Large-span steel structure roof hoisting construction method in complex environment

A technology with complex environments and construction methods, applied in the direction of roofs, building components, building structures, etc., can solve the problems of unable to guarantee the synchronous operation of cranes, installation deviation structure collision, affecting installation projects, etc., to improve operation safety, avoid side effects. The effect of partial and simplified construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

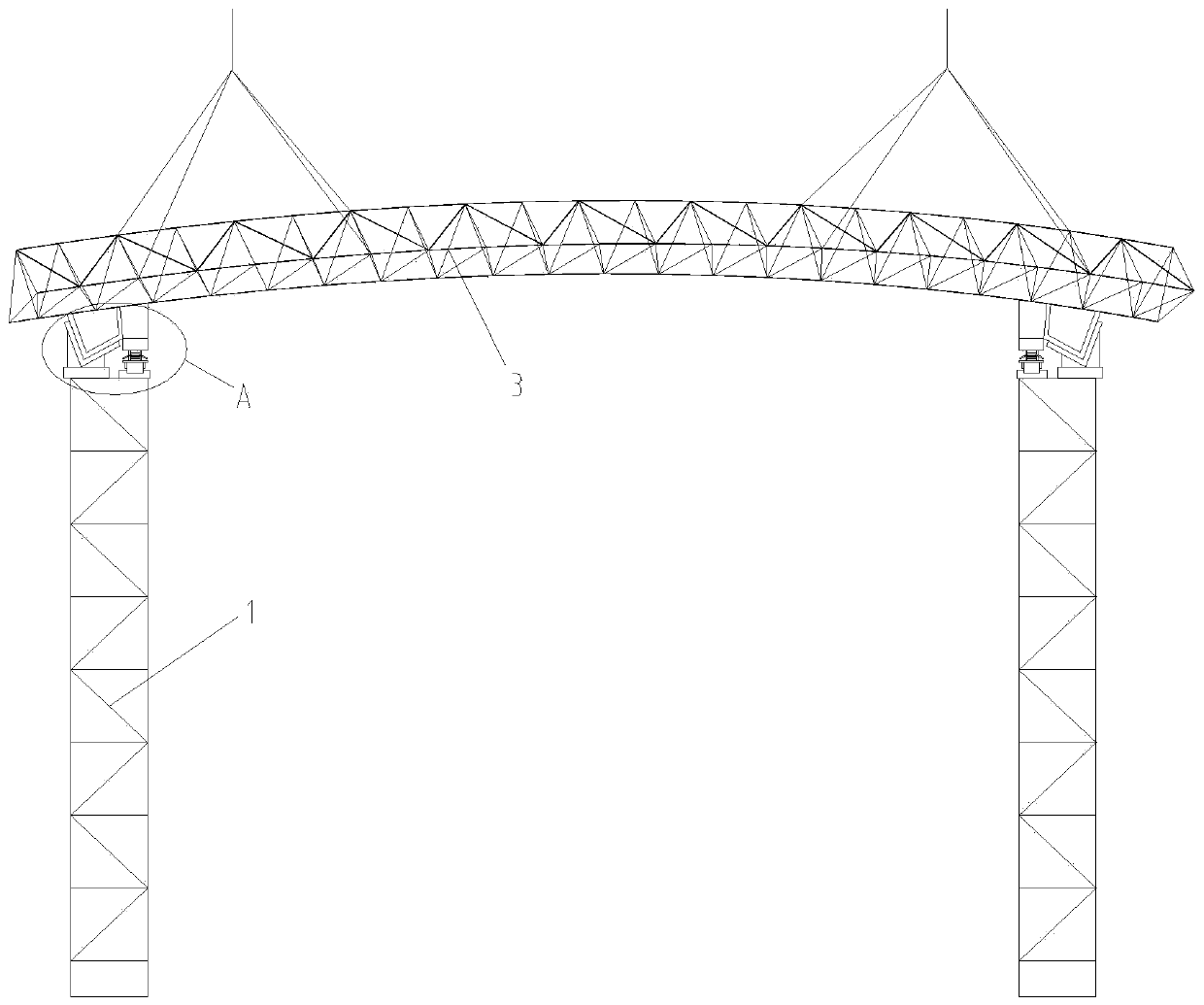

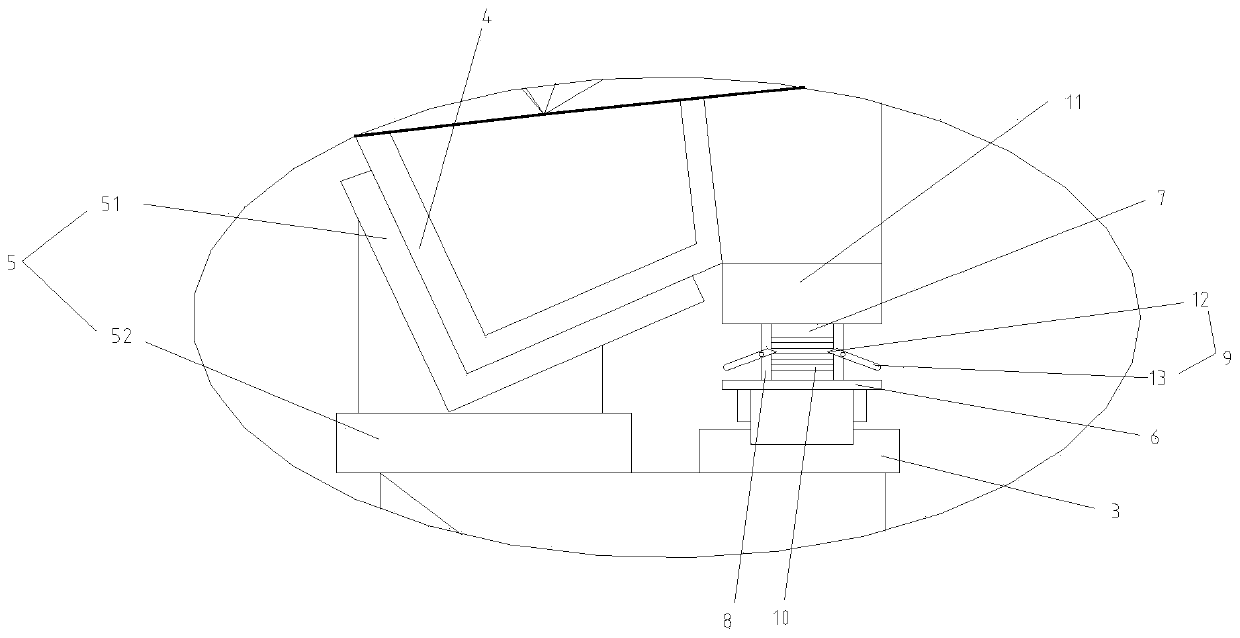

[0022] refer to Figure 1 to Figure 2 As shown, a hoisting construction method of a large-span steel structure roof in a complex environment includes the following steps,

[0023] S1, fixedly install a walking track 2 on the top of the preset vertical support column 1 on both sides, and ensure that the walking track 2 is located on the same horizontal plane;

[0024] S2, assembling each short-shaped steel frame into a complete segmented steel truss roof 3, and fixing a fixing part 4 and a walking wheel assembly on the bottom of the steel truss roof 3;

[0025] S3. Divide three equal points evenly on the segmented steel truss roof 3, and set four lifting points evenly around each equal point, and use two crawler cranes to simultaneously lift the steel truss roof through the chain The walking wheel assembly at the bottom of the cover 3 matches the running track 2, and the angle between the chain and the steel truss roof 3 is 45°;

[0026] S4. Continue to use the crawler crane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com