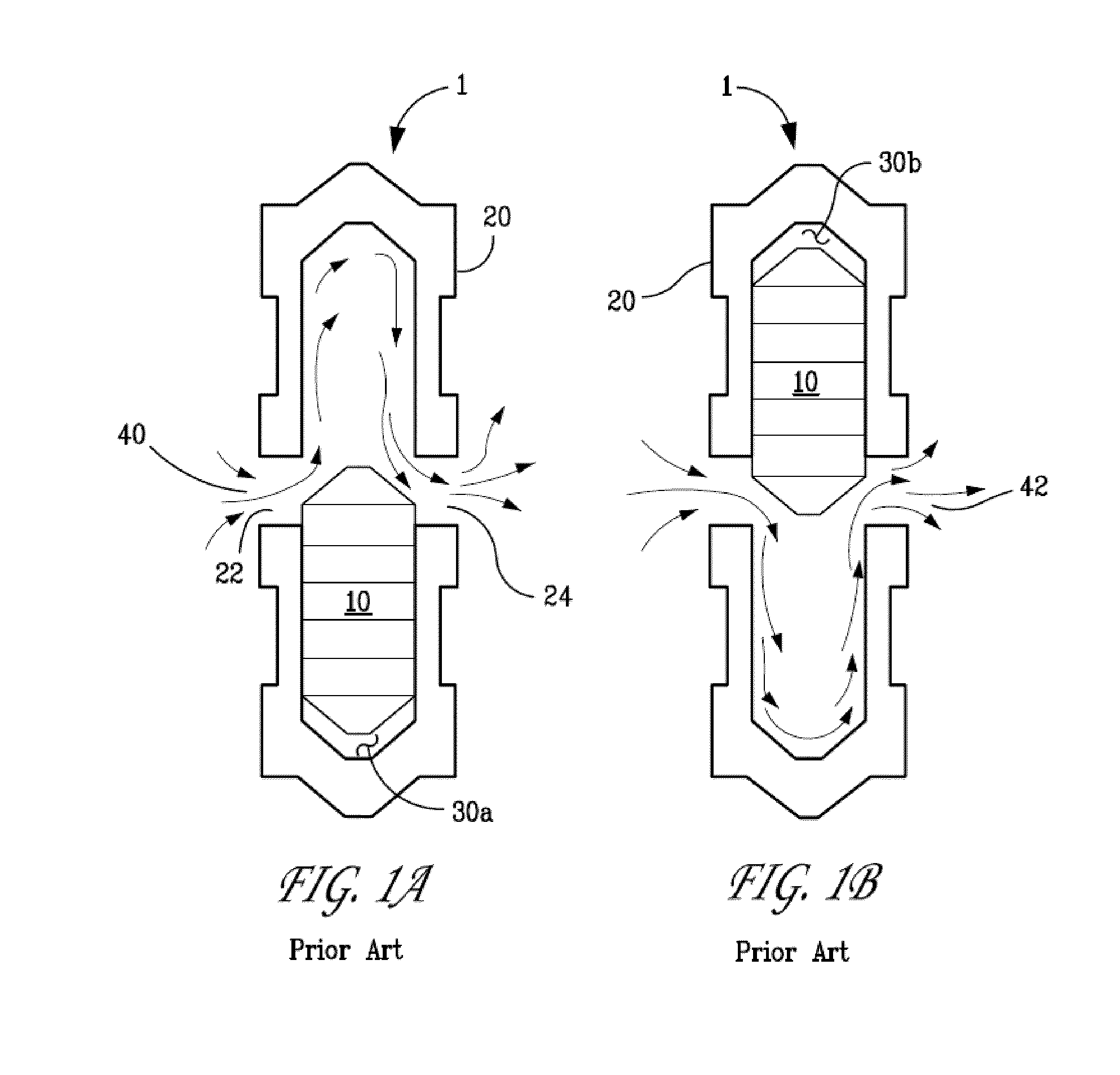

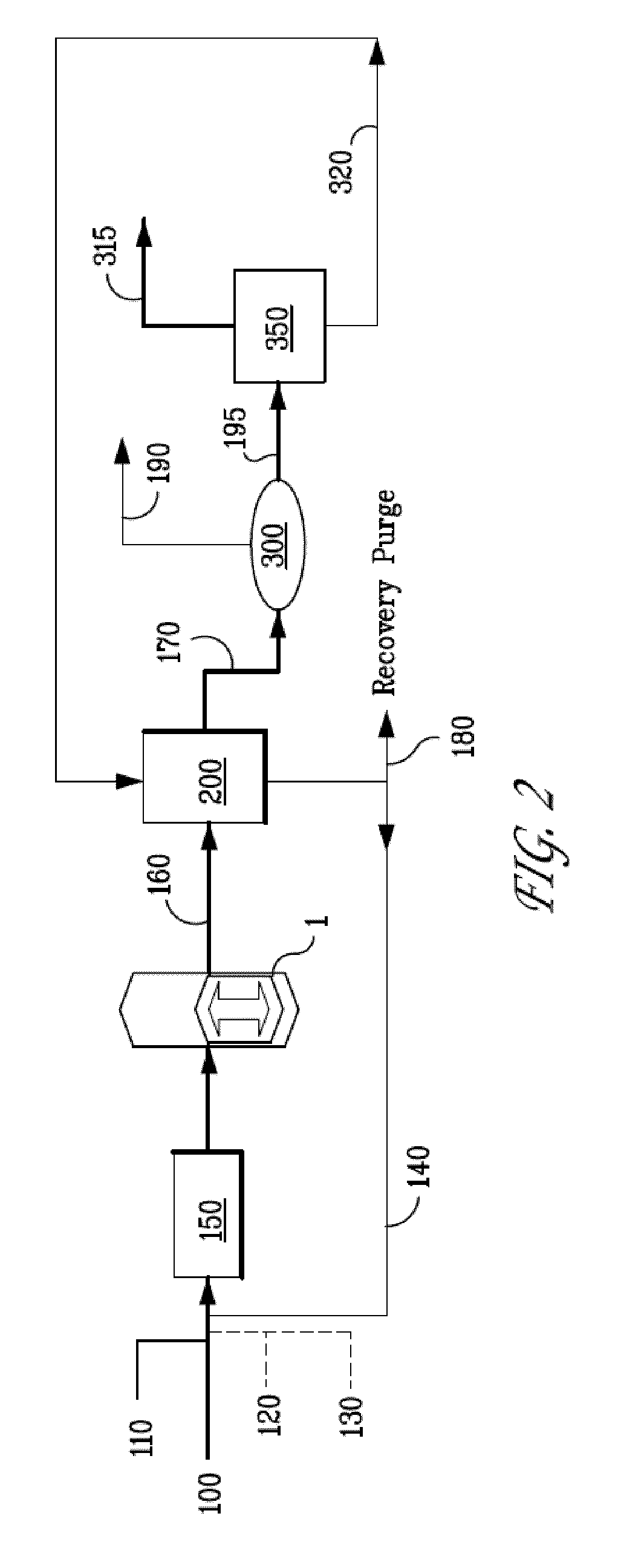

Compression Reactor And Process For Hydroprocessing

ActiveUS20110174682A1Reduce temperature and pressureReduce pressureThermal non-catalytic crackingUltra-high pressure processesLiquid hydrocarbonsResidence time

The present invention is directed to a process for hydroprocessing of a liquid hydrocarbon feedstock, comprising: (a) mixing liquid, partially vaporized and / or vaporized hydrocarbon feedstock with molecular hydrogen; (b) feeding said mixture into a compression reactor; (c) compressing said mixture to a pressure, a temperature and for a residence time sufficient to: i) thermally crack at least a portion of hydrocarbon molecules in said hydrocarbon feedstock, and ii) react hydrogen in the presence of a hydrogenation catalyst with unstable portions of the cracked molecules, forming a hydroprocessed product; and (d) expanding said mixture to reduce the pressure and temperature thereby reducing subsequent undesirable reactions.

