A drum feeder

A technology of feeder and drum motor, applied in the field of drum feeder, can solve the problems of reducing the working stability and reliability of the equipment, unable to guarantee the absorption of material liquid, and unable to guarantee the sugar material, so as to reduce the overflow of material and liquid, the principle of Feasible, quick humidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is further described:

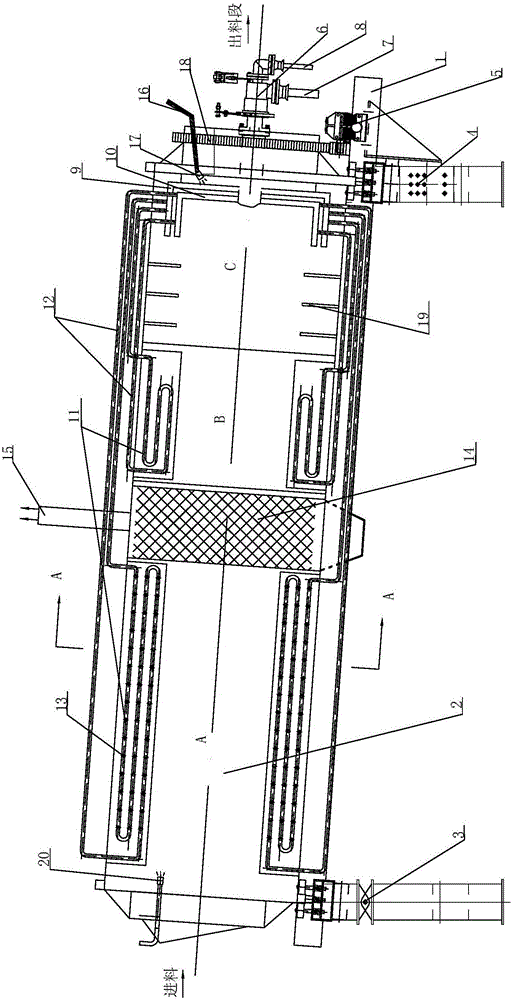

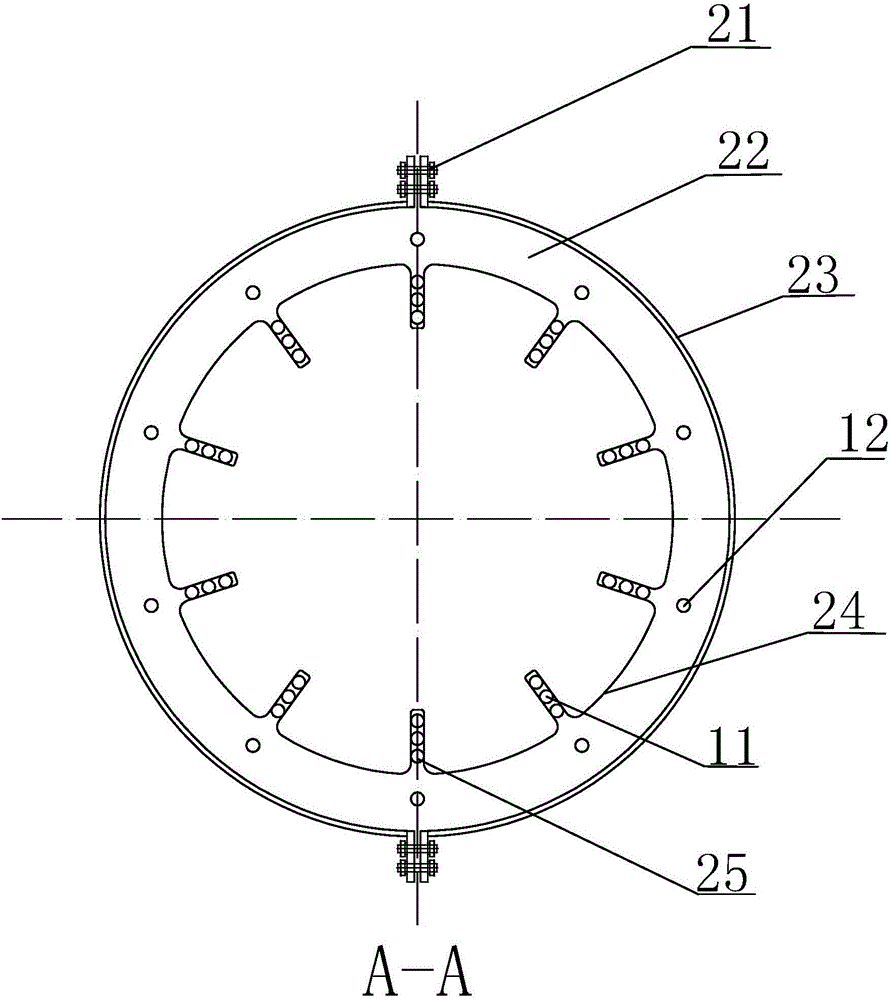

[0021] Such as figure 1 and figure 2 Shown, described a kind of drum feeder, comprises frame 1 and the drum 2 that is installed on frame 1, and drum 2 is driven by the drum motor 5 that is provided with on frame 1, and one end of described frame 1 is provided with Hinge 3, the other end is provided with latch 4, the hinge 3 and latch 4 cooperate to realize the inclination angle of the drum 2 on the frame 1 can be adjusted, it is characterized in that: the drum 2 is divided into a segment A for moistening leaves and a segment B for drying leaves section and feeding section C, the feeding section C section is provided with a single-medium nozzle 17, the single-medium nozzle 17 is connected by a hose 16, the hose 16 is supported by a universal bracket 18, and the drum 2 includes an outer ring fixed cylinder 23. The fastening screw 21 for fastening the outer ring fixing cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com