Patents

Literature

51results about How to "Save gas cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas Detection Apparatus

InactiveUS20090324449A1Reduce power consumptionLow costChemical analysis using combustionMaterial analysis by optical meansSignal processing circuitsFlammable gas

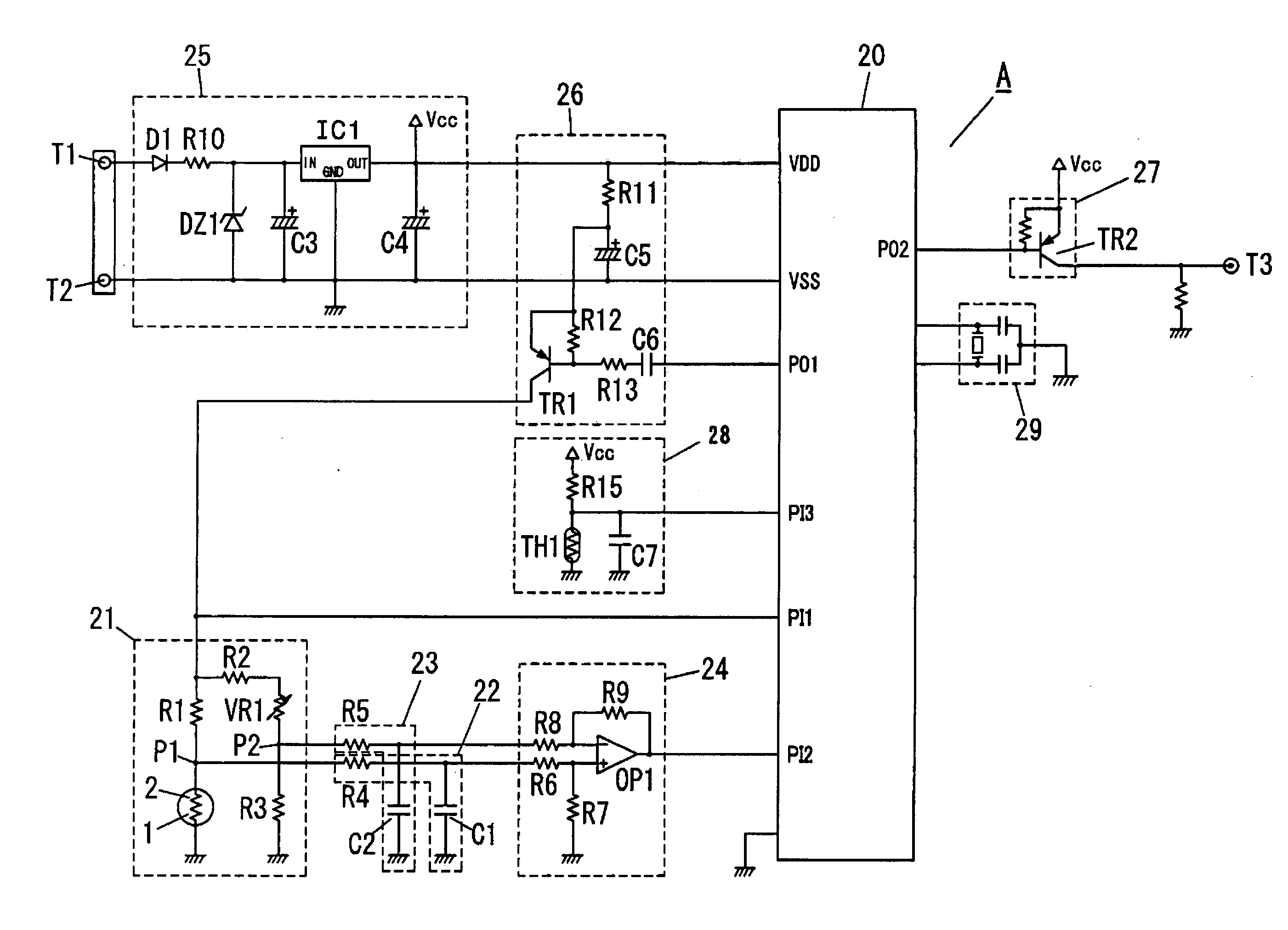

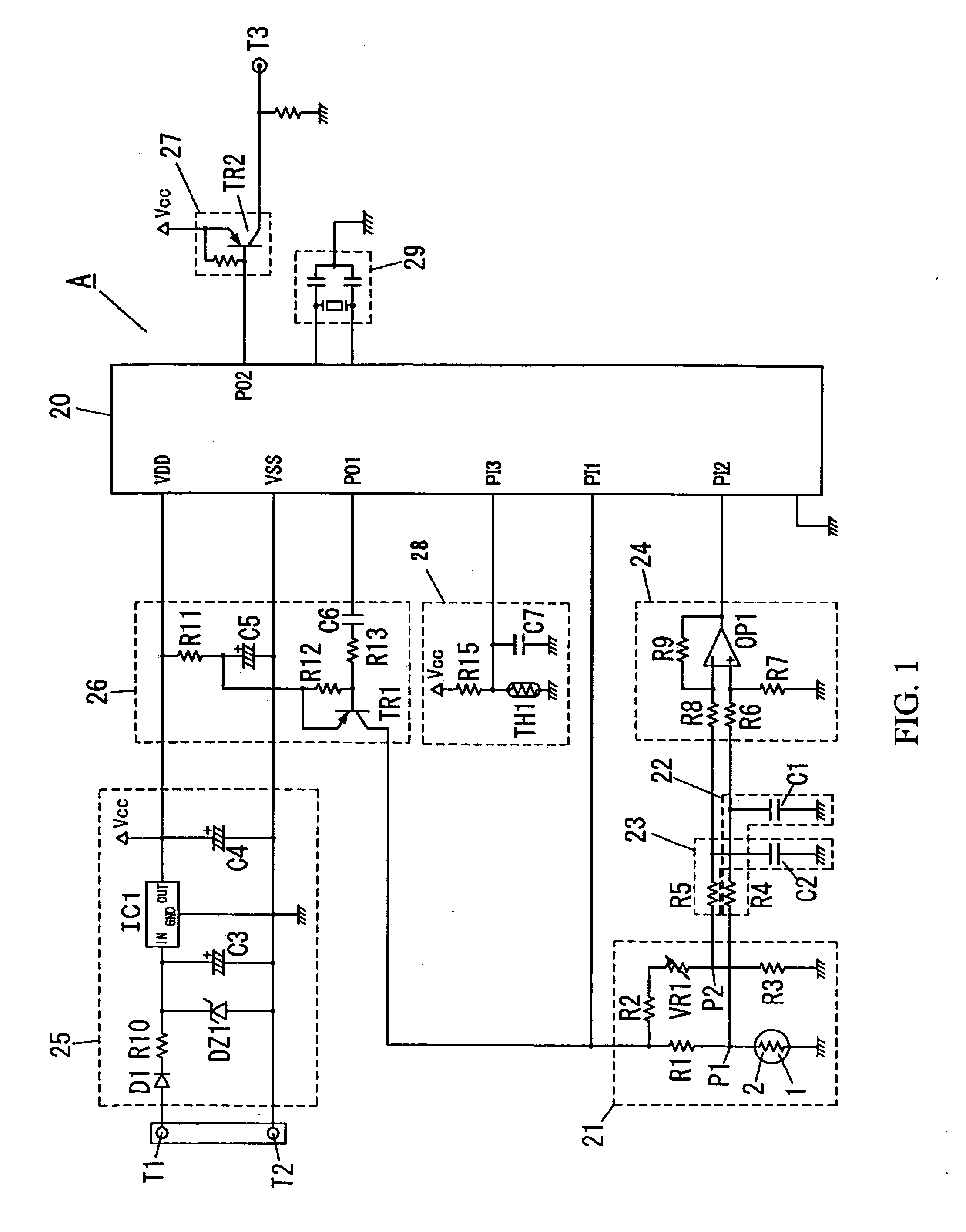

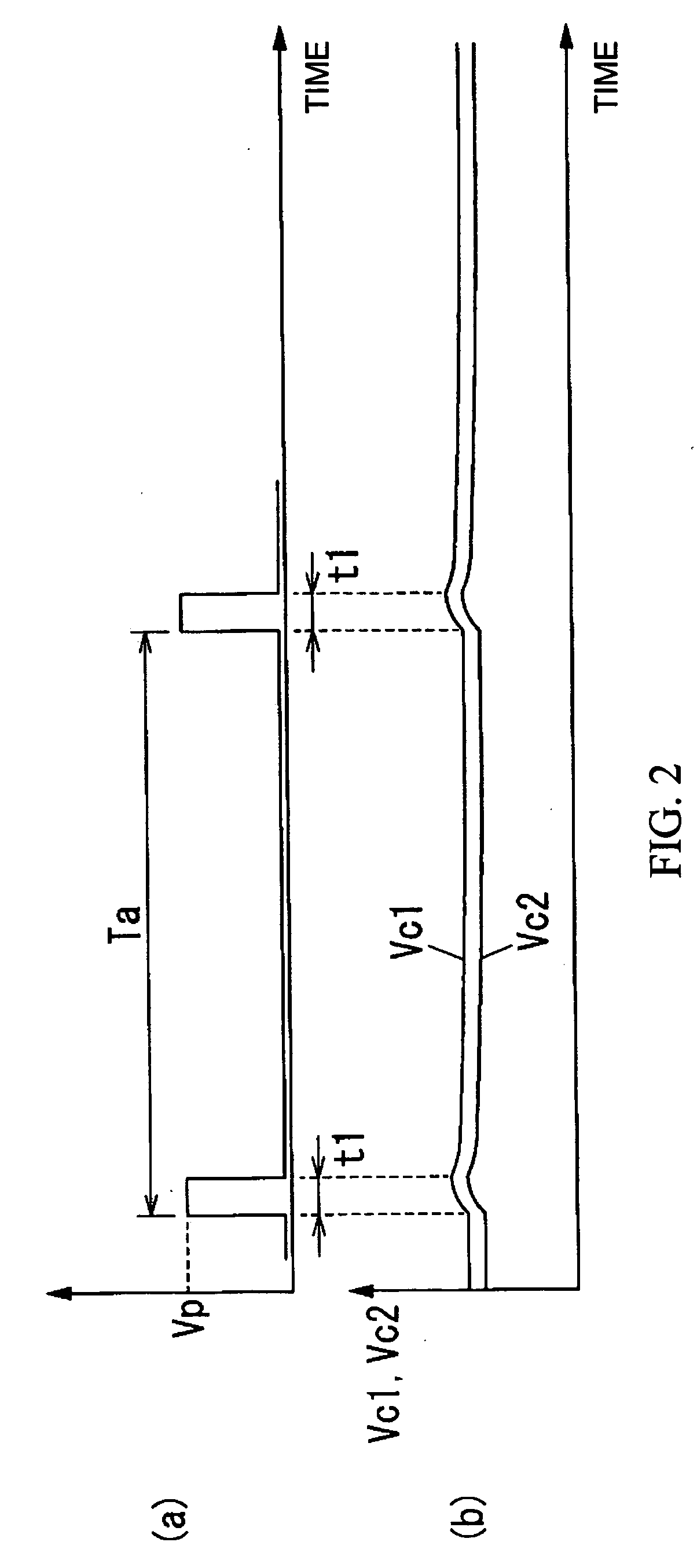

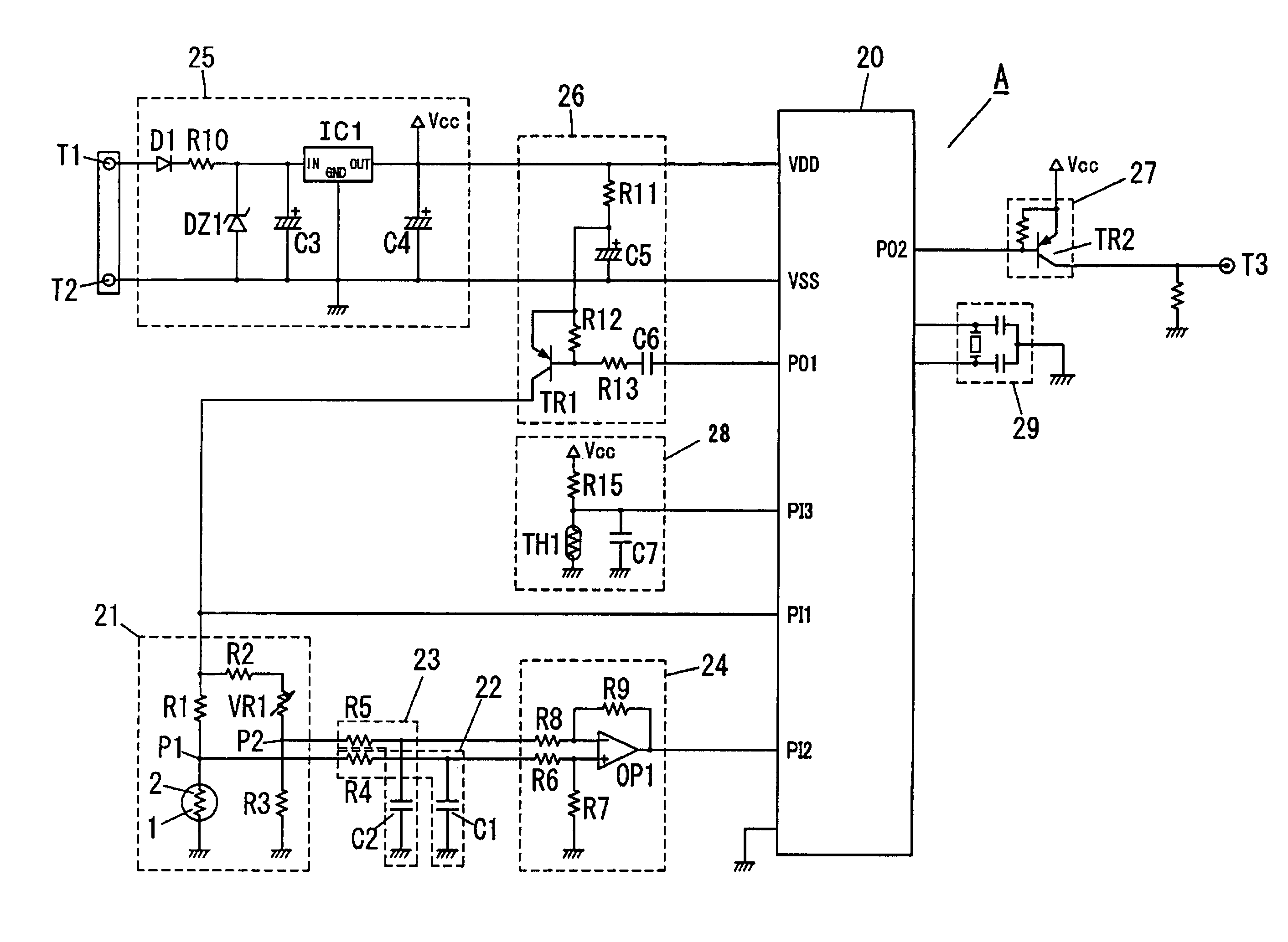

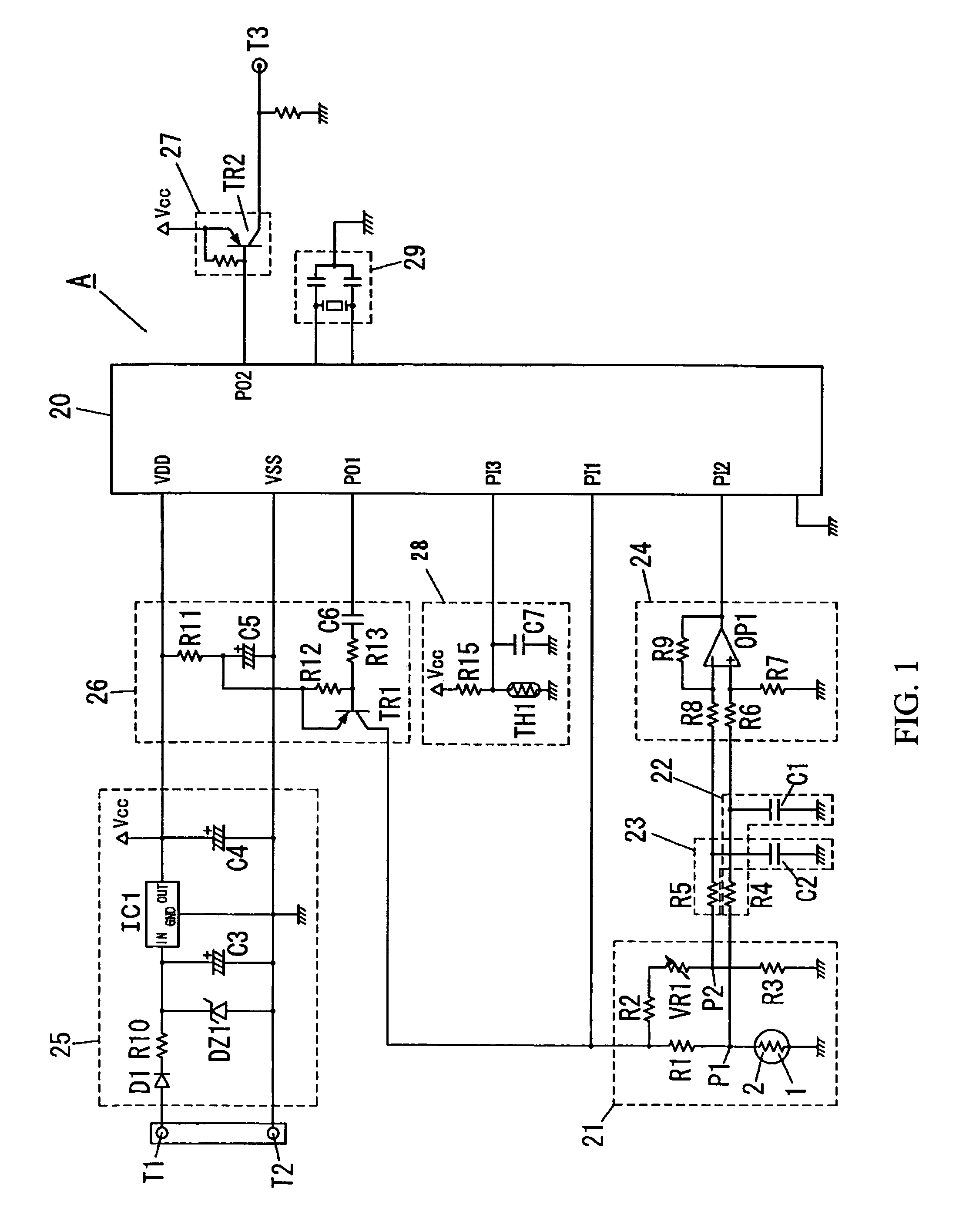

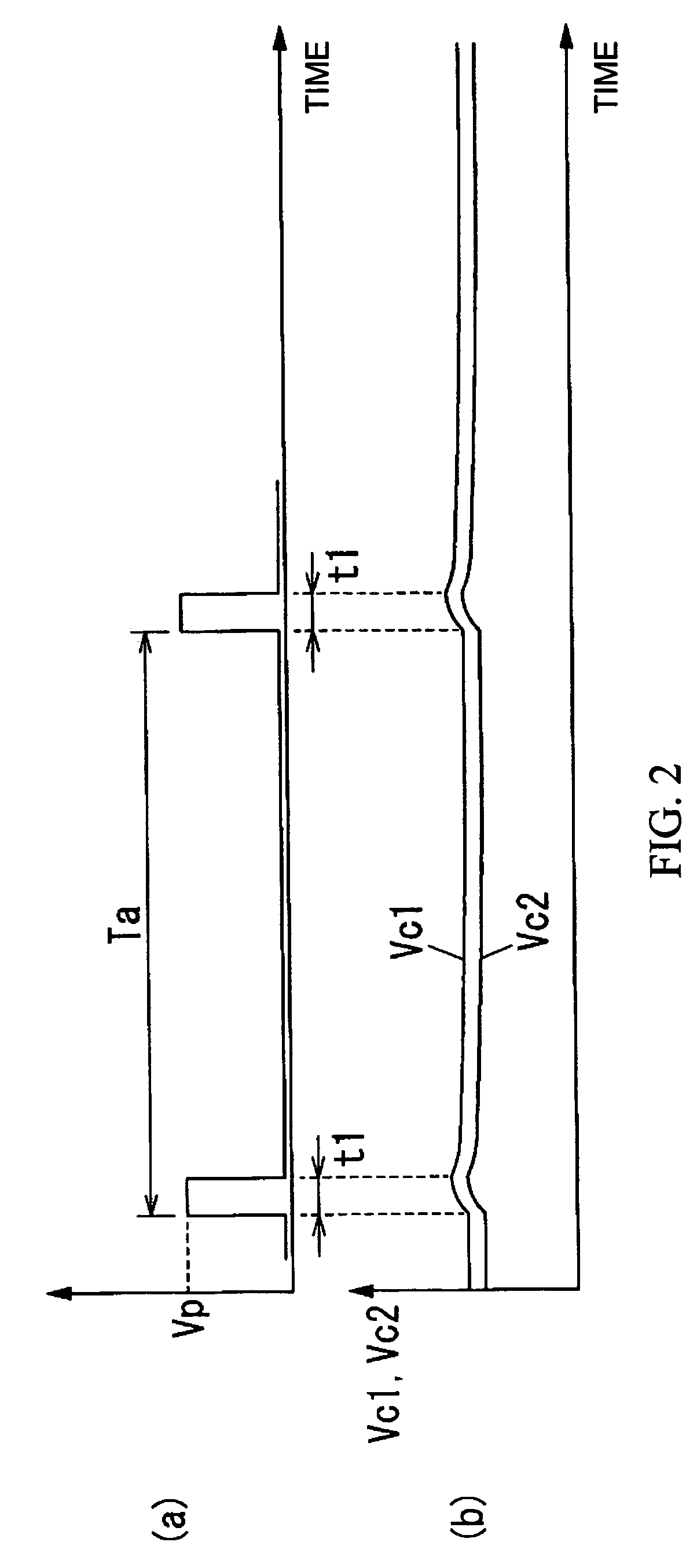

A gas detection apparatus A comprises a signal processing circuit 20, a Wheatstone bridge circuit 21, integrating circuits 22 and 23, a differential amplification circuit 24, a direct current power supply circuit 25, a heater voltage application circuit 26. The Wheatstone bridge circuit 21 is configured of parallel combination of series circuits: one composed of a catalytic combustion type gas sensor 1 and a load resistor R1, and the other composed of a resistor R2, a variable resistor VR1 and a resistor R3. The heater voltage application circuit 26 is configured to generate a pulsed heater voltage by