Application method of aluminium scraps in aluminium alloy cylinder cover casting

An application method, an aluminum alloy technology, applied in the field of aluminum scrap recycling, can solve problems such as product quality impact, resource waste, and high oxidation tendency, and achieve the effects of reducing production costs, reducing burning losses, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

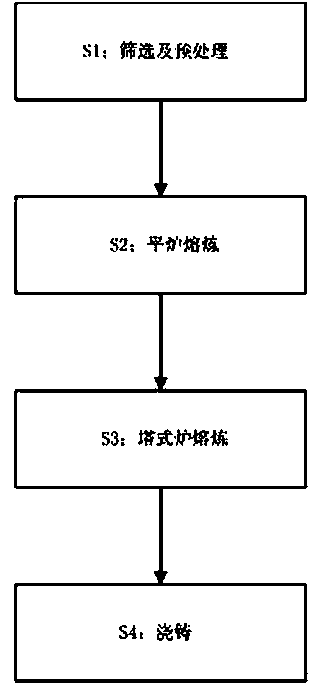

[0033] Such as figure 1 Shown, in order to meet the application method of a kind of aluminum shavings of the present invention in aluminum alloy cylinder head casting, comprise the steps:

[0034] S1: Screening and preprocessing

[0035] Screen out aluminum scraps and waste aluminum without iron inserts and store them in categories, put the aluminum scraps into the pretreatment system for water removal, oil removal, and drying;

[0036] S2: open hearth melting

[0037] Put the waste aluminum without iron inserts and the aluminum chips into the melting chamber of the open hearth furnace, heat to 750-790°C, take samples to detect the chemical components, compare the test results with the standard ingredients, and according to the comparison results Calculate the proportion of the aluminum master alloy that needs to be added, add the aluminum master al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com