Double-feedback fluid-control one-way throttle velocity modulation composite valve

A liquid-controlled one-way, throttling and speed-regulating technology, which is applied in the direction of wellbore/well valve devices, undisturbed core extraction devices, wellbore/well components, etc. Large and other problems, to achieve the effect of protecting the motor and preventing lateral deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

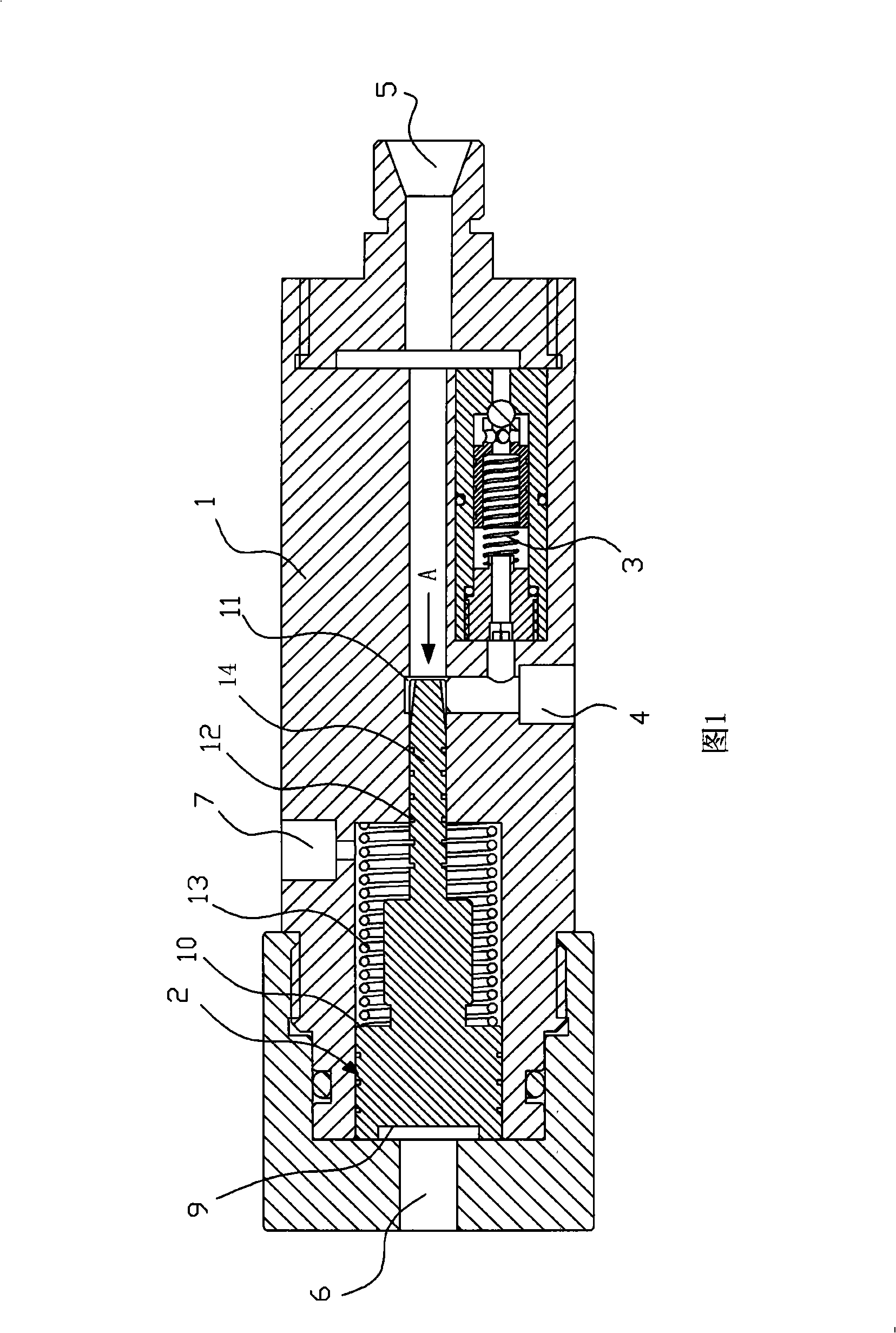

[0015] As shown in Figure 1, the present invention includes: a valve body 1, on which a first oil passage 4, a throttle port 11, and a second oil passage 5 for high-pressure oil inlet and outlet are sequentially arranged in series on the valve body 1, and There is a throttle valve 2 that controls the conduction or disconnection of the first oil passage 4 and the second oil passage 5 . A check valve 3 is further arranged in parallel between the first oil passage 4 and the second oil passage 5 .