switching a direct current voltage of the direct current power supply circuit 25 through a transistor TR1 for applying the pulsed heater voltage to the Wheatstone bridge circuit 21. The integrating circuit 22 integrates a voltage at a connection point between the gas sensor 1 and the load resistor R1. The integrating circuit 23 integrates a voltage at a connection point between the variable resistor VR1 and the resistor R3. The differential amplification circuit 24 is configured to amplify a differential voltage between the output voltages of the integrating circuits 22 and 23. The signal processing circuit 20 is configured to determine a concentration of a flammable gas from an output voltage of the differential amplification circuit 24.

Owner:FIDELITY NATIONAL INFORMATION SERVICES

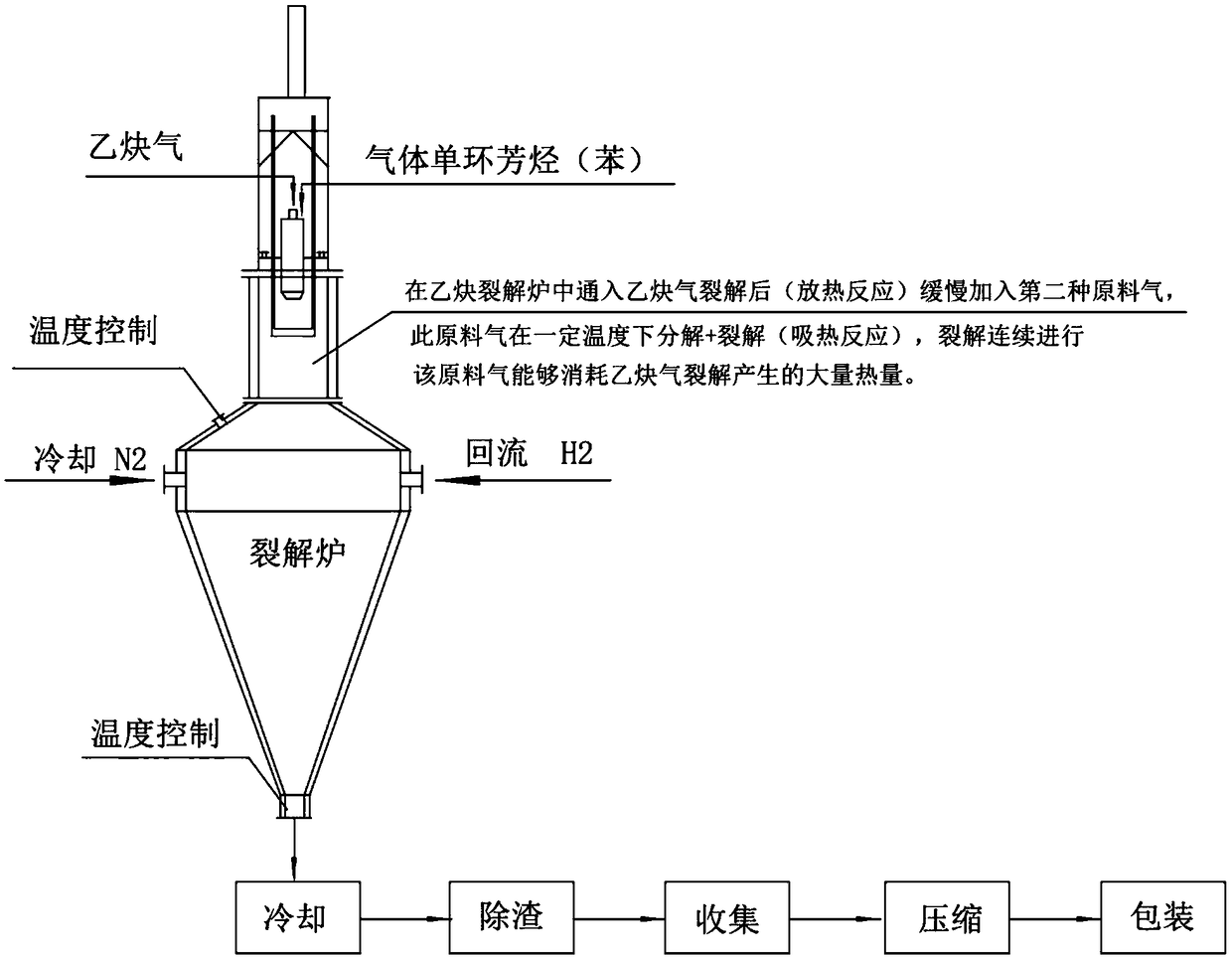

Production process of expanding single line capacity of acetylene black by mixing gas

The invention discloses a production process of expanding single line capacity of acetylene black by mixing gas. The production process comprises the following steps: a, transforming an acetylene cracking furnace, and additionally arranging a raw material gas inlet; b, introducing first raw material acetylene gas into the acetylene cracking furnace through the raw material gas inlet, and introducing second raw material gas into the acetylene cracking furnace through a newly arranged gas inlet after acetylene gas starts to crack, wherein the second raw material gas can absorb heat generated byacetylene cracking for self decomposition and cracking; c, when the acetylene gas is constant, controlling the outlet temperature of the cracking furnace according to the furnace pressure, and adjusting the amount of a cooling medium so as to achieve the purposes of intercepting flames and cooling, terminating a carbon black reaction, diluting concentration of carbon black and preventing coking; and d, carrying out follow-up cooling, deslagging, collecting, compressing and packaging steps on the diluted acetylene black. The production process can improve the treatment amount of acetylene gas,lower the raw material cost, improve the capacity and increase the economical benefit. The production process is simple and high in operability and can be popularized and applied quickly.

