Conveying device

A technology for conveying devices and conveyor belts, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc. It can solve the problems of wheel hub pushing deviation, affecting the normal operation of detection work, and inability to adjust the position, so as to achieve accurate lateral adjustment and prevent The effect of deviation and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

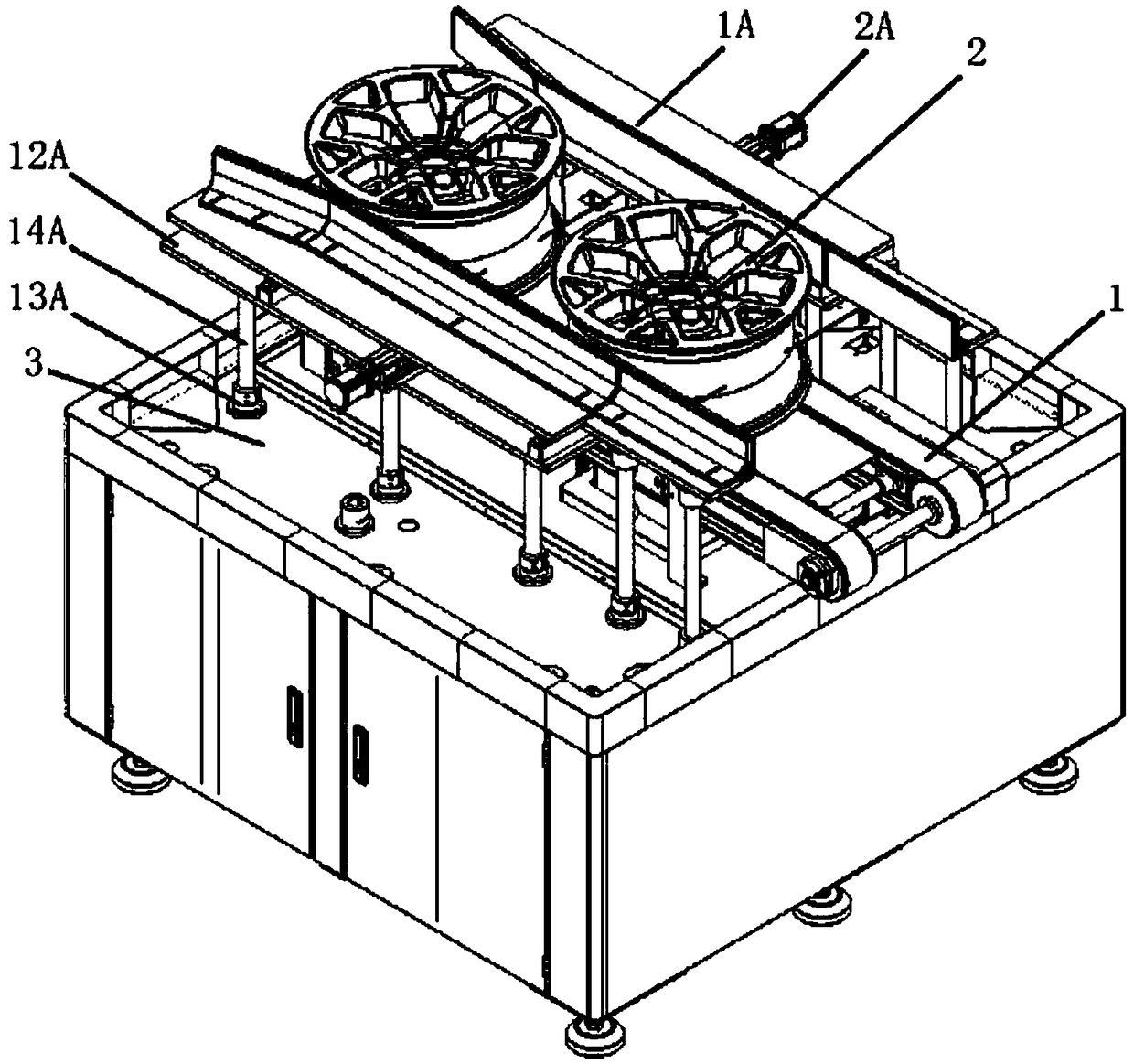