Owner:EXXONMOBIL CHEM PAT INC

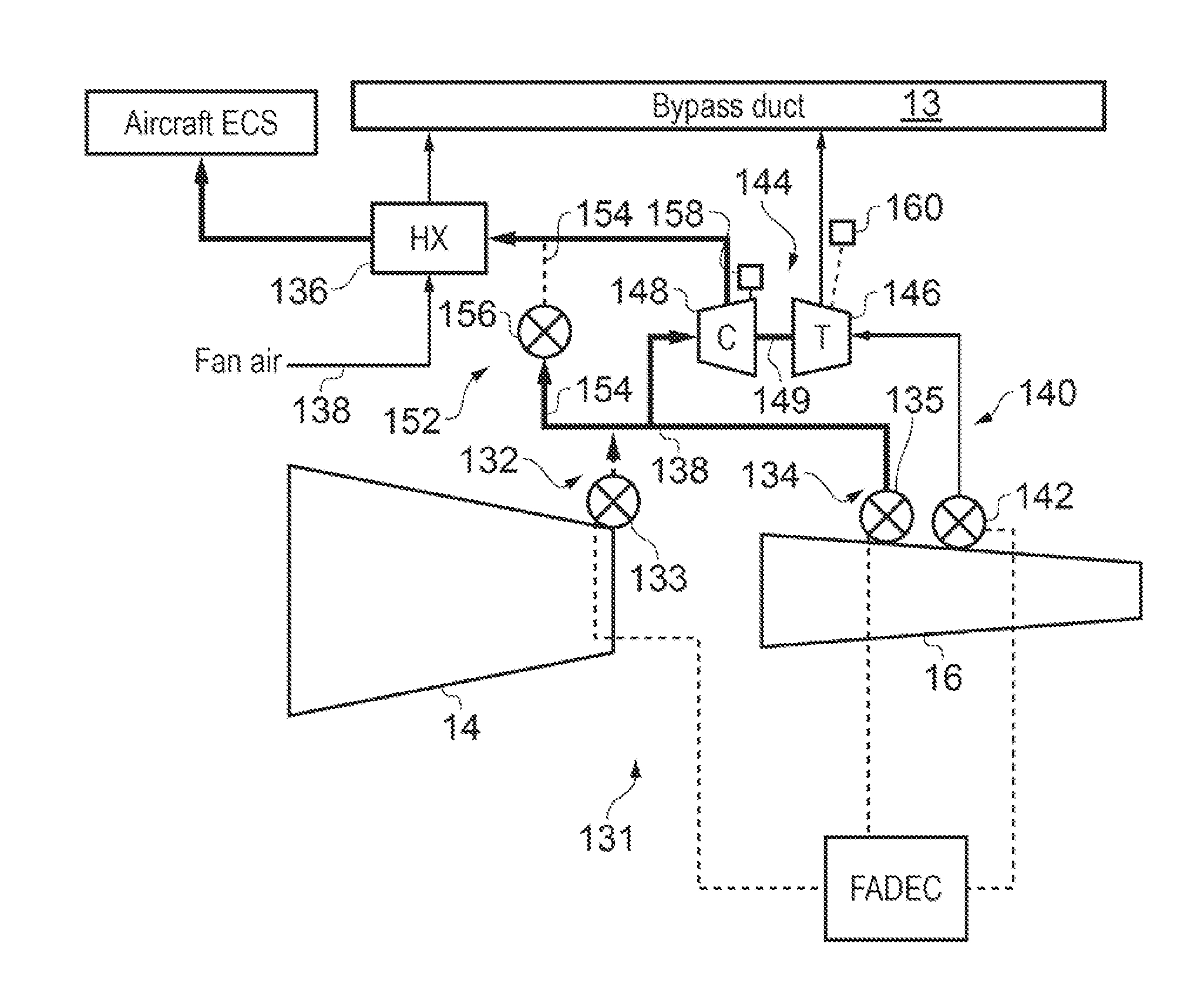

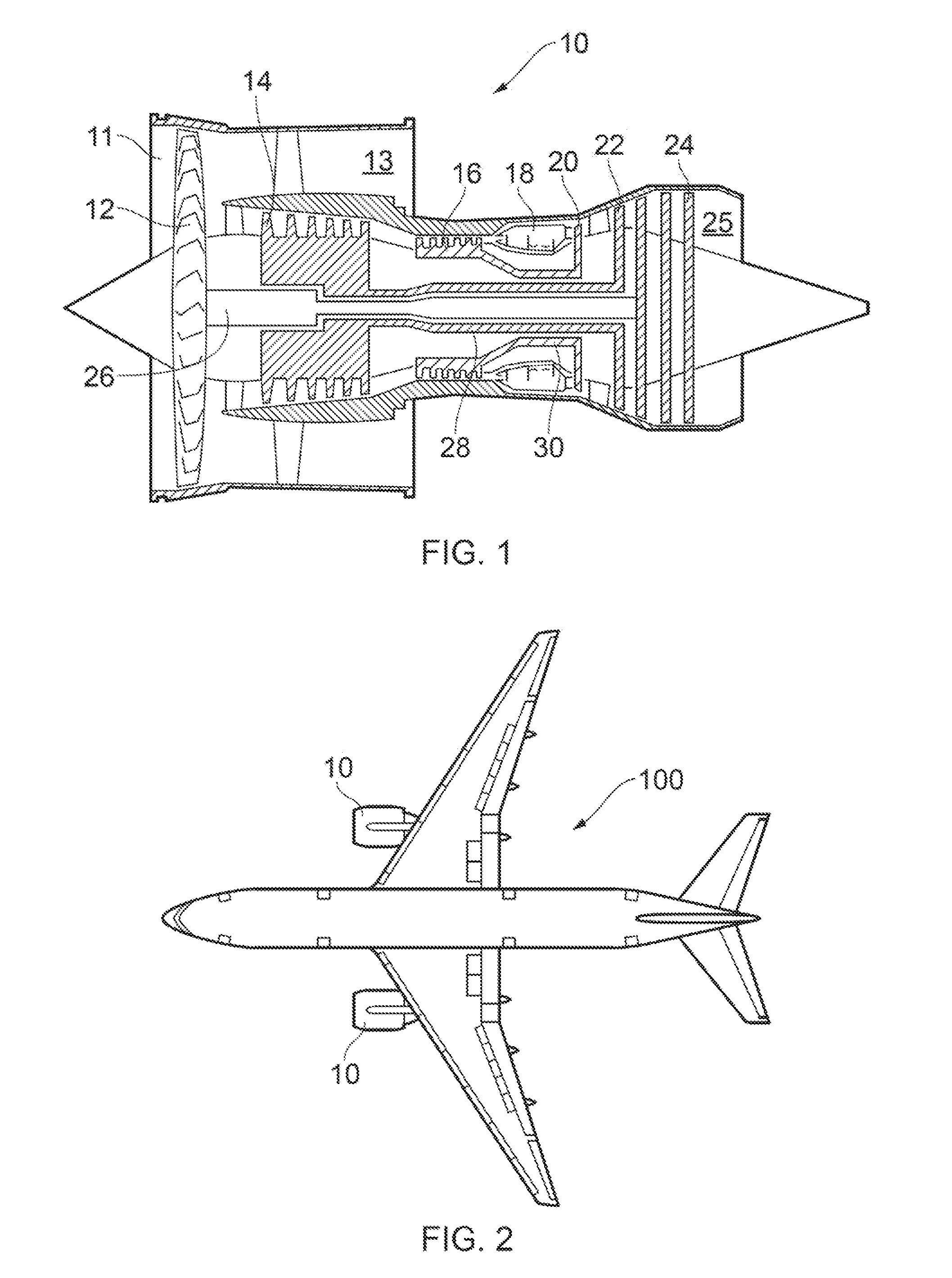

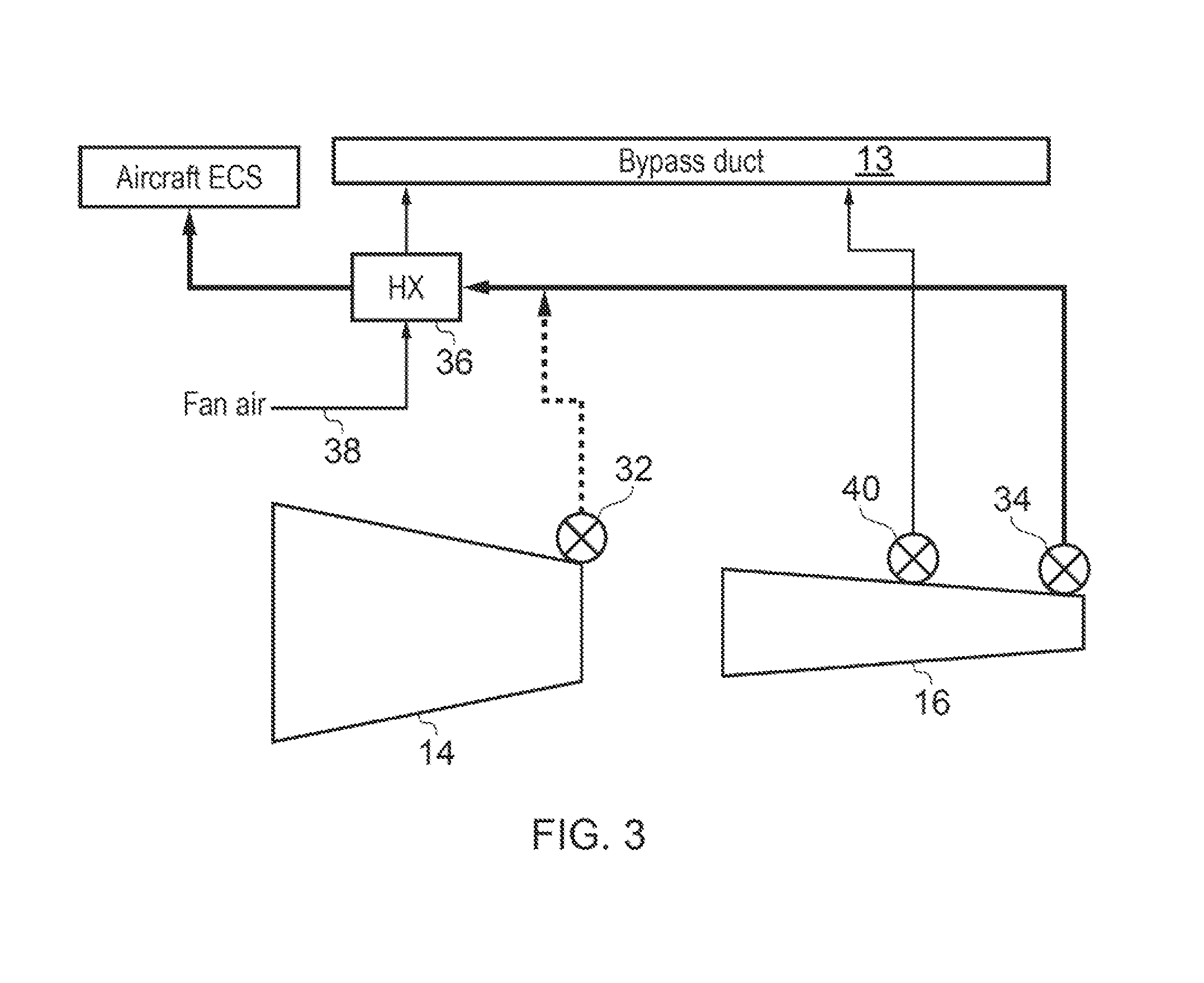

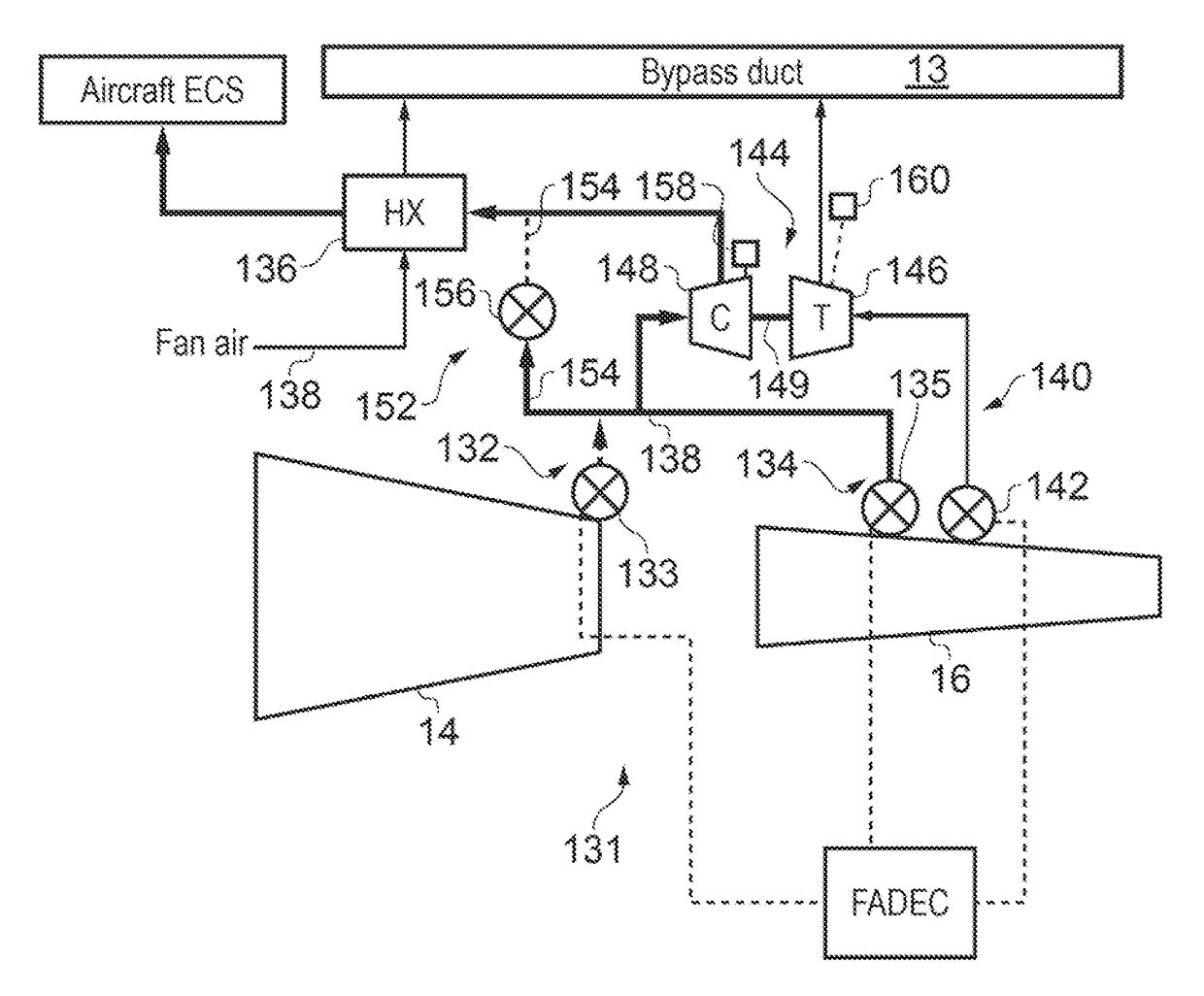

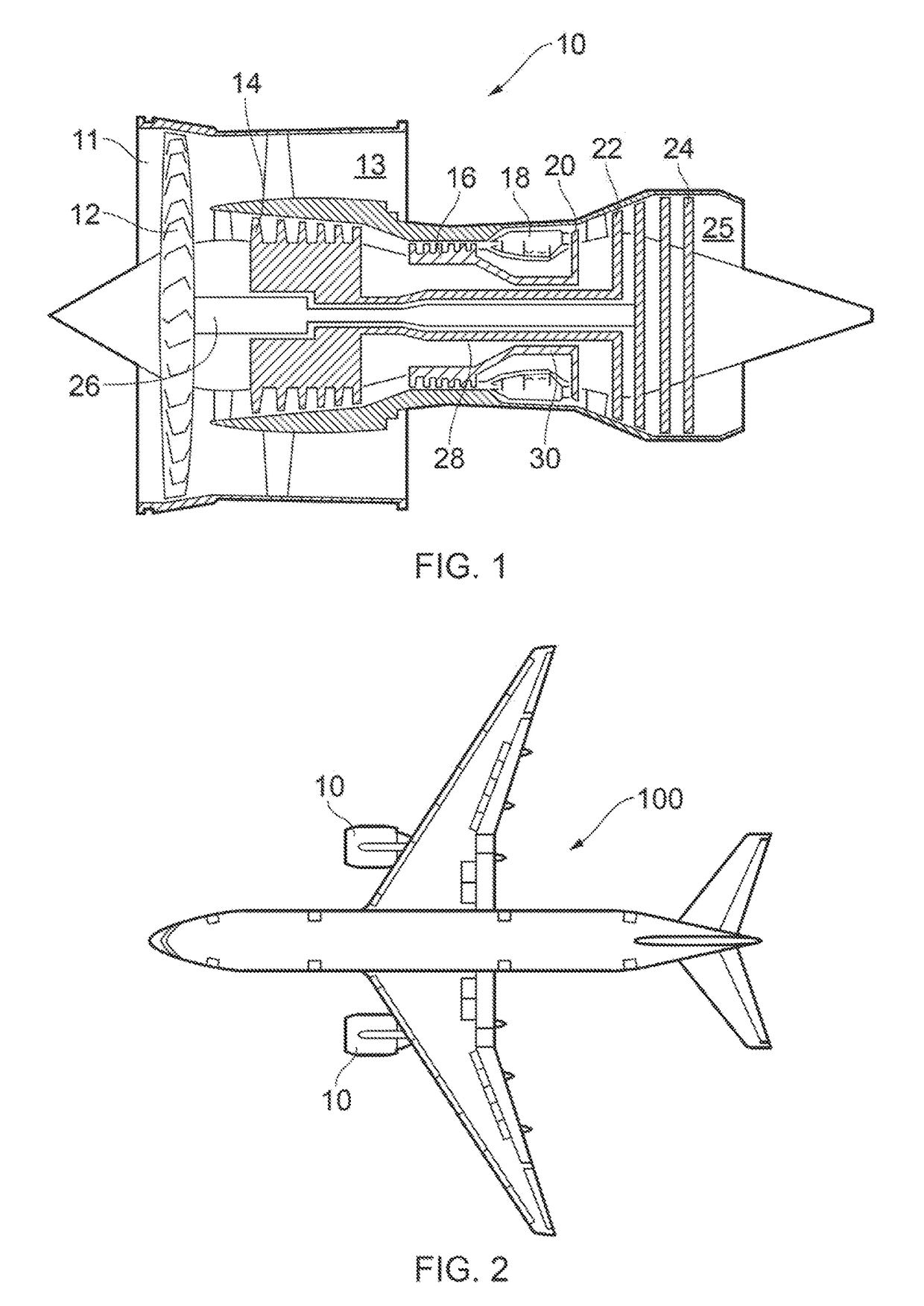

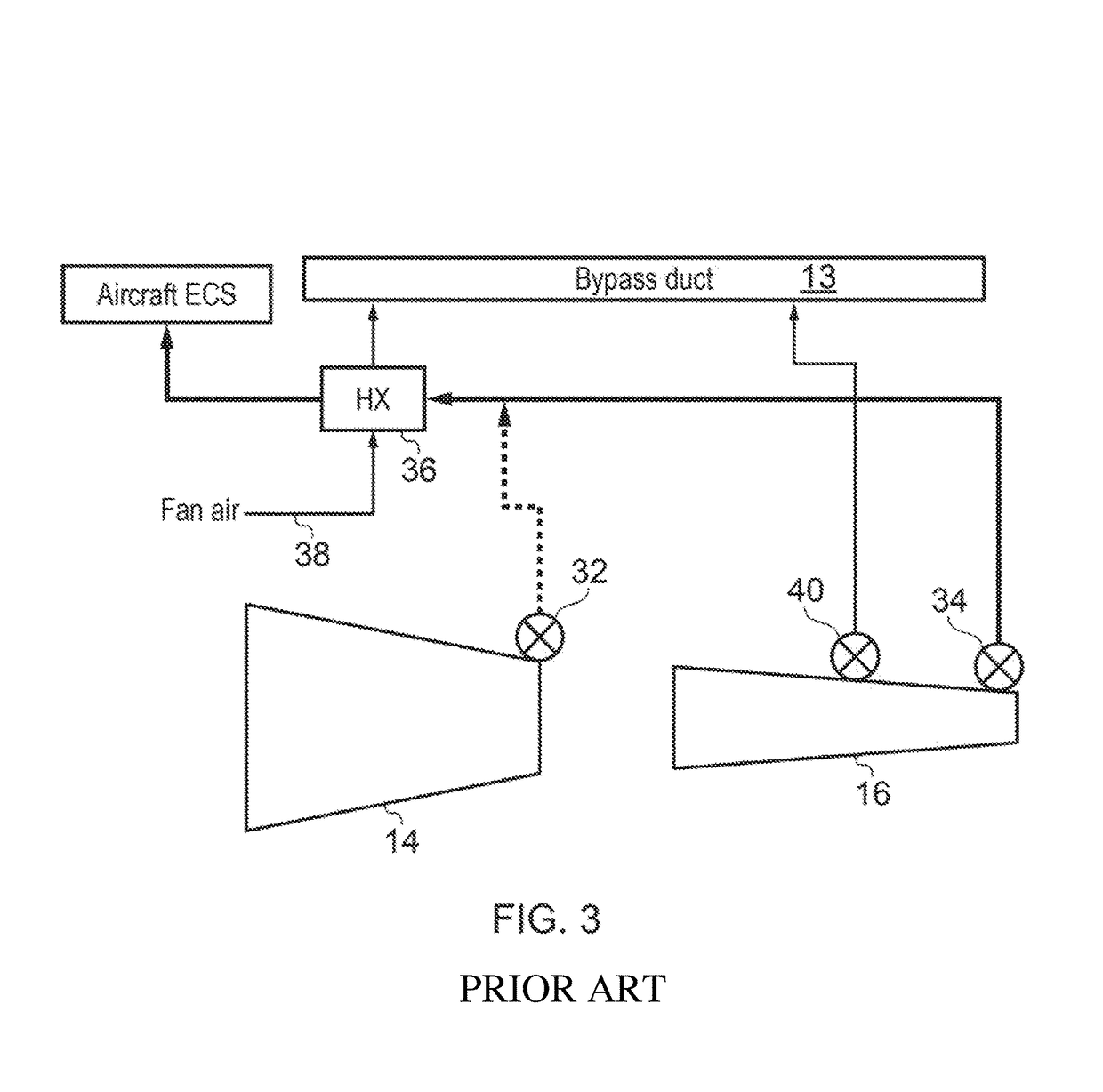

Pnuematic system for an aircraft

ActiveUS20150121842A1Reduce temperature and pressureReduced structureCosmonautic vehiclesCosmonautic propulsion system apparatusNacelleAirplane

A pneumatic system 131 for use with gas turbine engines 10 and aircraft 100. The pneumatic system 131 comprises a first engine core compressor bleed offtake in the form of an engine handling bleed offtake 140, and a second engine core compressor bleed offtake in the form of first and second cabin bleed offtake 132, 134, the handling bleed being configured to supply higher pressure air than the cabin offtakes 132, 134. The system 131 comprises a turbocompressor 144 comprising an air compressor 148 driven by a turbine 146. The handling bleed offtake 140 is in fluid communication with the turbocompressor air turbine 146 to thereby drive the air turbine 146, and the cabin bleed offtakes 132, 134 are in fluid communication with the turbocompressor air compressor 148 such that air from the offtakes 132, 134 is compressed by the turbocompressor air compressor 148.

Owner:ROLLS ROYCE PLC

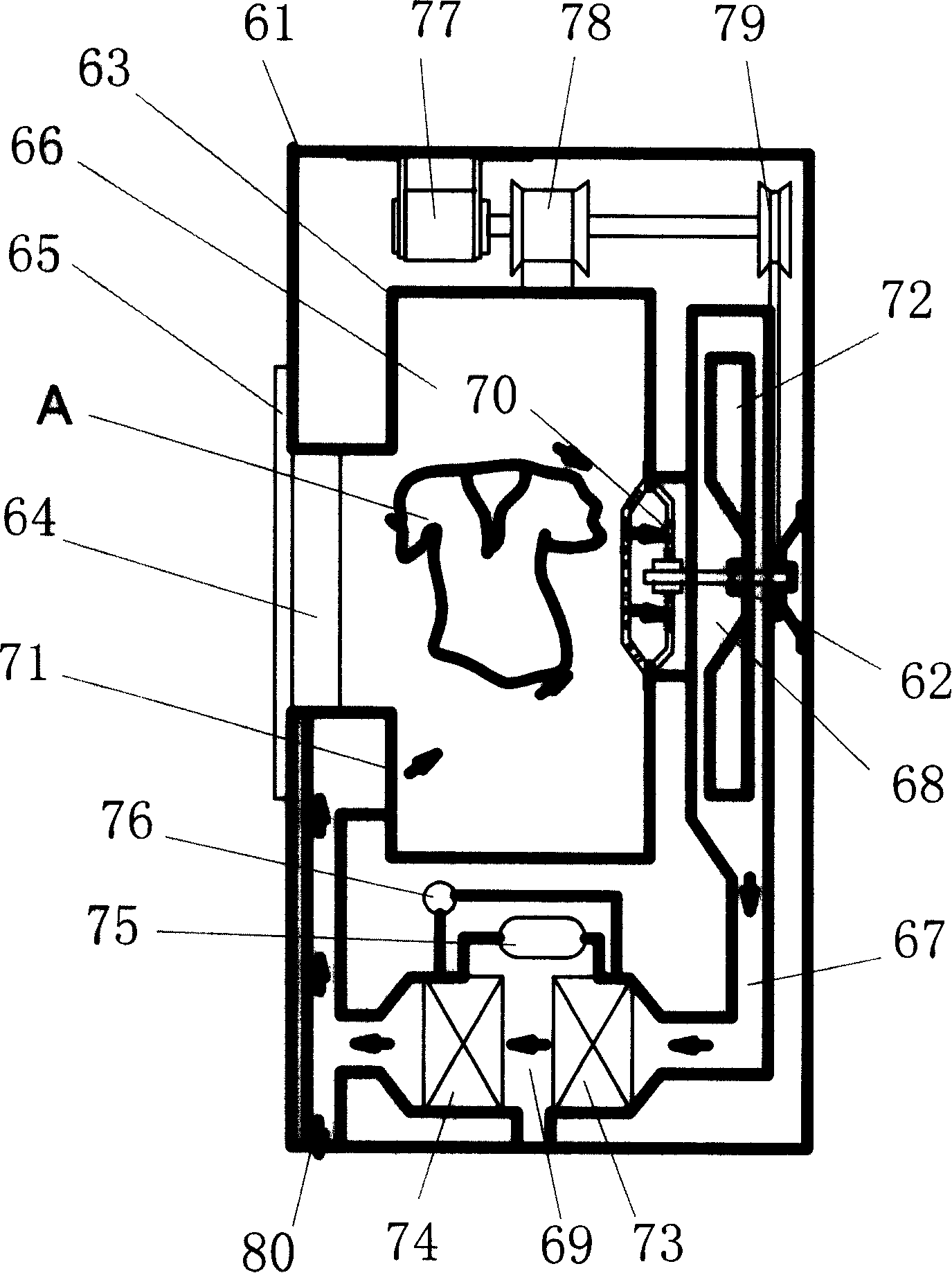

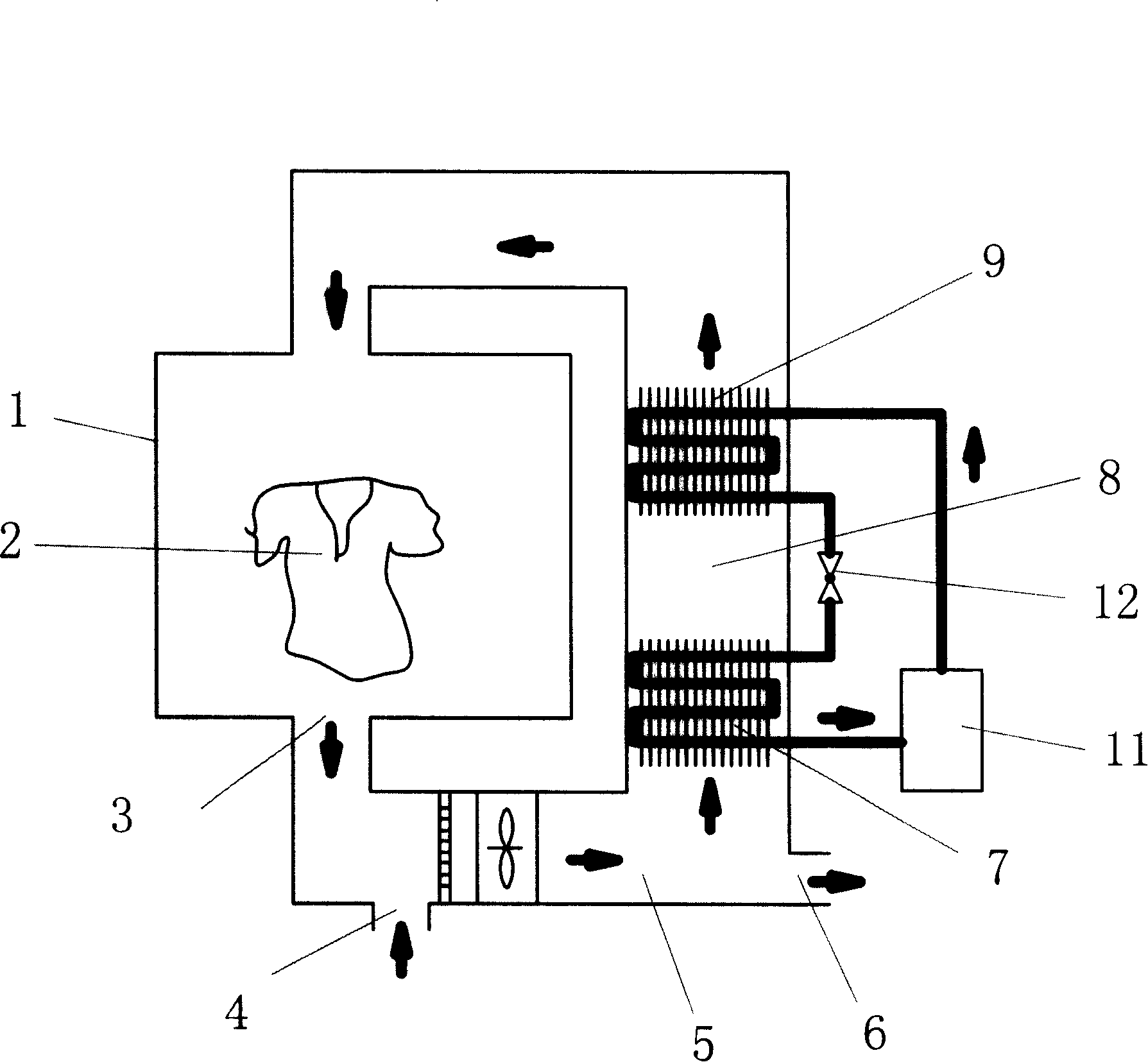

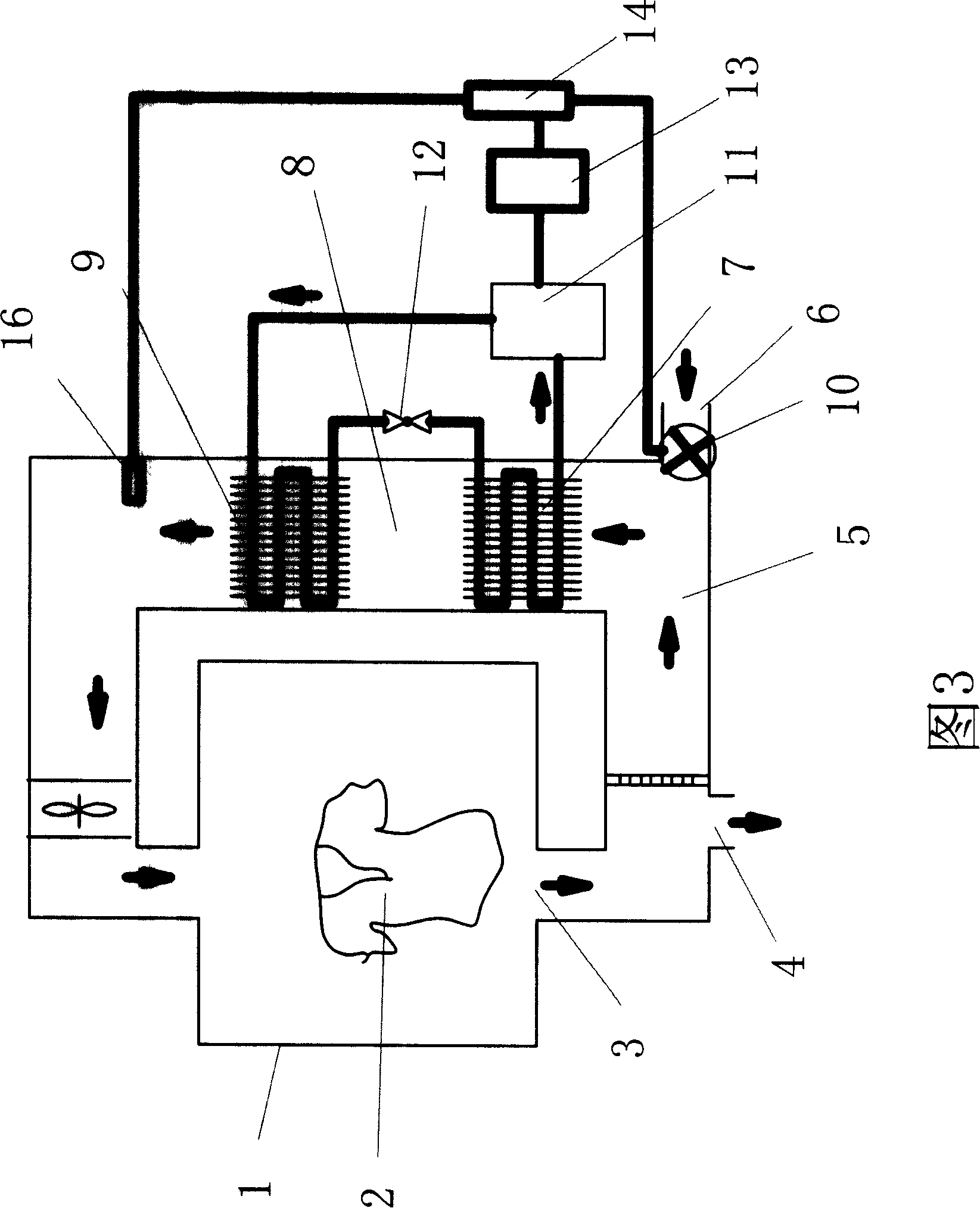

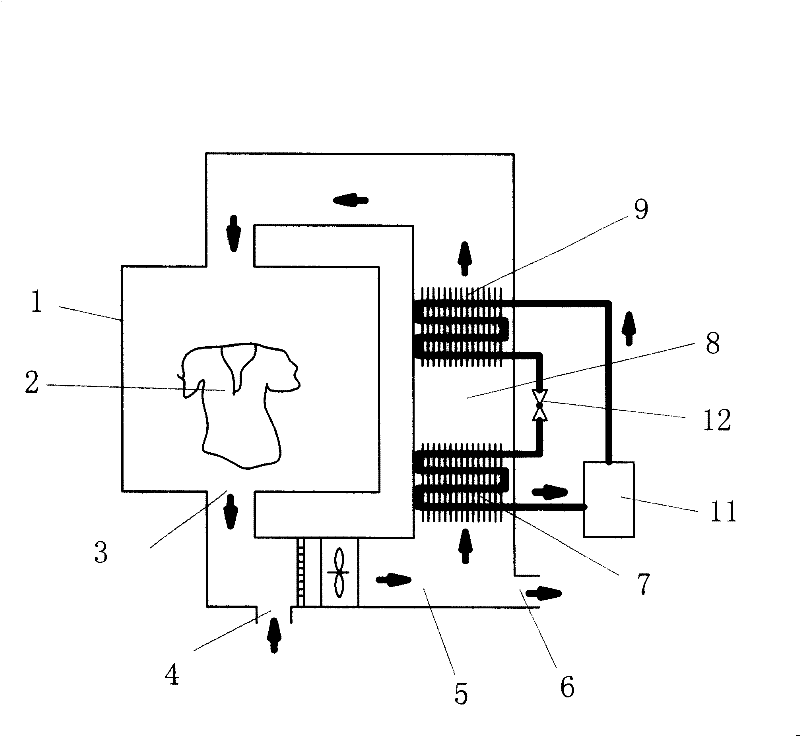

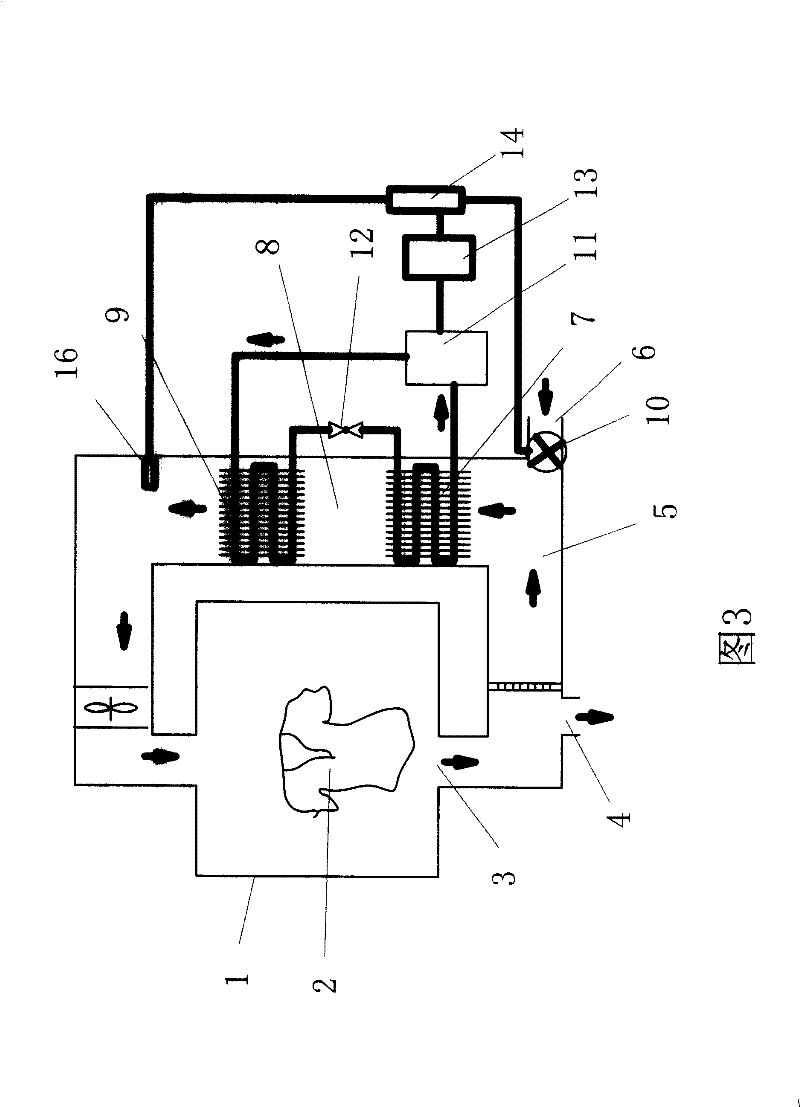

Heat pump clothes drying or clothes drying washing machine

ActiveCN101235587AReduce temperature and pressureReduce the temperatureWashing machine with receptaclesTextiles and paperAir cycleEngineering

The invention relates to a dry cleaning washing machine and in particular relates to a heat pump cloth drying or cloth drying washing machine, which comprises an air circulation channel which is composed of a drying chamber, a blast chamber and a heat exchange chamber, wherein a heat absorber is arranged on one side of the heat exchange chamber which is close to the upper stream, a heat releaser is arranged on one side which is close to the lower stream, the heat absorber and the heat releaser are formed into a heat pump device through a compressor, a capillary tube and the like, an electronic control circuit is arranged, and an air inlet is arranged on the air circulation channel which connects the drying chamber and the heat exchange chamber, wherein an exhausting valve and a water-cooling condenser which are opened outside the machine are arranged on the upper stream of the heat absorber of the heat exchange chamber. When the environmental temperature is lower than a certain value, the control circuit controls the exhausting valve on the upper stream of the heat absorber to open to exhaust hot air outside the machine, when the environmental temperature is higher than a certain value, the control circuit controls the water-cooling condenser to operate, the temperature of air which enters into the heat absorber is lowered, which enables the temperature pressure of gaseous refrigerant which enters into the compressor to be comparatively low, and humid air is not exhausted outside the machine to deteriorate environment in hot summer.

