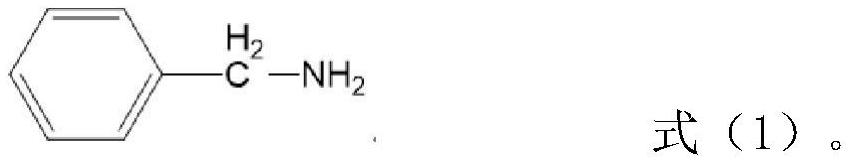

Catalyst for preparing alicyclic amine from aromatic amine as well as preparation method and application of catalyst

A catalyst and a technology for aromatic amines, which are applied in the field of aromatic amines for preparing alicyclic amines, catalysts and their preparation, can solve the problems of low selectivity and harsh reaction conditions, and achieve the effects of high selectivity, simple preparation process and easy industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

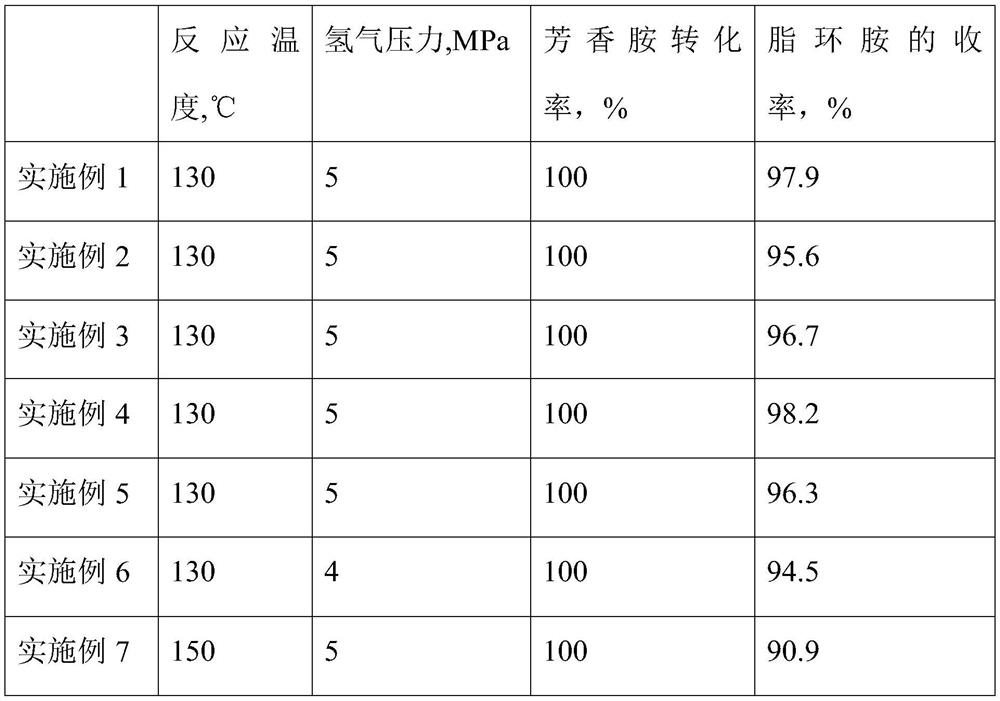

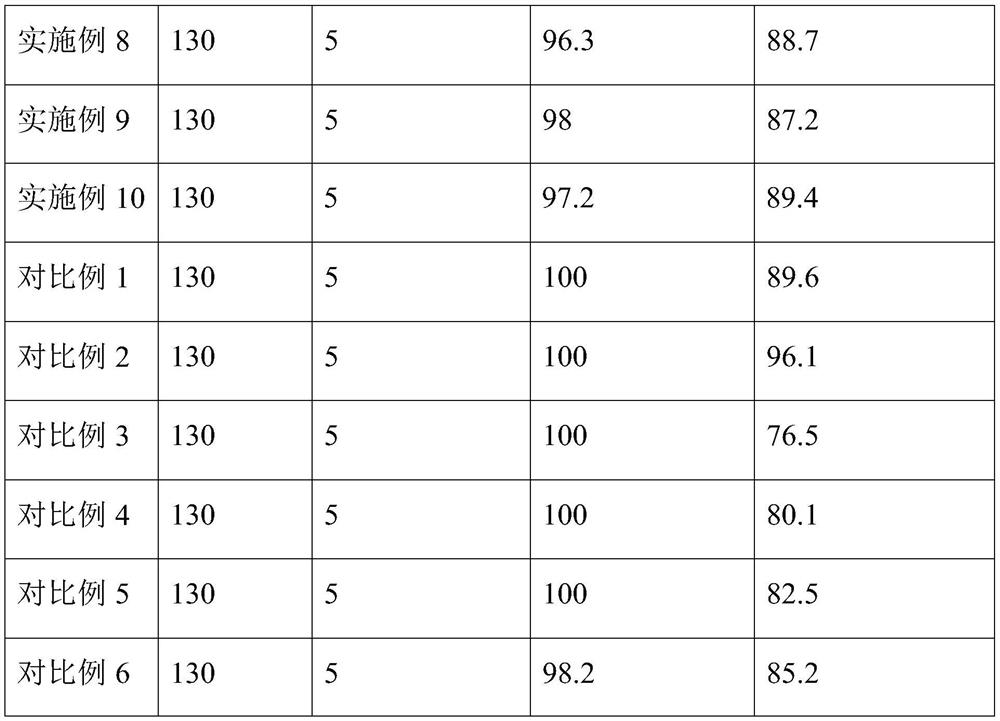

Examples

Embodiment 1

[0068] (1') At room temperature, 0.5132g of RuCl 3 ·3H 2 O was dissolved in 100mL deionized water to obtain a ruthenium source solution, and activated alumina was immersed in the ruthenium source solution and stirred for 10min, and then immersed for 12h. The volume ratio of the quality of the activated alumina to the ruthenium source solution was 0.05g / mL, After filtering, the precipitate was washed and filtered with deionized water and ethanol, dried at 100°C for 12h, calcined at 400°C for 5h under an air atmosphere, and then under a mixed atmosphere of hydrogen and nitrogen (wherein the volume percentage of hydrogen was 10%) , Reduction activation at 250°C for 6h;

[0069] (2') disperse the reductively activated product of step (1') in 100mL water to obtain a dispersion;

[0070] (3') Lithium hydroxide is added in the dispersion liquid of step (2'), the addition of described lithium hydroxide makes the mass percentage composition of lithium hydroxide in the obtained cataly...

Embodiment 2

[0073] This example uses the catalyst in Example 1, the only difference being that m-xylylenediamine is replaced by p-phenylenediamine during the performance test, and other conditions are exactly the same as those in Example 1.

Embodiment 3

[0075] This example uses the catalyst in Example 1, the only difference being that m-xylylenediamine is replaced by diaminodiphenylmethane during the performance test, and other conditions are exactly the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com