Twin-turbo EGR system and method for ship two-stroke diesel engine

A diesel engine and turbine technology, applied in the field of diesel engine intake and exhaust treatment devices, can solve the problems of reducing the output power of the turbine and affecting the output power of the turbocharger, so as to reduce the maximum burst pressure, save the space of the ship, and stabilize the scavenging flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

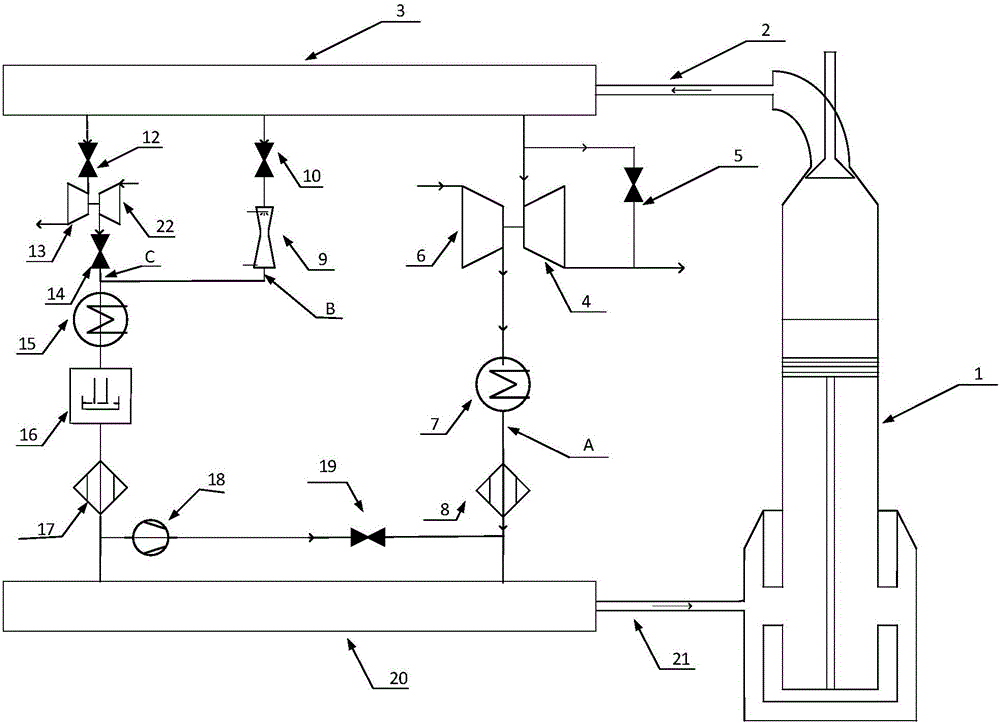

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0024] to combine figure 1 , the present invention is a marine two-stroke diesel engine twin-turbo EGR system, comprising an intake pipe, an exhaust pipe, a turbine, a compressor, a cooler, a scrubber and a water mist collector.

[0025] The EGR system includes a large turbine passage, an EGR passage and a small turbine passage. The large turbine passage is connected to the diesel engine through the exhaust manifold and the scavenging manifold; the EGR passage is connected to the diesel engine through the exhaust manifold and the scavenging manifold; the small turbine passage is It is connected with the diesel engine through the exhaust manifold and the scavenging manifold.

[0026] The passage of the large turbine includes the large turbine, the large compressor, the cooler, the mist collector A and the waste gas bypass circuit. The large turbine and compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com