Owner:HAIER GRP CORP +1

Pnuematic system for an aircraft

ActiveUS9879610B2Reduce temperature and pressureReduced structureEngine fuctionsAir-treatment apparatus arrangementsAir compressorHigh pressure

A pneumatic system 131 for use with gas turbine engines 10 and aircraft 100. The pneumatic system 131 comprises a first engine core compressor bleed offtake in the form of an engine handling bleed offtake 140, and a second engine core compressor bleed offtake in the form of first and second cabin bleed offtake 132, 134, the handling bleed being configured to supply higher pressure air than the cabin offtakes 132, 134. The system 131 comprises a turbocompressor 144 comprising an air compressor 148 driven by a turbine 146. The handling bleed offtake 140 is in fluid communication with the turbocompressor air turbine 146 to thereby drive the air turbine 146, and the cabin bleed offtakes 132, 134 are in fluid communication with the turbocompressor air compressor 148 such that air from the offtakes 132, 134 is compressed by the turbocompressor air compressor 148.

Owner:ROLLS ROYCE PLC

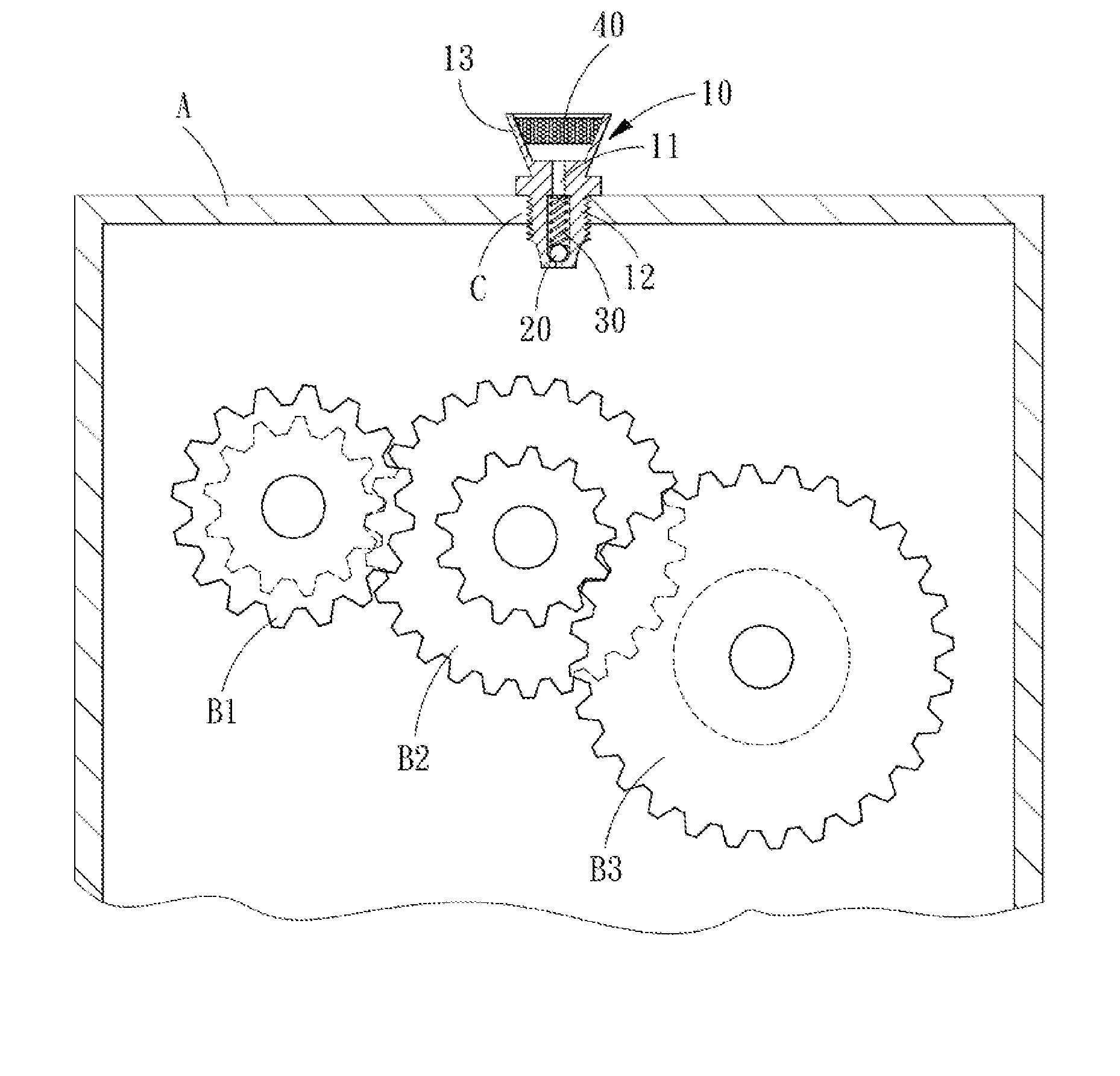

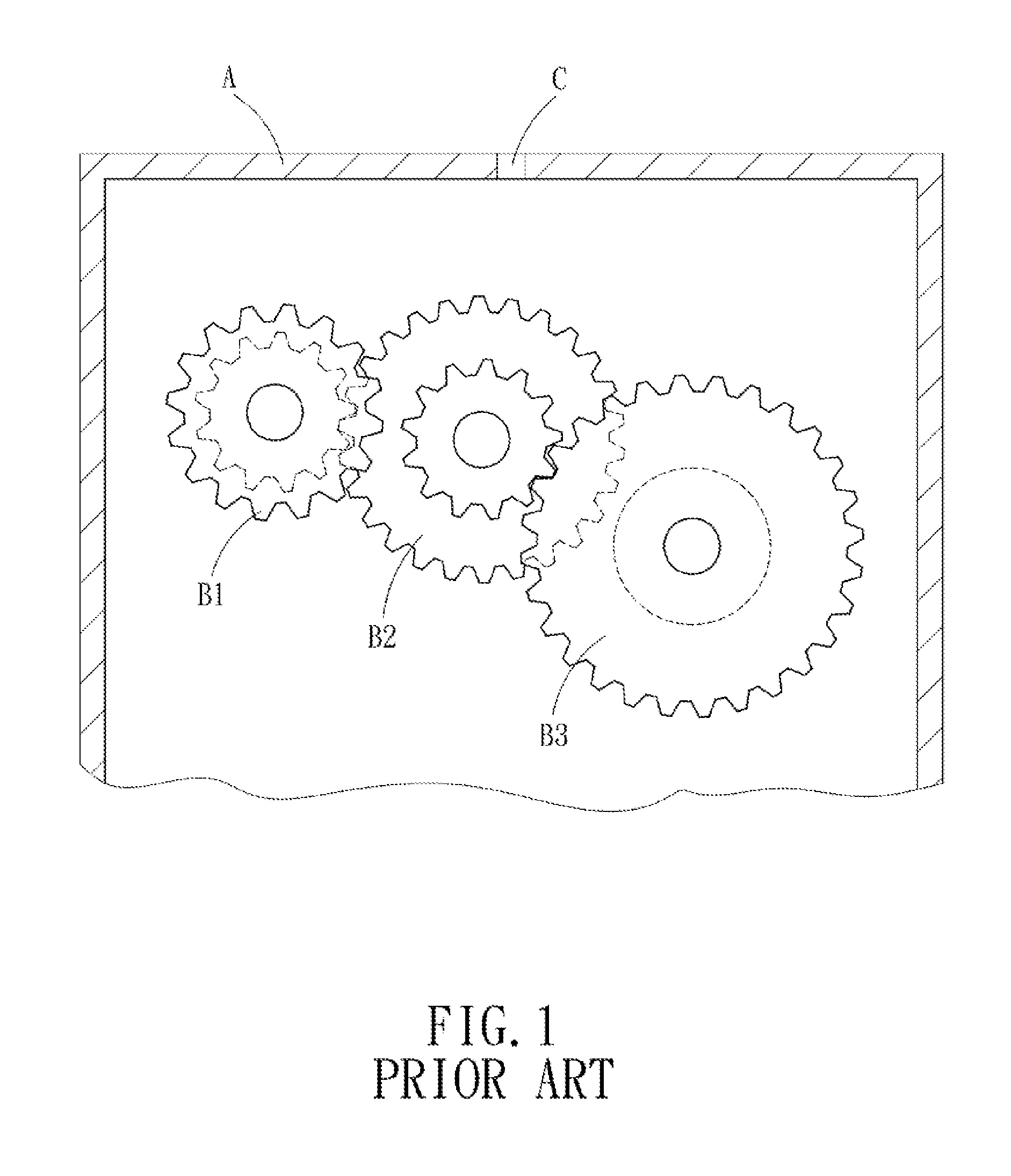

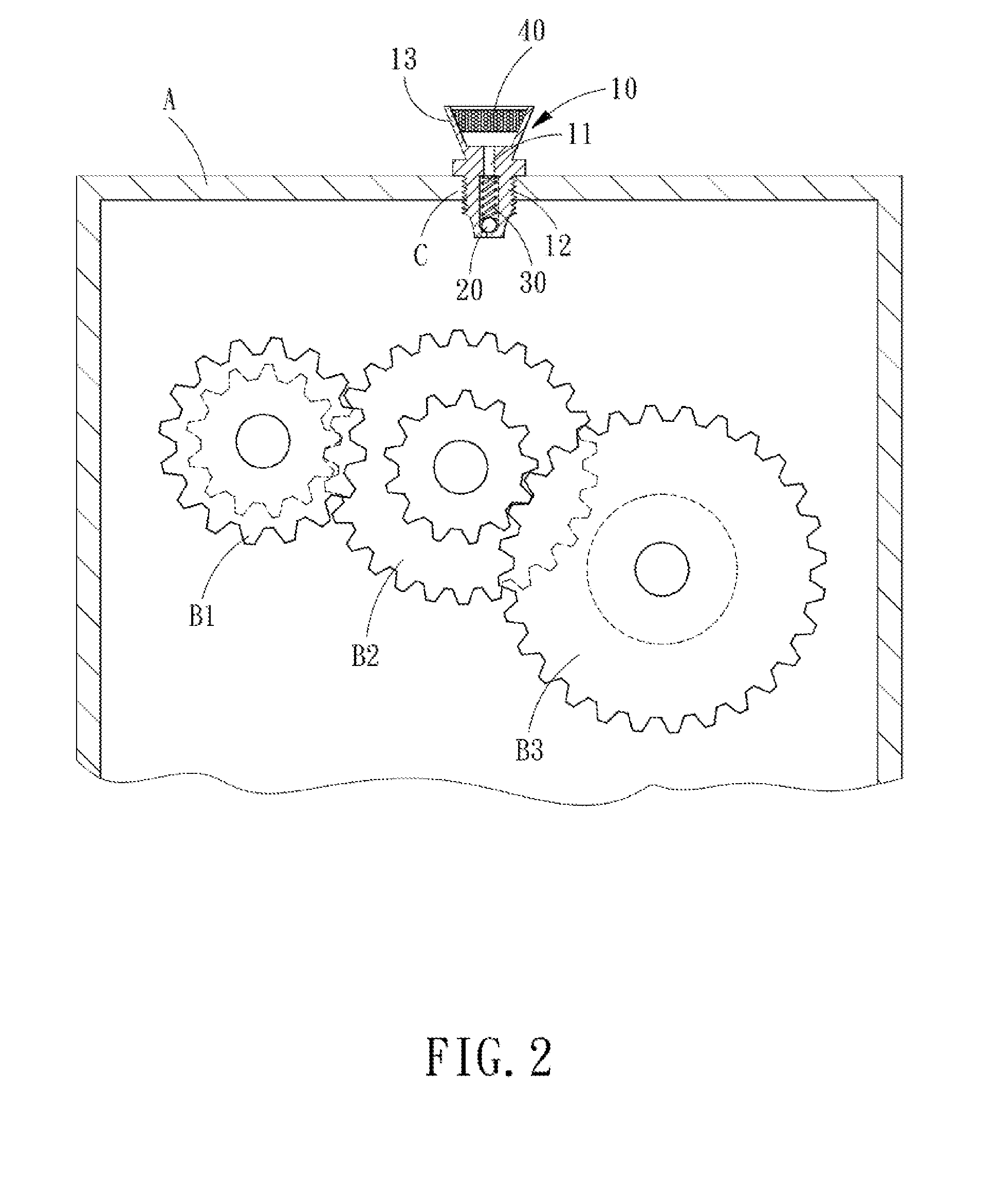

Pressure Relief Device for a Gear Box

InactiveUS20100032242A1Reduce pressureReduce the temperatureGear lubrication/coolingEqualizing valvesPressure riseEngineering

A pressure relief device for a gear box which is disposed in the gear box and comprises a body, a blocking member and a spring. The body is defined with a penetrating hole. The spring pushes the blocking member and makes it seal the penetrating hole. When the pressure rises since the temperature therein is risen, and when the gas pressure in the gear box is larger than the force of the spring, the gas can push the blocking member and compress the spring, and then discharge from the penetrating hole of the body, thus reducing the pressure and the temperature of the gear box.

Owner:LIN CHUNG CHUAN

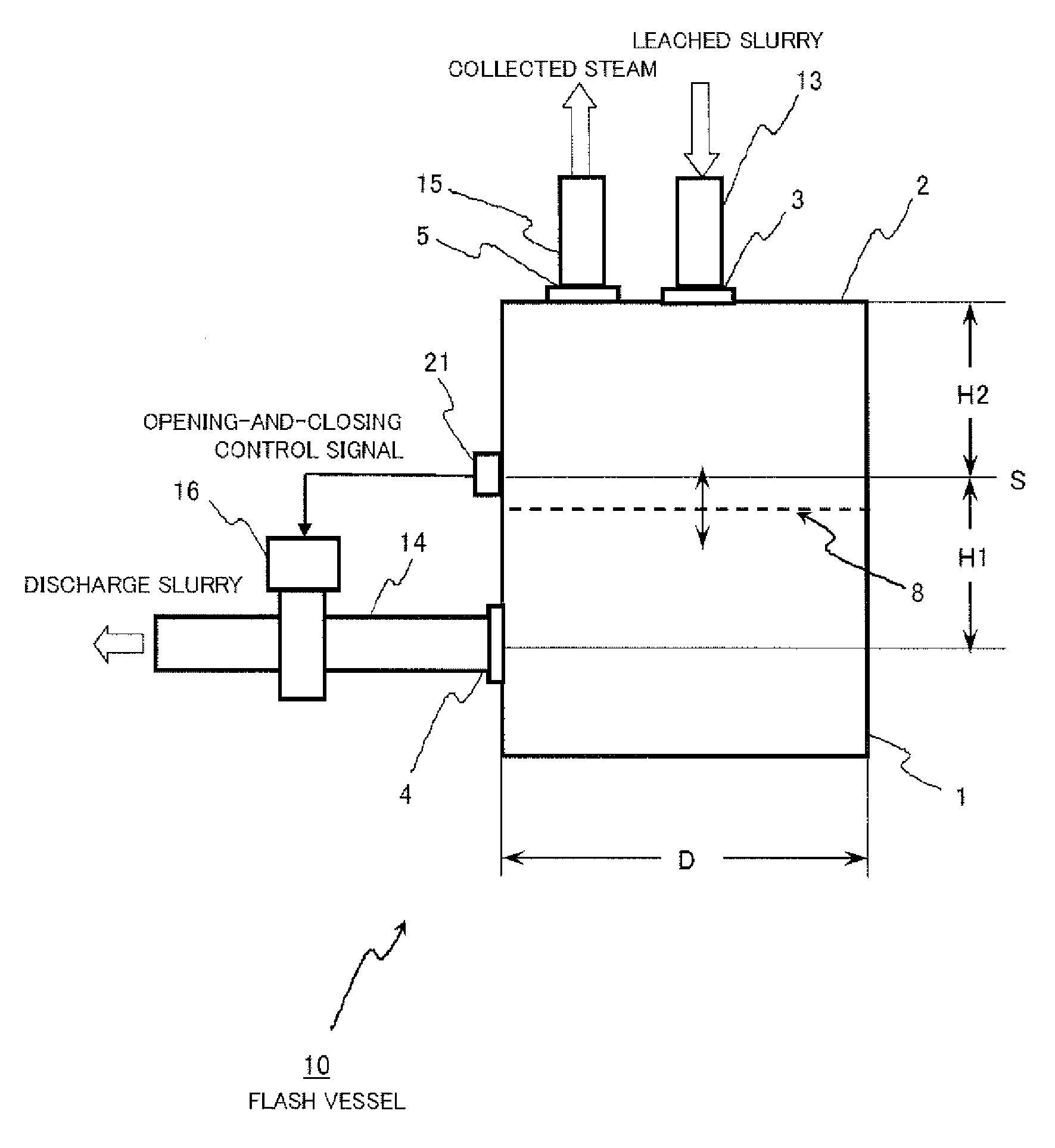

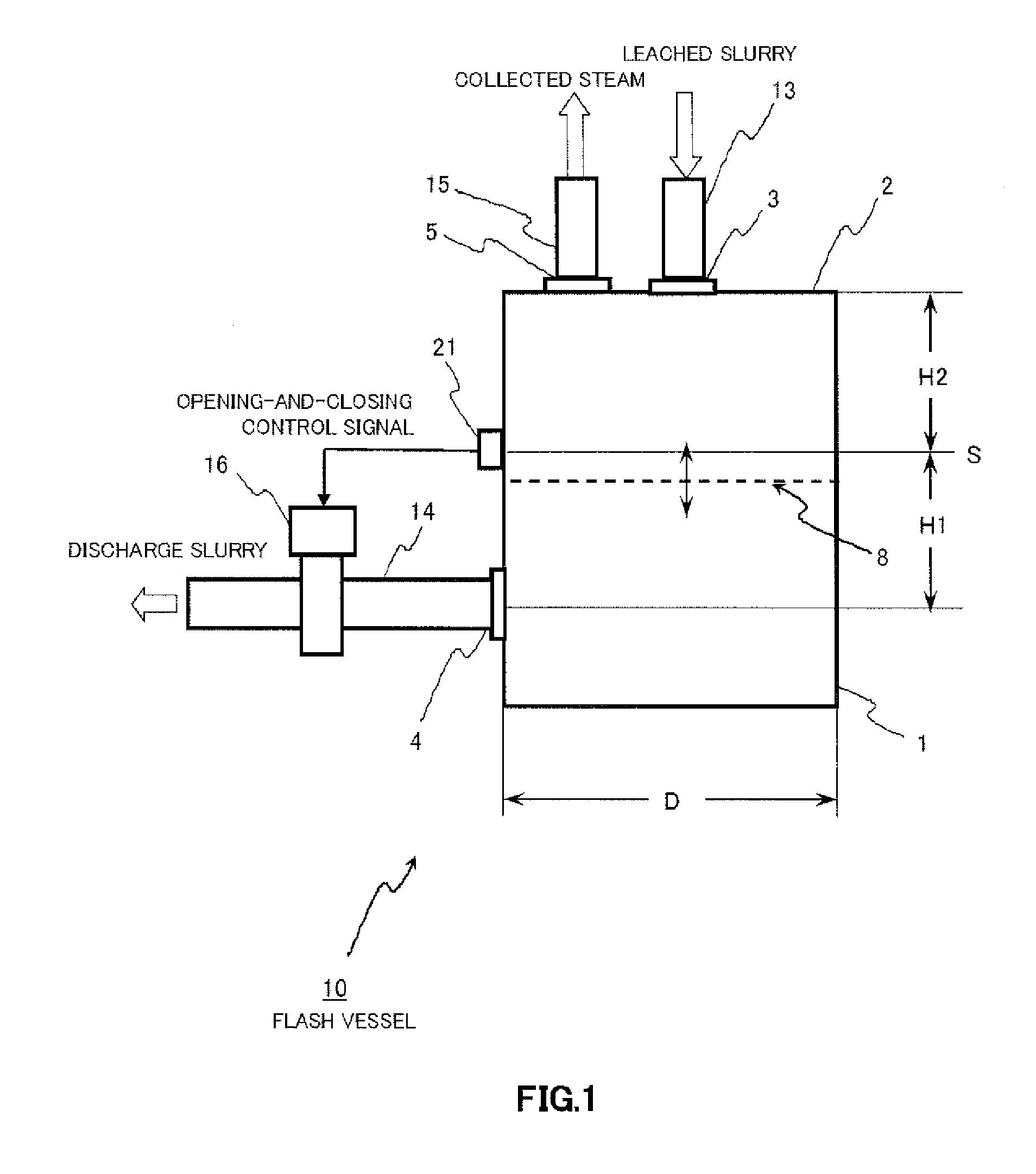

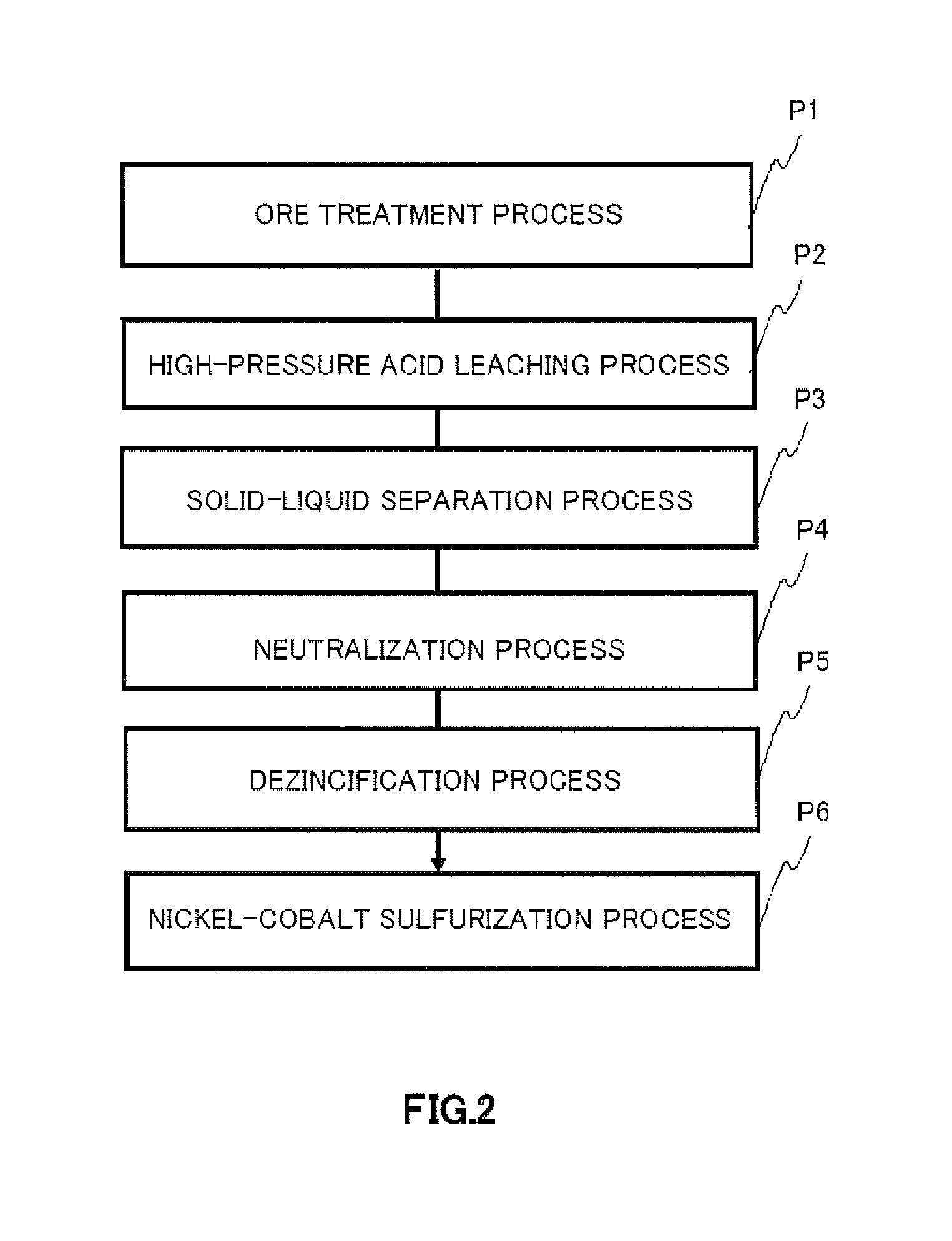

Method for operating flash vessel

InactiveUS20150044112A1Reduce temperature and pressureIncrease pressureSolvent extractionProcess efficiency improvementLiquid level sensorSlurry

The present invention is such that, with H1 being the height from a slurry outlet to a control liquid level, H2 being the height from the control liquid level to the top of a flash vessel, and being the diameter of the flash vessel, 0.35D≦H1≦0.45D, and 0.75D≦H2≦0.85D, and at least one liquid level sensor detects a slurry liquid surface at a control liquid level; when the liquid level sensor detects a slurry liquid surface which has risen, a slurry discharge valve installed on a slurry discharge pipe derived from the flash vessel is opened; and when the liquid level sensor detects a slurry liquid surface which has fallen, the slurry discharge valve is closed, whereby opening and closing of the valve is appropriately controlled thereby to reduce troubles with a steam discharge pipe, the slurry discharge pipe, and the slurry discharge valve.