Owner:中昊黑元化工研究设计院有限公司

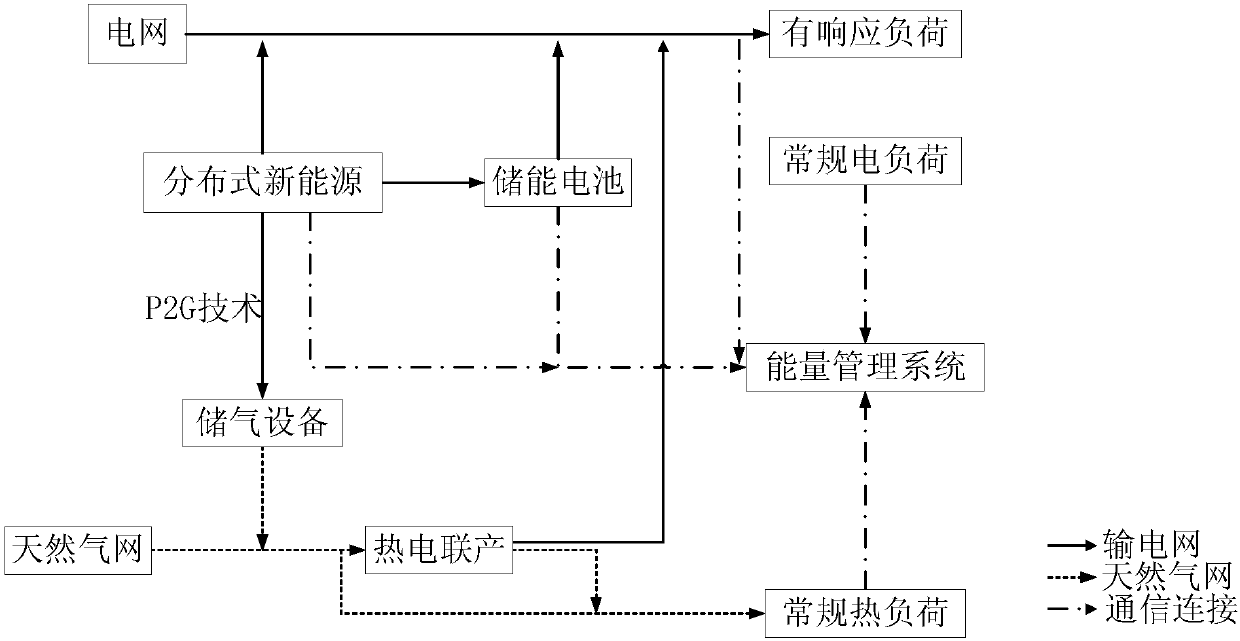

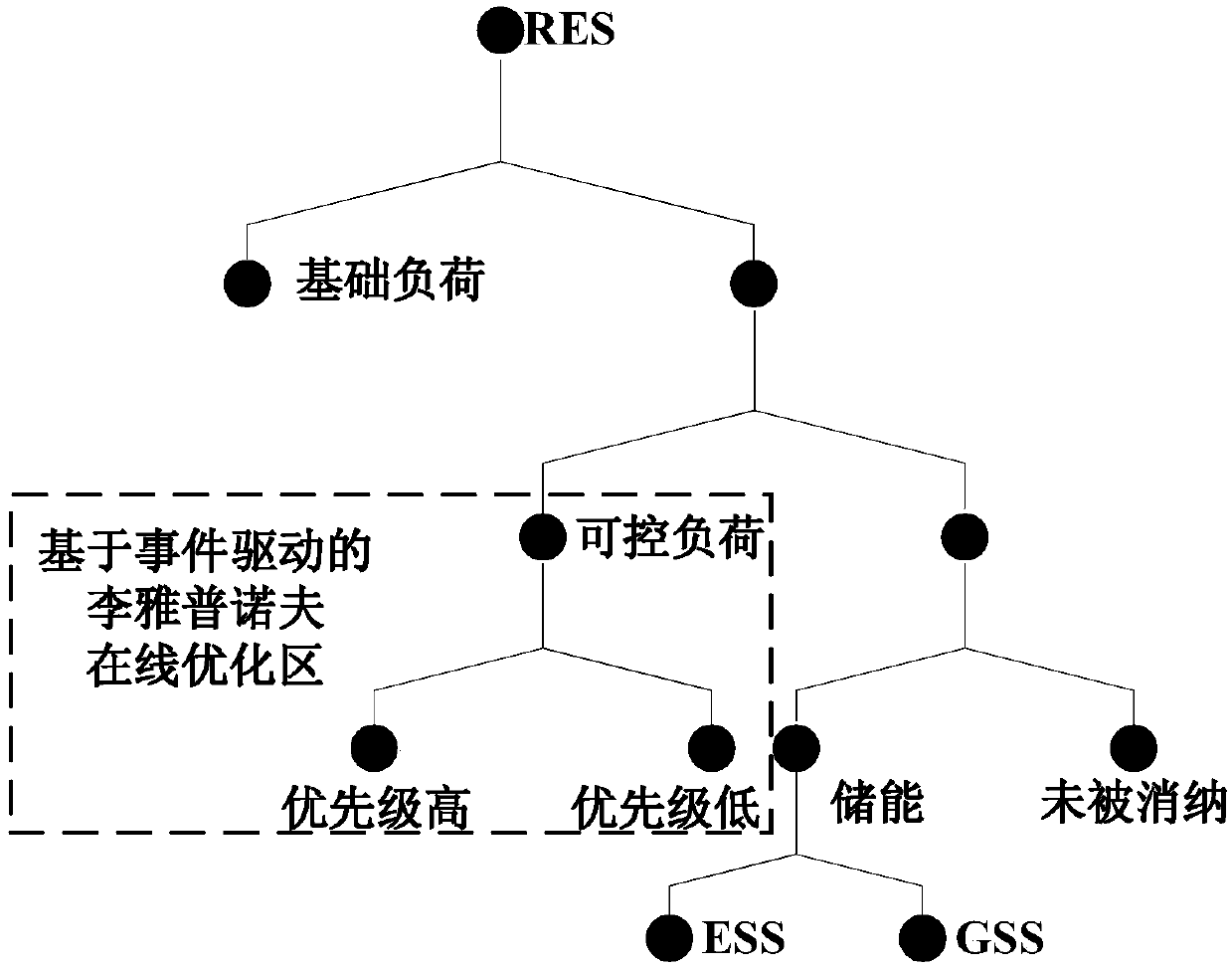

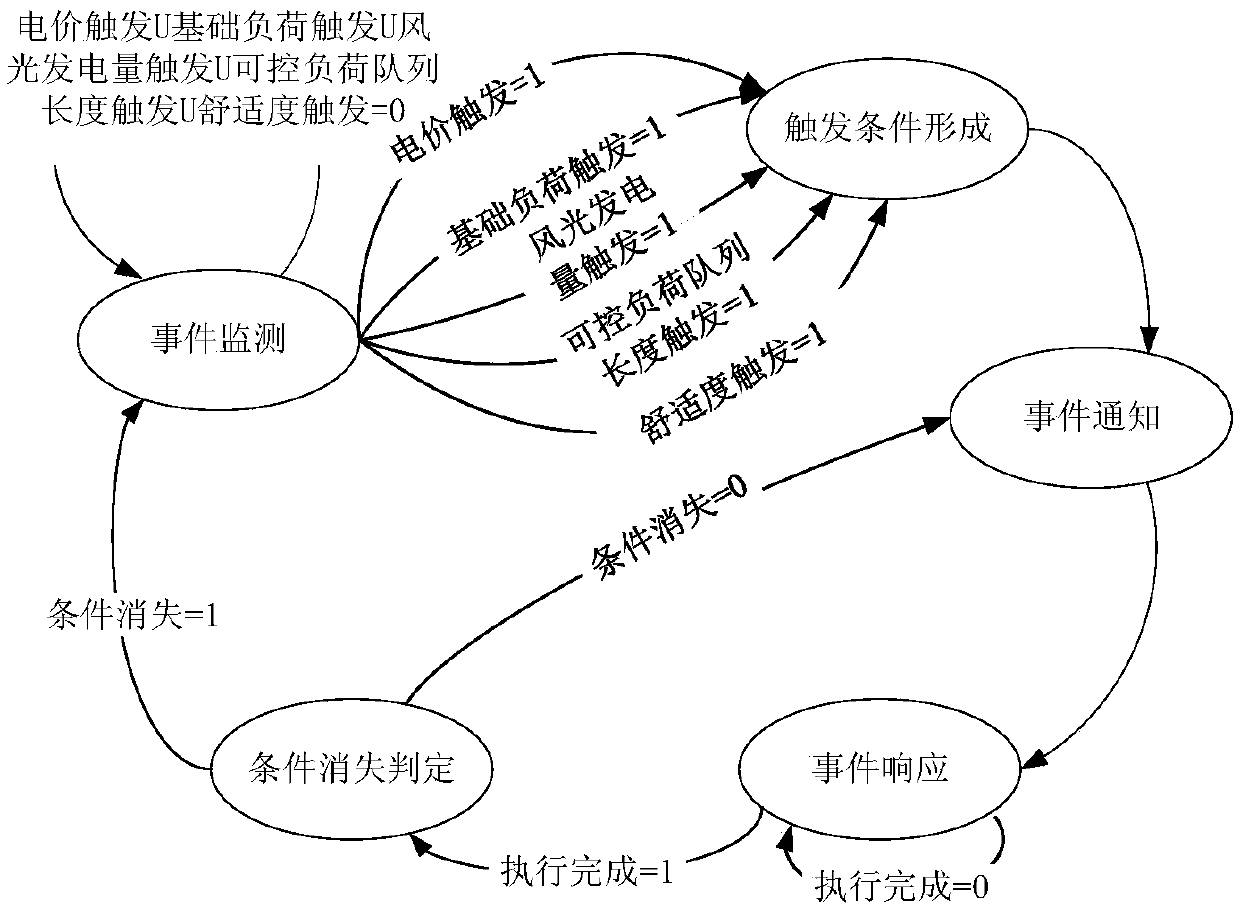

Power-to-gas conversion technology-based regional integrated energy system online optimization method

ActiveCN108494012ASave gas costAvoid peak electricity consumptionPower network operation systems integrationSingle network parallel feeding arrangementsTime informationIntegrated energy system

The invention relates to a power-to-gas conversion technology-based regional integrated energy system online optimization method. The method includes the following steps that: the real-time information of the status of a system is obtained; when an event is triggered, the system will generate triggering signals and notify a power controller to respond to the event; Lyapunov-based based energy online optimization is adopted to obtain the current optimal actual power consumption X(t) of HVAC; and energy scheduling is performed for other units in the system. According to the method of the invention, the controllable load HVAC is adopted as a decision-making subject, so that event-driven energy online optimization can be realized. The method aims to ensure the comfort of a user while minimizing the cost of the user, and at the same time, absorb renewable energy as much as possible, improve an energy utilization rate, and achieve online energy collaborative optimization for a supply side and a demand side. Since the HVAC is adopted as the decision-making subject, and collaborative optimization of the supply side and demand side is realized, the comfort of the user can be ensured, the cost of the user can be minimized, and therefore, a fast scheduling method can be expected to be provided for the energy management of an integrated energy system.

