High-pressure common rail pump and oil inlet and outlet valve module for same

A high-pressure common rail and oil inlet and outlet valve technology, applied in the field of common rail, can solve the problems of high machining accuracy, cumbersome processing procedures, and poor sealing, and achieve high connection strength, smooth oil inlet process, and not easy to bend laterally Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

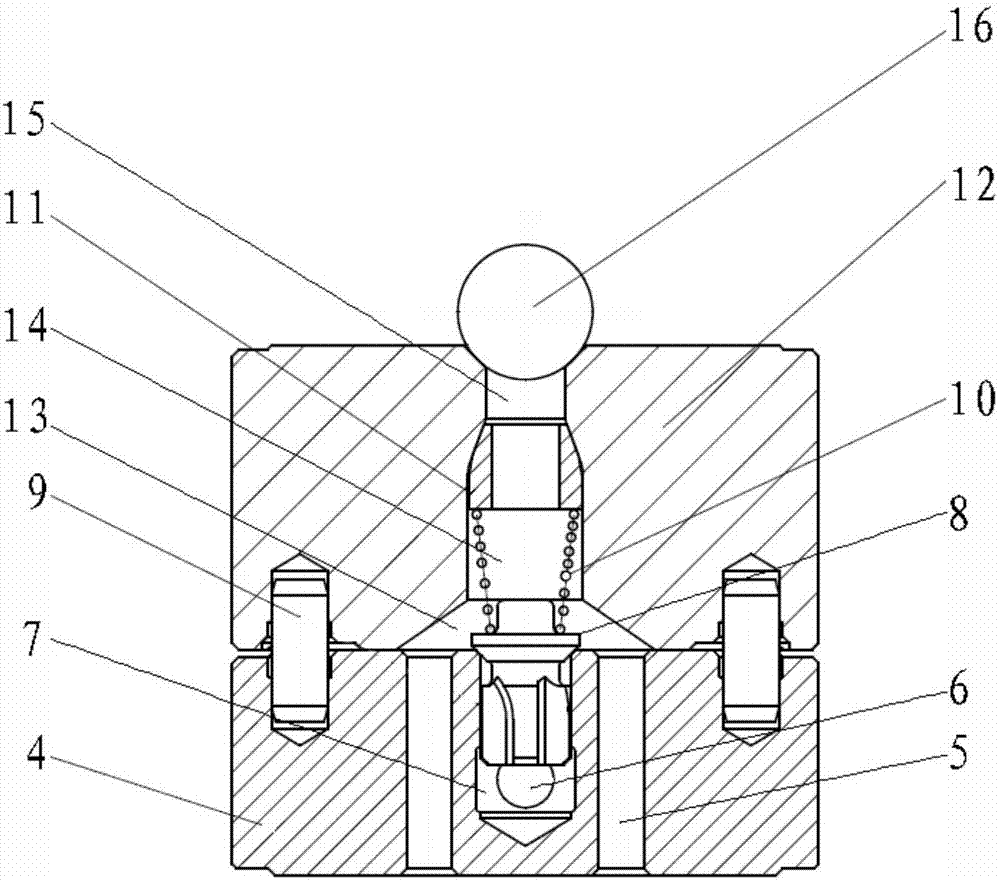

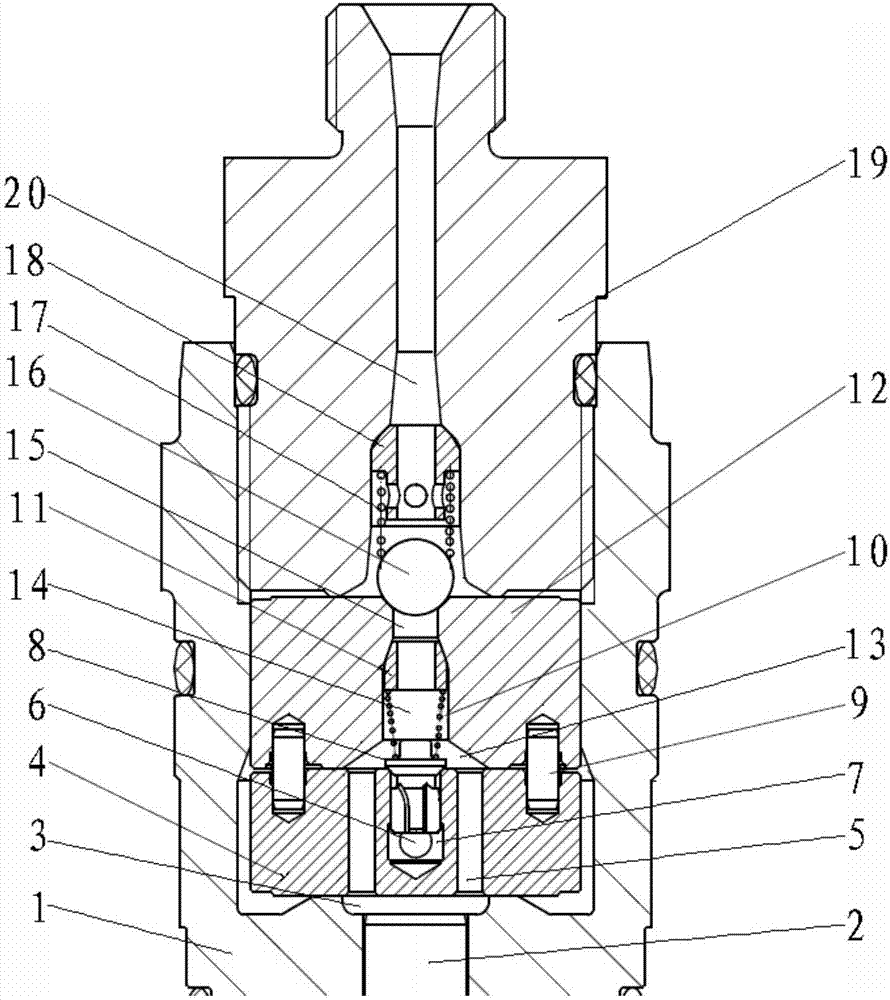

[0031] Such as figure 1 with figure 2 As shown, this embodiment is used for an oil inlet and outlet valve assembly of a high-pressure common rail pump, including an oil inlet mechanism and an oil outlet mechanism. In actual use, both the oil inlet mechanism and the oil outlet mechanism are installed in the plunger sleeve 1 of the high-pressure common rail pump. top of the institution.

[0032] Specifically, the oil inlet mechanism includes: an oil inlet valve seat 4, an oil inlet valve core 8 and an elastic part of the oil inlet valve.

[0033] The top end of the oil inlet valve seat 4 is provided with an inner guide hole 7 along the axial direction, and the bottom end of the inner guide hole 7 communicates with the oil inlet hole 6. The opening end of 7 is provided with inner guiding slope.

[0034] The oil inlet valve core 8 is sequentially provided with a columnar connecting portion, an inverted tapered sealing portion and a guiding portion from the top end to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com