Symmetrically-arranged high-speed double-turbine distributed excess pressure power generation system

A technology of symmetrical arrangement and residual pressure power generation, which is applied in combined engines, steam engine installations, machines/engines, etc. Solve problems such as axial force, and achieve the effect of improving output power, enhancing adaptability, and increasing steam flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

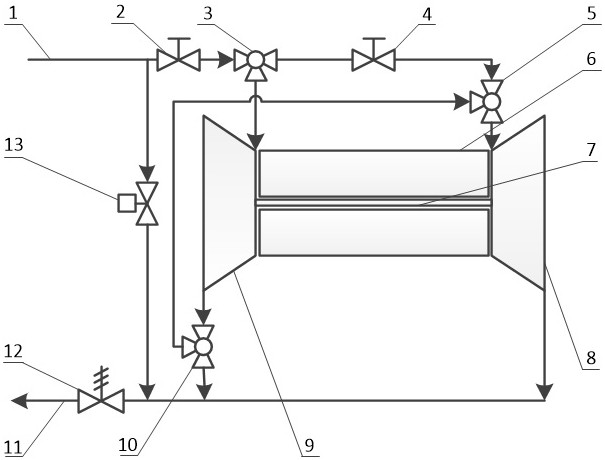

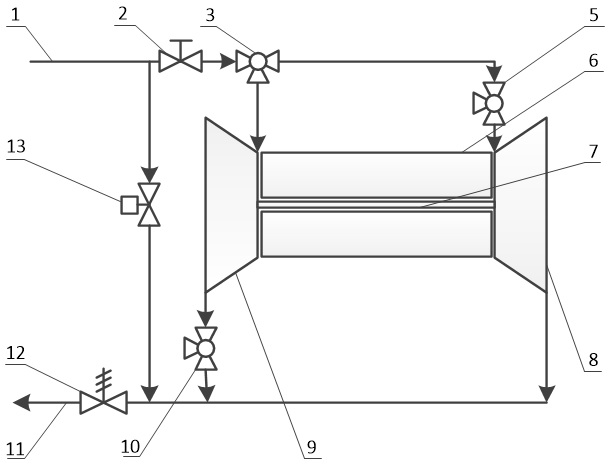

[0021] High-speed twin-turbine distributed residual pressure power generation system symmetrically arranged in parallel operation mode.

[0022] This embodiment discloses a symmetrically arranged high-speed twin-turbine distributed residual pressure power generation system (hereinafter referred to as "the system") under the parallel operation mode. To solve the problem of axial force, a symmetrically arranged high-speed twin-turbo expander structure is designed.

[0023] see figure 1 , figure 2 , the system includes No. 1 isolation valve 2, flow distribution valve 3, No. 2 isolation valve 4, No. 2 three-way switching valve 5, high-speed permanent magnet motor 6, No. 2 turbo expander 8, No. 1 turbo expander 9, and No. 1 No. 3-way switching valve 10, safety valve 12 and bypass isolation valve 13; No. 1 turbo expander 9 and No. 2 turbo expander 8 are antisymmetrically arranged, and high-speed permanent magnet motor 6 is arranged between No. 1 turbo expander 9 and No. 2 turbo e...

Embodiment 2

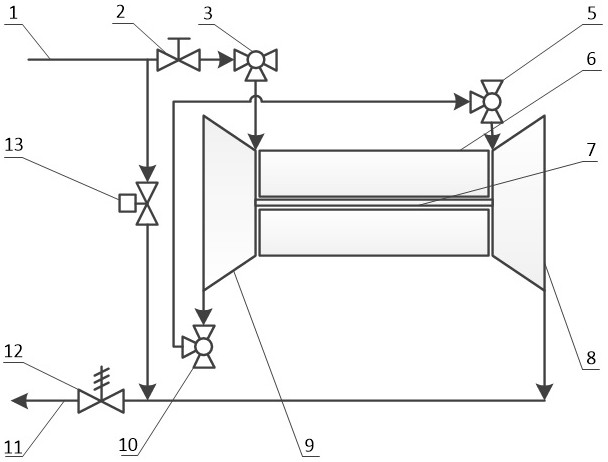

[0036] High-speed twin-turbine distributed residual pressure power generation system symmetrically arranged in series operation mode.

[0037] This embodiment discloses a symmetrically arranged high-speed twin-turbine distributed residual pressure power generation system (hereinafter referred to as "the system") under the series operation mode. The supply and demand mismatch system has low energy recovery efficiency and cannot solve the problem of axial force during operation, especially for high-pressure steam inlet pipeline 1 with high steam quality and large pressure difference operating conditions.

[0038] see figure 1 , image 3, the system includes No. 1 isolation valve 2, flow distribution valve 3, No. 2 isolation valve 4, No. 2 three-way switching valve 5, high-speed permanent magnet motor 6, No. 2 turbo expander 8, No. 1 turbo expander 9, and No. 1 No. 3-way switching valve 10, safety valve 12 and bypass isolation valve 13; No. 1 turbo expander 9 and No. 2 turbo ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com