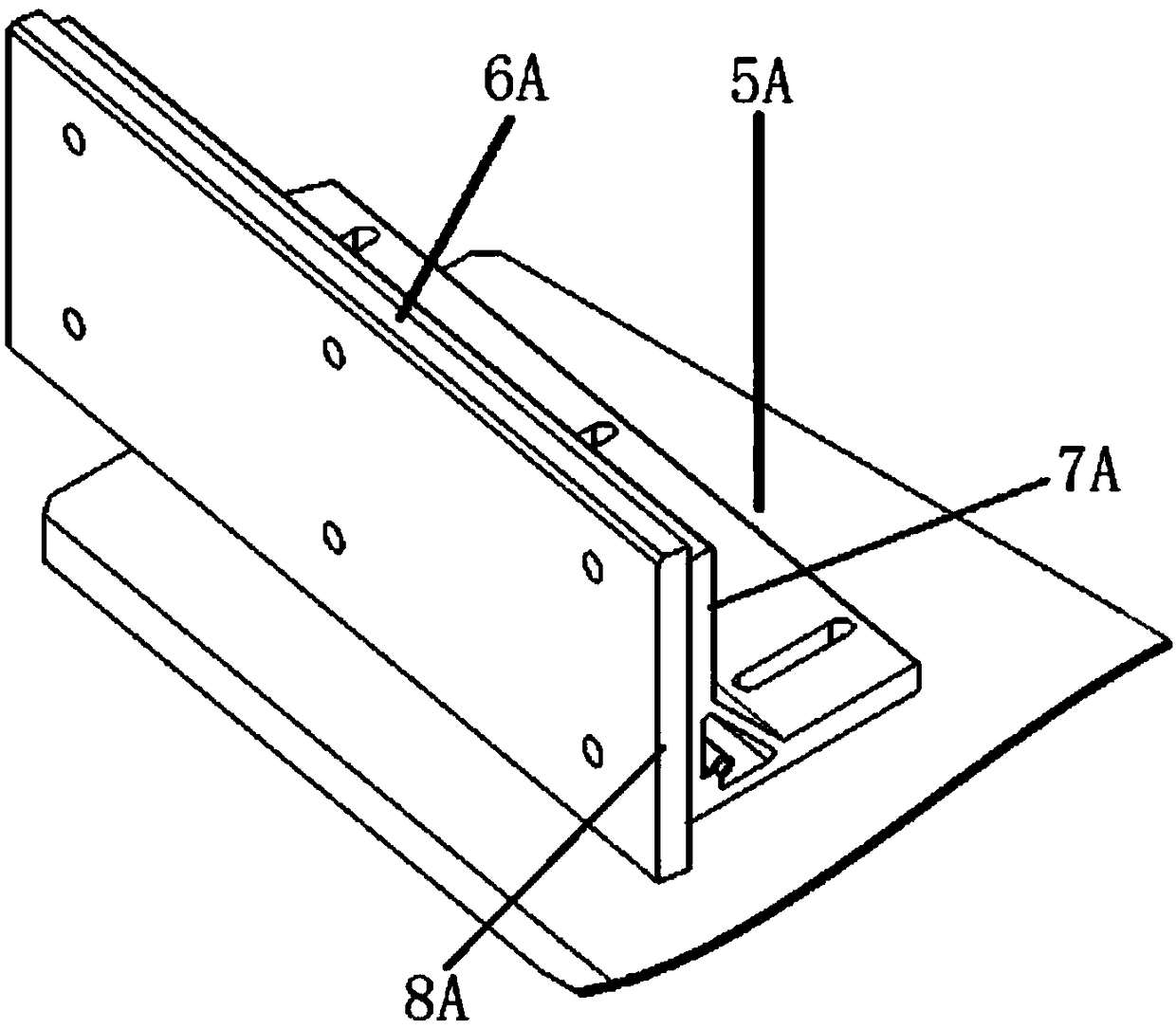

[0066] This embodiment provides a delivery device, such as figure 1 , Figure 4 As shown, it includes a conveying track 1, an adjustment structure and a mounting plate 12A.

[0067] The conveying track 1 has a conveying surface for conveying objects, and the object is a wheel hub 2 , and the conveying surface of the conveying track 1 is suitable for carrying the wheel hub 2 .