Owner:ZHEJIANG UNIV OF TECH

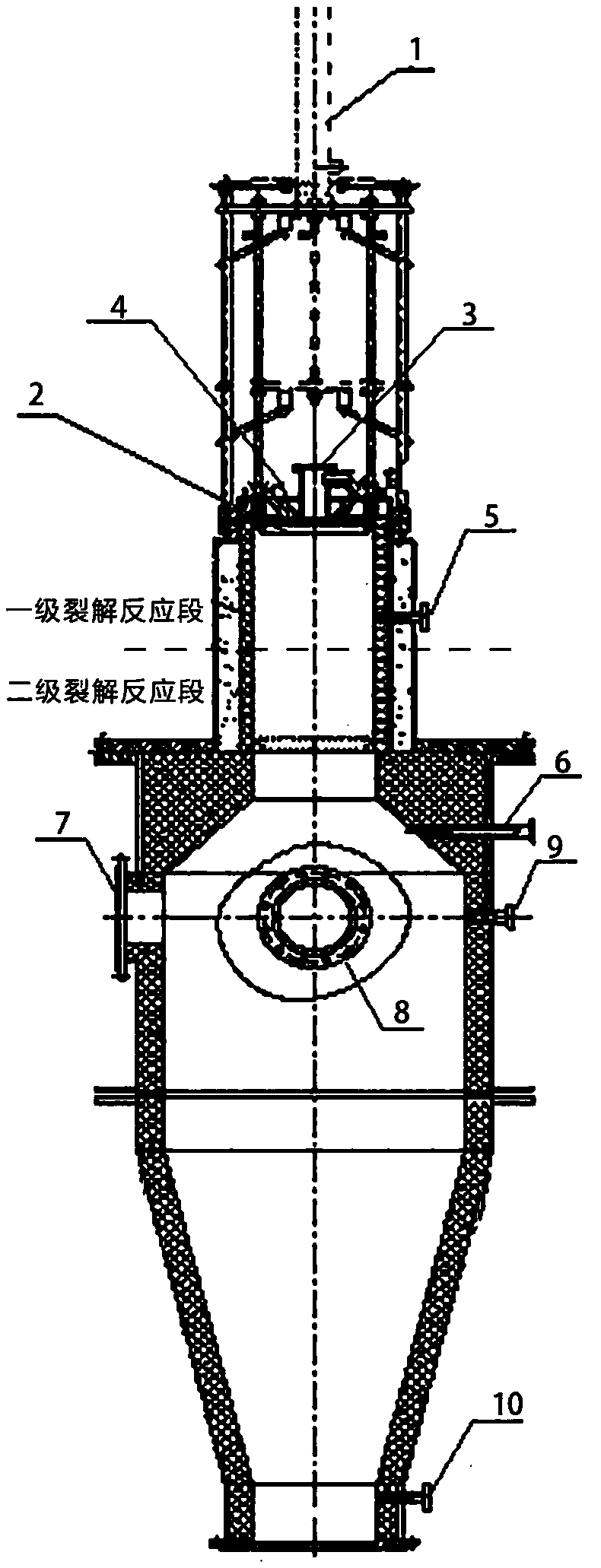

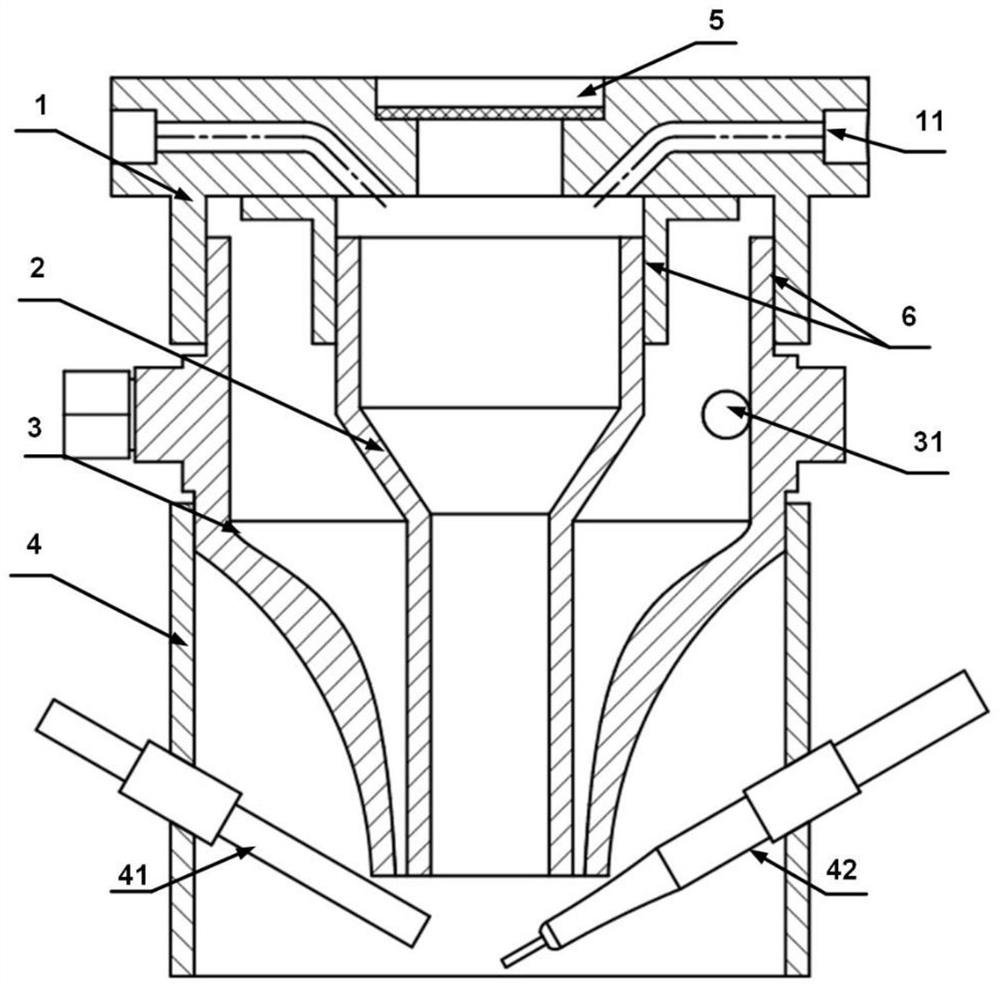

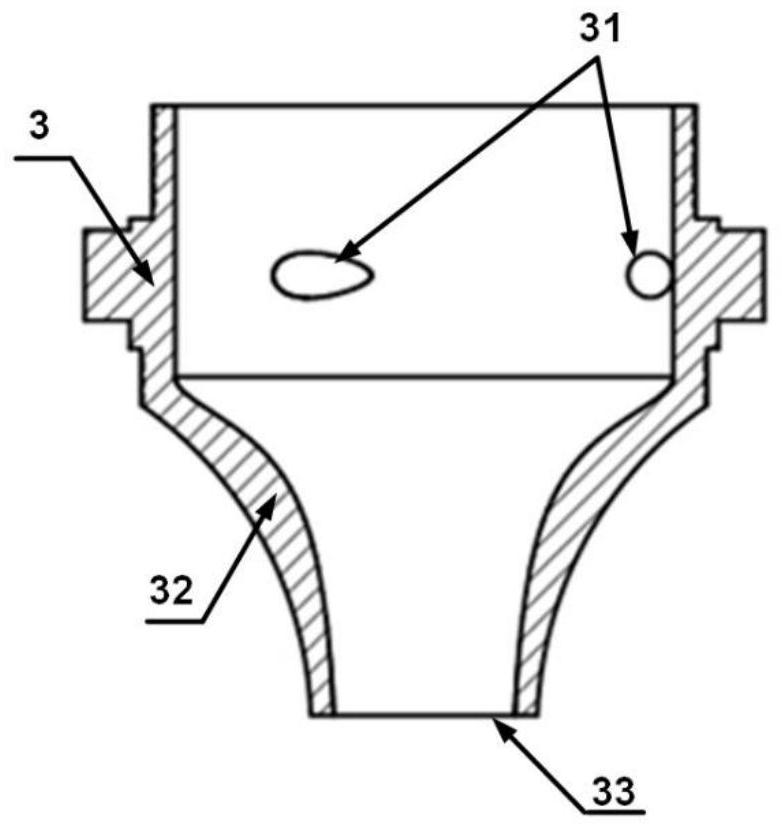

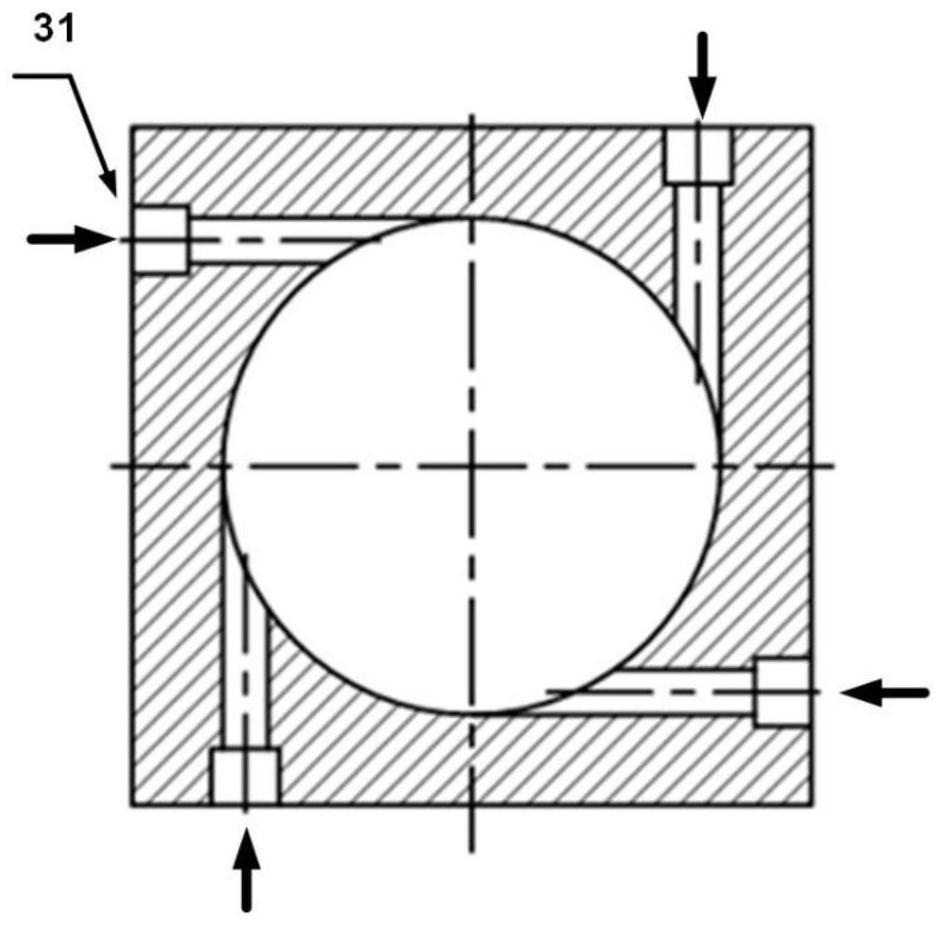

Gas mixing route acetylene black cracking furnace

InactiveCN109233351ASubtle impactIncreased single line capacityPigmenting treatmentHydraulic cylinderRefractory

