Method used for processing dichloroacetic acid in cocamidopropyl betaine

A technology for cocamidopropyl betaine and cocamidopropyl dimethylamine is applied in the field of processing dichloroacetic acid in cocamidopropyl betaine, and achieves the effects of obvious effect, reduced production cost and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

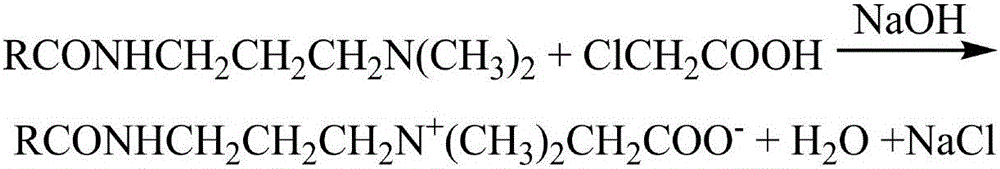

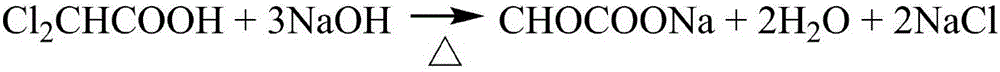

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put 516 grams of deionized water in the there-necked flask, join the cocamidopropyl dimethylamine of 1mol and 1.05mol chloroacetic acid (dichloroacetic acid content 0.6%) in the there-necked flask, then add 35% sodium hydroxide 24 grams of solution, stir and raise the temperature to 80°C, then add 96 grams of 35% sodium hydroxide solution, after the addition is complete, control the temperature at 80°C to 90°C, and pH between 8.5 and 9.5, keep for 3h, then Then add sodium hydroxide to increase the pH of the solution to 12-13, raise the temperature to 110°C, and after 5 hours, the reaction is completed and lower the temperature to below 70°C, add citric acid to adjust the pH to neutral, add deionized water to adjust the solid content to 35 %.

[0031] The detected dichloroacetic acid content is 90ppm (in the case of untreated residual dichloroacetic acid, calculated by product formula, the theoretical residual amount of dichloroacetic acid is 506ppm).

Embodiment 2

[0033] Put 516 grams of deionized water in the there-necked flask, join the cocamidopropyl dimethylamine of 1mol and 1.05mol chloroacetic acid (dichloroacetic acid content 0.6%) in the there-necked flask, then add 35% sodium hydroxide 24 grams of the solution, stirred and raised the temperature to 80°C, then added 96 grams of 35% sodium hydroxide solution, after the addition was completed, the temperature was controlled at 80°C to 90°C, and the pH was maintained at 8.5 to 9.5 for 3 hours, and then Add sodium hydroxide to raise the pH of the solution to 12-13, raise the temperature to 125°C, after 3 hours the reaction is complete, lower the temperature to below 70°C, add citric acid to adjust the pH to neutral, add deionized water to adjust the solid content to 35% .

[0034] The detection of dichloroacetic acid content is 37ppm (in the case of untreated residual dichloroacetic acid, calculated by product formula, the theoretical residual content of dichloroacetic acid is 506pp...

Embodiment 3

[0036] Put 516 grams of deionized water in the there-necked flask, join the cocamidopropyl dimethylamine of 1mol and 1.05mol chloroacetic acid (dichloroacetic acid content 0.6%) in the there-necked flask, then add 35% sodium hydroxide 24 grams of the solution, stirred and raised the temperature to 80°C, then added 96 grams of 35% sodium hydroxide solution, after the addition was completed, the temperature was controlled at 80°C to 90°C, and the pH was maintained at 8.5 to 9.5 for 3 hours, and then Add sodium hydroxide to increase the pH of the solution to 12-13, raise the temperature to 150°C, and after 1 hour, the reaction is completed and lower the temperature to below 70°C, add citric acid to adjust the pH to neutral, add deionized water to adjust the solid content to 35% .

[0037] The content of dichloroacetic acid was detected to be 45ppm (in the case of untreated residual dichloroacetic acid, calculated by product formula, the theoretical residual amount of dichloroacet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com