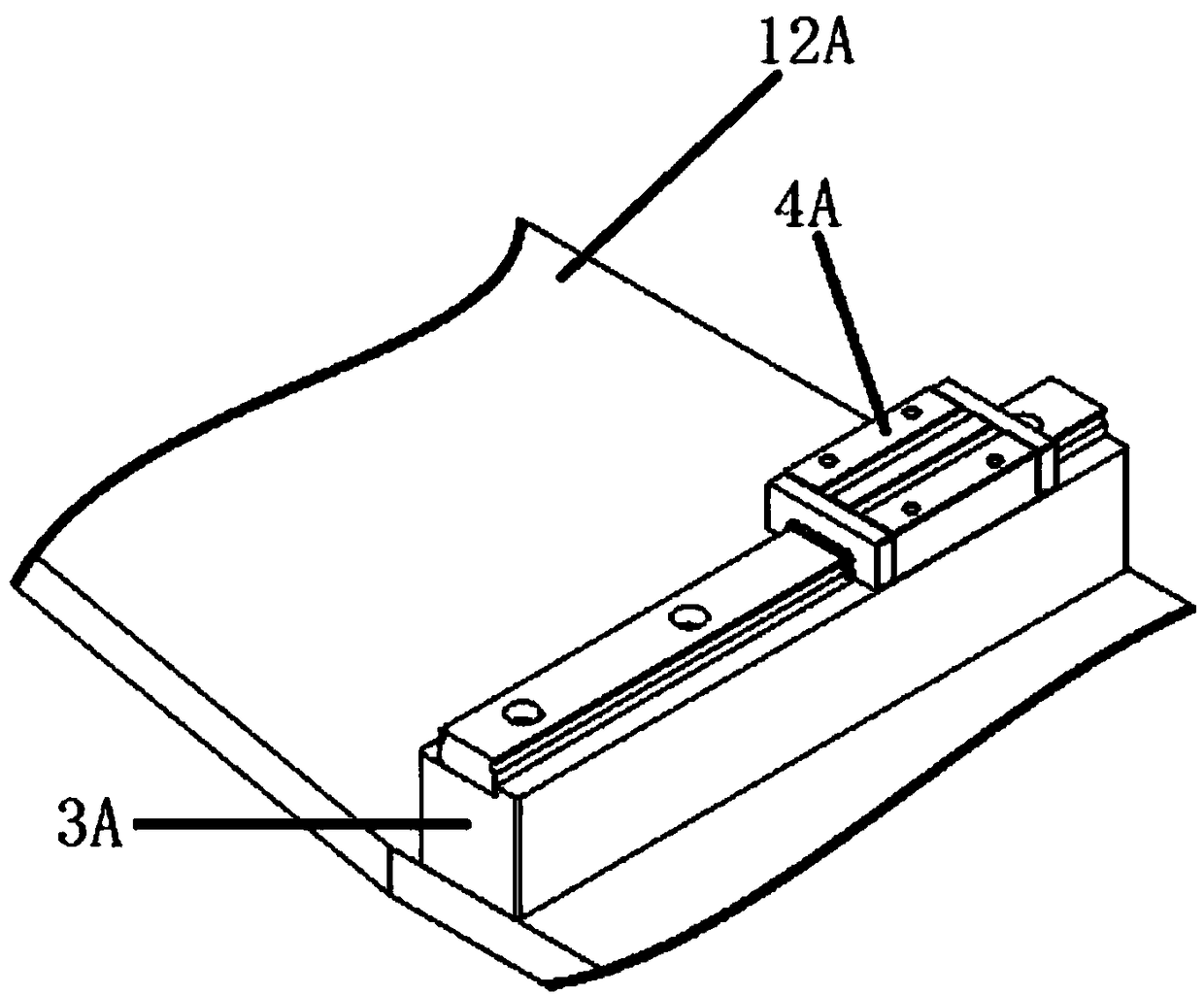

[0068] The adjustment structure is installed on the installation plate 12A, and the installation plate 12A is fixedly installed on the base 3 through the vertical adjustment structure.

[0069] The vertical adjustment structure includes a connecting base 13A and a column 14A, and the connecting bases 13A are fixed on the mounting plate 12A and the base 3 oppositely in pairs, and the connecting bases 13A opposite in pairs are The upright post 14A is supported therebetween, and the upright post 14A is inserted into the connection seat 13A and connected with the connection seat 13A in a tight manner.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com