Radial dual turbosupercharging fan and air pipe machine

A supercharger fan and twin-turbine technology, which is applied to radial flow pumps, machines/engines, mechanical equipment, etc., can solve the problems of less optimistic effect size and small wind output, and achieves simple structure and improved performance. Effects of wind pressure, boost weight and wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

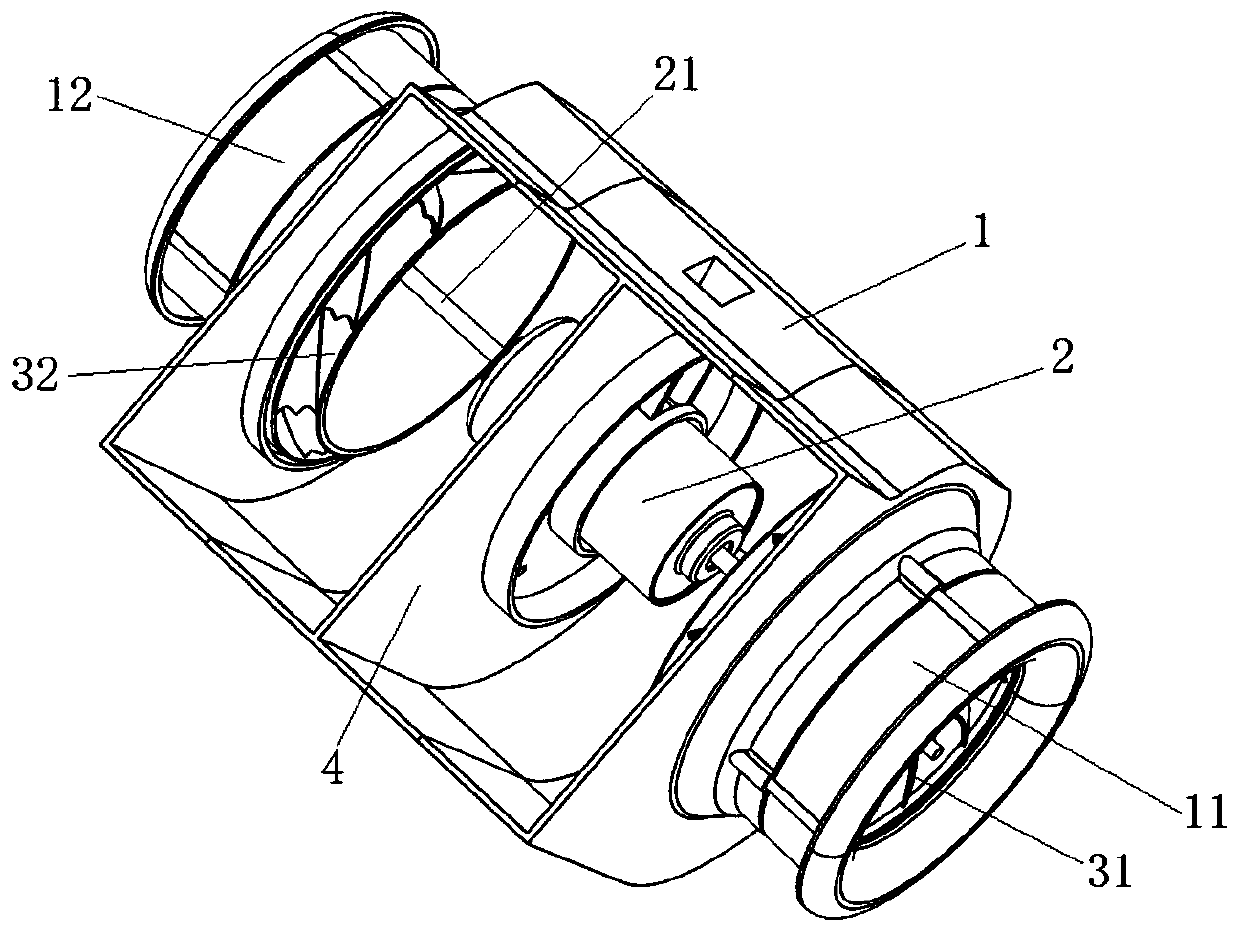

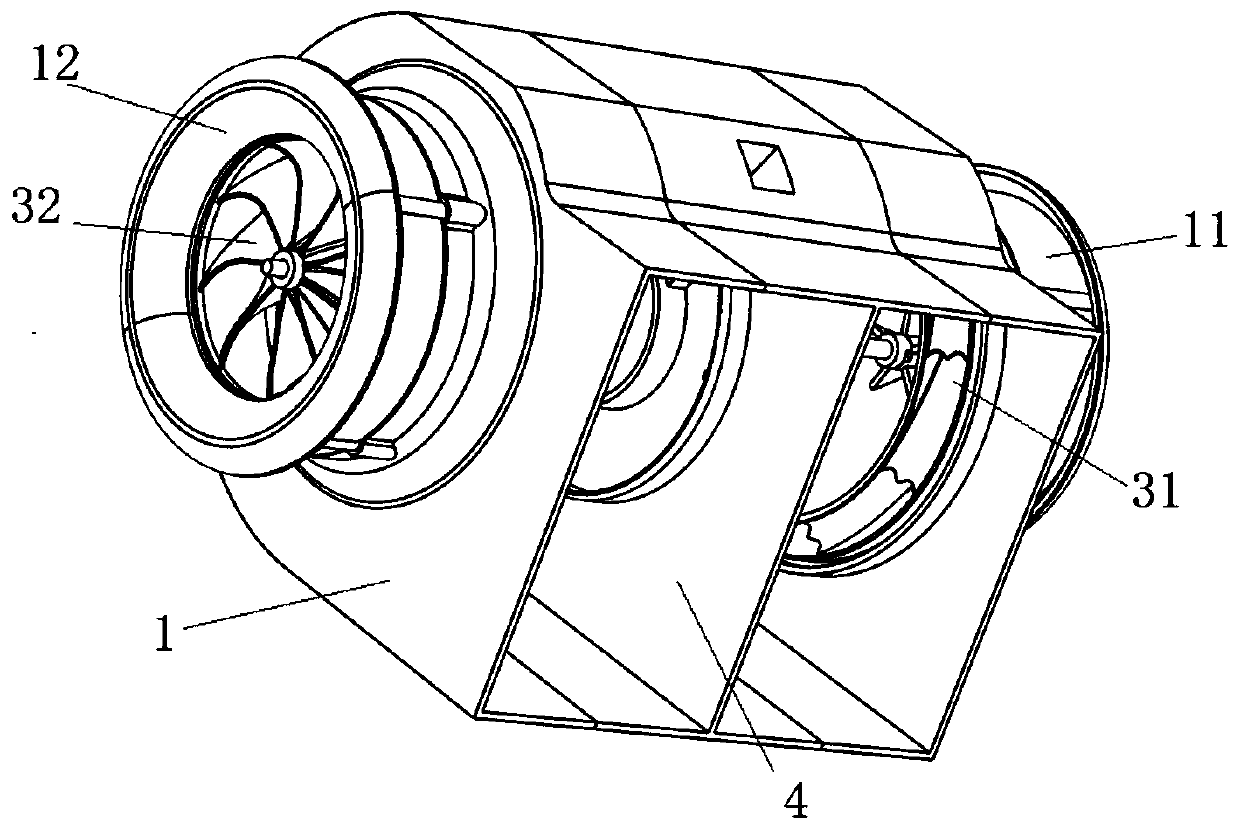

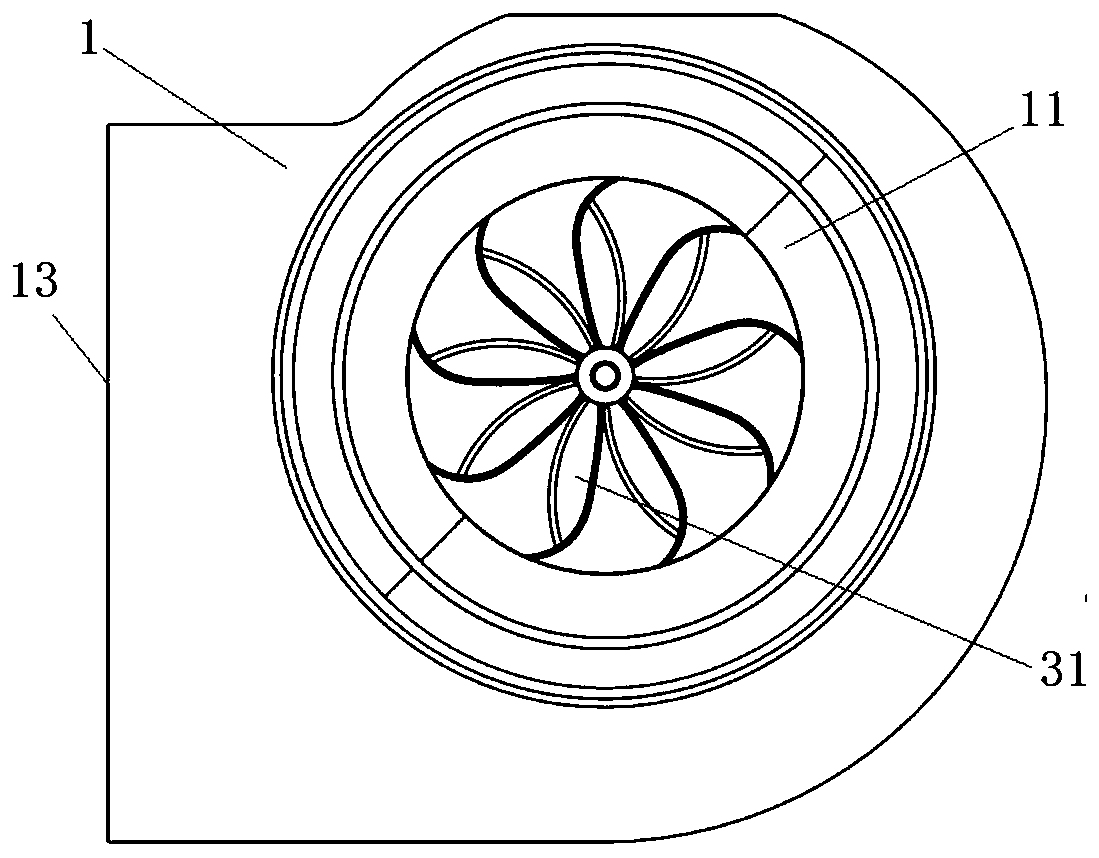

[0052] see figure 1 , figure 2 and image 3 , the present invention provides a radial twin-turbocharged blower, including a casing 1 , a driving motor 2 , a first helical impeller 31 and a second helical impeller 32 . Wherein, the casing 1 is provided with a first casing air inlet 11 and a second casing air inlet 