Owner:SUMITOMO METAL MINING CO LTD

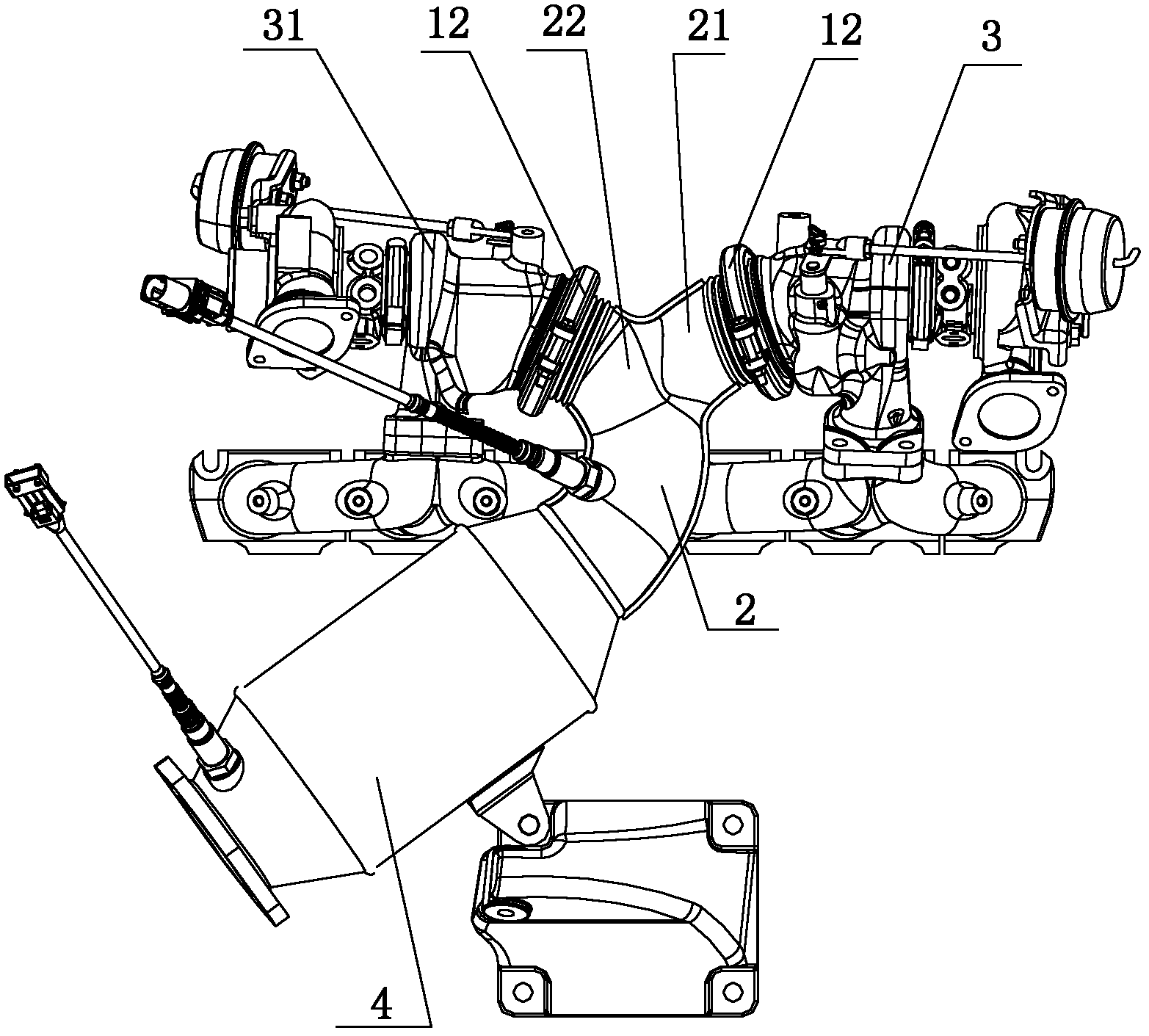

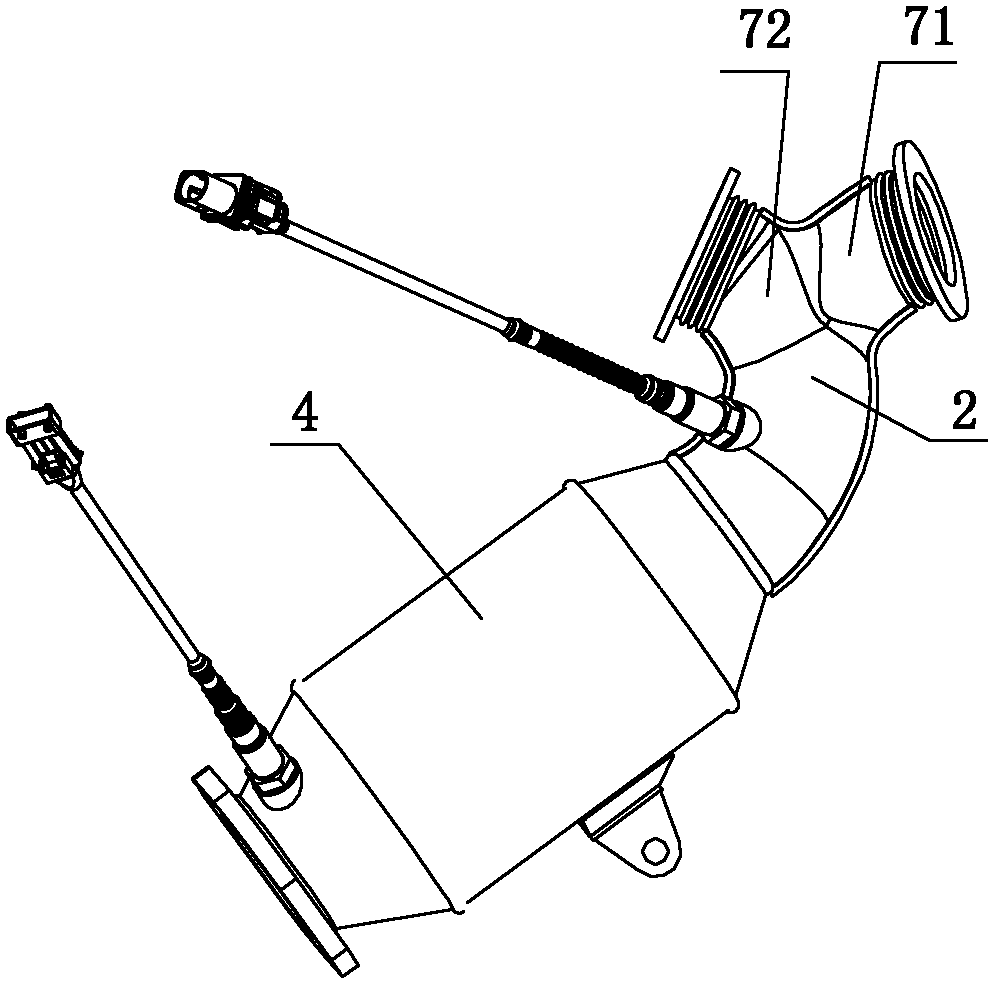

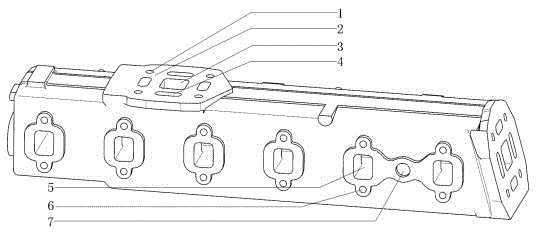

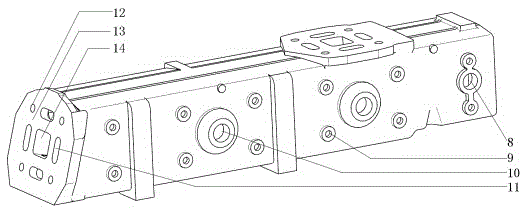

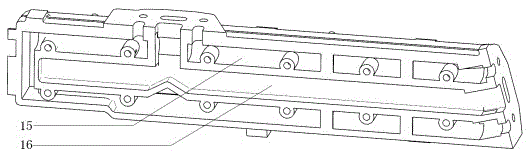

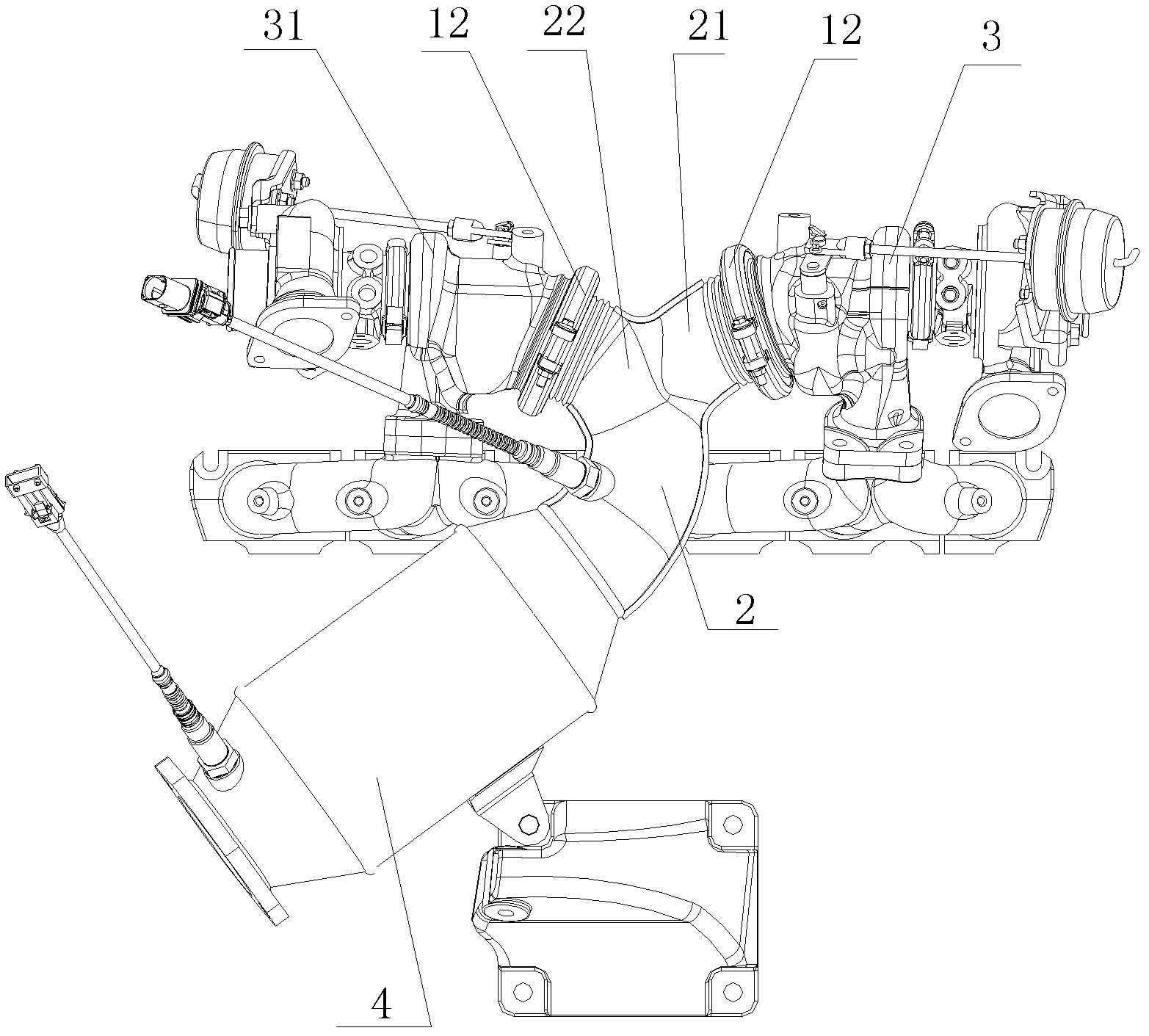

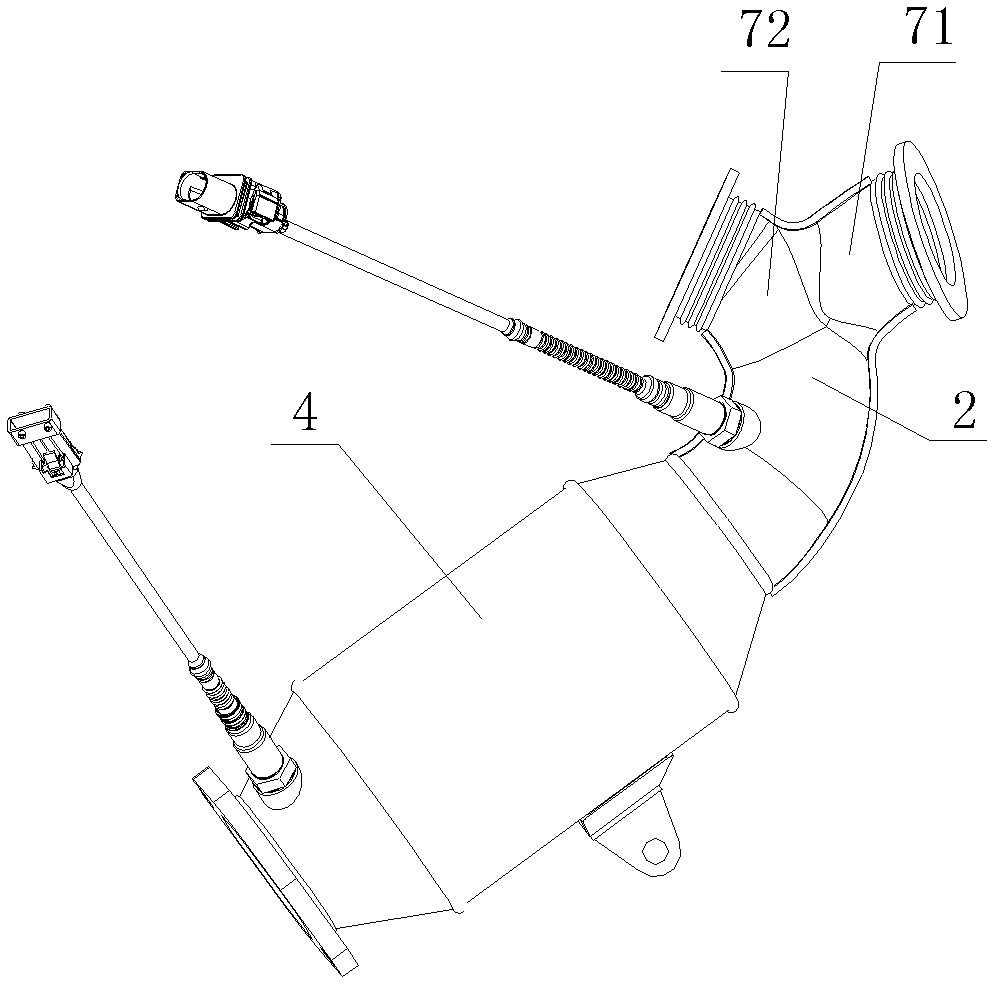

Waste gas post-processing system of twin-turbo supercharged engine

InactiveCN102588051AReduce temperature and pressurePass smoothlyInternal combustion piston enginesExhaust apparatusProcess engineeringTwin-turbo

The invention discloses a waste gas post-processing system of a twin-turbo supercharged engine, which belongs to the technical field of engines and is aiming at solving the problem that the three-way catalytic conversion efficiency is low in the prior art. The waste gas post-processing system of a twin-turbo supercharged engine comprises a first gas exhaust manifold and a second gas exhaust manifold, wherein a gas inlet of the first gas exhaust manifold is connected to a waste gas outlet of a first turbo supercharger; a gas inlet of the second gas exhaust manifold is connected to a waste gas outlet of a second turbo supercharger; the gas outlet of the first gas exhaust manifold and the gas outlet of the second gas exhaust manifold are connected to a three-way catalyst; a meeting chamber is arranged among the gas outlet of the first gas exhaust manifold and the gas outlet of the second gas exhaust manifold and the three-way catalyst; the gas outlets of the first gas exhaust manifold and the second gas exhaust manifold are connected to the meeting chamber after being converged; and the meeting chamber is connected to the catalyst. The waste gas post-processing system of a twin-turbo supercharged engine disclosed by the invention is used for processing the waste gas produced by an engine.

Owner:GREAT WALL MOTOR CO LTD

Preparation method of p-chlorophenylglycine

InactiveCN111470994AAvoid poisoningAvoid pollutionOrganic compound preparationCatalystsChlorobenzenePtru catalyst

The invention provides a preparation method of p-chlorophenylglycine, which comprises the following steps: adding a mixed solution of a chloroform solution, a catalyst and p-chlorobenzaldehyde into asodium hydroxide solution, mixing, and dropwisely adding liquid ammonia while stirring for 2-6 hours; after finishing dropwise adding the liquid ammonia, adding an ammonium bicarbonate solution, and reacting for 5-10 hours at room temperature; after the reaction is finished, distilling and concentrating a reaction solution, decolorizing and filtering by using activated carbon, adjusting the pH value of a filtrate to 6.0 by using an inorganic acid, cooling and filtering to obtain a crude product and mother liquor, washing the crude product by using water, ethanol and diethyl ether, and drying to obtain a finished product p-chlorophenylglycine; wherein the catalyst is trioctyl methyl ammonium chloride; wherein the molar ratio of the p-chlorobenzaldehyde to the trioctyl methyl ammonium chloride to the chloroform to the sodium hydroxide to the ammonium bicarbonate is 1.0 : (0.02-0.38) : (1.5-2.5) : (6.0-10.0) : (0.03-0.07). The synthesis process is simple, raw materials are easy to obtain,the reaction is milder, and toxicity and pollution of cyanide are avoided.

Owner:上海开荣化工科技有限公司

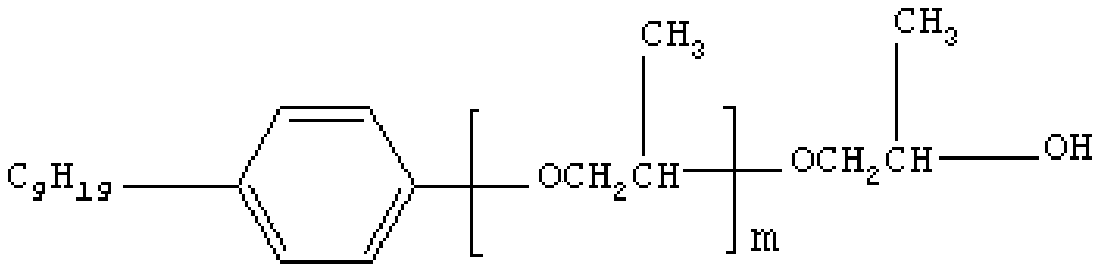

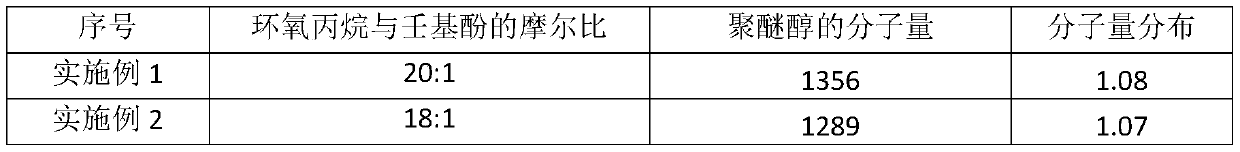

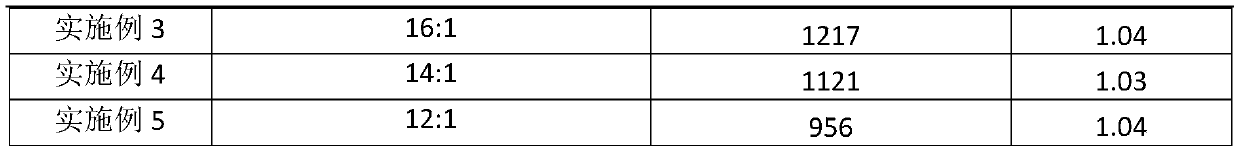

Polyether amine, preparation method thereof and application of polyether amine in gasoline detergent

InactiveCN110483760AHigh molecular weightReduce breakageLiquid carbonaceous fuelsAlcoholPolymer science

A preparation method of polyether amine comprises the following main steps: preparation of polyether alcohol, preparation of polyether ketone and preparation of polyether amine; the preparation of polyether amine from polyether alcohol is divided into two steps of dehydrogenation and ammoniation hydrogenation, the two steps can be carried out in the same reaction kettle, and the catalysts are thesame, i.e., reaction equipment does not need to be additionally arranged; aiming at the two steps, different main catalysts and cocatalysts are designed, so that the conversion rate of each step can be enhanced in a targeted manner; furthermore, on the premise of ensuring the conversion rate, the reaction temperature and pressure of each step are adjusted, and the possibility of ether chain breakage is reduced as much as possible; finally, the polyether amine with the molecular weight of 900 to 1300 and high molecular weight consistency is prepared.