The invention discloses a gas mixing route acetylene black cracking furnace. The gas mixing route acetylene black cracking furnace comprises a cracking furnace body, wherein the cracking furnace bodyis divided into a gas coke removal section, a cracking primary reaction section, a cracking secondary reaction section, a cooling section and a remaining section from top to bottom, the top of the cracking furnace is provided with a transmission apparatus, and an inner layers of the cracking primary and secondary reaction sections, the cooling section and the remaining section are lined with a refractory material; and the transmission apparatus is a hydraulic cylinder, the hydraulic cylinder is provided with a scraper blade apparatus, a first raw material gas inlet and a second raw material gas inlet, the first raw material gas inlet is connected with an acetylene gas source, the second raw material gas inlet is connected with a mononuclear aromatics gas source, the second raw material gasinlet is provided with a flow valve, and the scraper blade apparatus and the first raw material gas inlet are respectively provided with a water cooling jacket; and the cracking primary and secondaryreaction sections are respectively provided with a thermocouple.

Owner:中昊黑元化工研究设计院有限公司

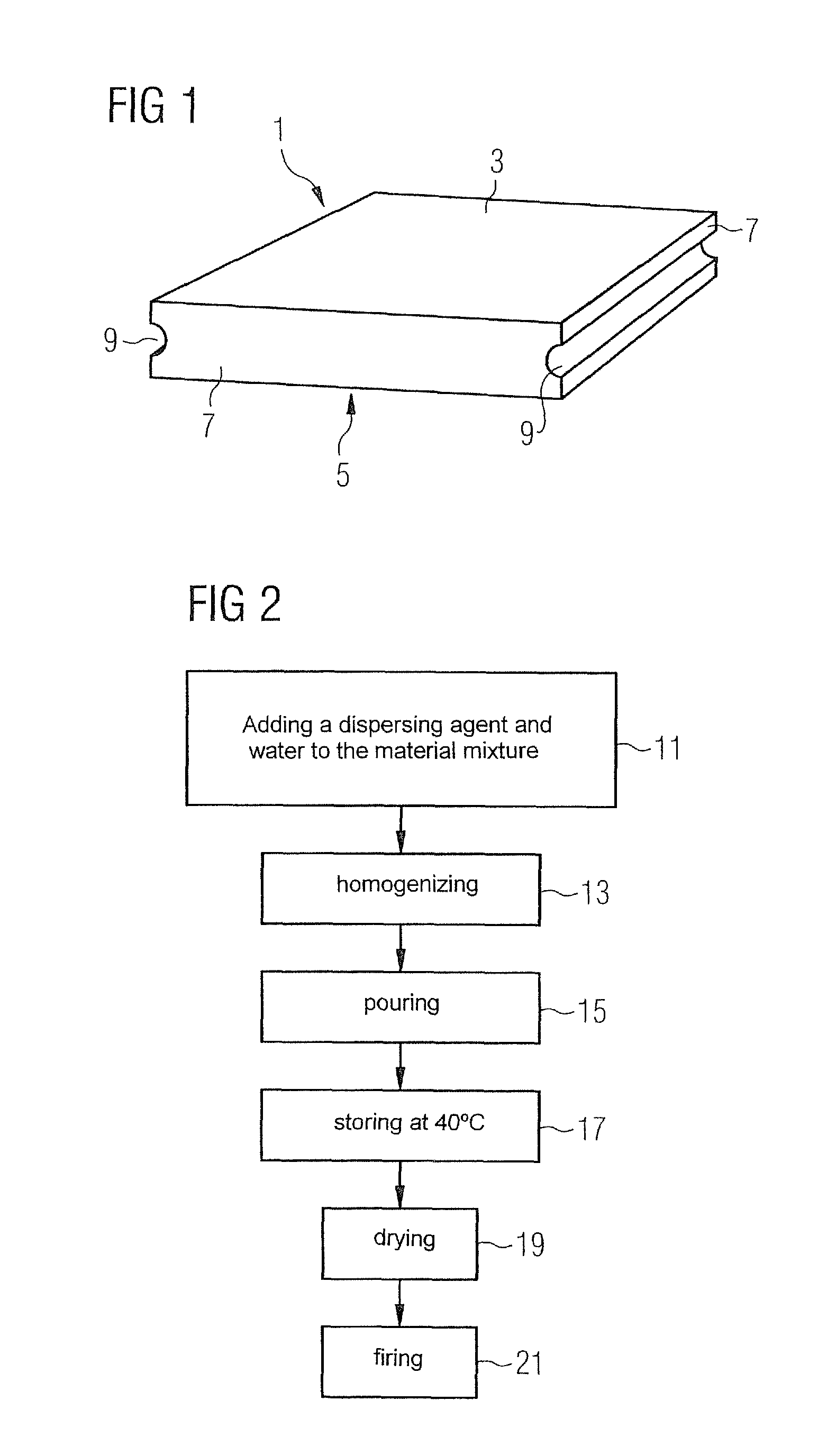

Material Mixture for Producing a Fireproof Material, Fireproof Molded Body and Method for the Manufacturing Thereof

InactiveUS20110237420A1Suitably producedAdvantageously producedContinuous combustion chamberCasings/liningsZirconium oxideSpinel

A material mixture for producing a fireproof material, including spinel and zirconium oxide and a coarse-grained fraction with a weight fraction of greater than 50% and a fine-grained fraction, wherein the coarse-grained fraction includes coarse grains with dimensions larger than 20 μm and the fine-grained fraction includes fine grains with dimensions smaller than 20 μm.

Owner:SIEMENS AG

Air brick fired at low temperature by using gel and preparation process thereof

The invention relates to an air brick fired at low temperature by using a gel and a preparation process of the air brick. The raw materials of the air brick include an aggregate and a fine powder, wherein the weight ratio of the aggregate to the fine powder is 6.5:3.5-7:3; the alumina gel fine powder is used as a binding agent; due to the addition of the alumina gel particle having quite high chemical activity into the air brick in the firing process of the air brick at the temperature being lower than 800 DEG C, the air brick body has high strength; the addition of chromium sesquioxide fine powder can effectively improve the capacities of resisting the permeability of molten steel and the erosion by the steel slag in the use process of the air brick, so as to ensure the good application performance of the air brick; and the firing temperature of the air brick provided by the invention is controlled at 500-800 DEG C, but the firing temperature of a traditional air brick is generally higher than 1300 DEG C, and therefore, the cost of the fuel gas can be saved by about 60% and the firing time can be shortened by about 50%.

Owner:洛阳利尔功能材料有限公司

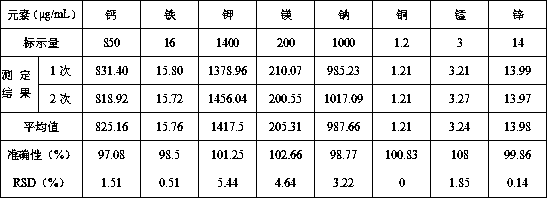

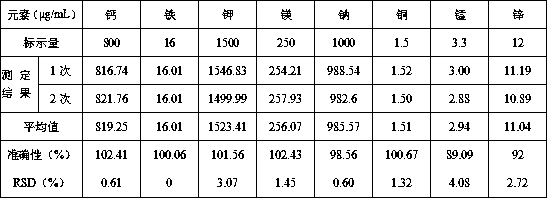

Method for determining content of mineral elements in formulated food which is used for special medical application

InactiveCN107782719ASmall amount of sampleSimple, safe and reliable operationPreparing sample for investigationAnalysis by thermal excitationChemistryMagnesium

The invention discloses a method for determining the content of mineral elements in a formulated food which is used for special medical application, and belongs to the technical field of component detection for a medical food. According to the method, an inductively-coupled plasma atomic emission spectrometer can determine the content of eight mineral elements, including sodium, potassium, calcium, magnesium, zinc, iron, copper and manganese, in a formulated food which is used for special medical application, at the same time. The method includes preparation of solutions, pretreatment of the solutions, preparation of a mixed standard solution and determination. The solutions include a blank solution and a sample solution. The pretreatment of the solutions is carried out through a nitric acid and microwave digestion method. The solutions are pre-digested through nitric acid and are digested via a microwave digestion device, the obtained products are diluted, and the diluted products undergo ICP-OES determination. The method is short in pretreatment time, less in sample consumption, complete in digestion degree, and high in efficiency, and allows high-temperature operation to be prevented. The sample can be well atomized into a stable plasma state, so that the RSD value in a determination process is efficiently reduced, and the determination result is real, stable and reliable.

