Gravity effect controls viscosity fingering optimization method and device in surfactant flooding

A surfactant and gravity effect technology, applied in earthwork drilling, wellbore/well components, measurement, etc., can solve problems affecting oil displacement efficiency, low viscosity of aqueous solution, and instability of displacement front

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

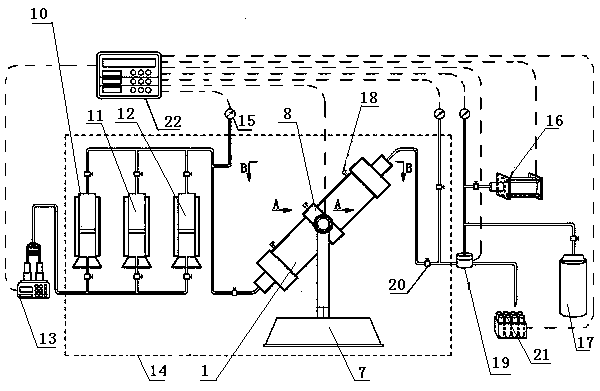

[0049] Below in conjunction with accompanying drawing, the present invention will be further described:

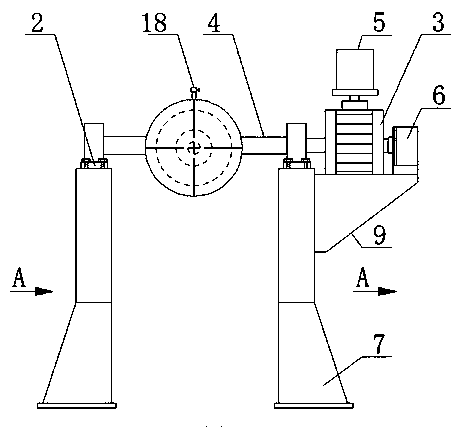

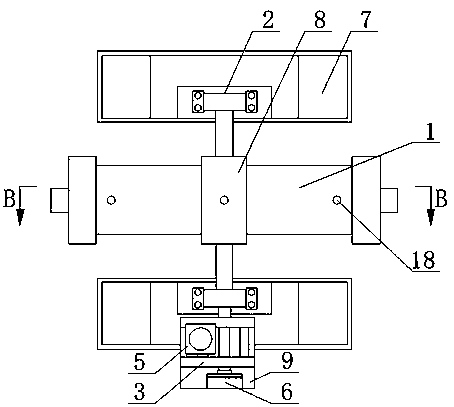

[0050] like figure 1 As shown, the device used in the viscosity fingering optimization method in surfactant flooding controlled by gravity effect includes a stainless steel sand packing physical model 1 with a diameter of 50 mm and a length of 500 mm connected to the turning shaft 4 by a slip joint 8. Wherein one end of the overturning shaft 4 is fixed to the rotating bearing seat 2 on the support frame 7 by bolts, and the other end is connected to the single-head worm gear reducer 3 on the triangular welding platform 9 at a 45° angle between the side of the support frame 7 and the horizontal plane, to obtain The single-head worm gear reducer 3 is driven when it outputs power, so as to carry the sand filling physical model 1 to rotate the injection end downward and the production end upward, so as to realize the change of the inclination angle of the injection-production e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com