Owner:天津中石化悦泰科技有限公司

Water-cooling exhaust pipe for natural gas engine not for vehicle

InactiveCN106523110AReduce temperature and pressureExtended service lifeInternal combustion piston enginesExhaust apparatusAutomotive engineeringWater cycle

A water-cooling exhaust pipe for a natural gas engine not for a vehicle is used for a natural gas engine. A supercharger installation face is provided with an exhaust hole and water outlet holes. The exhaust hole communicates with a gas chamber in a water-cooling exhaust pipe, the gas chamber communicates with gas inlet holes of the water-cooling exhaust pipe, and the gas inlet holes communicate with an engine cylinder cover exhaust hole. The water outlet holes communicate with a water jacket in the water-cooling exhaust pipe, the water jacket communicates with a water inlet hole of the water-cooling exhaust pipe, and the water inlet hole communicates with an engine cylinder cover water outlet hole. According to the water-cooling exhaust pipe, by means of circular cooling of cooling water, the temperature of an exhaust manifold body can be reduced to 200 DEG C or lower from 650 DEG C, the temperature of the exhaust manifold body and the temperature and the pressure of exhausted waste gas are obviously reduced, and the service life of the engine is prolonged.

Owner:普创新能源动力科技有限公司

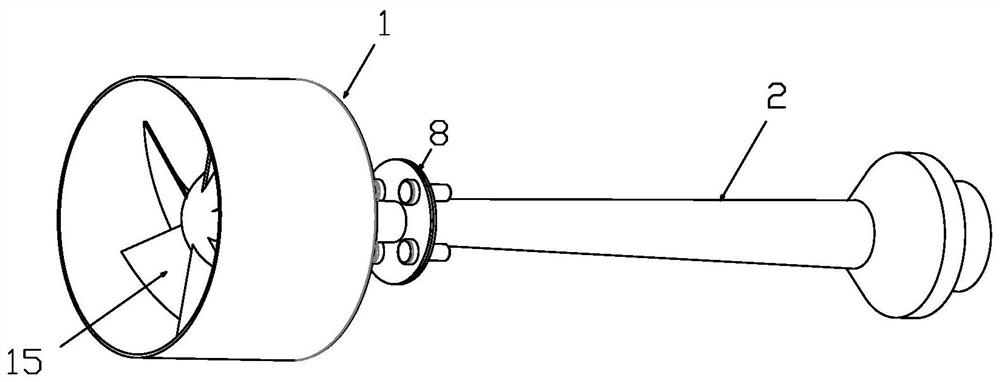

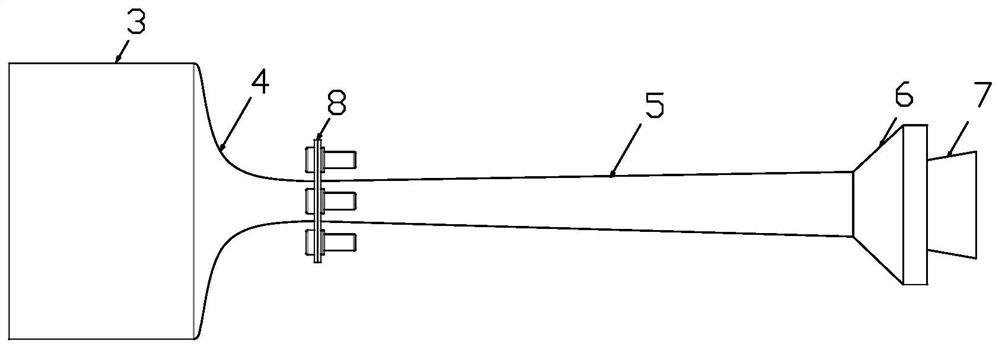

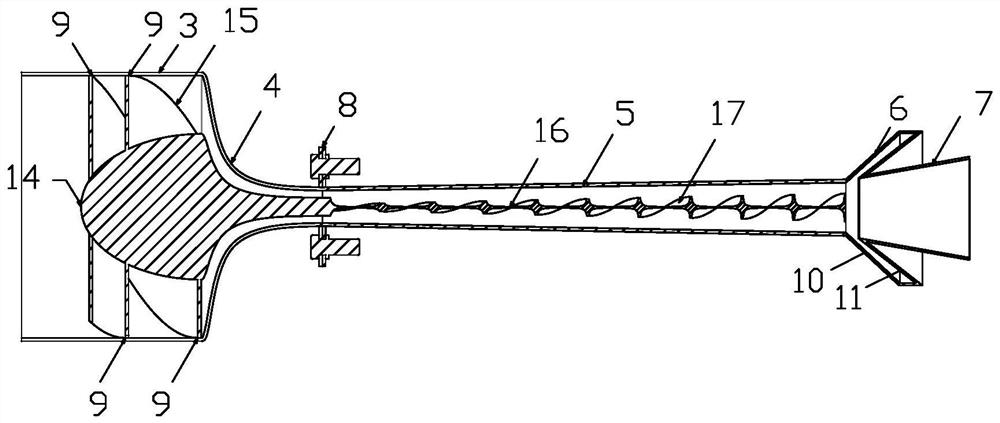

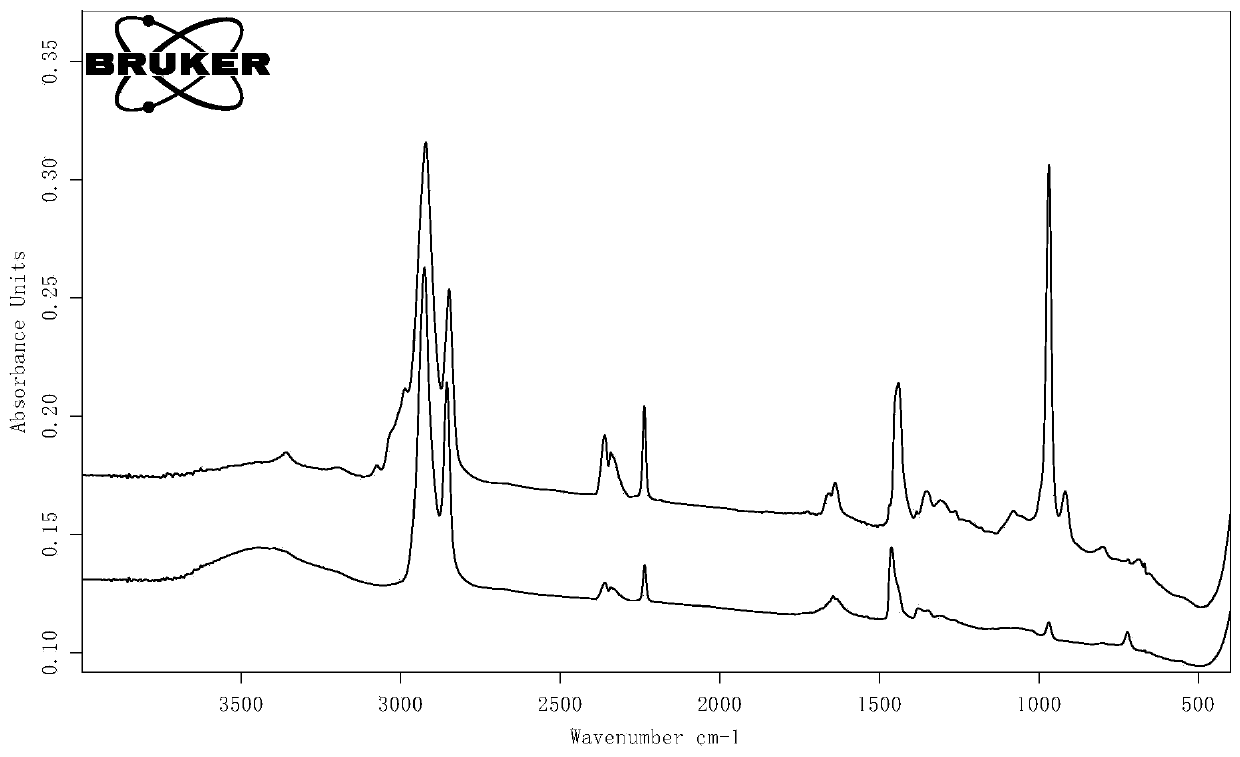

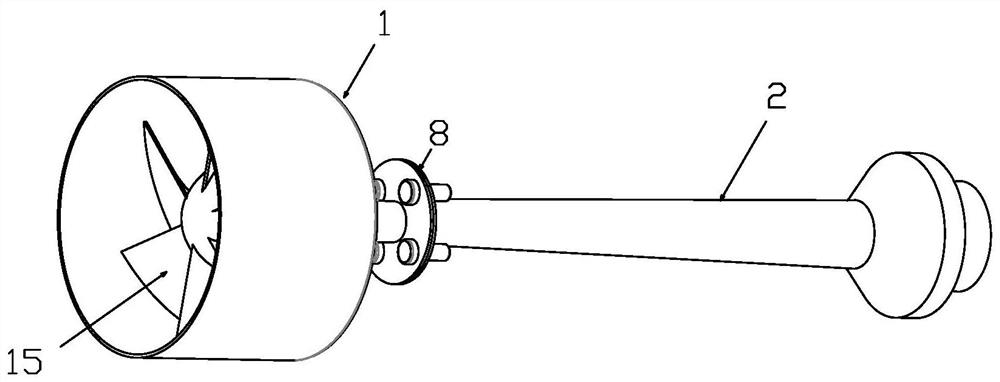

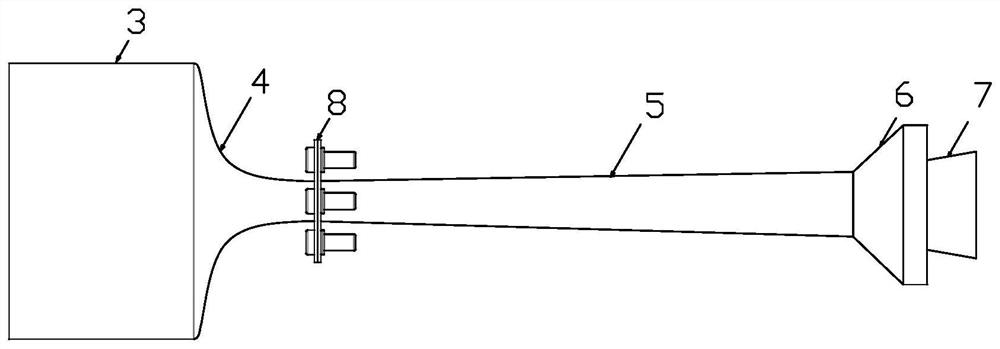

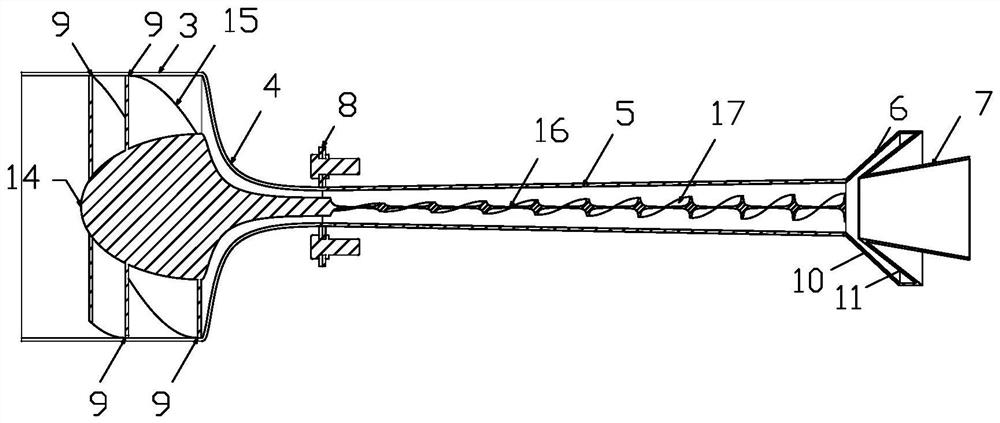

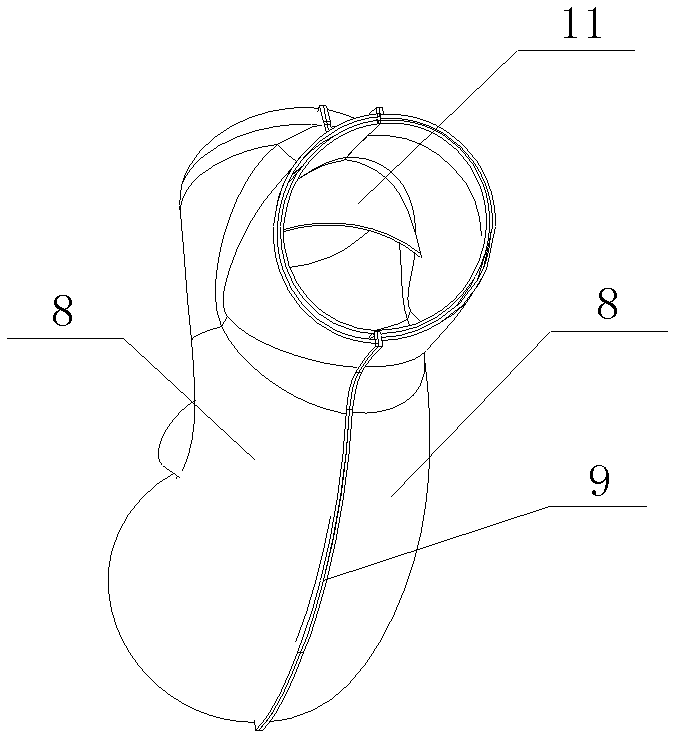

Full-rotational-flow supersonic separation device

ActiveCN111763547AMinimizes the effect of droplet re-evaporationStrong swirl abilityGas treatmentDispersed particle separationEngineeringMechanical engineering

The invention discloses a full-rotational-flow supersonic separation device. The full-rotational-flow supersonic separation device comprises a shell and a central rotational flow component. The shellcomprises a direct-current flow stabilizing section, a Laval spray pipe reducing section, a Laval spray pipe expanding section and the like. The central rotational flow component comprises a front central rotational flow component and a rear central rotational flow component. The front central rotational flow component is positioned in the direct-current flow stabilizing section and the Laval spray pipe reducing section, and the rear central rotational flow component is positioned in the Laval spray pipe expanding section. When gas enters the direct-current flow stabilizing section and the Laval spray pipe reducing section, gas flow expands in a rotational flow state and reaches supersonic speed after reaching the Laval spray pipe expanding section, the temperature and the pressure are further reduced, the gas begins to condense, and the process of condensing during rotational flow can effectively reduce the influence of re-evaporation of liquid drops. Besides, the rotational flow component is also arranged in the Laval spray pipe expanding section, the rotational flow capacity of the rotational flow component is high and durable, and the separation effect and the separation efficiency of the device are guaranteed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

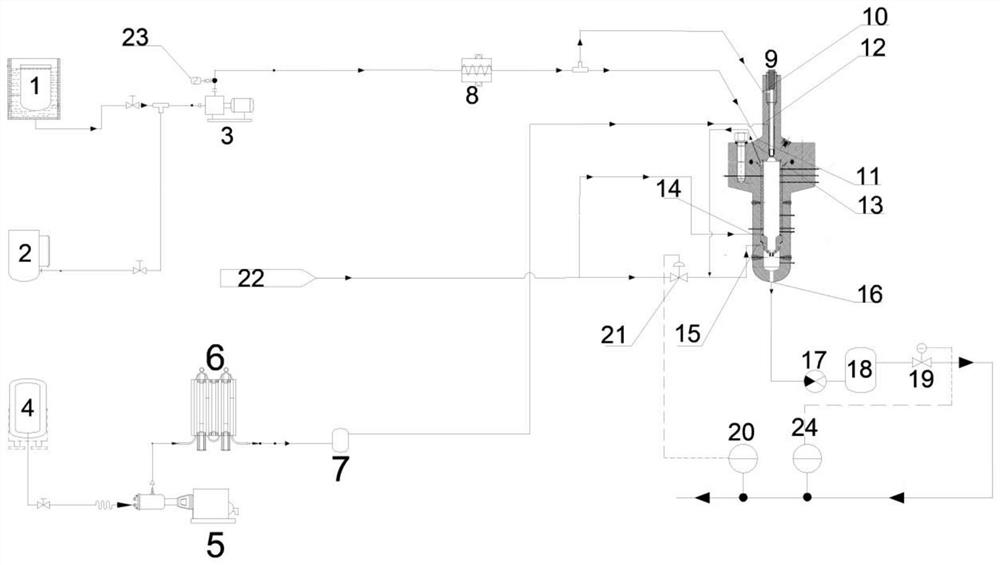

Self-adaptive control supercritical hydrothermal combustion type multi-element thermal fluid generating system

PendingCN113756764AReduce ignition delayImprove mining efficiencyLiquid fuel feeder/distributionFluid removalProcess engineeringCombustion

A self-adaptive regulation and control supercritical hydrothermal combustion type multi-element thermal fluid generation system comprises a reactor, a material pretreatment module, an oxidizing agent supply module, a cooling module, a temperature and pressure regulating module and the like, and the reactor, the material pretreatment module, the oxidizing agent supply module and the supercritical hydrothermal combustion reaction module are used for generating multi-element thermal fluid; the pressure and the temperature of the multi-element thermal fluid are adjusted through the temperature and pressure adjusting module, the wall face of the reactor is protected through the cooling module, the multi-element thermal fluid meeting the exploitation requirement is safely and stably produced, and a feasible scheme is provided for efficient exploitation of thickened oil.

