Heat pump clothes drying or clothes drying washing machine

A technology for washing machines and clothes dryers, applied in the field of clothes dryers or clothes dryers and washing machines, can solve the problems of affecting the surrounding environment, increasing compressor load, increasing temperature or humidity, etc., and achieving the effect of facilitating removal and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

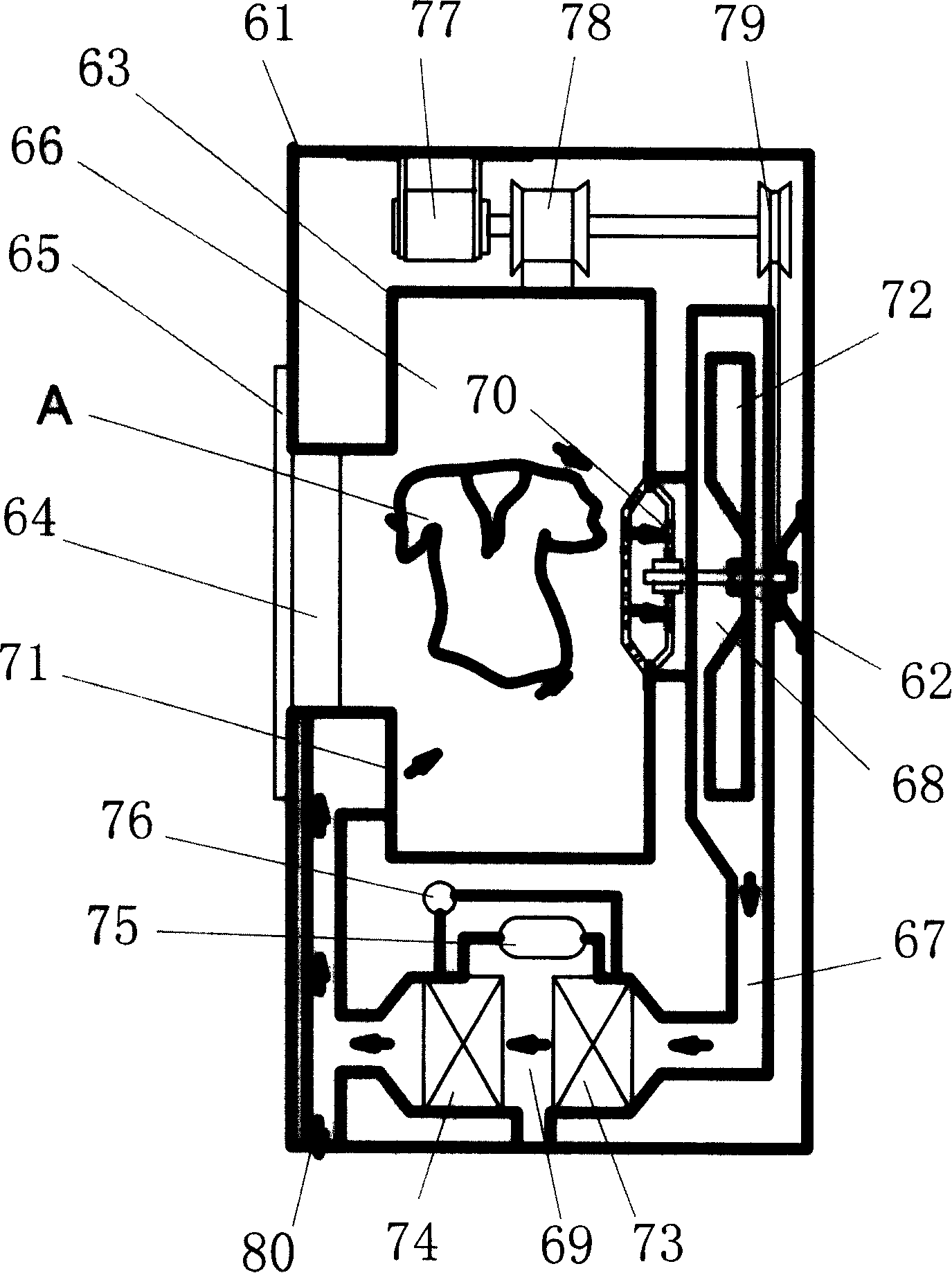

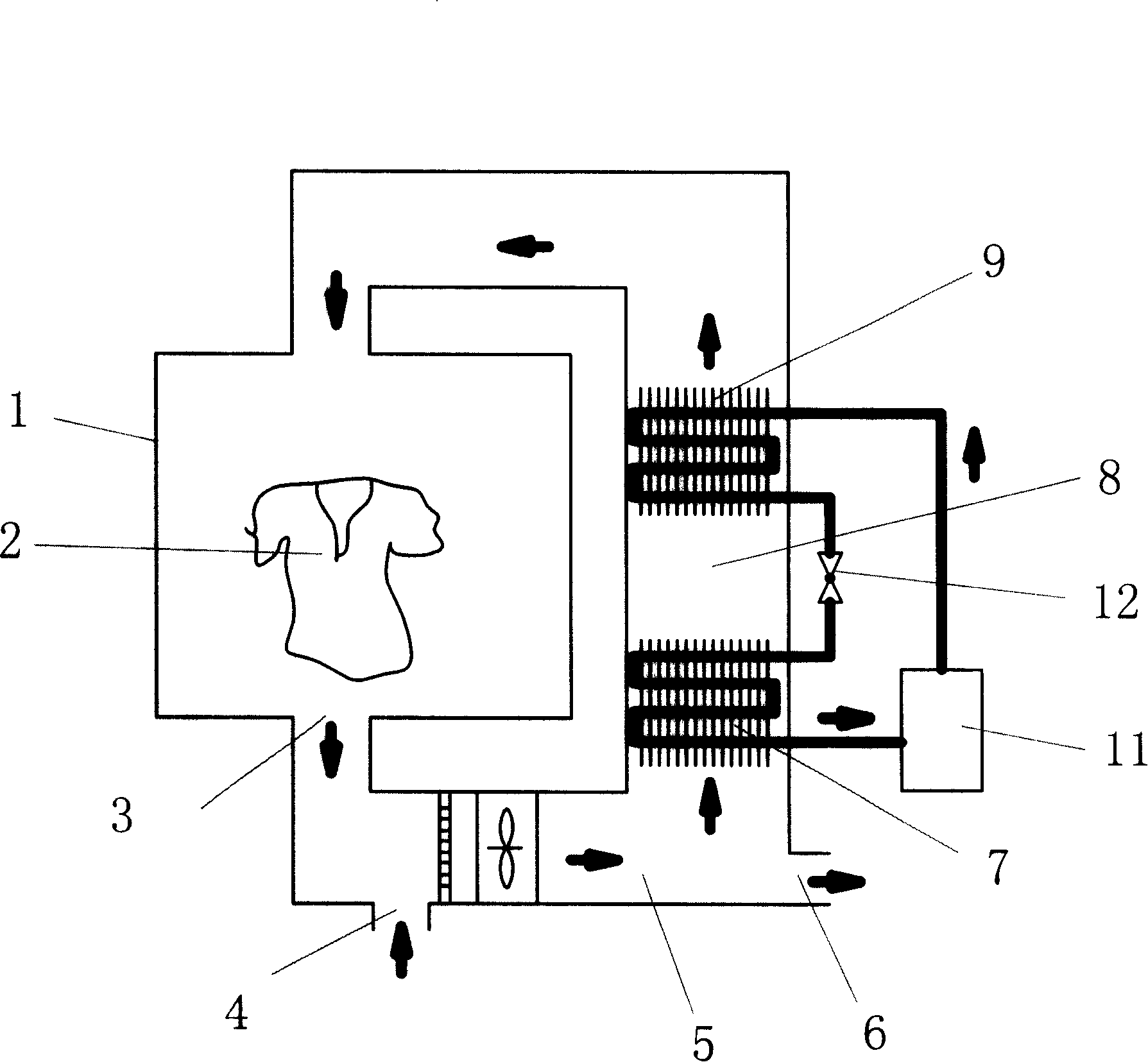

[0036] Figure 5 , 6 is a schematic diagram of the structure of the heat pump drying clothes, or the washing and drying machine of the present invention and the hot air circulation air duct of the first embodiment. The heat pump dry clothes provided by the present invention, or dry clothes washing machine, comprises: the air circulation channel 24 that is formed by the drying chamber 21 that is provided with drum 20, blast chamber 22, heat exchange chamber 23; The air outlet 25 of drying chamber 21 Connect the heat exchange chamber 23, the blast chamber 22 is located in the air circulation channel, Figure 5 In the specific embodiment shown, the blast chamber 22 is arranged on the air inlet 26 of the drying chamber 21, and the outlet of the heat exchange chamber 23 is connected to the air inlet 26 of the drying chamber 21 through the blast chamber 22; The advantage of such an arrangement is that the drum 20 and the fan 28 can be driven simultaneously by a driving motor 27; of...