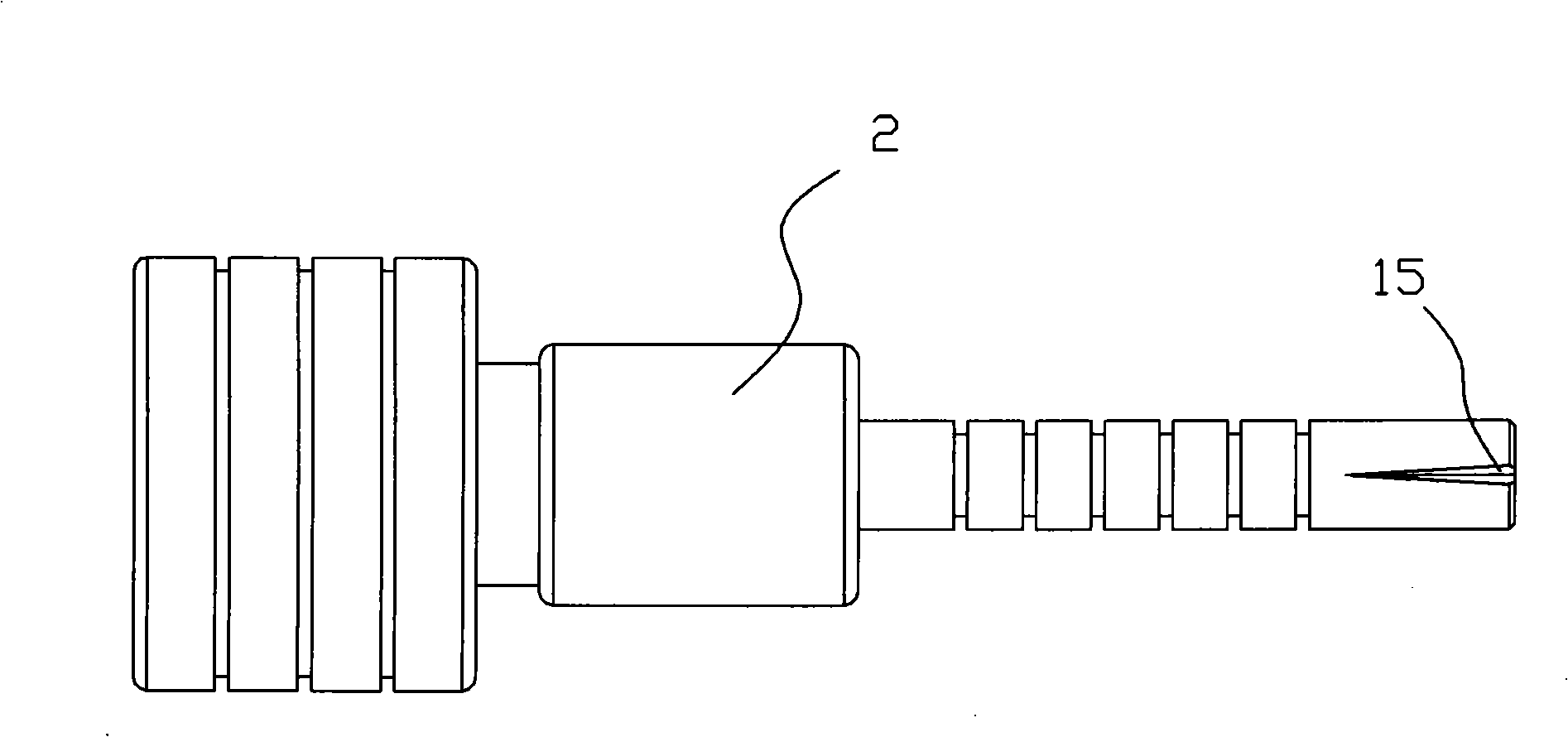

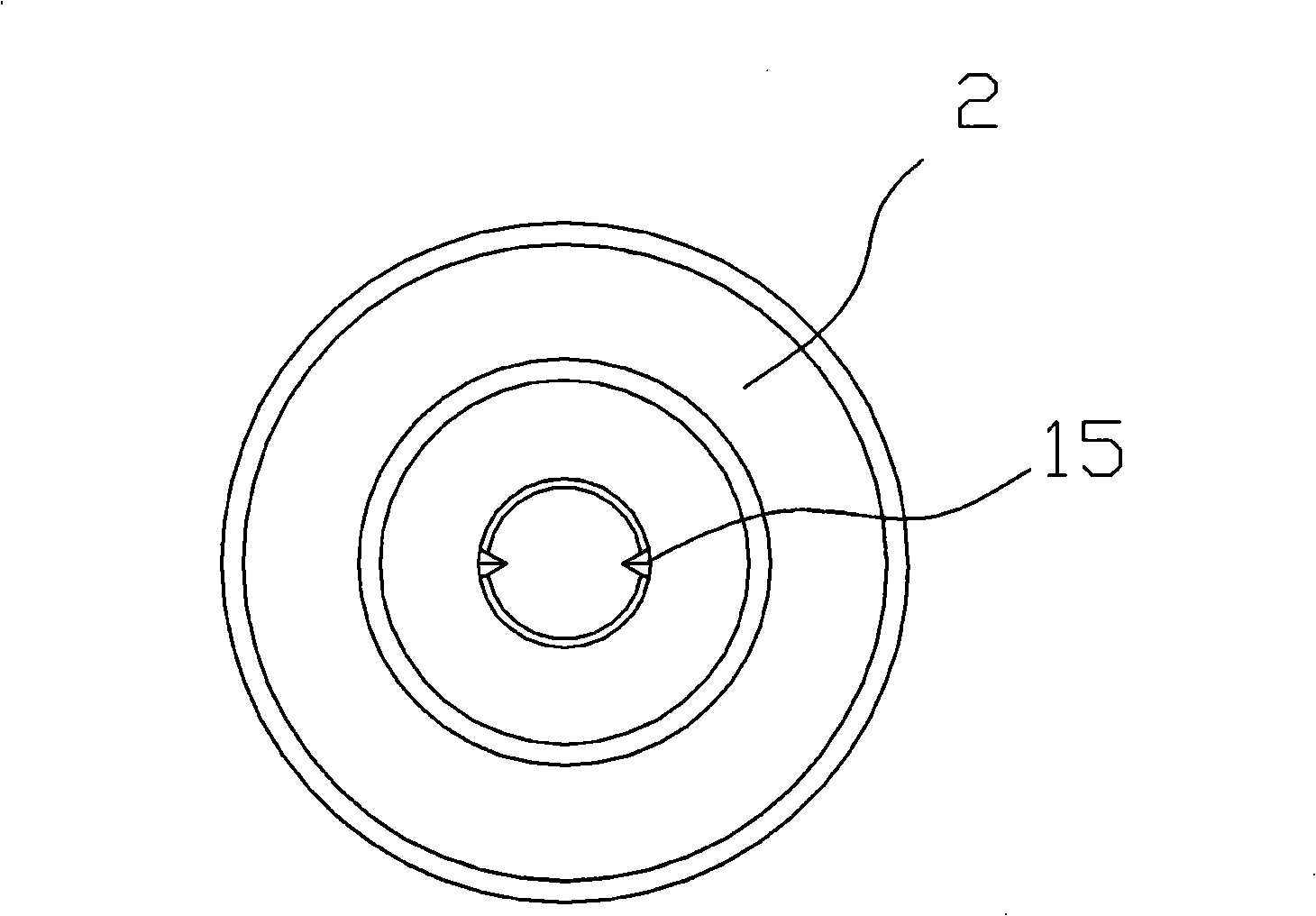

[0016] As shown in Figures 1, 2 and 3, the throttle valve 2 includes a throttle valve core 14 and a throttle valve spring 13, one end of the throttle valve core 14 is inserted into the throttle port 11, and the throttle valve spring 13 is set On the throttle valve spool 14 , an elastic force away from the throttle port 11 is exerted on the throttle valve spool 14 , that is, the force in direction A in the figure.

[0017] The conduction or disconnection of the first oil circuit 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com