Owner:HUAREN PHARMACEUTICAL CO LTD

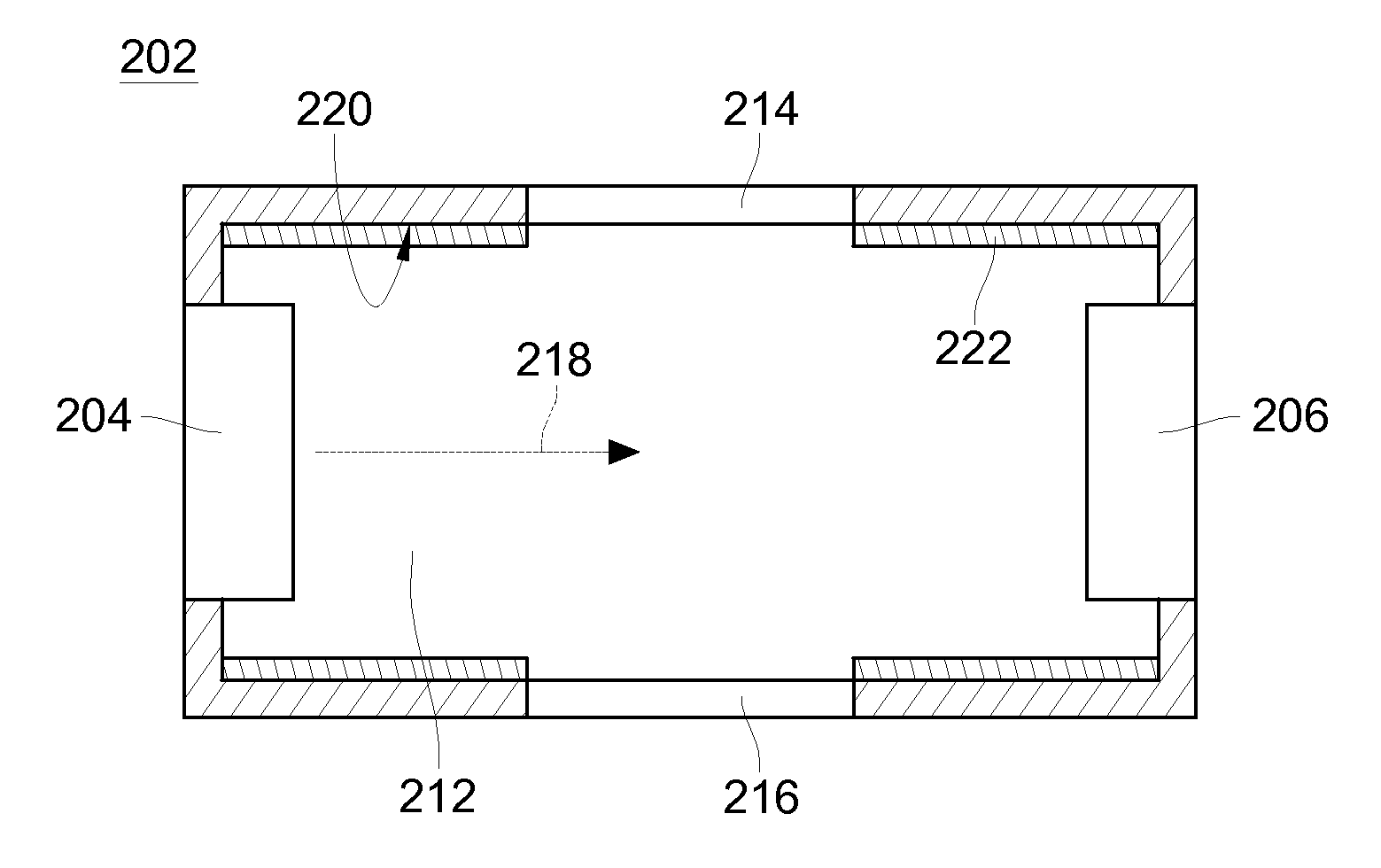

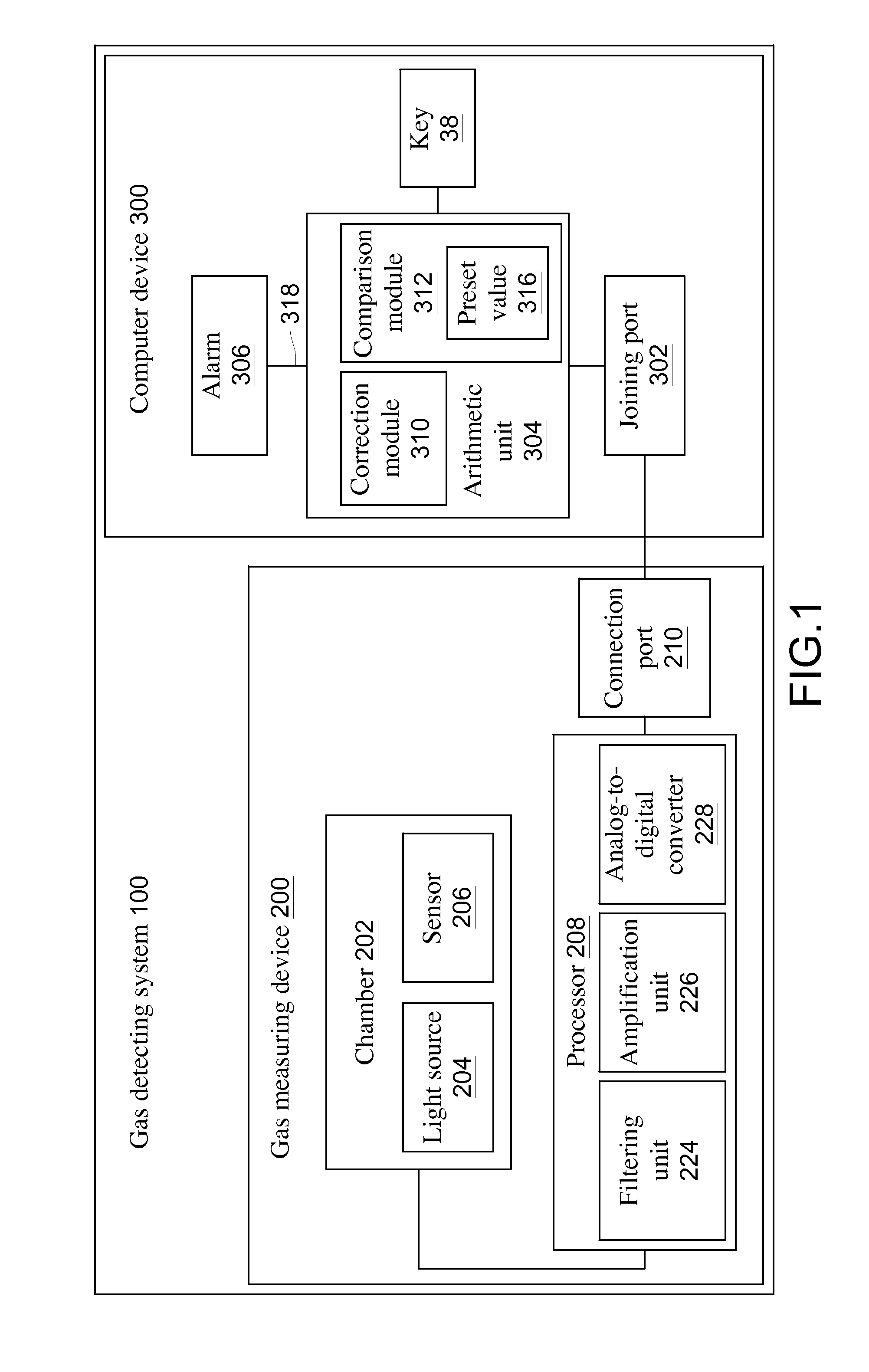

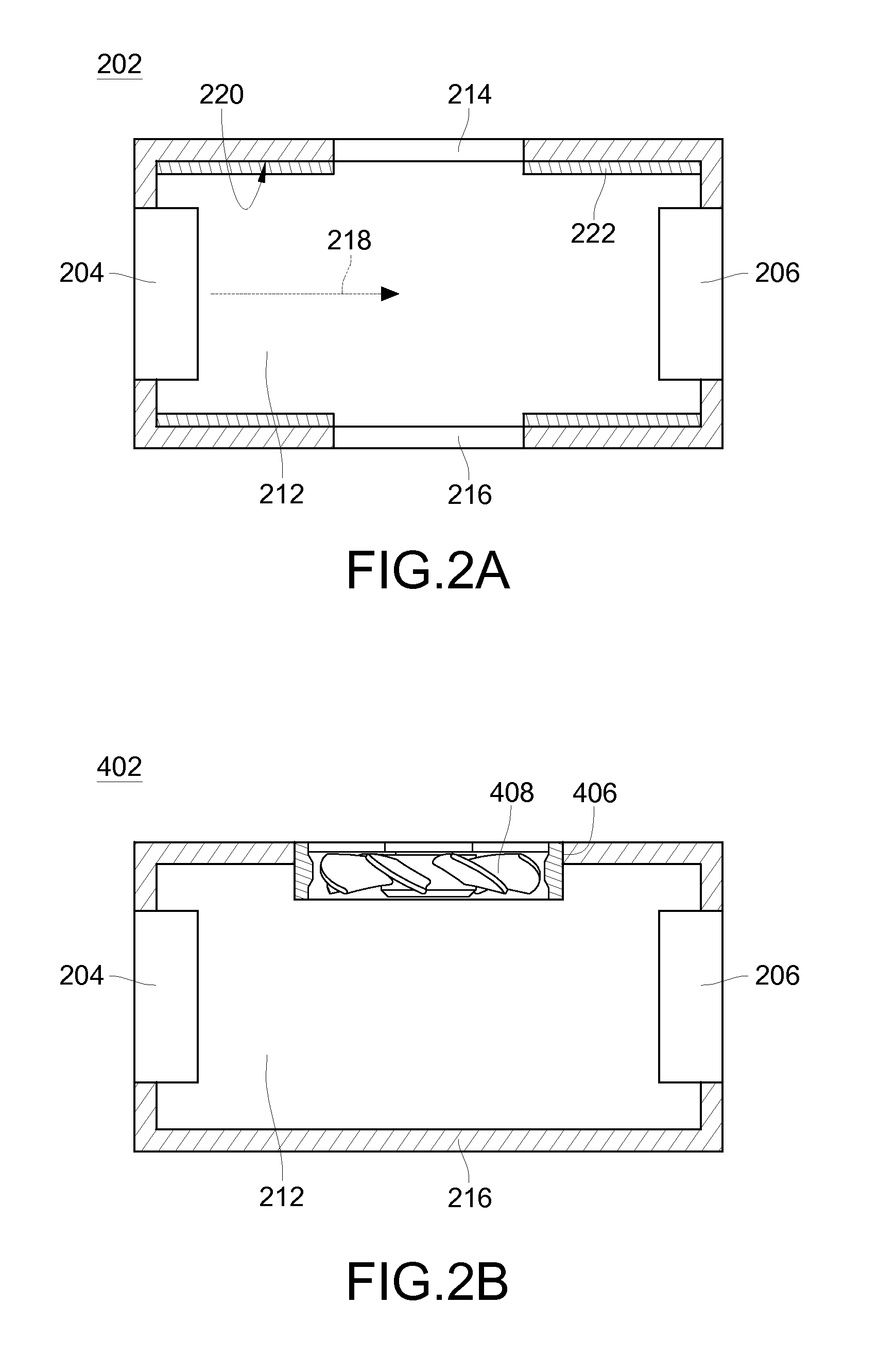

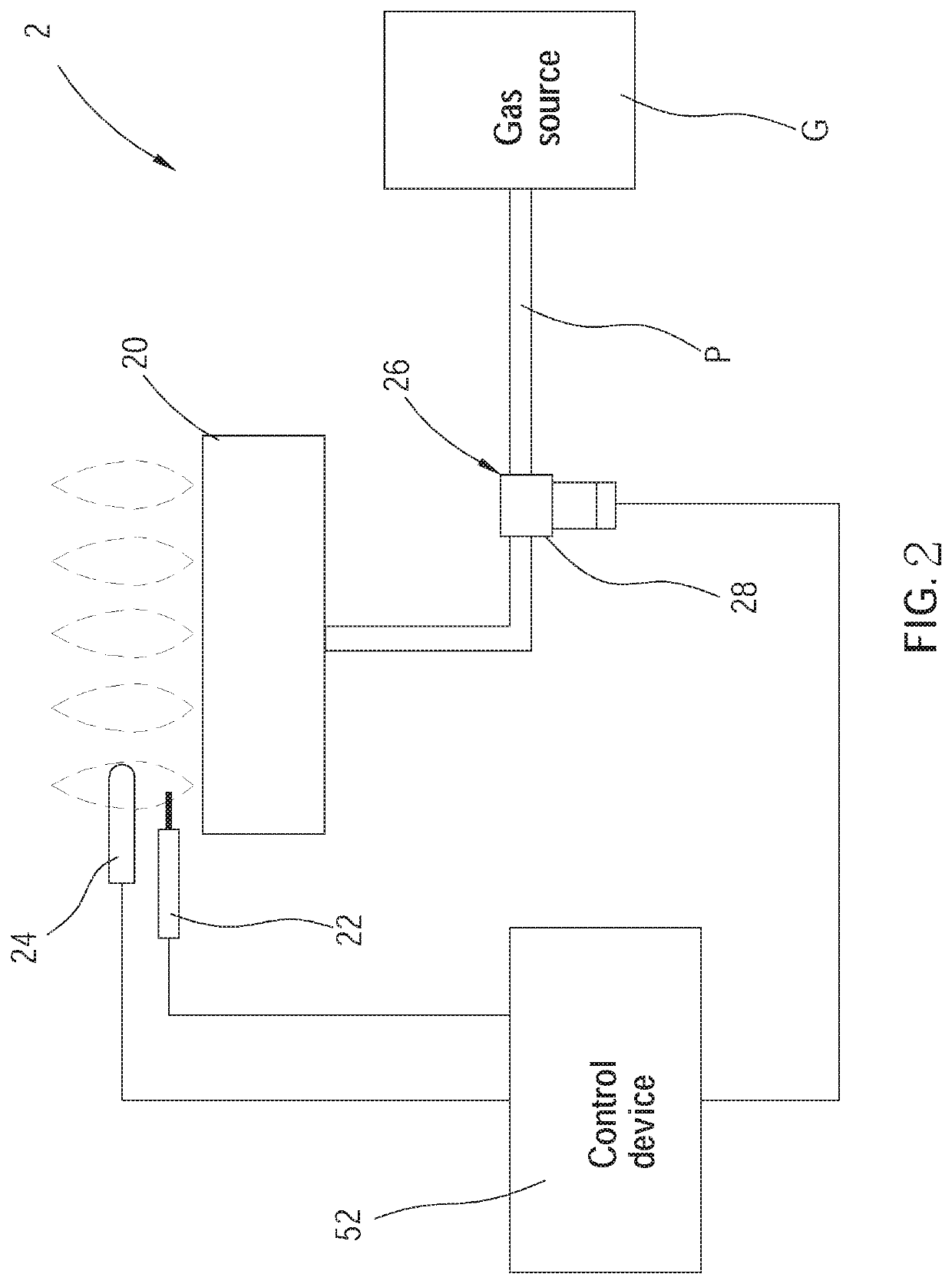

Gas detecting system and method therof

InactiveUS20120173162A1Save gas costReduce manufacturing costTransmissivity measurementsColor/spectral properties measurementsAir cellComputer device

A gas detecting system includes a gas measuring device and a computer device. The gas measuring device includes a chamber, at least one light source, at least one sensor, a processor, and a connection port. The computer device includes a joining port and an arithmetic unit, and the connection port is electrically connected to the joining port. The arithmetic unit outputs at least one control signal after a control procedure. The