Reducer depressurization system

A reducer and machine body technology, applied in the direction of mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problem that the reducer cannot achieve pressure equalization, and achieve the effect of reducing oil leakage, temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

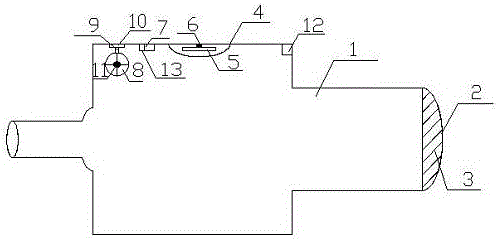

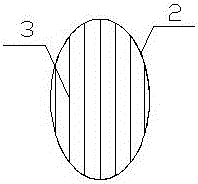

[0016] like figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure of the ventilation hood of the present invention, a depressurization system of a reducer, including a body 1, the tail of the body 1 is provided with a ventilation hood 2, the ventilation hood 2 is provided with a dustproof device 3, and the inner top wall of the body 1 is provided There is a dust cover 4, a signal converter 7, a fan base 10 and a power port 12, and a temperature sensor 5 is arranged inside the dust cover 4, and the temperature sensor 5 is fixed on the inner top wall of the body 1 by a fixing device 6, and the fan The base 10 is connected with a bracket 9 by bolts, one end of the bracket 9 is fixed on the fan base 10, the other end is welded with a rotating shaft 11, the rotating shaft 11 is provided with fan blades 8, the temperature sensor 5, the signal converter 7, the rotating shaft 11 Both are connected with the power p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com