Owner:XI AN JIAOTONG UNIV

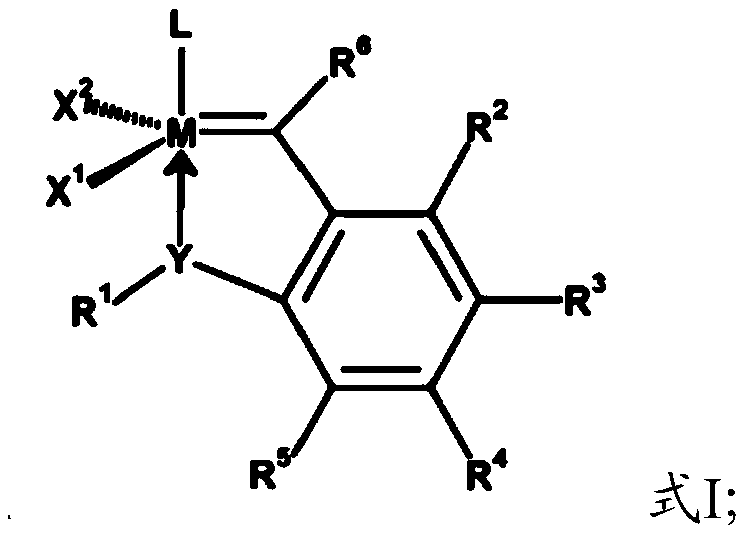

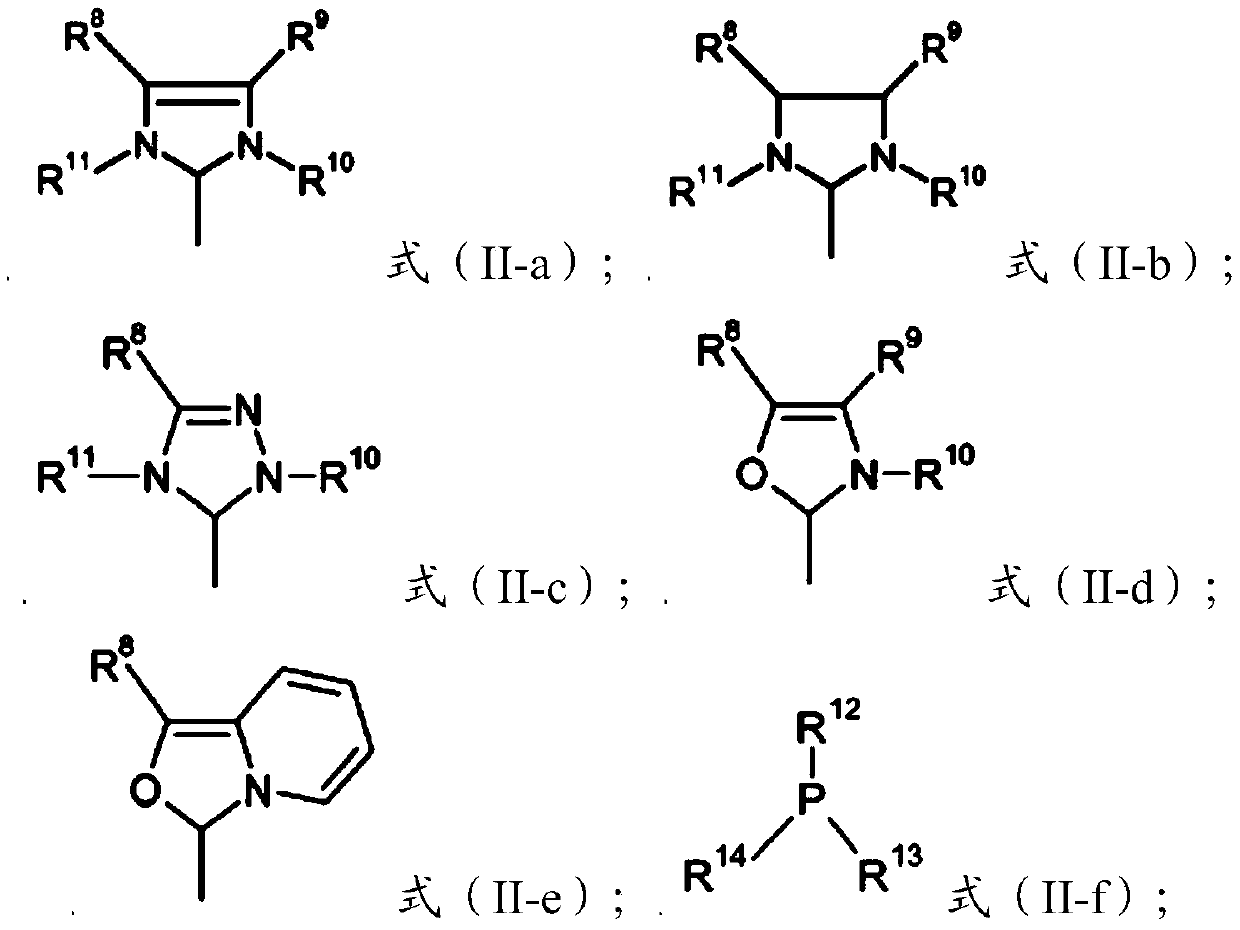

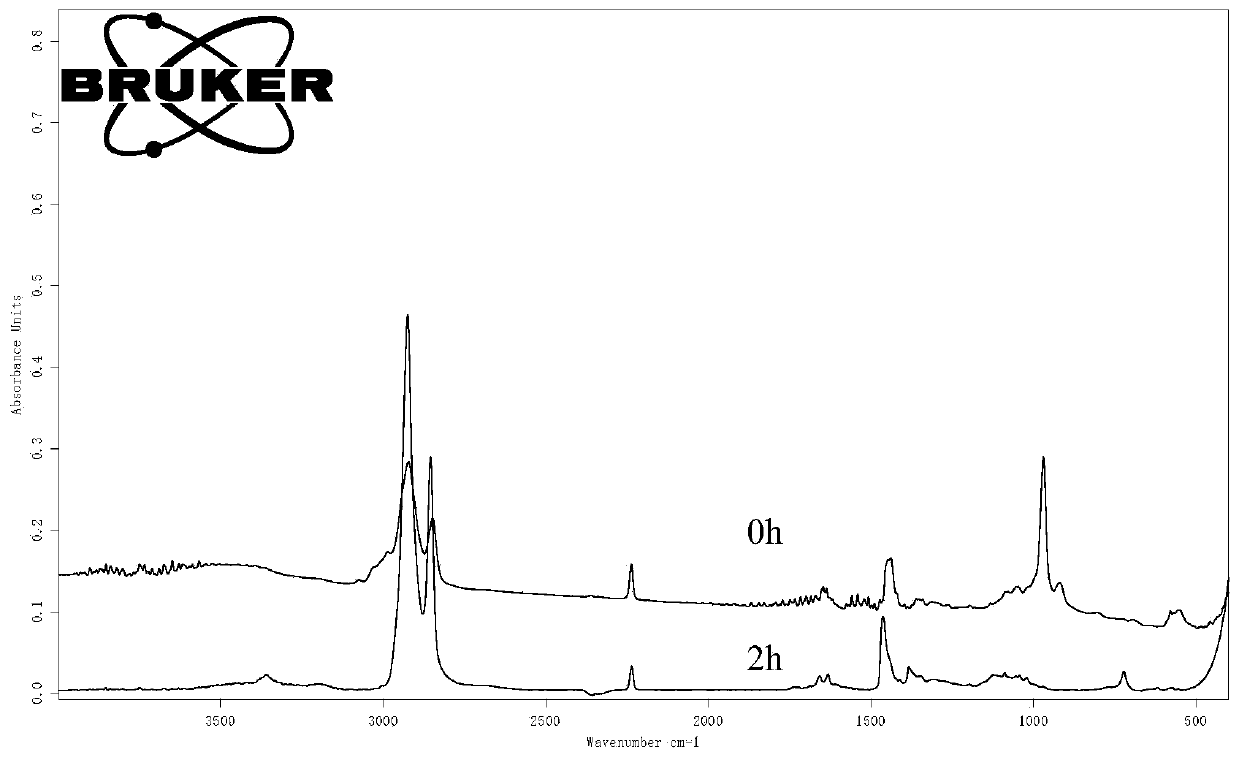

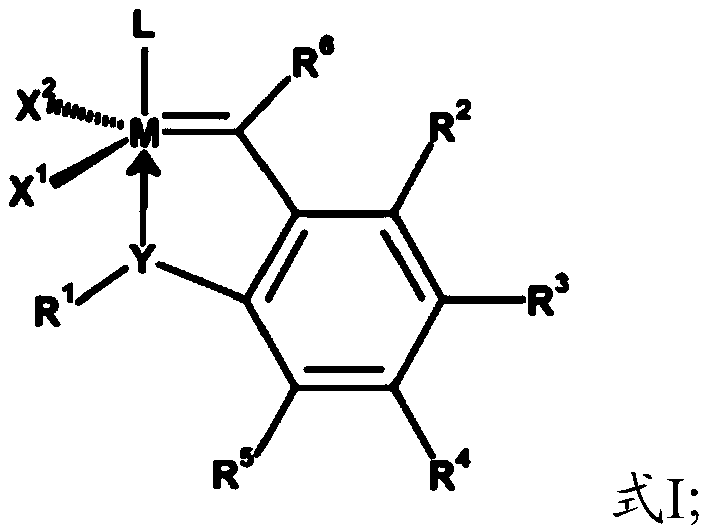

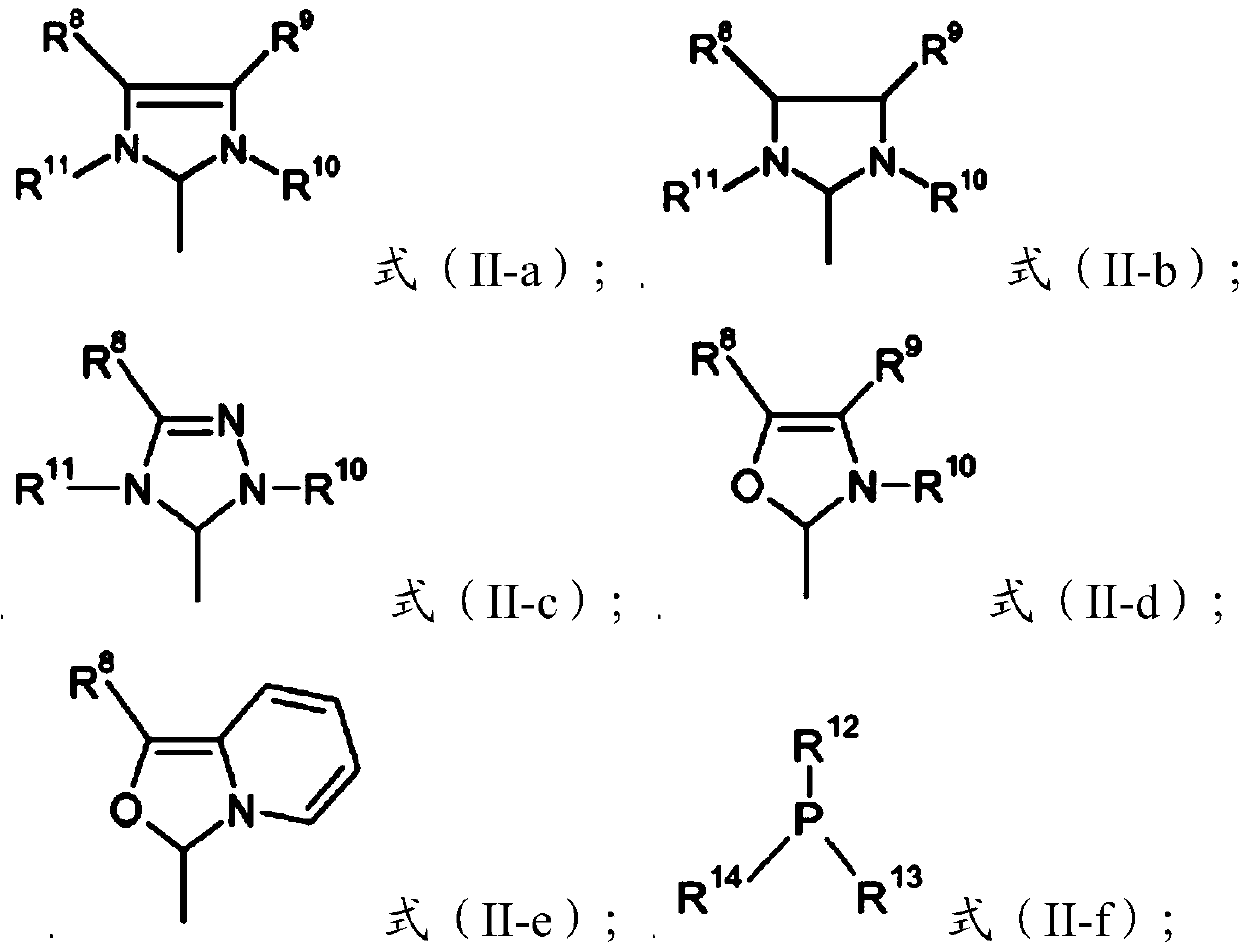

Catalyst composition and use thereof in selective hydrogenation of conjugated diene latex

PendingCN111330647AReduce usageHydrogenation conditions are not harshOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPtru catalystReaction rate

The invention provides a catalyst composition, which comprises a VIII group metal compound catalyst shown as formula I and an auxiliary agent, wherein the auxiliary agent is sodium dodecyl benzene sulfonate. The catalyst system provided by the invention can realize effective hydrogenation of latex, can significantly reduce the use amount of the catalyst, improve the catalytic efficiency and reducethe industrial cost by adding a small amount of the auxiliary agent, has no participation of an organic solvent in the reaction process, and is beneficial to green chemical industry. The reaction rate of the reaction system is increased, the usage amount of the catalyst is low, the cost can be reduced, the reaction conditions are mild, the reaction efficiency is high, and rapid industrializationis facilitated.

Owner:山东京博中聚新材料有限公司 +2

Catalyst composition and application thereof on selective hydrogenation of conjugated diene latexes

PendingCN111359665AReduce usageHydrogenation conditions are not harshOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPtru catalystReaction rate

The invention provides a catalyst composition, which comprises a VIII group metal compound catalyst represented by a formula I and an auxiliary agent, and the auxiliary agent is lauryl sodium sulfate.The catalyst system provided by the invention can realize effective hydrogenation of latex, the use amount of the catalyst is obviously reduced by adding a small amount of the auxiliary agent, the catalytic efficiency is improved, and the industrial cost is reduced. No organic solvent participates in the reaction process, and green chemical industry is facilitated. The reaction rate of the reaction system is increased, the usage amount of the catalyst is low, the cost can be reduced, the reaction conditions are mild, the reaction efficiency is high, and rapid industrialization is facilitated.

Owner:山东京博中聚新材料有限公司 +2

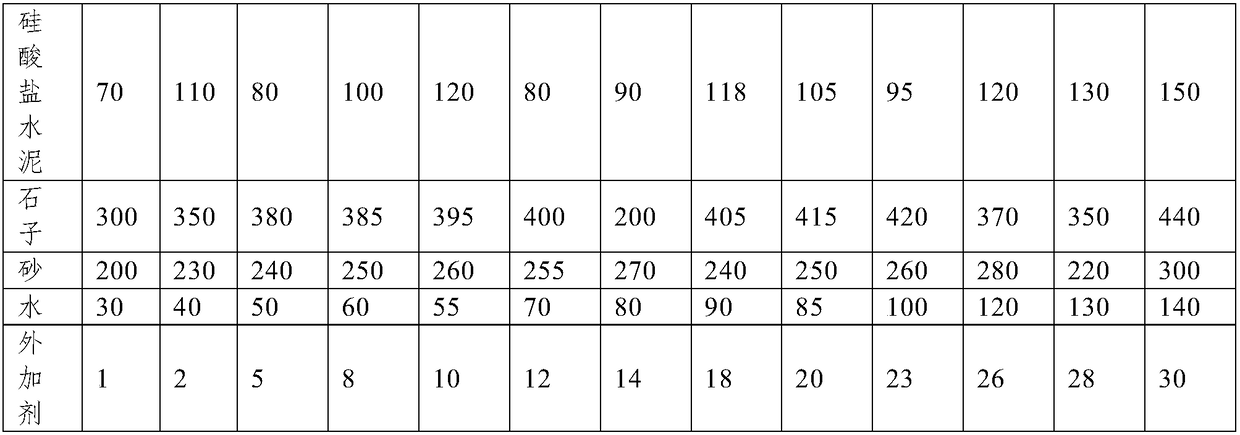

Concrete material used for pouring pier stud, admixture and usage method thereof

The invention relates to a concrete material used for pouring a pier stud, an admixture and a usage method of the concrete material. The concrete material comprises the following components in parts by weight: 80 to 120 parts of Portland cement, 350 to 420 parts of cobblestone, 220 to 280 parts of sands, 2 to 26 parts of an admixture, and 40 to 120 parts of water; wherein, the admixture comprisesthe following components in parts by weight: 10-20 parts of lignosulfonate, 50-70 parts of fly ash, 1-5 parts of calcium nitrate, 0.5-2 parts of sodium nitrite, 1-5 parts of zeolite powder, and 1-5 parts of hemp fiber. The concrete material adopts the admixture, so that when the concrete is used for pouring the large pier stud, the good appearance quality can be presented, and the phenomena such as segregation, cracking, honeycomb, spongy surface, cavity and bubbles can be effectively avoided. The admixture can be used for concrete materials of the pier stud for bridges, high-speed rails, viaducts, and the like, and can be also used in combination with steel bars for antivibration resistance.

Owner:北京城建十六建筑工程有限责任公司

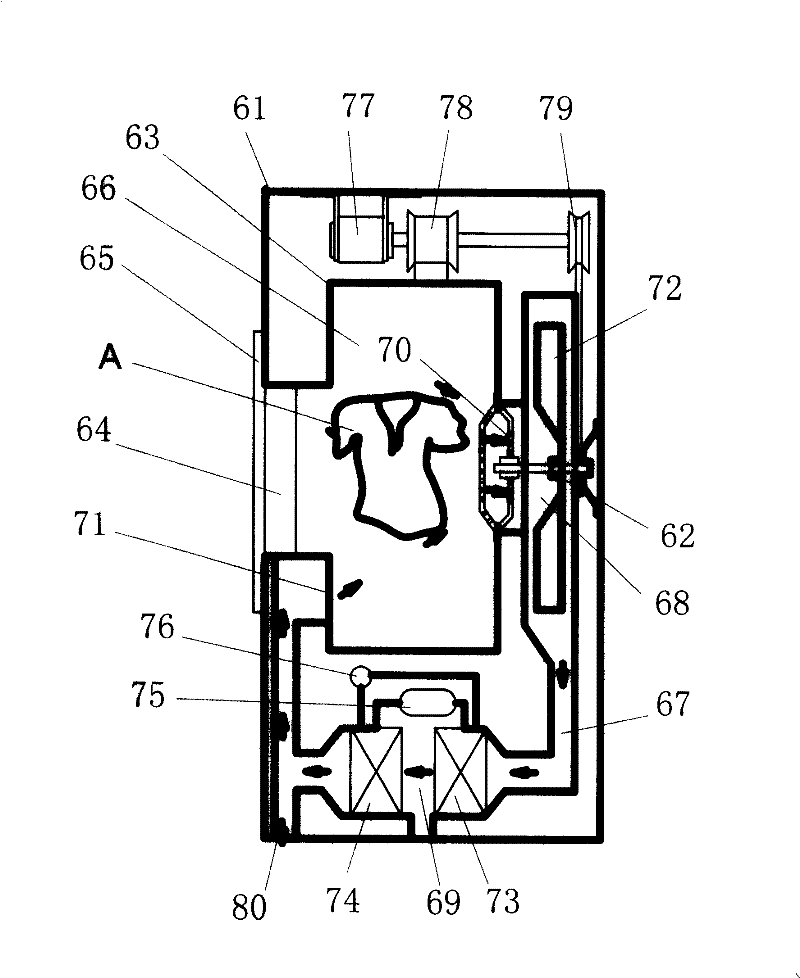

Heat pump clothes drying machine

ActiveCN101235587BReduce temperature and pressureReduce the temperatureWashing machine with receptaclesTextiles and paperEngineeringControl circuit

The invention relates to a heat pump clothes dryer which comprises an air circulation channel which is composed of a drying chamber, a blast chamber and a heat exchange chamber, wherein a heat absorber is arranged on one side of the heat exchange chamber which is close to the upper stream, a heat releaser is arranged on one side which is close to the lower stream, the heat absorber and the heat releaser are formed into a heat pump device through a compressor, a capillary tube and the like, an electronic control circuit is arranged, and an air inlet is arranged on the air circulation channel which connects the drying chamber and the heat exchange chamber, wherein an exhausting valve and a water-cooling condenser which are opened outside the machine are arranged on the upper stream of the heat absorber of the heat exchange chamber. When the environmental temperature is lower than a certain value,the control circuit controls the exhausting valve on the upper stream of the heat absorber to open to exhaust hot air outside the machine, when the environmental temperature is higher than a certain value, the control circuit controls the water-cooling condenser to operate, the temperature of air which enters into the heat absorber is lowered, which enables the temperature pressure of gaseous refrigerant which enters into the compressor to be comparatively low, and humid air is not exhausted outside the machine to deteriorate environment in hot summer.

Owner:HAIER GRP CORP +1

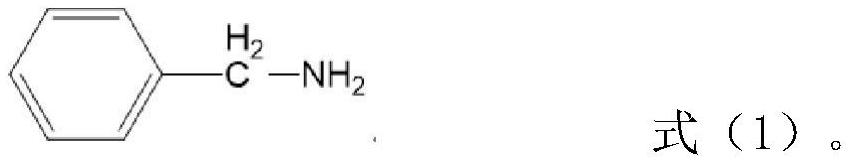

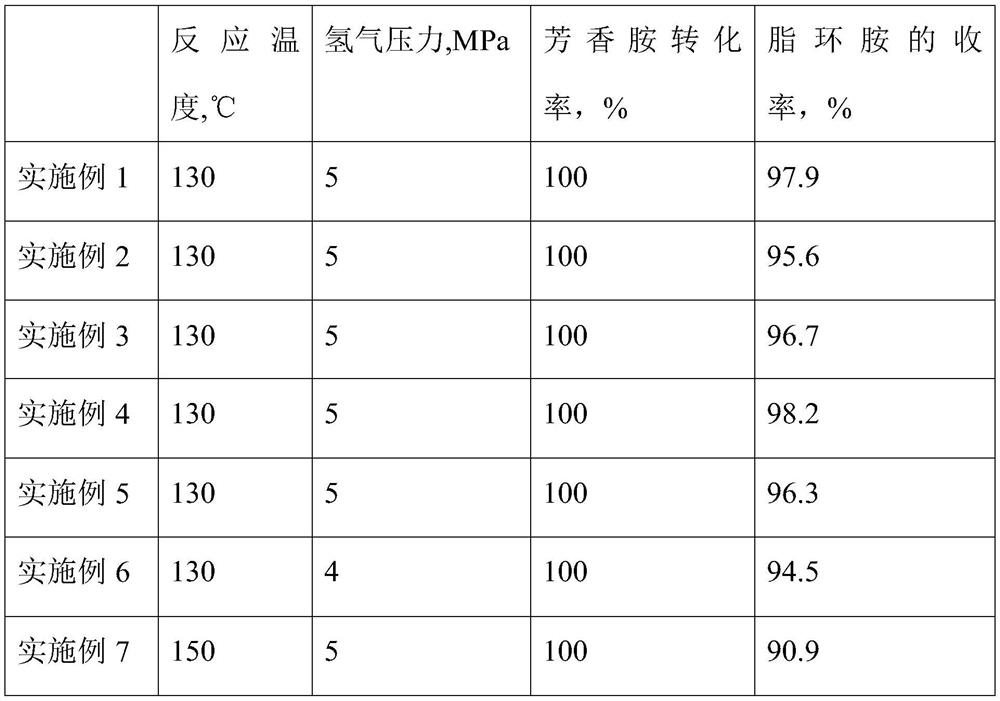

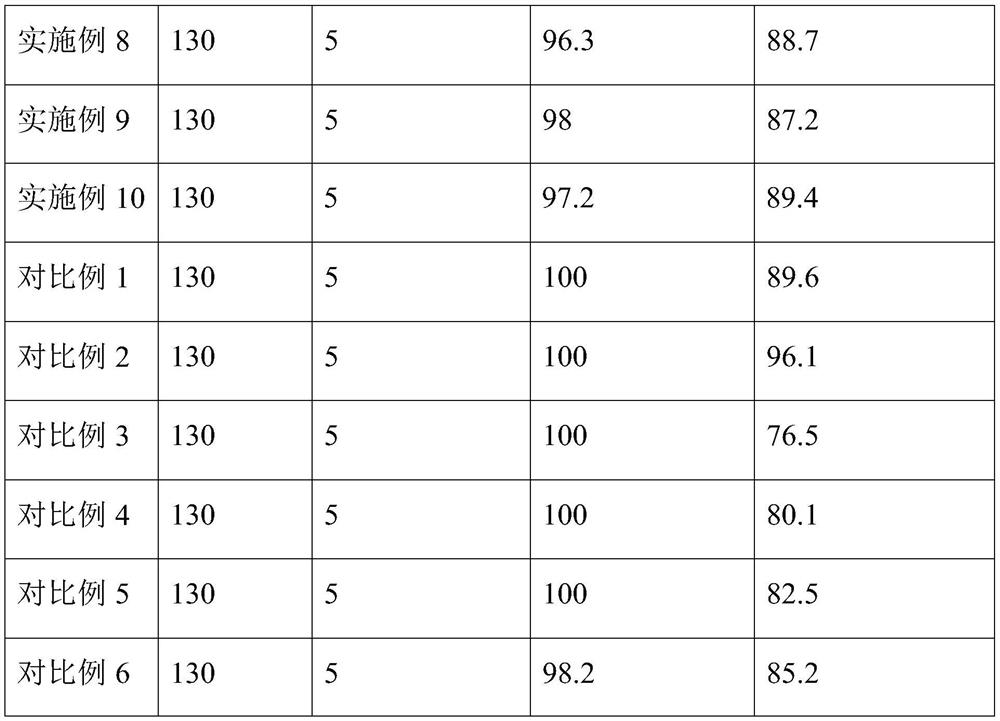

Catalyst for preparing alicyclic amine from aromatic amine as well as preparation method and application of catalyst

InactiveCN112473663AImprove performanceReduce temperature and pressureOrganic compound preparationAmino compound preparationAluminium oxidesAromatic amine

The invention relates to a catalyst for preparing alicyclic amine from aromatic amine as well as a preparation method and application of the catalyst. The catalyst comprises a carrier, and an active component and an auxiliary agent which are loaded on the carrier, wherein the active component is ruthenium, the auxiliary agent is an alkali metal modifier, and the carrier is aluminum oxide. According to the invention, the catalyst uses alumina as the catalyst carrier, ruthenium as the active component and the alkali metal modifier as the auxiliary agent, and the synergistic effect among alumina,ruthenium and the alkali metal modifier significantly improves the reaction activity of the catalyst; and when the catalyst is used for catalyzing aromatic amine to prepare alicyclic amine, catalyticreaction conditions are mild, and high temperature and high pressure are not needed, so the cost of the process of preparing alicyclic amine from aromatic amine is obviously reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

