Soft material fluidity detection device

A detection device and fluidity technology, applied in the directions of flow characteristics, measurement device, analysis materials, etc., can solve the problems of complex steps, large random errors, poor device stability, etc., and achieve good real-time detection, wide application range, and convenient experimentation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

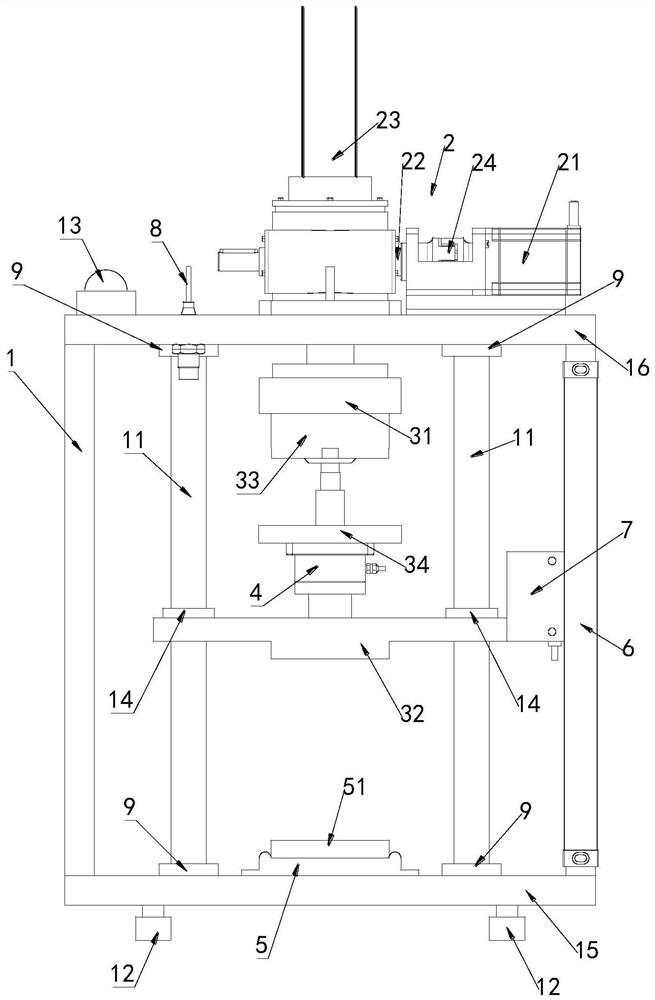

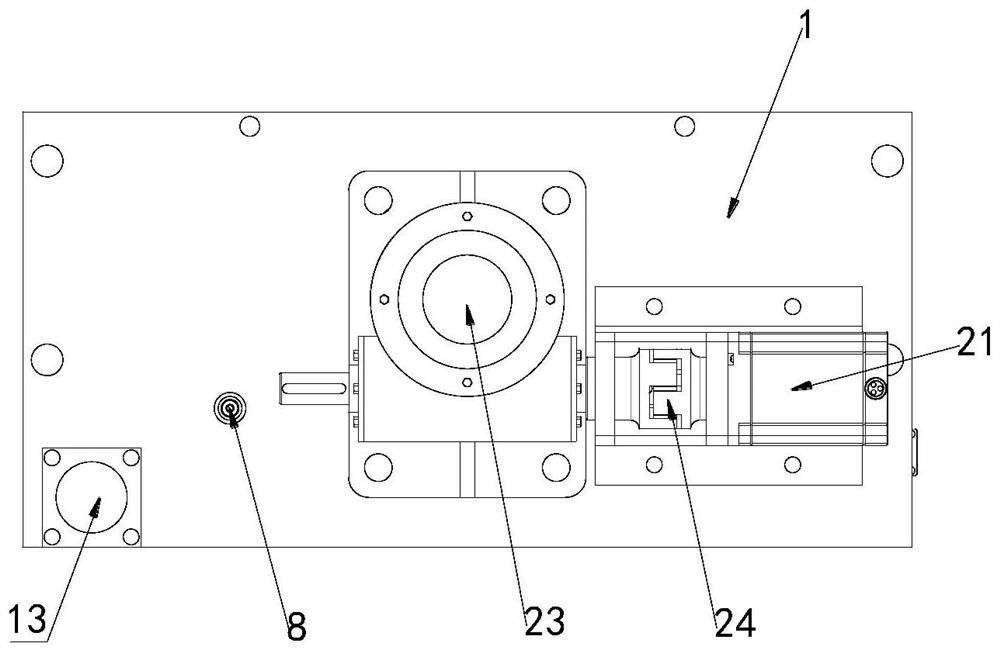

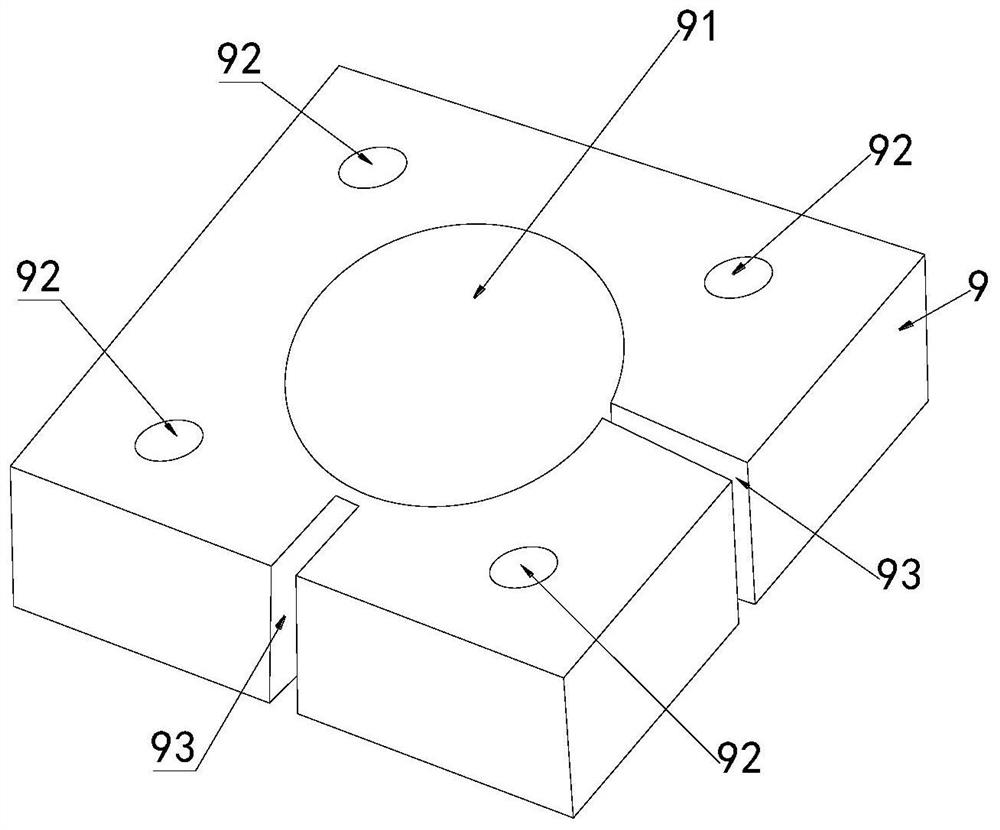

[0034] Such as figure 1 and figure 2 As shown, a soft material fluidity detection device of this embodiment includes a bracket 1, a driving device 2, an upper pressure mechanism 3, a pressure detection device 4, a lower support part 5 and a displacement detection device, and the driving device 2 is installed On the bracket 1, the driving device 2 is connected with the upper pressing mechanism 3 and drives the upper pressing mechanism 3 to move downward, and the lower supporting part 5 is located in the bracket 1 and on the upper Below the pressing mechanism 3 , the pressure detection device 4 is installed on the upper pressing mechanism 3 , and the displacement detecting device is installed on the support 1 and detects the displacement of the upper pressing mechanism 3 .

[0035]In this embodiment, the driving device is used to drive the upper pressing mechanism to move downward, and the upper pressing mechanism is used to squeeze the material on the lower support part. The ...

Embodiment 2

