Mud scraper for settling ponds of waterworks

A technology for water plants and sedimentation tanks, which is used in sedimentation separation, feeding/discharging devices for sedimentation tanks, chemical instruments and methods, etc. Solve the effect of excessive wear, prolong service life and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

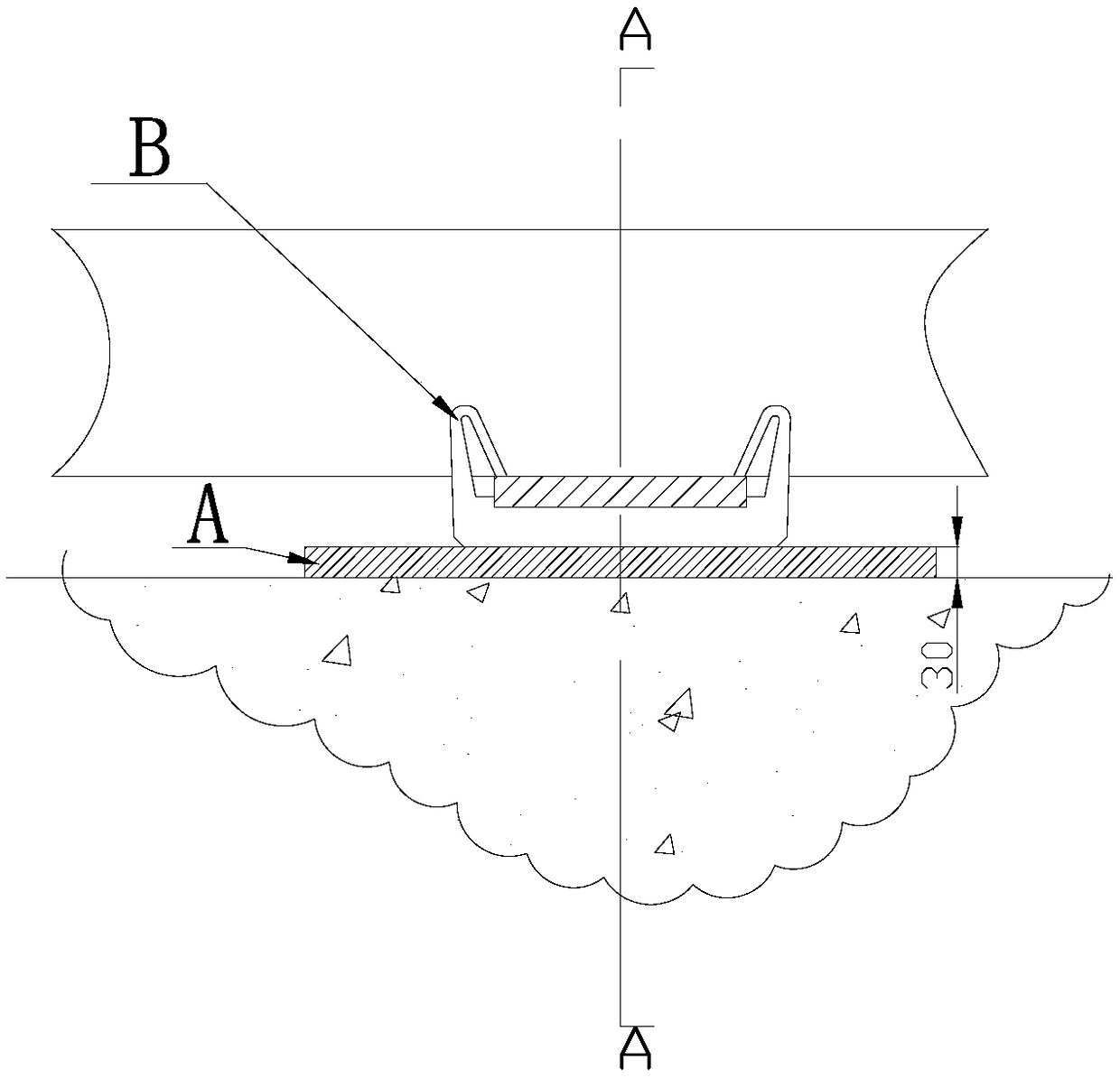

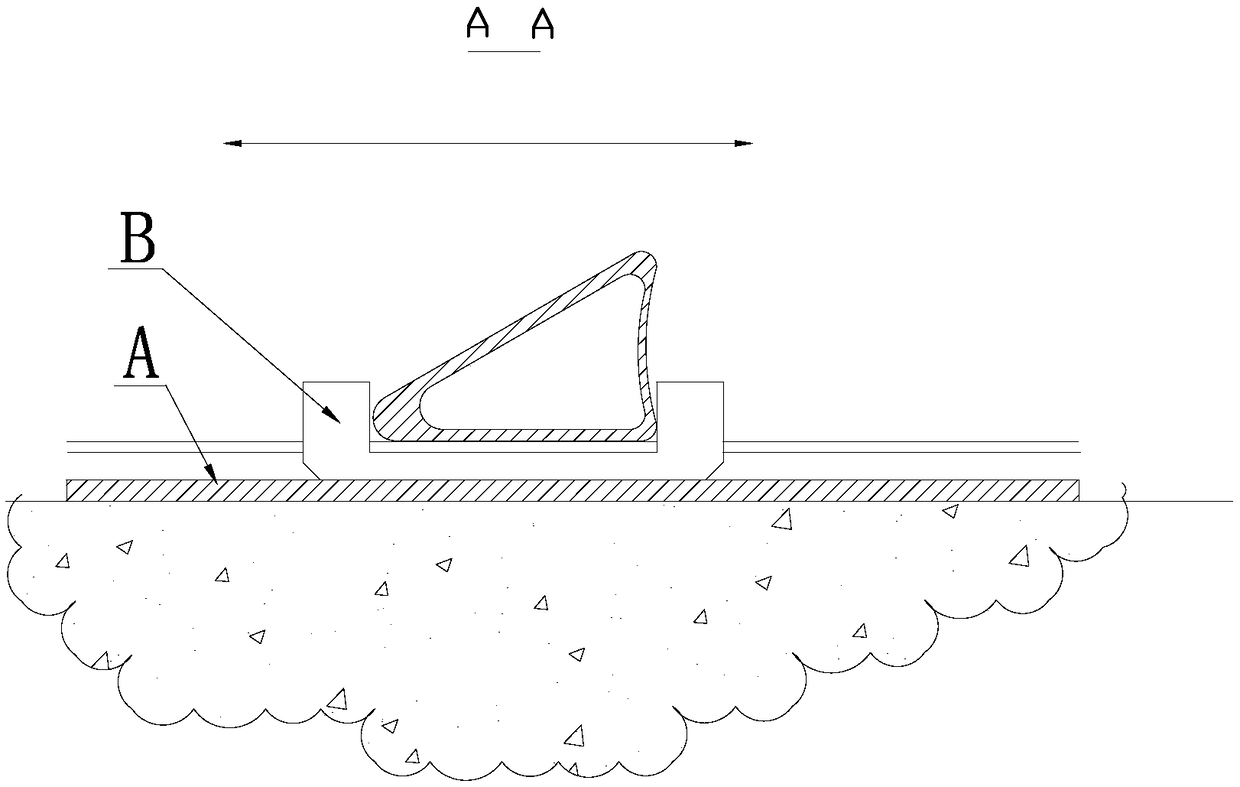

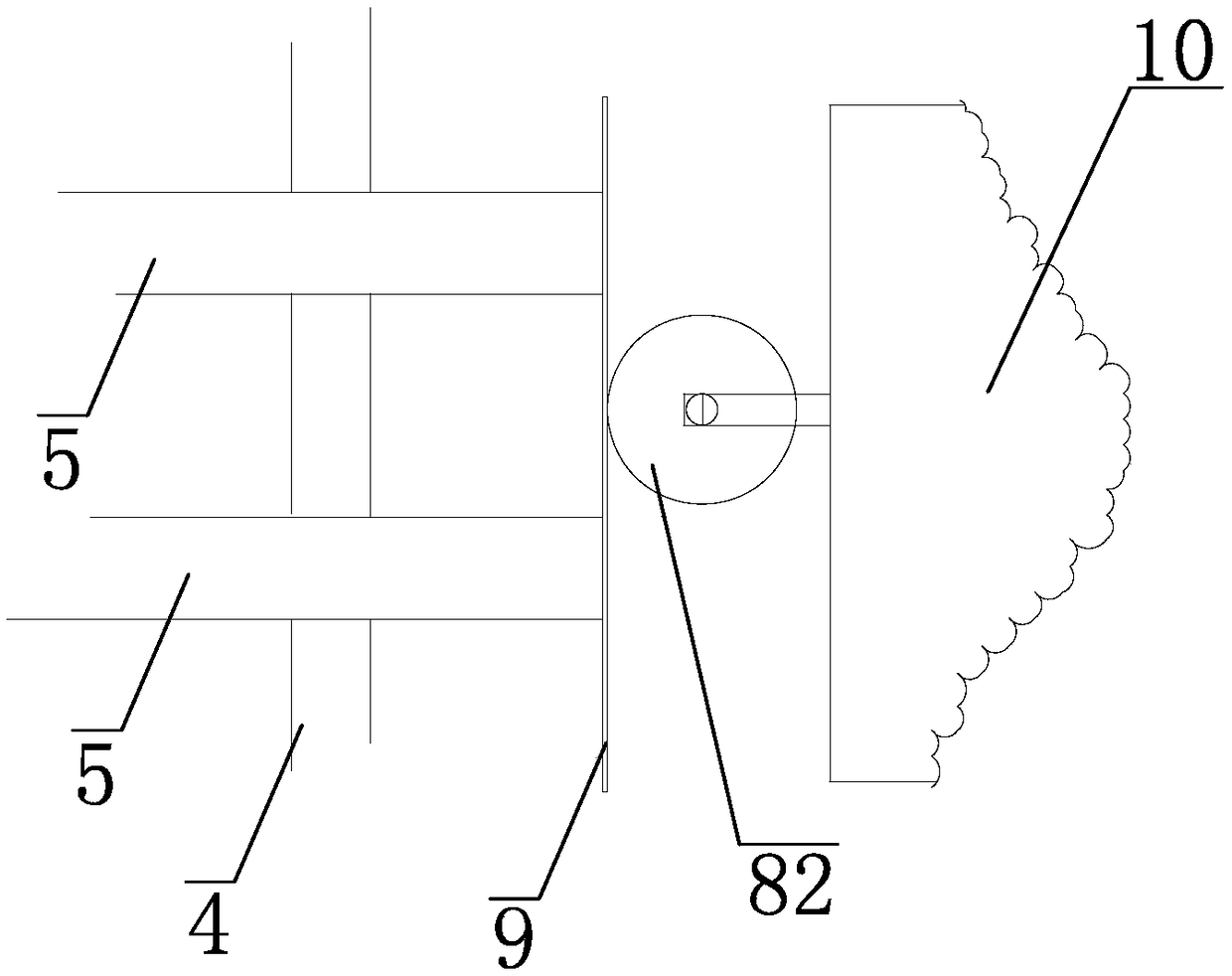

[0023] Such as Figure 3-7 As shown, a mud scraper for a sedimentation tank of a waterworks includes a power unit 1, a power transmission device 2 and a mud scraper 3; wherein the mud scraper 3 is a plurality of channel steel 4 distributed in parallel, and the upper end surface of the channel steel 4 A number of scrapers 5 are fixed, and a number of balls 6 are rolled on the bottom of the channel steel 4 .

[0024] A guide rail plate 7 is provided at the bottom of the sedimentation tank 10, and the balls 6 are located on the guide rail plate 7.

[0025] Several said scrapers 5 are vertically distributed with the channel steel 4, and said scrapers 5 are right-angled triangles. fixed.

[0026] A groove 41 is arranged on the channel steel 4, and the width of the groove 41 is slightly larger than the diameter of the ball; the longitudinal direction of the groove 41 is provided with a front and rear flat steel baffle plate 42; Small, but the groove 41 will not clamp the ball 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com