Water-cooling exhaust pipe for natural gas engine not for vehicle

An exhaust pipe and engine technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problems of affecting the service life of the engine, large exhaust gas volume, and reduced output power, so as to reduce engine product accessories and increase power , The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

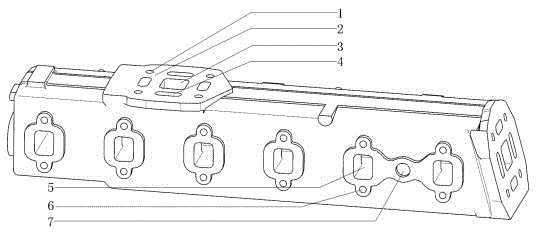

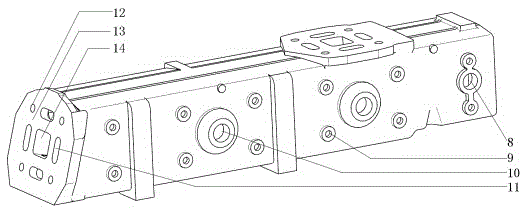

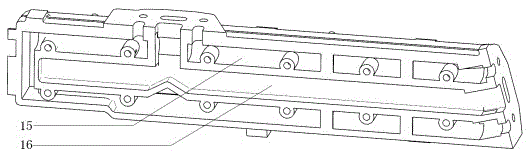

[0018] Such as figure 1 , figure 2 , image 3 As shown, the water-cooled exhaust pipe of the present invention is formed by integral casting, and the main body is in the shape of a cuboid. One end and one side of the water-cooled exhaust pipe are provided with a supercharger installation surface 2, and the supercharger is installed on the water-cooled exhaust pipe through the installation hole 1. Through the design of the two supercharger installation surfaces 2, it is convenient According to the different needs of users, the choice of installation methods is increased, and the accessories of engine products are reduced; the installation surface 2 is provided with an exhaust hole 3 and four water outlet holes 4, and the exhaust hole 3 is located in the center of the supercharger installation surface, and the water-cooled exhaust The air chamber 16 inside the pipe communicates; the air chamber 16 is located at the central axis of the main body of the water-cooled exhaust pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com