Coal gasification black water treatment system and treatment process

A technology of treatment system and treatment process, which is applied in the field of coal gasification black water treatment system and treatment process, can solve the problems of poor heat and power recovery, heavy equipment maintenance workload, long process flow, etc. The effect of reducing the amount of maintenance and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

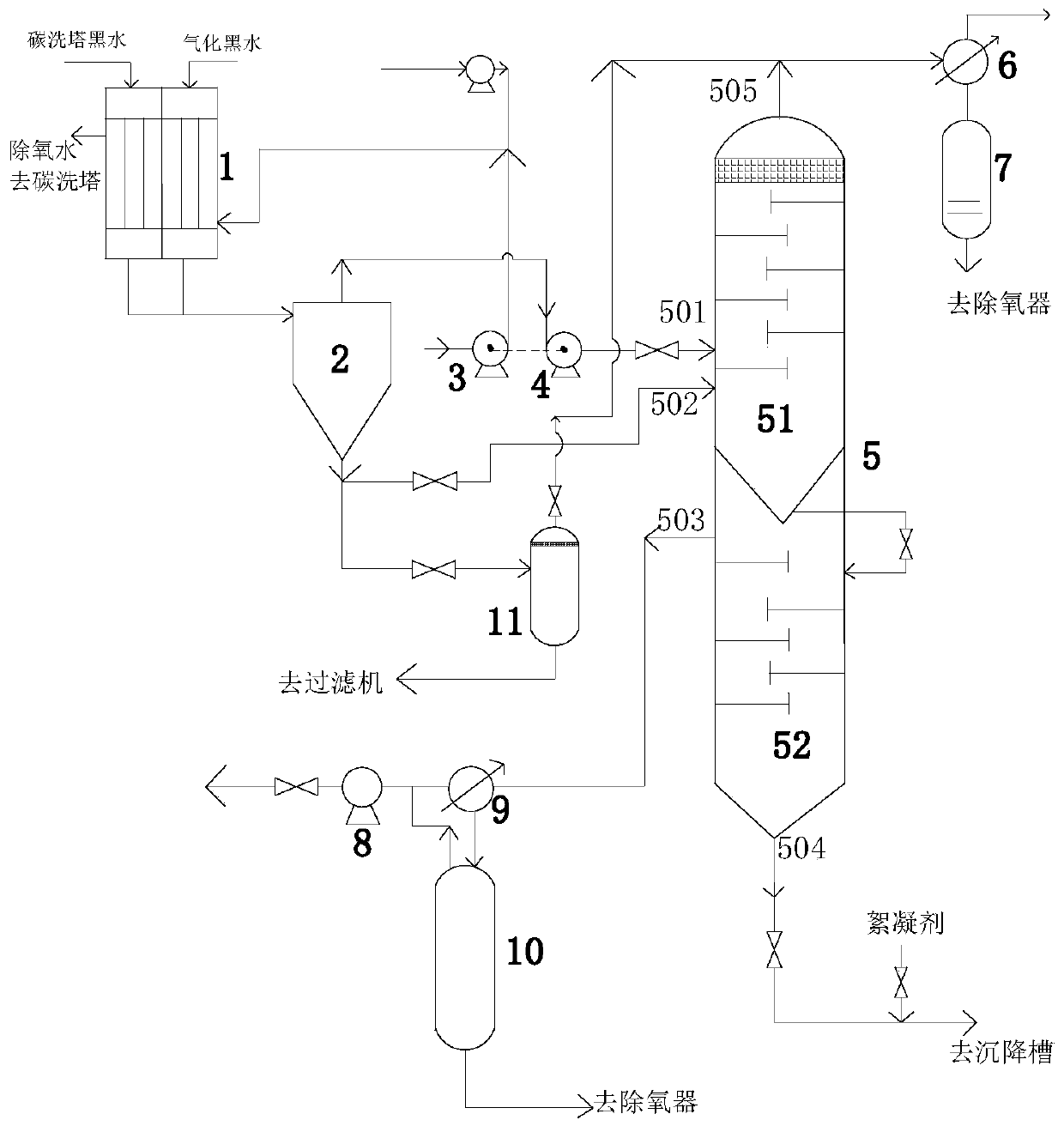

[0041] see figure 1 , The coal gasification black water treatment system includes a deaeration water heater 1, a vortex separator 2, a hydraulic deaeration water pump 3, a hydraulic turbine pump 4, a separation tank 5, an atmospheric gas cooler 6, and a vacuum gas cooler 9 and separator 11.

[0042] see figure 1 , in this embodiment, the deaeration water heater 1 is connected to the vortex separator 2 and the hydraulic deaeration water pump 3 through pipelines respectively; the top of the vortex separator 2 is connected to the hydraulic turbine pump 4 and the separation tank in turn through pipelines 5 connected; the hydraulic turbine pump 4 and the hydraulic deaeration water pump 3 are coaxially connected; the bottom end of the vortex separator 2 is connected to the separator 11 and the separation tank 5 through pipelines; the top end of the separator 11 is connected to the normal pressure gas cooler 6 are connected; the top of the separation tank 5 is connected with the no...

Embodiment 2

[0053] The coal gasification black water treatment system that present embodiment provides, its processing technology comprises the following steps:

[0054] 1) Reduce the heat in the black water to be treated by heat exchange, and recover the heat carried in the black water;

[0055] 2) step 1) the black water after cooling is roughly separated to obtain fine slag water and clear water,

[0056] After the clean water passes through the energy recovery equipment to recover part of the kinetic energy in the clean water, proceed to step 3);

[0057] The fine slag water directly enters step 3) to achieve separation or directly use the separation equipment to achieve separation; the saturated steam carried in the fine slag water is separated, and then the saturated steam is further cooled to obtain gas and condensed water, the gas is reused as process gas, and the condensed water Deoxygenated water is obtained through deoxidation; fine slag water separated from saturated steam is...

Embodiment 3

[0073] The coal gasification black water treatment system that present embodiment provides, its processing technology comprises the following steps:

[0074] 1) Reduce the heat in the black water to be treated by heat exchange, and recover the heat carried in the black water;

[0075] 2) step 1) the black water after cooling is roughly separated to obtain fine slag water and clear water,

[0076] After the clean water passes through the energy recovery equipment to recover part of the kinetic energy in the clean water, proceed to step 3);

[0077] The fine slag water is directly separated by the separation equipment; the saturated steam carried in the fine slag water is separated, and then the saturated steam is further cooled to obtain gas and condensed water, the gas is reused as process gas, and the condensed water is deoxidized to obtain deoxygenated water; Separation and removal of fine slag water from saturated steam is sent to slag removal;

[0078] 3) Atmospheric pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com