Pipeline sludge removing machine

A sludge and pipeline technology, applied in the field of pipeline sludge removal machines, can solve the problems of inability to achieve, cleaning and scraping, etc., to achieve the effect of improving efficiency, wide adaptability, and improving dredging and dredging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

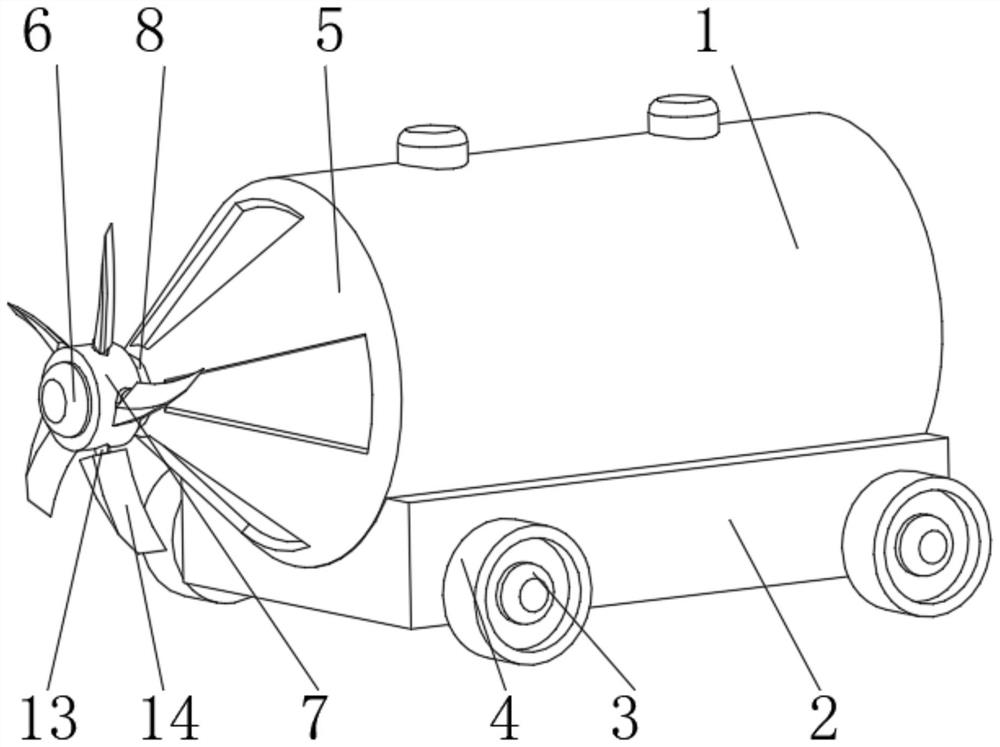

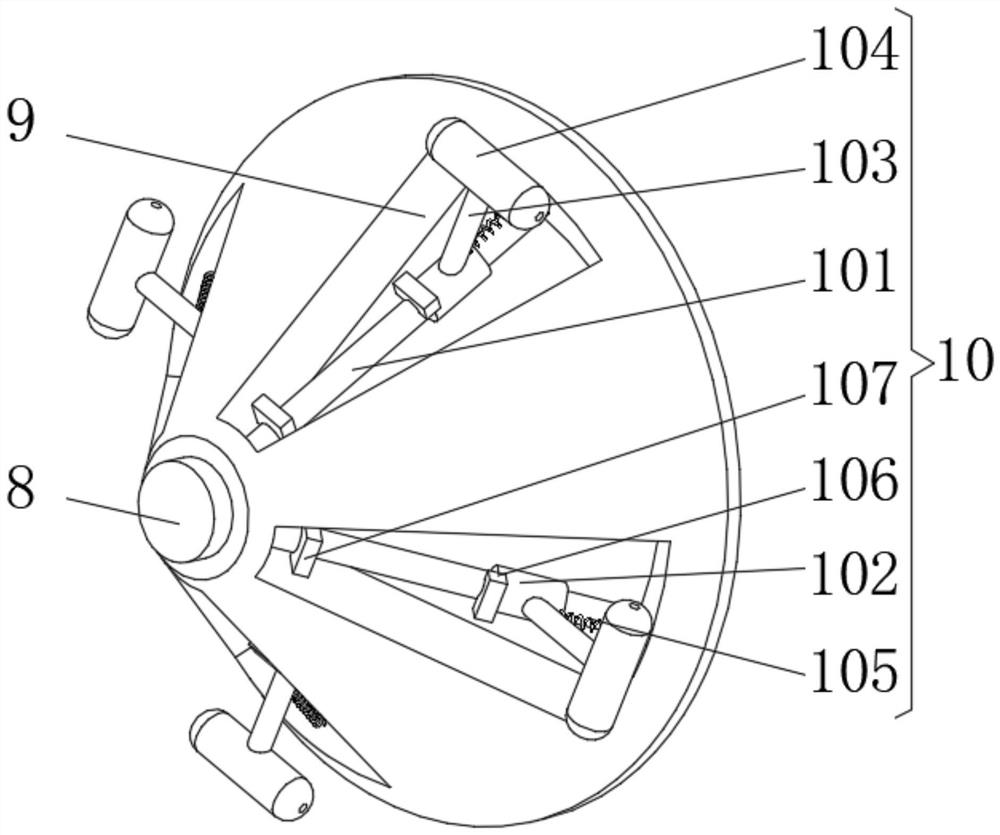

[0029] see Figure 1-3 , the present invention provides a technical solution: a pipeline sludge removal machine, including a housing 1, the bottom of the housing 1 is fixedly connected with a base 2, one side of the base 2 is symmetrically installed with a connecting shaft 3, and the end of the connecting shaft 3 is far away from the base 2 The moving wheel 4 is symmetrically connected, and one side of the shell 1 is rotatably connected with a conical shell 5, and the side of the conical shell 5 away from the shell 1 is equipped with a rotary motor 6, and the output end of the rotary motor 6 is rotatably connected with a rotary disc 7, and the rotating disc 7 is rotated. The side of the disk 7 away from the rotary motor 6 is fixedly connected with a connecting column 8, and the end of