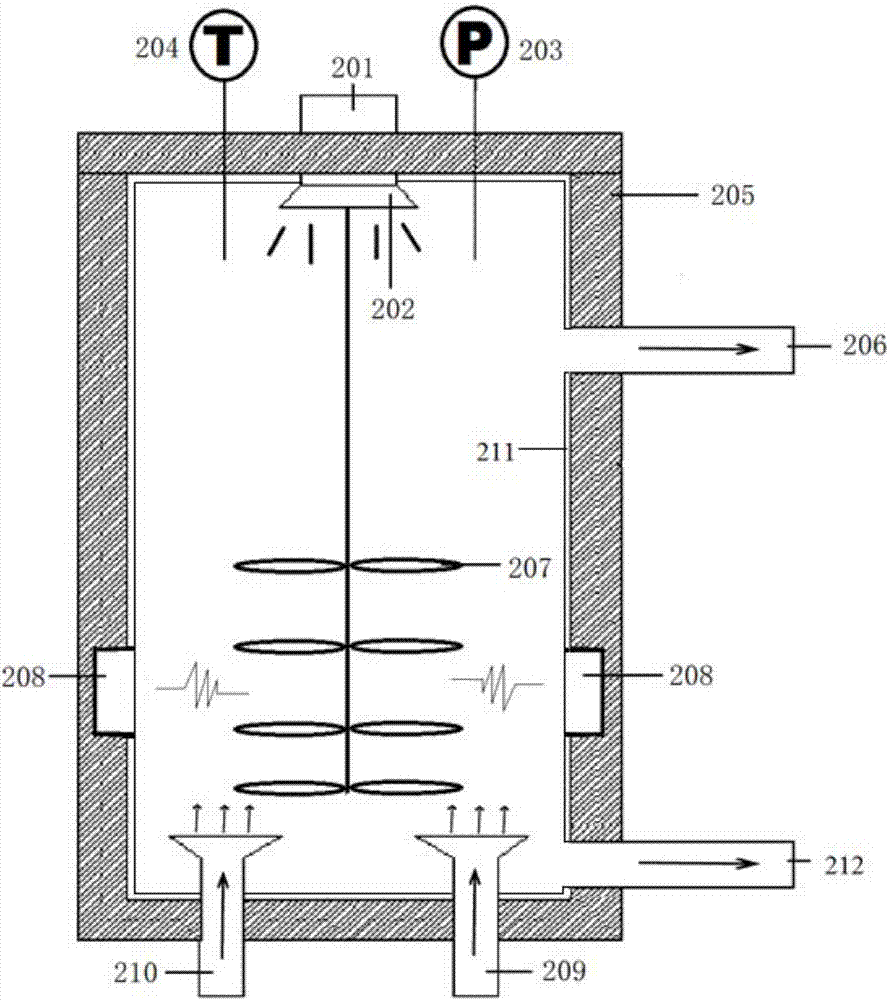

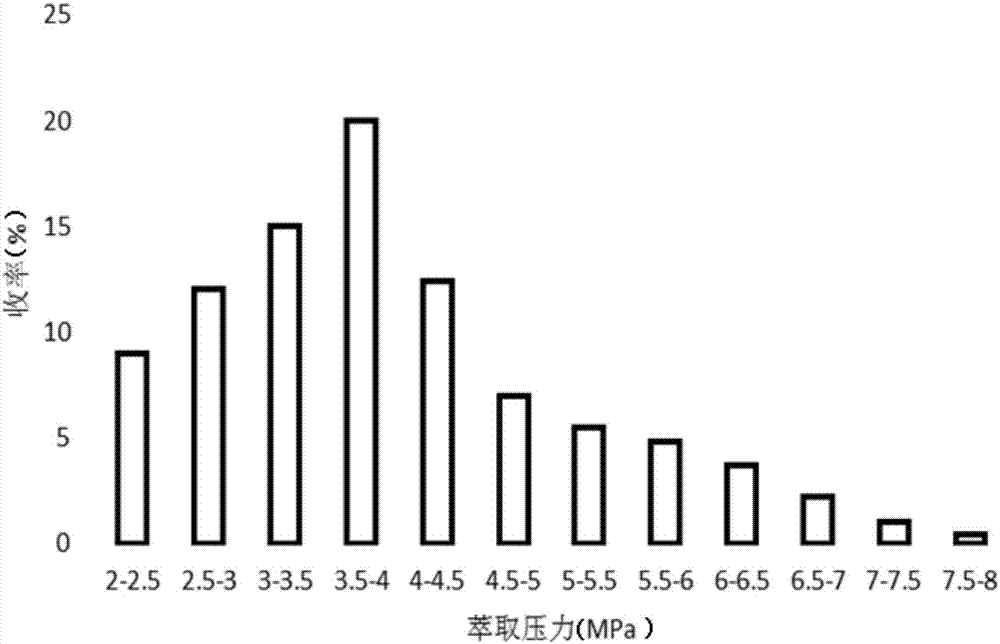

Extraction separation device used for catalytic cracking clarified oil and extraction separation method thereof

PendingCN106902548AReduce temperature and pressureSave operating timeLiquid solutions solvent extractionEnergy based chemical/physical/physico-chemical processesSolventSupercritical fluid extraction

The invention discloses an extraction separation device used for catalytic cracking clarified oil and an extraction separation method thereof, and relates to the field of devices for pretreatment of catalytic cracking oil slurry. The technical purpose is to solve the technical problem that an existing supercritical fluid extraction device is high in extraction pressure and low in extraction rate in catalytic cracking oil slurry pretreatment. The device comprises a tank body, an ultrasonicator, an ultrasonic transducer, a pressure gauge, a temperature meter, a thermal insulation jacket, an agitator blade and a microwave generator, wherein the ultrasonicator is arranged at the outer side at the top end of the tank body, the ultrasonic transducer is arranged on the inner side of the top end of the tank body, the microwave generator is arranged on the side wall of the tank body, the bottom of the tank body is provided with a solvent inlet and an inlet of an object to be extracted, and the side wall at the upper portion of the tank body is provided with a mixture outlet. The method comprises the first step of conducting feeding, the second step of conducting mixed heating, and the third step of raising the pressure to conduct extraction. Under an ultrasound and microwave effect, the extraction separation device lowers the supercritical fluid extraction temperature and pressure, shortens the operation time, and improves the extraction efficiency. The extraction separation device is used in pretreatment of the catalytic cracking oil slurry.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Mass concrete and preparation method thereof

InactiveCN112062521AReduce temperature and pressureAvoid temperature cracksUltimate tensile strengthMechanical engineering

The invention provides mass concrete and a preparation method thereof, and the mass concrete is characterized by comprising the following components in parts by weight: 170 KG / M < 3 > of water, 308 KG / m < 3 > of cement, 70 KG / M < 3 > of mineral powder, 56 KG / M < 3 > of fly ash, 10.3 KG / M < 3 > of an admixture, 694 KG / M < 3 > of sand and 1076 KG / M < 3 > of stone. The performance of the mass concrete produced according to the invention can meet the requirements of strength grade, impermeability, volume stability and the like, and the hydration temperature rise of a cementing material is also controlled, so that the purposes of reducing temperature and pressure and preventing temperature cracks are achieved.

Owner:天津市堃淏混凝土有限公司

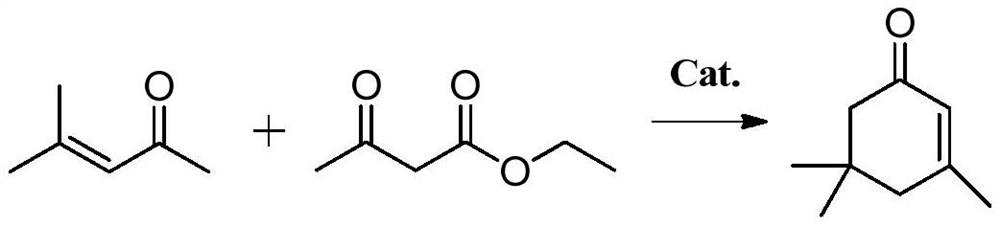

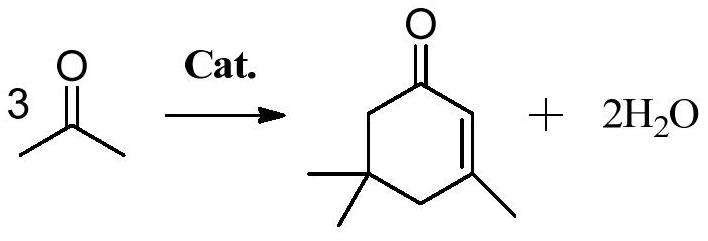

Preparation method of α-isophorone

ActiveCN110885286BImprove conversion rateHigh selectivityOrganic compound preparationCarbonyl compound preparationPolymer sciencePtru catalyst

Owner:SHANDONG NHU VITAMIN CO LTD

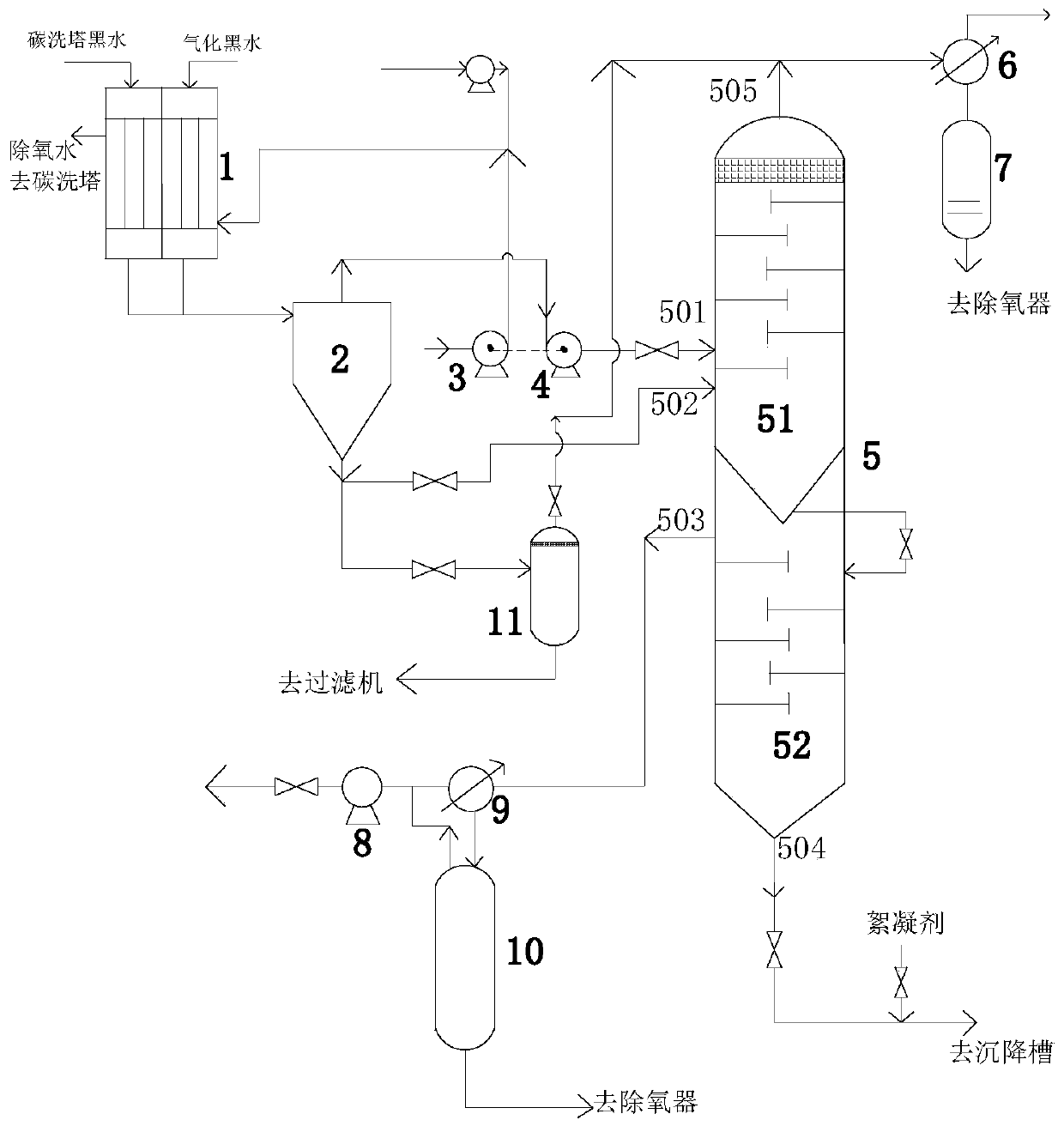

Coal gasification black water treatment system and treatment process

PendingCN111453906ARealize separate recyclingAchieve recyclingWater/sewage treatment by centrifugal separationSpecific water treatment objectivesBlackwaterWater treatment system

The invention belongs to the technical field of coal chemical industry and relates to a coal gasification black water treatment system and a treatment process. The treatment comprises a deoxygenated water heater, a vortex separator, a hydraulic deoxygenated water pump, a hydraulic turbine pump, a separation tank, a normal-pressure gas cooler and a vacuum gas cooler, wherein the deoxygenated waterheater is connected with the vortex separator; the top end of the vortex separator is connected with the separation tank through the hydraulic turbine pump; and the bottom end of the vortex separatoris connected with the separation tank and the separator; heat and kinetic energy in the black water are recycled separately, the heat is recycled into a carbon washing tower, and the kinetic energy serves as a part of power source of the hydraulic deoxygenated water pump; the low-temperature black water with heat recovered is further separated after being subjected to coarse separation; and the separated saturated steam can be recycled as process gas. According to the invention, heat, kinetic energy and steam in the black water can be recycled, so that the cold consumption and kinetic consumption of the black water of the system can be reduced, the operation and maintenance workload is low, the process flow is short, the equipment is less, and the investment is small.

Owner:陕西聚能新创煤化科技有限公司

Optical glass element with light absorption layer and preparation method of optical glass element

InactiveCN111423136AReduce temperature and pressureLow equipment requirementsGlass tempering apparatusOptical elementsLight absorbanceReflectivity

The invention relates to an optical glass element with a light absorption layer and a preparation method of the optical glass element, wherein the preparation method comprises the steps: pretreating optical glass to form a nano-scale or micron-scale gas diffusion channel on the surface of the optical glass; carrying out reduction treatment on the pretreated optical glass in a reducing atmosphere;and carrying out post-treatment on the optical glass subjected to reduction treatment to obtain the optical glass element with the light absorption layer. The optical glass element comprises an optical glass substrate and the light absorption layer, the light absorption layer is located on the periphery of the optical glass substrate, and the interface reflectivity between the light absorption layer and the optical glass substrate is smaller than 1%. The light absorption layer is a self-substrate light absorption layer, and the light absorption rate of the light absorption layer is greater than 99%. According to the preparation method, the problem that the light absorption layer is difficult to prepare in the optical glass with a compact structure is solved, and the problem that the lightabsorption layer falls off after being heated or subjected to external acting force does not exist.

Owner:CHINA BUILDING MATERIALS ACAD

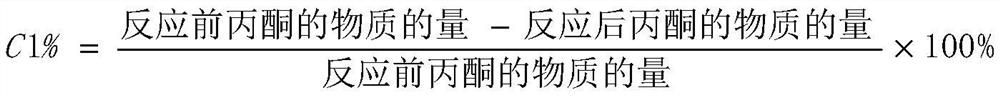

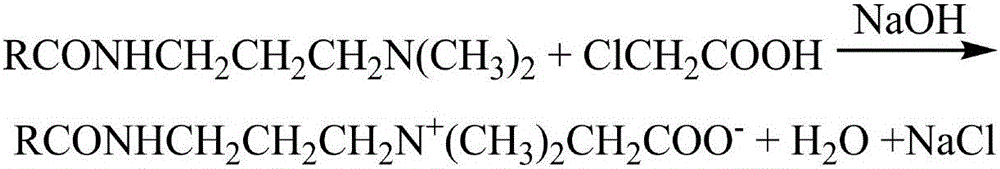

Method used for processing dichloroacetic acid in cocamidopropyl betaine

InactiveCN106748867AReduce the content of dichloroacetic acidDoes not affect product qualityOrganic compound preparationCarboxylic acid amide separation/purificationAcetic acidReaction temperature

The invention discloses a method used for processing dichloroacetic acid in cocamidopropyl betaine. According to the method, in processing of cocamidopropyl betaine prepared taking chloroacetic acid as a raw material, the temperature, pH value, and reaction time of hydrolysis of PKO (intermediate cocamidopropyl dimethylamine) with chloroacetic acid are adjusted so as to ensure that other indexes are capable of according with national standard requirements, sodium hydroxide is added in an obtained system without influencing product quality after synthesis reaction of cocamidopropyl betaine, and dichloroacetic acid in the reaction system is removed via controlling reaction temperature, pH value, and reaction time. According to the method, the content of dichloroacetic acid in cocamidopropyl betaine prepared from chloroacetic acid raw material of common quality can be reduced, and no other impurities are introduced.

Owner:四川花语精细化工有限公司

A full cyclone supersonic separation device

ActiveCN111763547BMinimizes the effect of re-evaporationEasy to separateGas treatmentGaseous fuelsSupersonic speedNozzle

The invention discloses a full-swirl supersonic separation device, which comprises a shell and a central swirl component. The casing includes the straight-flow steady flow section, the Laval nozzle converging section and the Laval nozzle expansion section. The central swirl component includes a front central swirl component and a rear central swirl component; the front central swirl component is located in the straight flow stabilization section and the Laval nozzle tapering section; the rear central swirl component is located in the Laval nozzle expansion section. When the gas enters the straight-line steady flow section and the tapering section of the Laval nozzle, the gas flow expands in a swirling state, and reaches supersonic speed after reaching the expansion section of the Laval nozzle, the temperature and pressure further decrease, and the gas begins to condense. The process of streamside condensation can effectively reduce the influence of droplet re-evaporation; in addition, a swirl component is also installed in the expansion section of the Laval nozzle, and its swirl capacity is strong and durable, which ensures the separation effect and separation efficiency of the device.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Waste gas post-processing system of twin-turbo supercharged engine

InactiveCN102588051BReduce temperature and pressurePass smoothlyInternal combustion piston enginesExhaust apparatusProcess engineeringTwin-turbo

The invention discloses a waste gas post-processing system of a twin-turbo supercharged engine, which belongs to the technical field of engines and is aiming at solving the problem that the three-way catalytic conversion efficiency is low in the prior art. The waste gas post-processing system of a twin-turbo supercharged engine comprises a first gas exhaust manifold and a second gas exhaust manifold, wherein a gas inlet of the first gas exhaust manifold is connected to a waste gas outlet of a first turbo supercharger; a gas inlet of the second gas exhaust manifold is connected to a waste gas outlet of a second turbo supercharger; the gas outlet of the first gas exhaust manifold and the gas outlet of the second gas exhaust manifold are connected to a three-way catalyst; a meeting chamber is arranged among the gas outlet of the first gas exhaust manifold and the gas outlet of the second gas exhaust manifold and the three-way catalyst; the gas outlets of the first gas exhaust manifold and the second gas exhaust manifold are connected to the meeting chamber after being converged; and the meeting chamber is connected to the catalyst. The waste gas post-processing system of a twin-turbo supercharged engine disclosed by the invention is used for processing the waste gas produced by an engine.

Owner:GREAT WALL MOTOR CO LTD

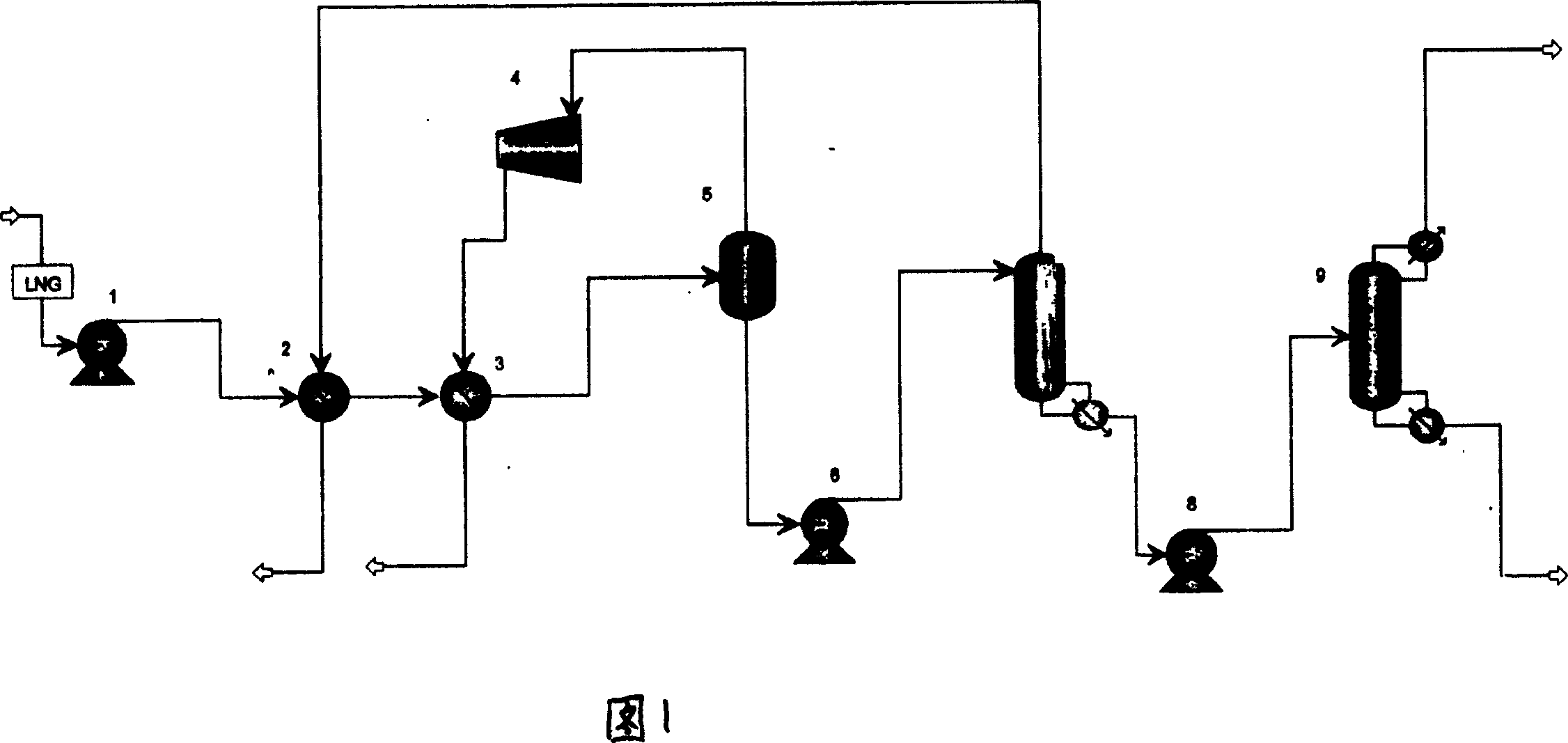

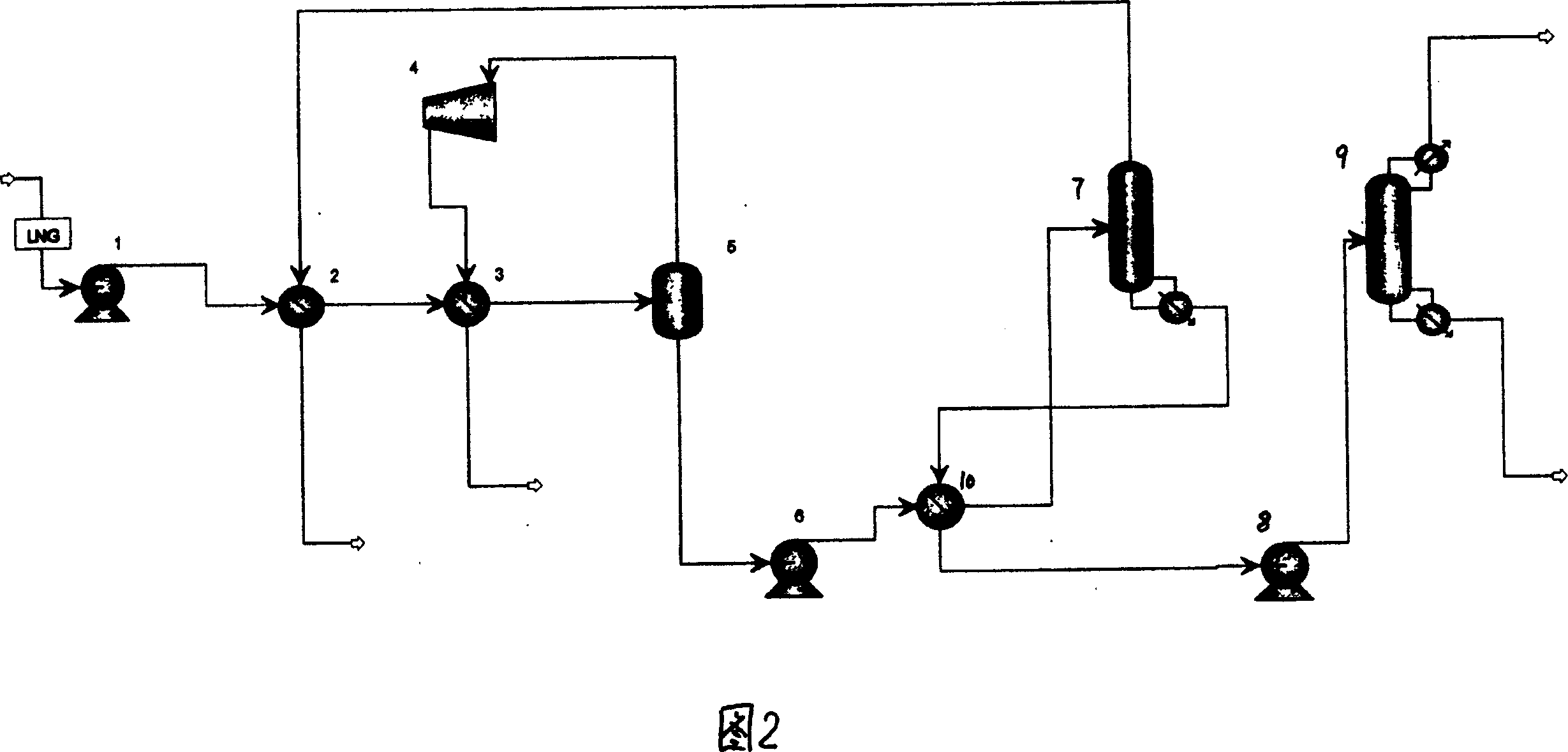

Method for separating light hydrocarbon from liquified natural gas

InactiveCN1318543CImprove conversion rateHigh selectivityLiquid hydrocarbon mixture recoveryGas phaseMethane gas

The invention relates a process for the light ends separation of liquefied natural gas, comprising the following steps: preliminary heating the raw material of liquefied natural gas, separating methane and condensing it, demethanizing and making it liquefy, deethanizing and transferring the gas phase ethane to the ethylene cracking unit through pipe line, and finally getting the liquid phase discharging including weight constituent of dimethylmethane and butane. The invention utilizes part refrigerating of LNG, because it is conserved in low-temperature liquid methane after ethane and propane is reclaimed from LNG; only 60% methane gas is needed to be compressed, so the power consumption of compresser is reduced; it is convenient to store liquid methane because its pressure is low. The ethane from said invention is high output, separation flow process is simple, and equipment investment is only a little, running period is long, and operating cost is cheap.

