Antibiotic wastewater degradation method and device based on combined action of electrolysis and cavitation

A technology of antibiotic wastewater and combined action, which is applied in chemical instruments and methods, special compound water treatment, oxidized water/sewage treatment, etc. It can solve the problems of low treatment efficiency, no treatment effect, and failure to meet the requirements of wastewater treatment by physical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

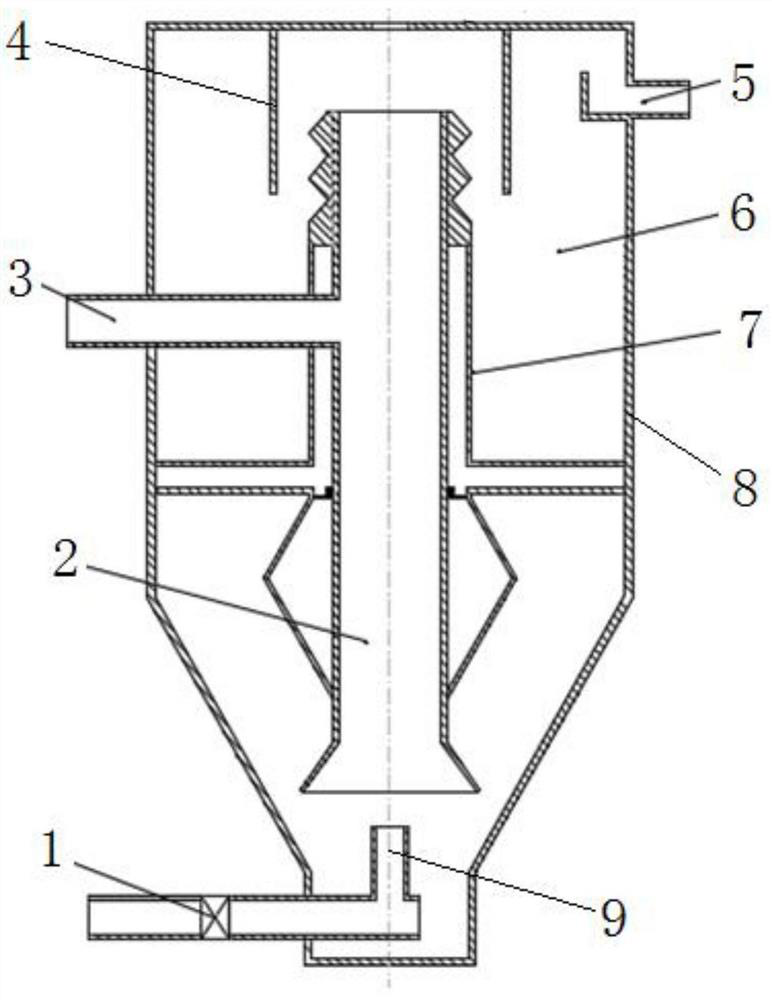

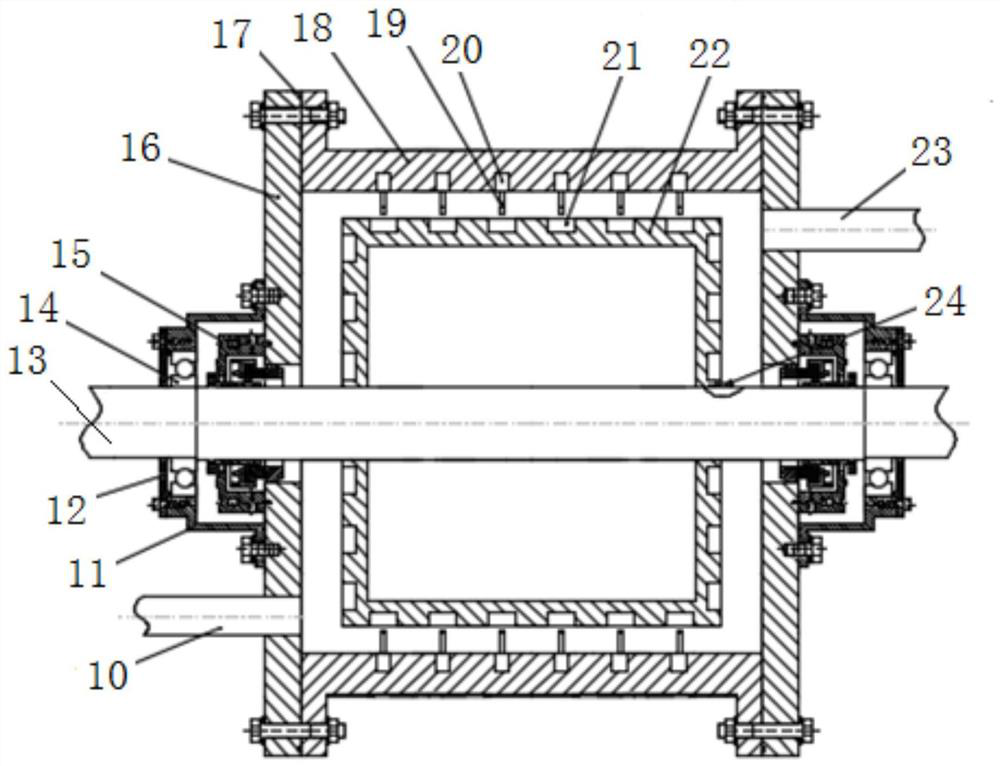

[0048] The present invention proposes a method for degrading antibiotic wastewater based on the joint action of electrolysis and hydraulic ultrasonic cavitation, and designs a new type of hydraulic-ultrasonic cavitation device, which can fully combine the advantages of the two cavitation effects to achieve double improvement in degradation effect and degradation efficiency.

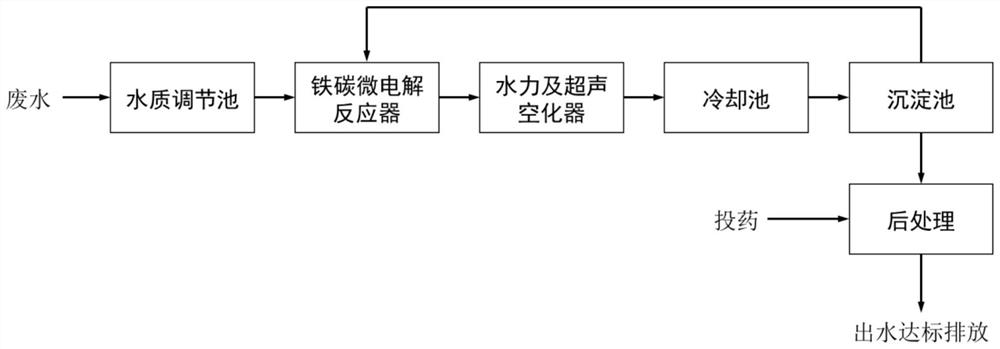

[0049] The antibiotic wastewater degradation device of the present invention utilizes the iron-carbon micro-electrolysis method for pretreatment, utilizes hydraulic power and ultrasonic cavitation to degrade antibiotic wastewater, and the process flow is as follows figure 1 As shown, the antibiotic waste water enters the wastewater tank, water quality adjustment tank, iron-carbon micro-electrolysis reactor, hydraulic and ultrasonic cavitator, cooling tank, sedimentation tank and post-treatment tank in turn for treatment. Specifically include the following processes.

[0050] 1. The antibiotic wastewater f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com