12 oppositely, and the casing 1 is also provided with a fan outlet; the driving motor 2 is arranged in the casing 1, and the driving motor 2 has A drive shaft 7321 that runs through the drive motor 2, the two ends of the drive shaft 7321 correspond to the first casing air inlet 11 and the second casing air inlet 12; and the first helical impeller 31 and the second helical impeller 32, the first The spiral impeller 31 is installed in the air inlet 11 of the first casing through the driving shaft 7321, and the second spiral impeller 32 is installed in the air inlet 12 of the second casing through the driving shaft 7321. The first spiral impeller 31 and the second spi...

Embodiment 2

[0056] The present invention also provides a radial twin-turbocharged air duct machine on the basis of the fan, please refer to image 3 , Figure 5 and Image 6 , including the box body 5 and the above-mentioned radial twin-turbocharged blower; the box body 5 is provided with a box air outlet 52 and a box air inlet 51, and an air duct 6 is arranged between the fan air outlet and the body air outlet of the fan. The present invention is provided with two-way helical impellers, wherein the helical directions of the first helical impeller 31 and the second helical impeller 32 are opposite; Realize one motor and two impellers; achieve the effect of twin turbocharging, increase the weight and wind force, increase the wind pressure at the fan outlet of the housing 1, and the air outlet of the housing 1 passes through the air duct 6 in the box 5 to be regular The air is blown out after guiding the air, which makes the structure of the air duct machine simple, light and small, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com