Extraction separation device used for catalytic cracking clarified oil and extraction separation method thereof

A catalytic cracking and separation device technology, applied in the direction of separation methods, chemical instruments and methods, chemical/physical/physicochemical processes using energy, etc., can solve the problems of high extraction pressure, low extraction rate, complicated operation, etc., and achieve extraction High efficiency, shortened operating time, reduced temperature and pressure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

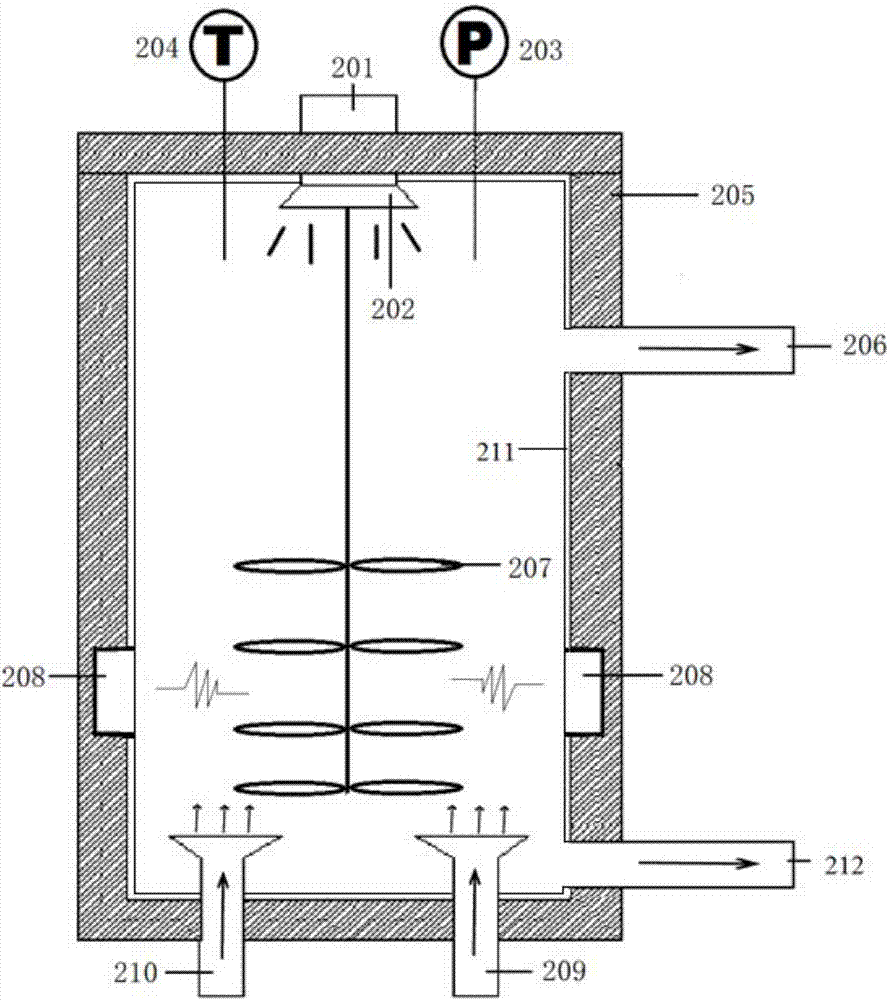

[0019] Specific Embodiment 1: In this embodiment, the ultrasonic and microwave-enhanced supercritical fluid extraction device includes: a tank body 211, an ultrasonic generator 201, an ultrasonic transducer 202, a pressure gauge 203, a thermometer 204, a heating insulation jacket 205, and a stirring paddle 207 and a microwave generator 208, wherein the ultrasonic generator 201 is arranged outside the top of the tank body 211, the ultrasonic transducer 202 is arranged inside the top end of the tank body 211, a pressure gauge 203 and a temperature gauge 204 are set near the ultrasonic generator 201, and the microwave The generator 208 is arranged on the side wall of the tank body 211, the bottom of the tank body 211 is provided with a solvent inlet 209 and a substance to be extracted inlet 209, the upper side wall of the tank body 211 is provided with a mixture outlet 206, and the stirring paddle 207 is vertically arranged on the inside of the tank body 211. In the middle positio...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the thickness of the heating insulation jacket 205 is 10-100 mm, and the insulation material is one of polyurethane foam, perlite insulation layer, benzene board, extruded plastic board and polyethylene One or more composite materials. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the height of the microwave generator 208 is 1 / 3 of the tank body 211 . Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com