Device and method for treating oil and gas field produced water by utilizing organic matter degradation self-supply energy

A technology for extracting water and oil and gas fields, applied in mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of increased treatment cost, deformation, lack of continuity, etc., to increase the scale of treatment, improve treatment efficiency, The effect of improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

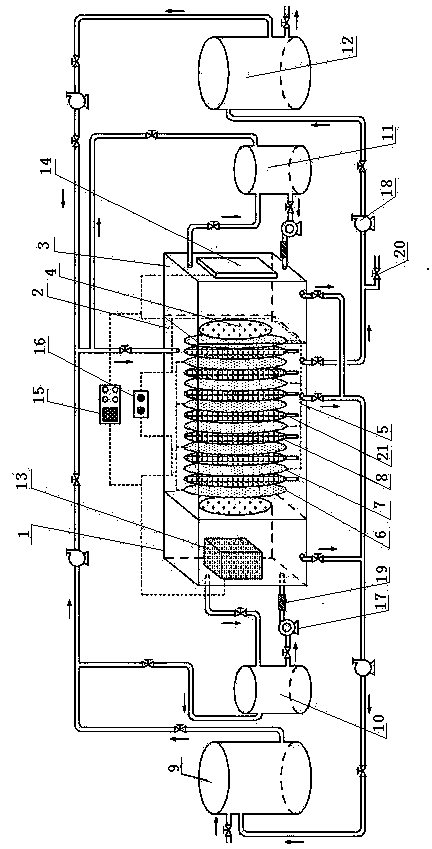

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

[0036] Such as figure 1 As shown, the device for self-supplied treatment of oil and gas field produced water by organic matter degradation includes an anode pool 1, a desalination pool 2, and a cathode pool 3 with a cubic structure of equal height. The volume ratio of the three is 1:2:1. The anode pool 1 and the cathode pool 3 are adjacently arranged in the center and left and right respectively, and there are cut-outs with a diameter of 1 / 2 of the height of the cubic structure in the same space on the side of the anode pool 1, desalination pool 2, and cathode pool 3. The holes are connected to each other, but in order to open the cathode and anode electrochemical reactions and balance the pH value of the system, a cation exchange membrane 4 is installed at the communication positions of the cut holes, so that the desalination pool 2 and the anode pool 1, The desalinatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com