Owner:SOUTH CHINA UNIV OF TECH

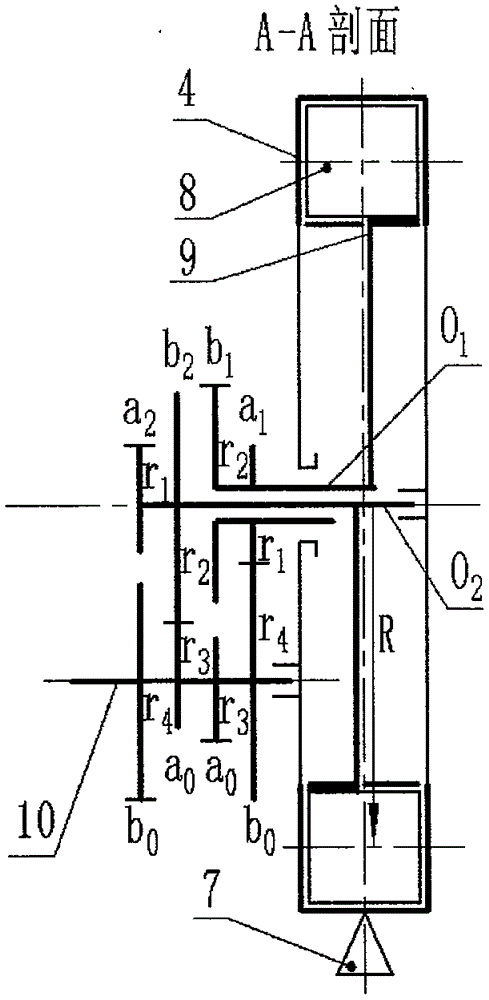

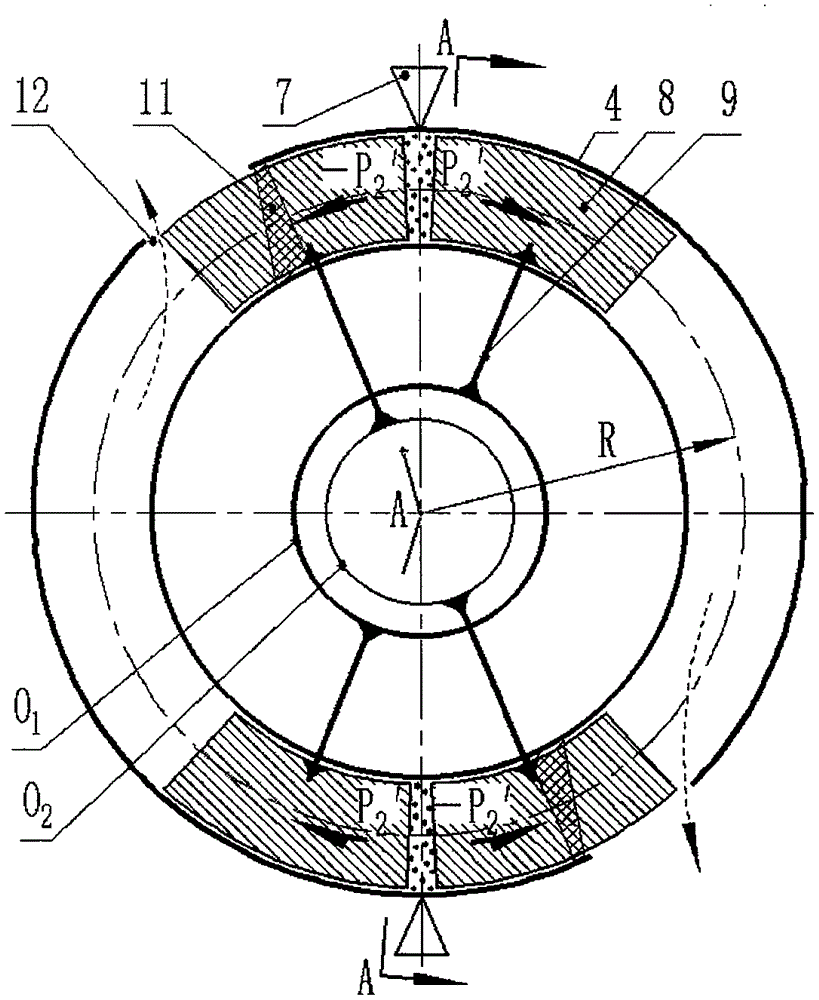

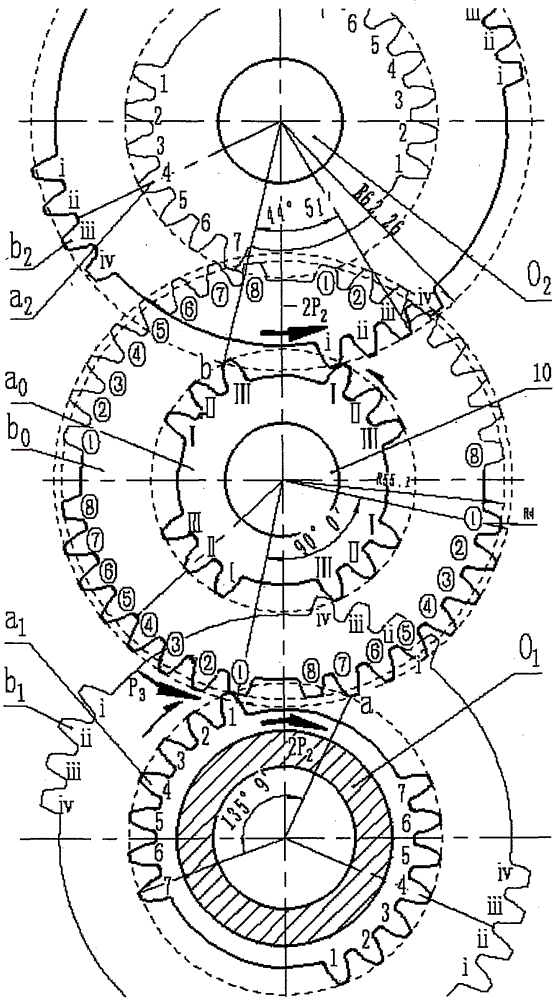

Mechanism for tooth profile modification force transformation

InactiveCN106368808AImprove effective thermal efficiencyReduce temperature and pressureInternal combustion piston enginesPistonGear transmission

A mechanism for gear transmission force transformation applied to internal combustion engines is composed of intermittent gears and is characterized in that the mechanism has a tooth profile modification function; damage collision, interference or tight occlusion does not take place during alternate meshing of the intermittent gears; two reverse torques of the driving intermittent gears could be transformed into a machine axis single-way torque; and fuel gas push force can be transformed into machine axis torsion and can be increased by about five multiples. The mechanism is applicable to piston-swing internal combustion engines and piston-rotary internal combustion engines.

Owner:黎耕

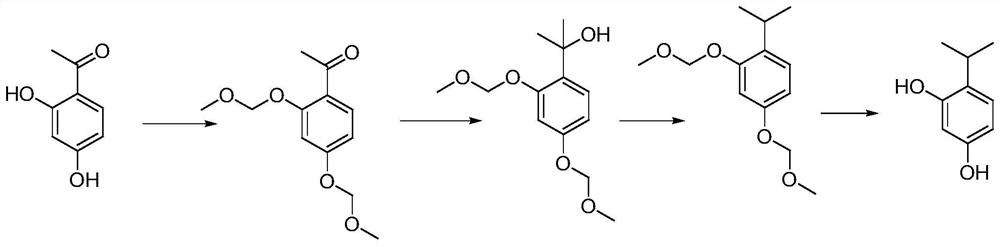

A kind of synthetic method of 4-isopropyl resorcinol

ActiveCN107556164BReduce temperature and pressureEasy to deal withOrganic chemistryOrganic compound preparationMethylmagnesium chlorideGrignard reaction

The invention discloses a synthesis method of 4-isopropylresorcinol. The method comprises the following steps: group protection, Grignard reaction, hydrodeoxygenation and deprotection. According to the method, a novel protecting group halomethyl methyl ether is adopted for protecting phenolic hydroxy, then the Grignard reaction is performed on 3 milliliters of methylmagnesium chloride or methylmagnesium bromide, hydrogenation is performed under low pressure and normal temperature in the presence of acid, and the protecting group is removed with hydrochloric acid to obtain the 4-isopropylresorcinol. The problem of difficulty in treatment after Witting reaction is solved, the temperature and the pressure of hydrogenation reaction are reduced, the hydrogenation time is shortened, deprotectionis finally implemented under a mild condition, and the whole process is a safe production process capable of implementing industrial production.

Owner:济南美高生物医药科技有限公司

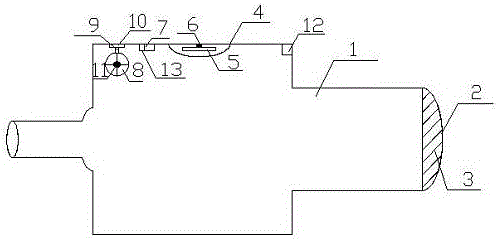

Reducer depressurization system

InactiveCN106382360AReduce temperature and pressureReduce oil spillsGear lubrication/coolingAgricultural engineeringInternal temperature

The invention relates to the technical field of reducers, in particular to a reducer depressurization system which comprises an engine body, wherein a ventilation hood is arranged at the tail of the engine body; an antidust device is arranged on the ventilation hood; a dust cover, a signal converter, a fan base and a power supply port are arranged on top wall of inner side of the engine body; a temperature sensor is arranged in the dust cover and is fixed on top wall of inner side of the engine body through a fixing device; a bracket is connected onto the fan base through a bolt; one end of the bracket is fixed on the fan base; a rotary shaft is arranged at the other end of the bracket; fan blades are arranged on the rotary shaft; the temperature sensor, the signal converter, the rotary shaft and the power supply port are connected through internal lines; and the power supply port provides power supply. According to the reducer depressurization system, a reducer provided with the ventilation hood is designed, and the fan is additionally arranged, so that the purpose of rapidly reducing internal temperature and pressure in the reducer is realized, and the oil leakage phenomenon is reduced.

Owner:常州耐强传动机械有限公司

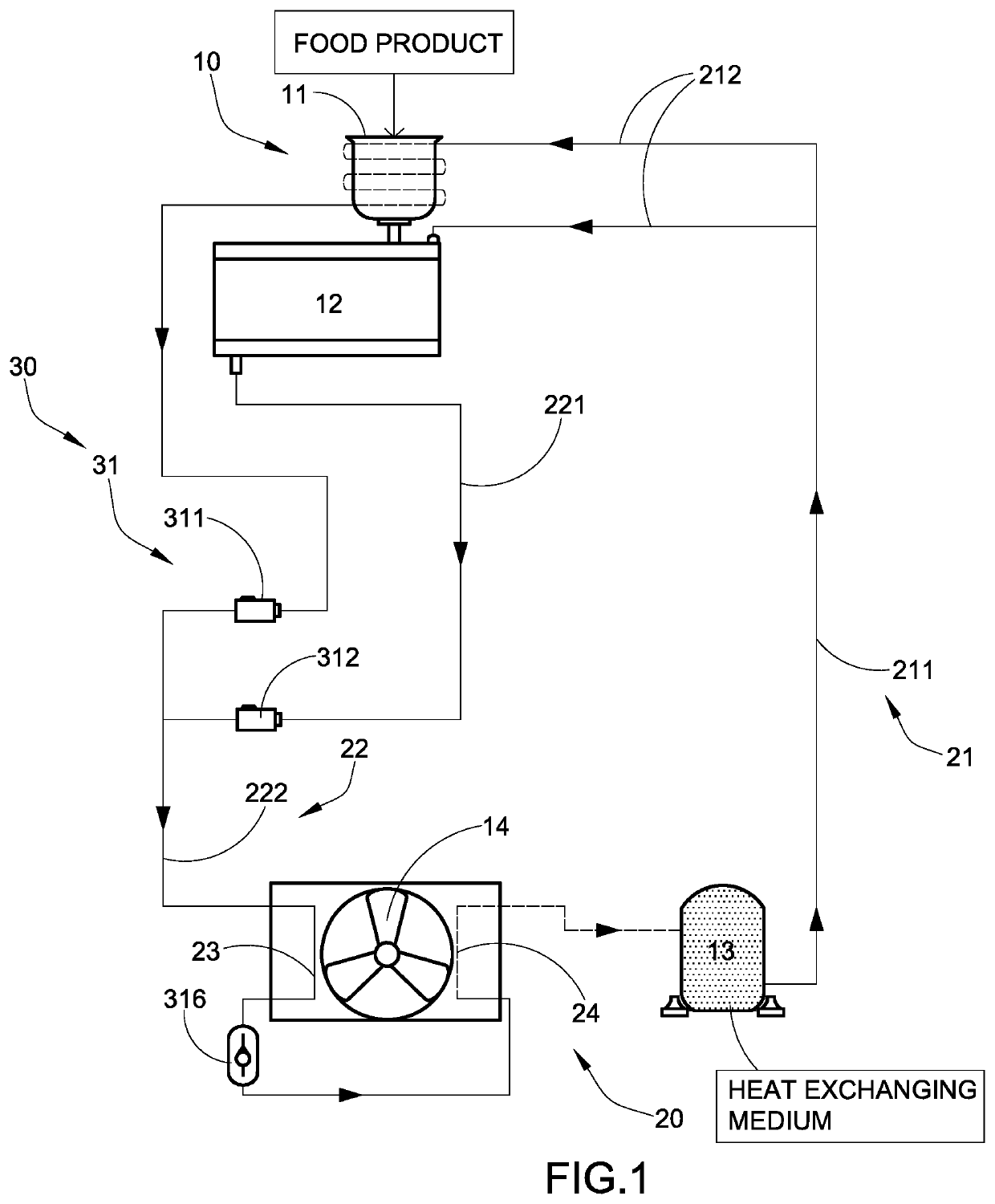

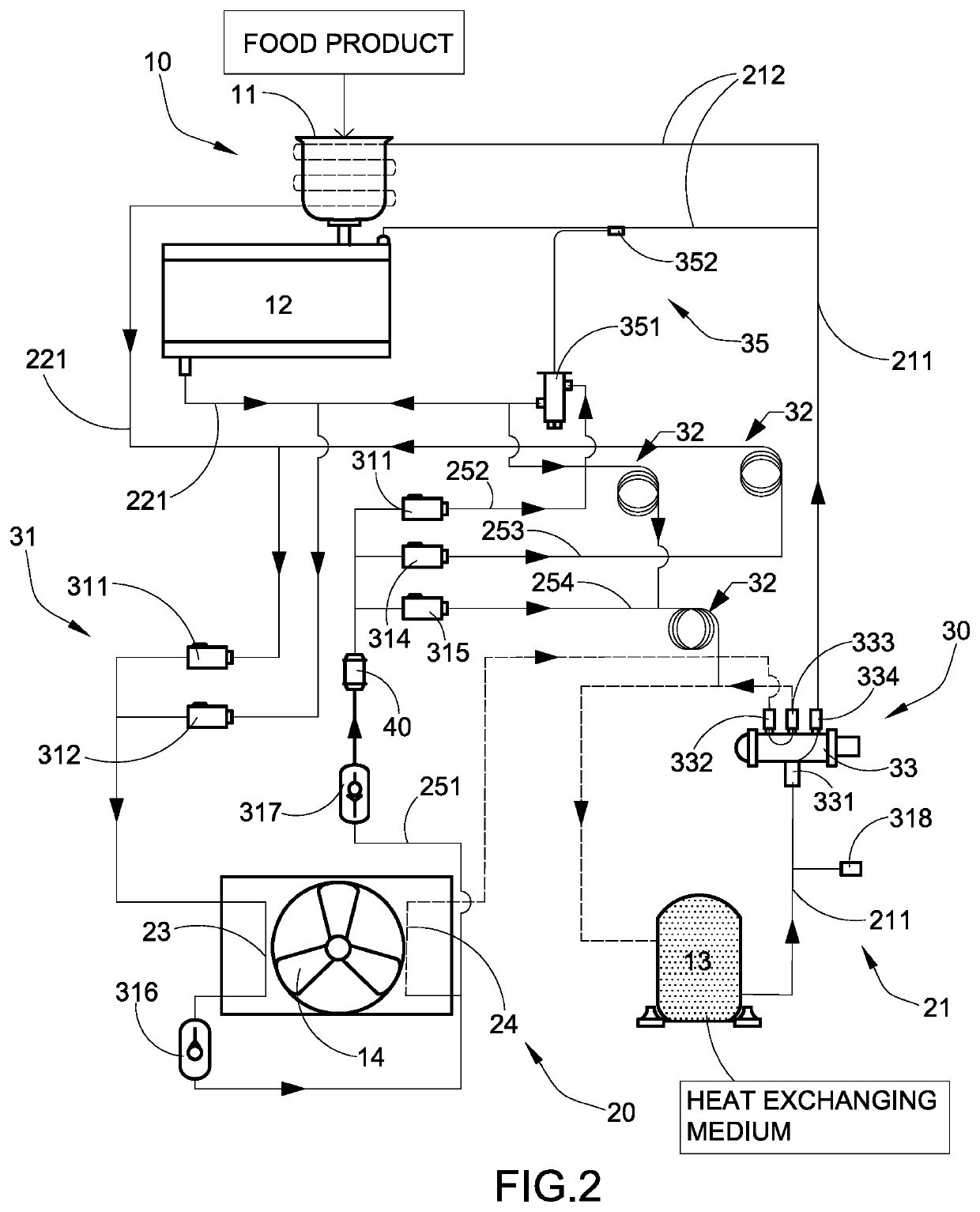

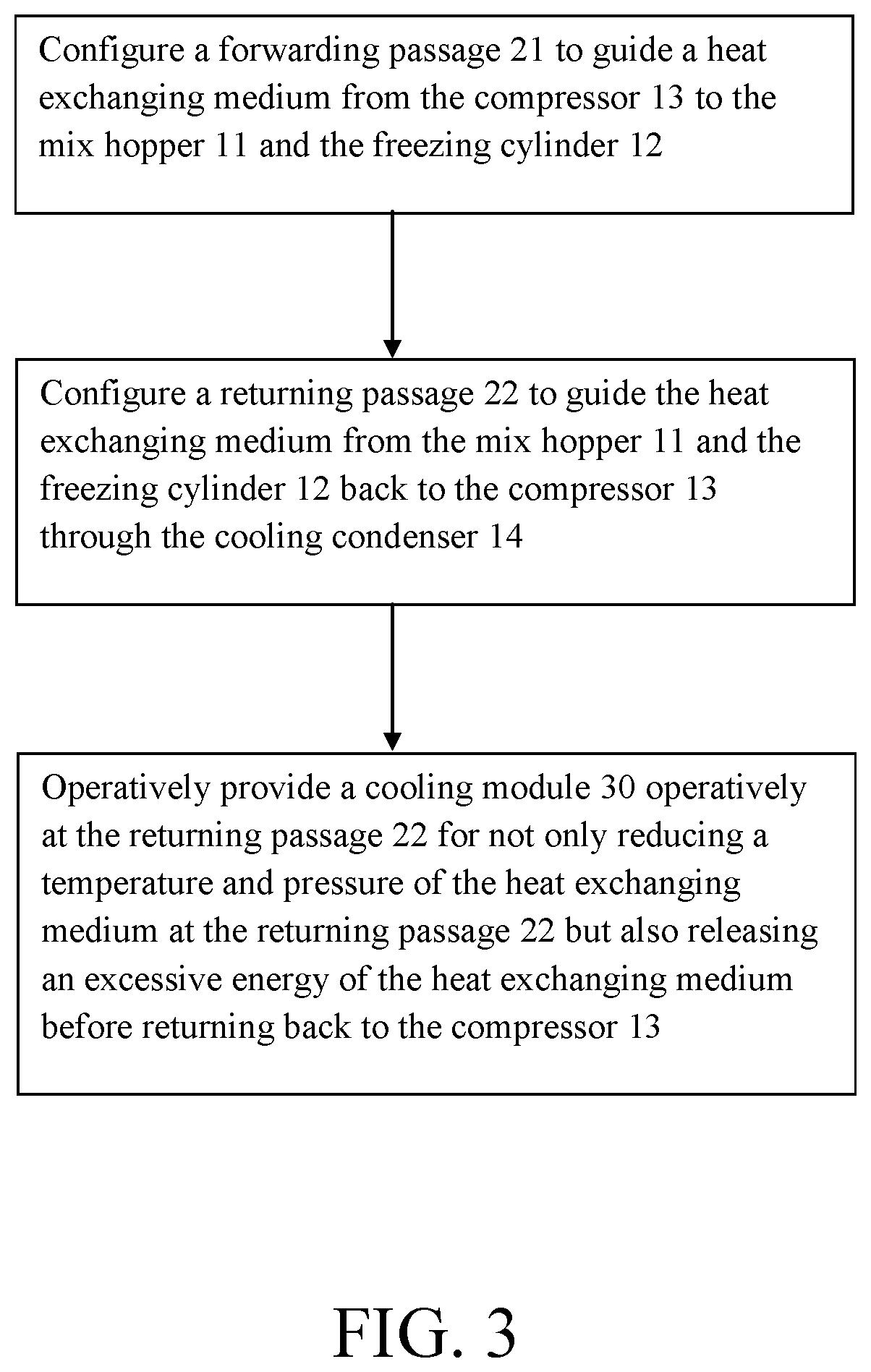

Pasteurization System For Liquid Food Product

PendingUS20210127694A1Unwanted substanceReduce temperature and pressureMilk preservationFood preservationProcess engineeringLiquid food

A pasteurization system is configured for incorporating a food treatment system which includes a mix hopper, a freezing cylinder, and a cooling condenser. The pasteurization system includes a pasteurizing pipeline and a cooling module. The pasteurizing pipeline includes a forwarding passage guiding a heat exchanging medium from the compressor to the mix hopper and the freezing cylinder, and a returning passage guiding the heat exchanging medium from the mix hopper and the freezing cylinder back to the compressor through the cooling condenser. The cooling module is operatively coupled at the returning passage for not only reducing the temperature and pressure of the heat exchanging medium at the returning passage but also releasing an excessive energy of the heat exchanging medium before returning back to the compressor.

Owner:DONG LINGYU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com