Embodiment 2

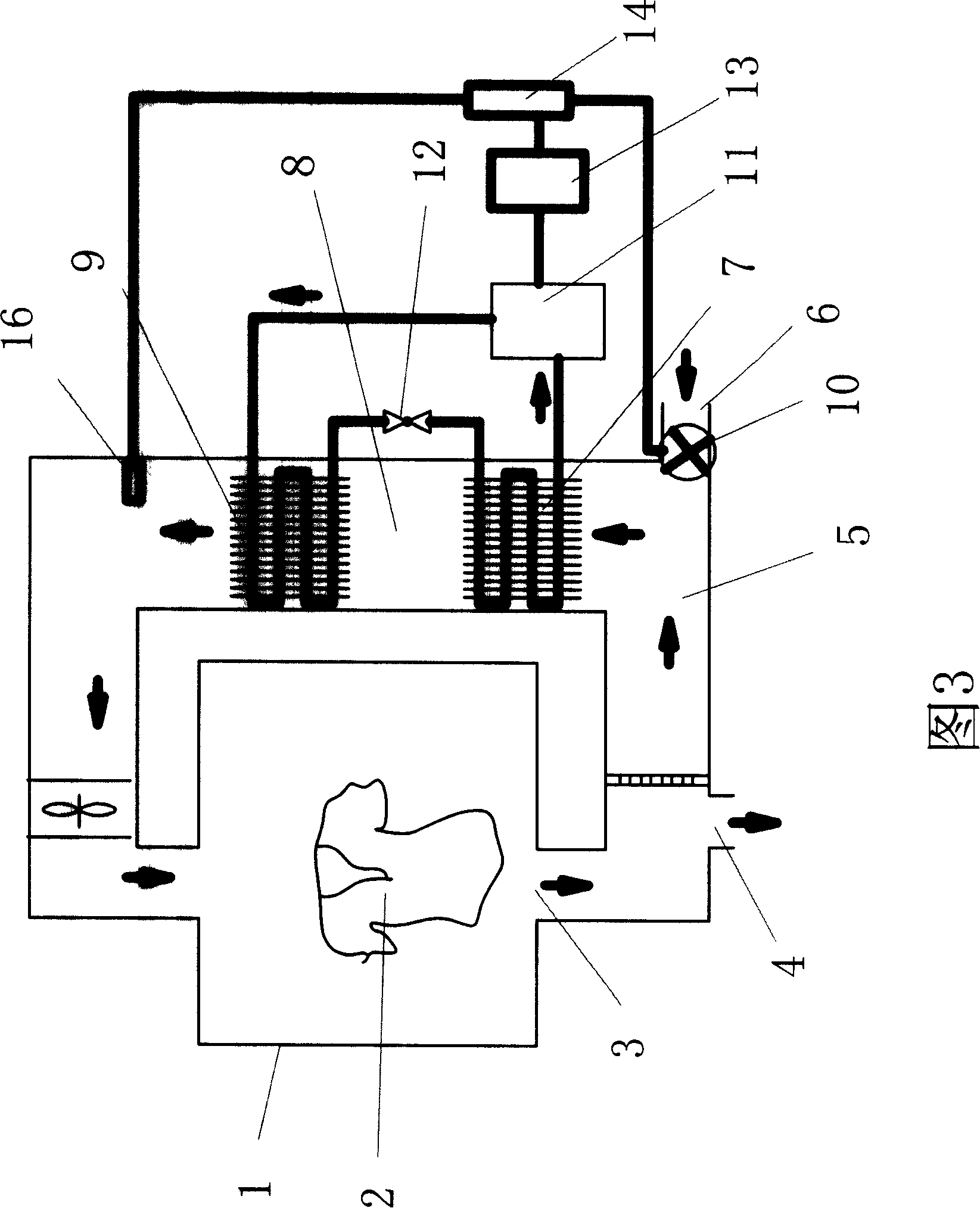

[0045] Fig. 7 is a schematic structural diagram of the heat pump drying clothes, or washing and drying machine and the hot air circulation air duct of the second embodiment of the present invention. The difference between the heat pump dry clothes or clothes dry washing machine provided in this embodiment and the first embodiment is that the temperature detection unit for detecting the working condition of the heat pump is arranged on the refrigerant output pipeline of the heat absorber. The state detection unit arranged on the refrigerant output pipeline of the heat absorber is a temperature detection unit or a pressure detection unit.

[0046] When the temperature sensor for monitoring the ambient temperature on the casing detects that the ambient temperature is lower than a certain set value, such as lower than 10°C in winter, and the temperature detection unit 39 for detecting the working condition of the heat pump detects the refrigerant in the heat absorber The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com