A kind of synthetic method of 4-isopropyl resorcinol

A technology of propyl resorcinol and synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. It can solve problems such as difficult purification and complex product composition, and achieve lower temperature and pressure and shorter hydrogenation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

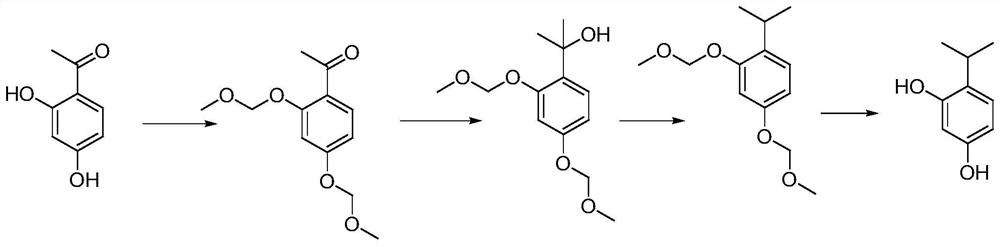

[0020] Such as figure 1 As shown, a method for synthesizing 4-isopropylresorcinol includes the following steps:

[0021] S1, group protection: in the presence of solvent and potassium carbonate, 2,4-dihydroxyacetophenone and halomethyl ether react to form 2,4-dioxymethoxyacetophenone;

[0022] S2, Grignard reaction: 2,4-Dioxymethoxy acetophenone reacts with Grignard reagent to prepare 2,4-dioxomethoxy phenylpropanol;

[0023] S3. Hydrodeoxygenation: 2,4-Dioxymethoxyphenylpropanol undergoes a hydrogenation reaction in the presence of a hydrogenation catalyst to obtain 2,4-dioxymethoxycumene;

[0024] S4. Deprotection: 2,4-Dioxymethoxycumene is deprotected in the presence of a solvent and concentrated hydrochloric acid to obtain 4-isopropylresorcinol.

[0025] In S1, the solvent is N,N-dimethylformamide, and the halomethyl ether is chloromethyl ether.

[0026] In S1, add 2,4-dihydroxyacetophenone to N,N-dimethylformamide, then add anhydrous potassium carbonate and chloromethyl methyl ethe...

specific Embodiment 1

[0032] S1: Add 100 grams of 2,4-dihydroxyacetophenone to 1 liter of N,N-dimethylformamide, add 200 grams of anhydrous potassium carbonate, and then add 115 grams of chloromethyl methyl ether, react at 60 degrees After 8 hours, cool and filter, add 3L of water for liquid separation, then extract the aqueous phase with ethyl acetate for 3 times, then combine with the organic phase, dry and evaporate the solvent to obtain 150 grams of product;

[0033] S2: Add 150 g of the product obtained from S1 to 2 liters of anhydrous tetrahydrofuran, cool to 0°C, add 250 ml of 3M methylmagnesium chloride dropwise, then react at 0°C for 2 hours, add 1 liter of saturated ammonium chloride aqueous solution to quench The aqueous layer obtained after liquid separation was extracted 3 times with ethyl acetate, then the organic phases were combined, dried, and the solvent was evaporated to obtain 144 g of the product;

[0034] S3: Add 144 g of the product obtained from S2 to 1 liter of methanol, then ad...

specific Embodiment 2

[0037] S1: Add 100 grams of 2,4-dihydroxyacetophenone to 1 liter of N,N-dimethylformamide, add 200 grams of anhydrous potassium carbonate, and then add 115 grams of chloromethyl methyl ether, react at 50 degrees After 10 hours, cool and filter, add 3L of water for liquid separation, then extract the aqueous phase with ethyl acetate 4 times, then combine with the organic phase, dry and evaporate the solvent to obtain 148 grams of product;

[0038] S2: Add 148 g of the product obtained from S1 to 2 liters of anhydrous tetrahydrofuran, cool to 0°C, add 250 ml of 3M methylmagnesium bromide dropwise, then react at 0°C for 2 hours, add 1 liter of saturated ammonium chloride The aqueous solution was quenched, and the aqueous layer obtained after liquid separation was extracted 3 times with ethyl acetate, then the organic phases were combined, dried, and the solvent was evaporated to obtain 140 g of the product;

[0039] S3: Add 140 g of the product obtained from S2 to 1 liter of methanol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com