[0038] Such as figure 1 and figure 2 As shown, a soft material fluidity detection device of this embodiment includes a bracket 1, a driving device 2, an upper pressure mechanism 3, a pressure detection device 4, a lower support part 5 and a displacement detection device, and the driving device 2 is installed On the bracket 1, the driving device 2 is connected with the upper pressing mechanism 3 and drives the upper pressing mechanism 3 to move downward, and the lower supporting part 5 is located in the bracket 1 and on the upper Below the pressing mechanism 3 , the pressure detection device 4 is installed on the upper pressing mechanism 3 , and the displacement detecting device is installed on the support 1 and detects the displacement of the upper pressing mechanism 3 .

[0039] Such as figure 1 As shown, the upper pressing mechanism 3 of this embodiment includes a flange 31 and a pressure plate 32, the flange 31 is connected to the driving device 2, the pressure plate 32 ...

Embodiment 3

[0053] Such as figure 1 and figure 2 As shown, a soft material fluidity detection device of this embodiment includes a bracket 1, a driving device 2, an upper pressure mechanism 3, a pressure detection device 4, a lower support part 5 and a displacement detection device, and the driving device 2 is installed On the bracket 1, the driving device 2 is connected with the upper pressing mechanism 3 and drives the upper pressing mechanism 3 to move downward, and the lower supporting part 5 is located in the bracket 1 and on the upper Below the pressing mechanism 3 , the pressure detection device 4 is installed on the upper pressing mechanism 3 , and the displacement detecting device is installed on the support 1 and detects the displacement of the upper pressing mechanism 3 .

[0054] Such as figure 1 As shown, the upper pressing mechanism 3 of this embodiment includes a flange 31 and a pressure plate 32, the flange 31 is connected to the driving device 2, the pressure plate 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com