Polyether amine, preparation method thereof and application of polyether amine in gasoline detergent

A technology of polyetheramine and polyetherketone, which is applied in the field of small molecular weight polyetheramine, can solve the problems of long reaction time, low conversion efficiency in the ammoniation process, and wide molecular weight distribution of polyetheramine, so as to reduce the possibility of ether chain breakage , Shorten the reaction time at high temperature, the effect of high molecular weight consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

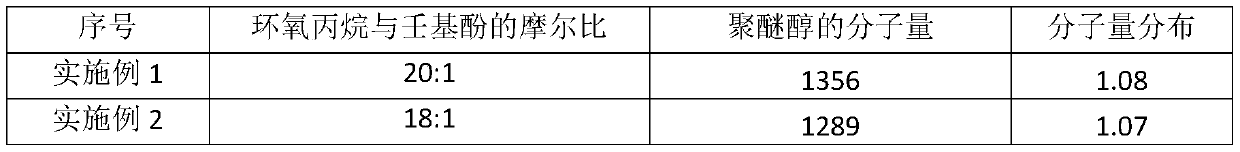

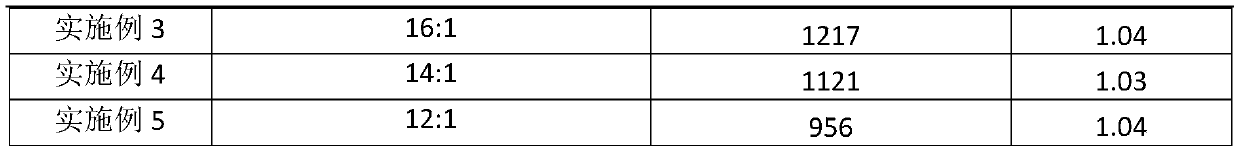

[0034] The preparation of embodiment 1-5 polyether alcohol

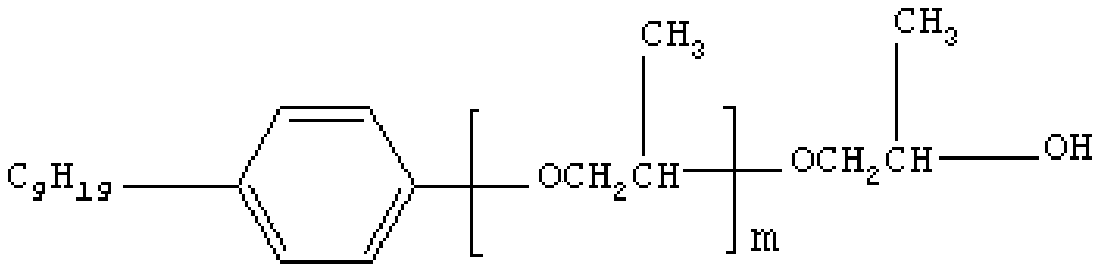

[0035] In the autoclave, add 100 parts of nonylphenol, KOH accounting for 0.2% of the weight of nonylphenol, replace the air in the autoclave with nitrogen 4 times, raise the temperature to 120°C, and dehydrate for 1h in a vacuum environment below -0.08MPa, the reaction forms Alkaline system of potassium nonylphenate; gradually add propylene oxide to the above alkaline system, the molar ratio of propylene oxide to nonylphenol is (11-20):1, at a pressure of 0.3MPa and a temperature of 130°C Stir under the conditions for 1 hour, polymerization reaction occurs, after the reaction, a crude polyether product is generated; after cooling to 80°C, add 85%wt phosphoric acid for neutralization to a pH value of 4, and add magnesium silicate for decolorization and adsorption; vacuum distillation Dehydration filtration makes polyether alcohol, molecular formula sees formula I, wherein, m=11-19, the molecular weight of polyether a...

Embodiment 6-18

[0041] The preparation of embodiment 6-18 polyether ketone and polyether amine

[0042] S2: Preparation of polyetherketone

[0043] In the high-pressure reactor, the main catalyst and the auxiliary catalyst are loaded according to the weight ratio (1-10): (0-1), wherein the main catalyst is a Raney nickel catalyst with different nickel-aluminum ratios, and 100 parts of S1 step obtained For polyether alcohol, replace the air in the kettle with nitrogen for 4 times, vacuumize, and simultaneously feed the hydrogen gas flow and the propylene gas flow through the two pipelines in the lower part of the reaction kettle. The flow ratio of the two gas flows is 1:2, and the two The flow rate of each gas flow should ensure that the vacuum degree of the reactor can reach below -0.08MPa, adjust the stirring speed to 500r / min, heat up to 200-260°C, and react for 5h. After the reaction is completed, the reactant is purged with nitrogen to obtain Crude polyether ketone, the crude polyether k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com