the connecting column 8 away from the rotating disk 7 is fixedly connected with the conical casing 5, and the outside of the conical casing 5 is uniformly provided with a device groove 9, and the ...

Embodiment 2

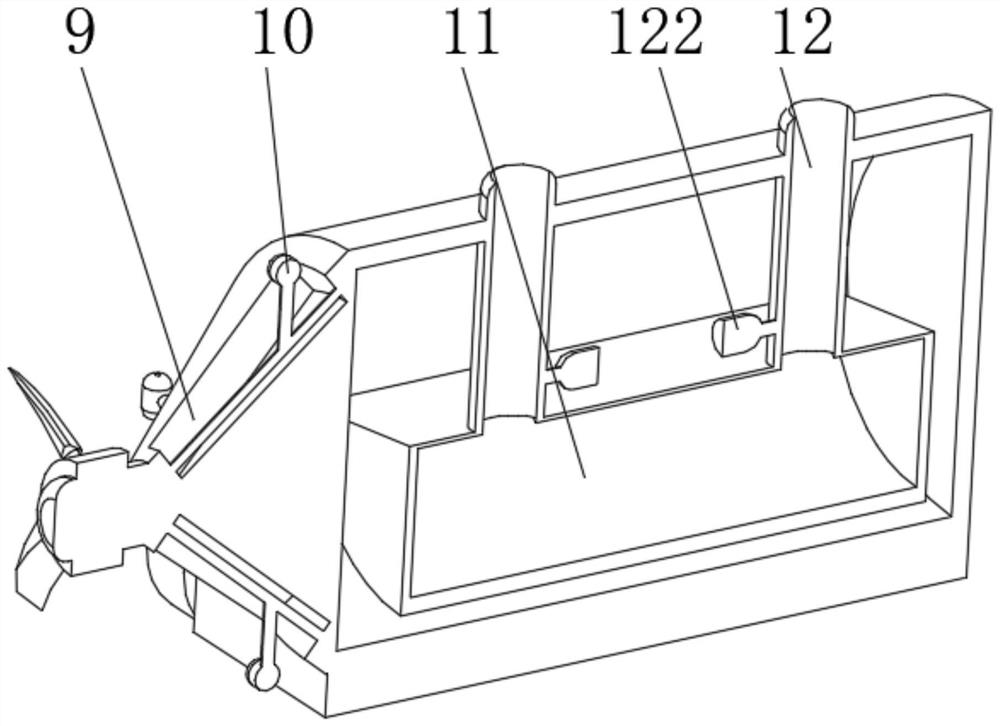

[0036] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a water storage frame 11 is installed inside the casing 1, and a water spray device 12 is evenly installed on one side of the water storage frame 11, and the water spray device 12 includes a water delivery pipe 121, one end of the water delivery pipe 121 communicates with the water storage frame 11, a water pump 122 is installed on the outside of the water delivery pipe 121 close to the water storage frame 11, and a semicircular arc plate is installed on the inner wall of the water delivery pipe 121 away from the water storage frame 11 123 , a water outlet 124 is evenly opened on one side of the semicircular arc plate 123 , and a water retaining plate 125 is slidably connected to the inner side of the semicircular arc plate 123 , and one side of the water retaining plate 125 runs through the water outlet 124 .

[0037] One side of semicircle arc plate 123 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com