Pressure Relief Device for a Gear Box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

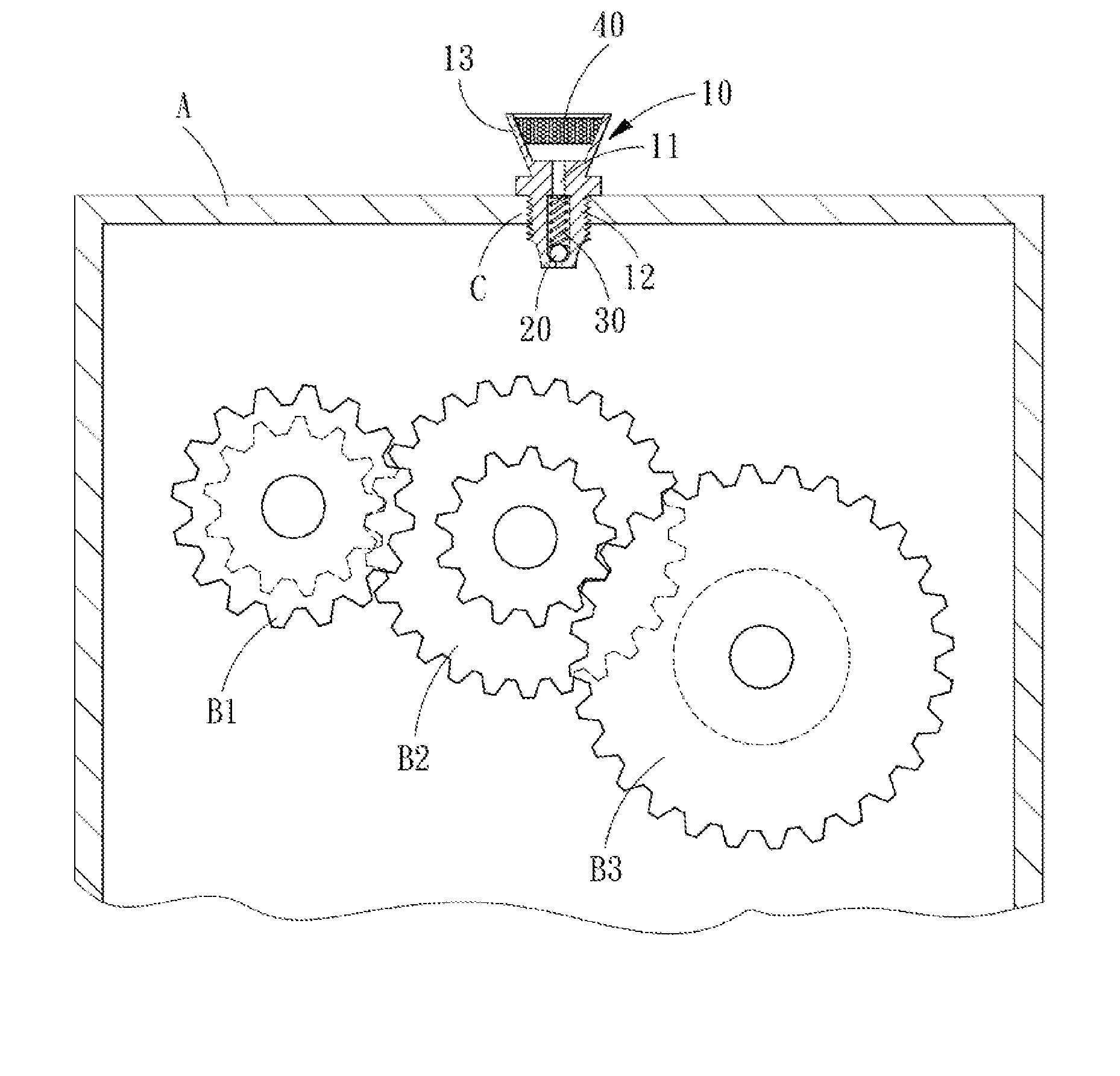

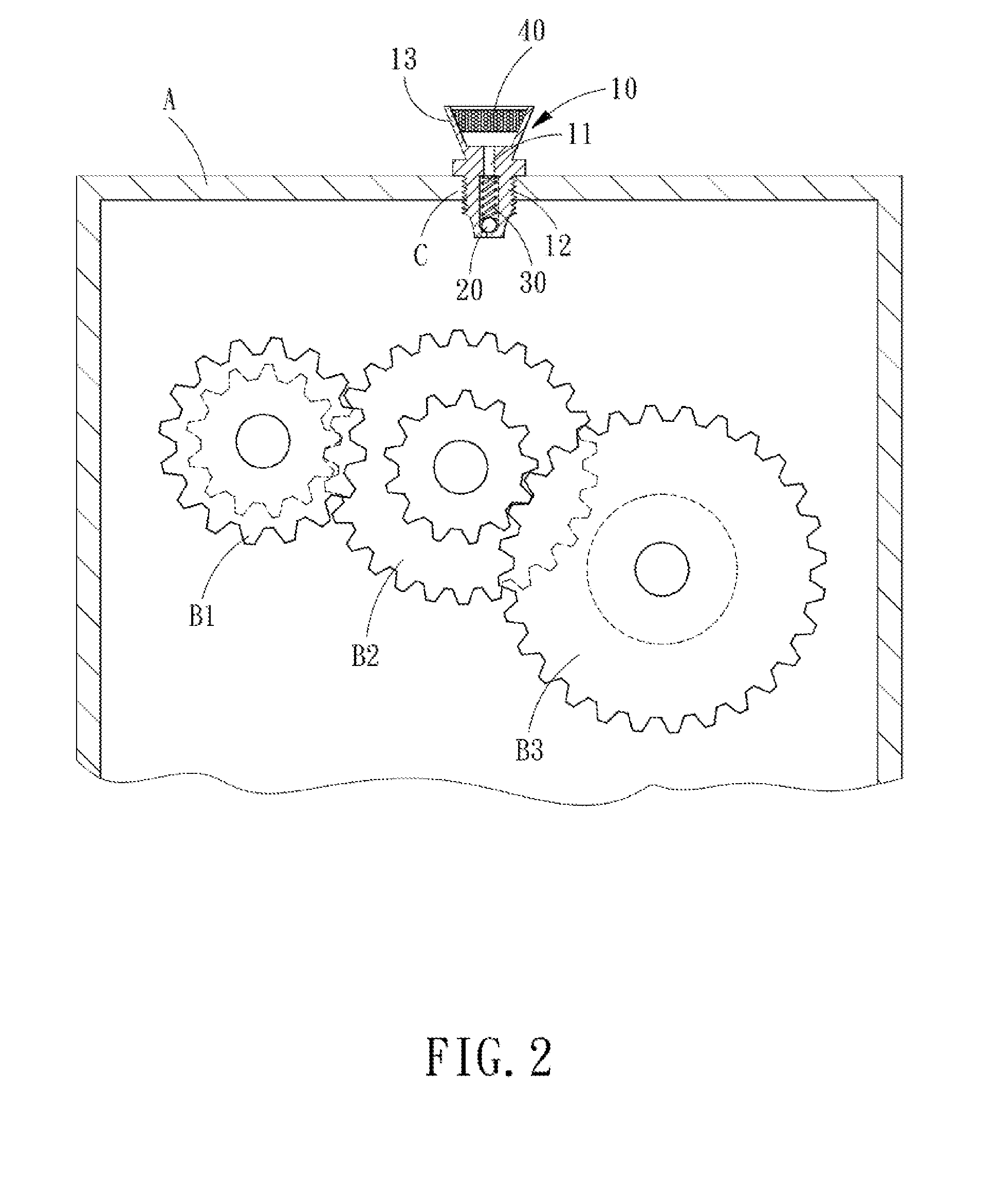

[0016]Referring to FIGS. 2 and 3, a pressure relief device for a gear box in accordance with the present invention is disposed in a through hole C of a housing A and comprises a body 10, a blocking member 20, an elastic member 30 and a sponge 40.

[0017]The body 10 is defined with a penetrating hole 11 and is pipe-shaped. One end of the body 10 is defined with outer threads 12, and the through hole C of the housing A is defined with inner threads to be threaded with the outer threads 12 of the body 10. The penetrating hole 11 of the body 10 enables an inner part to communicate with an outer part of the housing A. The penetrating hole 11 comprises three orderly connected portions, that is, an inlet portion 111, a ventilating portion 112 and an outlet portion 113. The inlet portion 111 is in communication with the inner part of the housing A, and the outlet portion 113 is in communication with the outer part of the housing A. The caliber of the inlet portion 111 is smaller than that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com