processor controls the light source disposed in the chamber to emit light which passes through an air cell of the chamber according to the control signal such that the sensor disposed in the chamber outputs a sensing signal to the processor. The processor outputs a characteristic value to the computer device according to the sensing signal. Therefore, the computer device can control and start the gas measuring device to perform gas detection through outputting the control signal.

Owner:GETAC TECH CORP

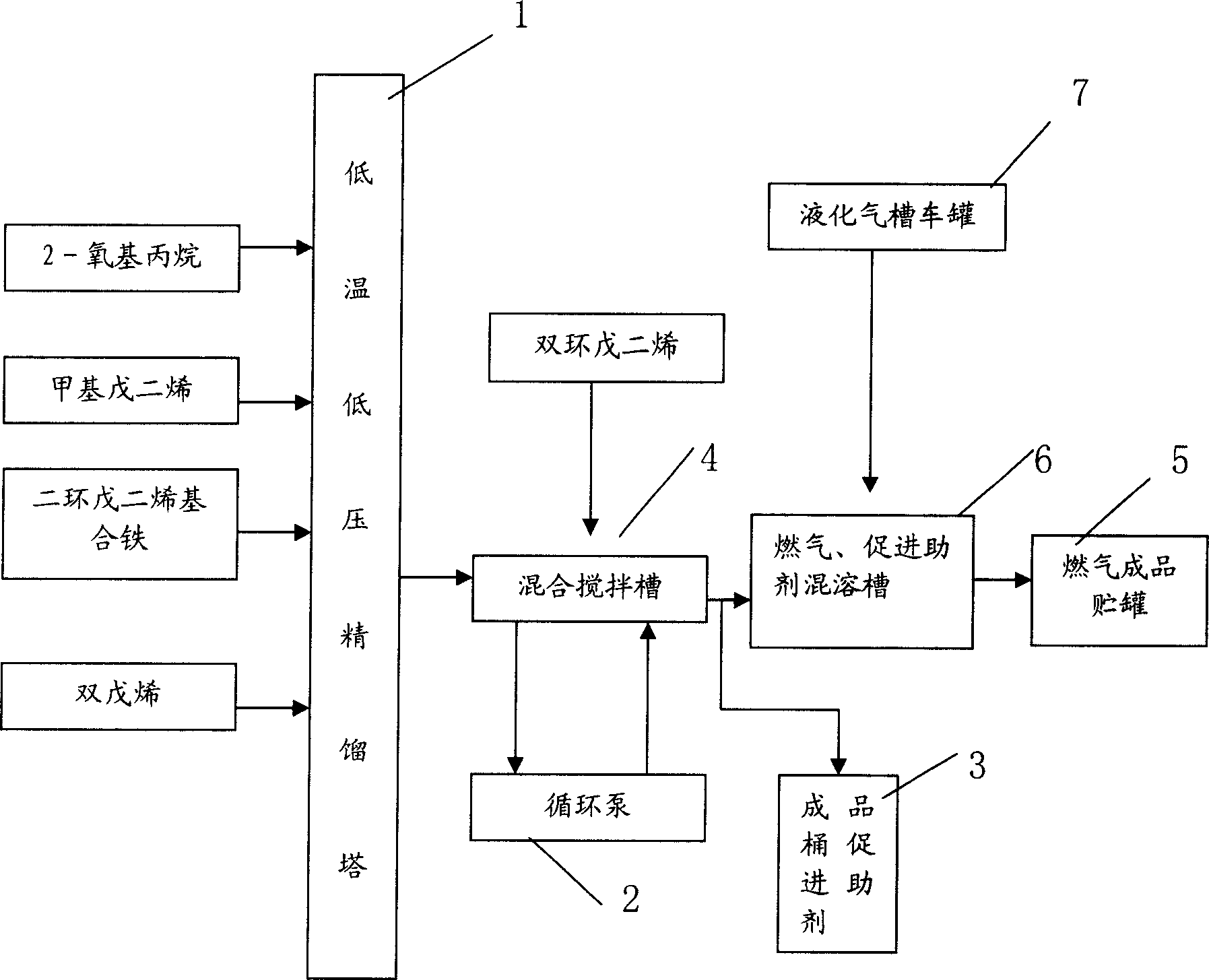

High-precision natural gas cutting gas

InactiveCN101985573ALow costGas cost increasesGaseous fuelsGas flame welding apparatusAnhydrous ethanolRosin

The invention discloses a high-precision natural gas cutting gas. Natural gas is taken as a major ingredient. Catalysis assistant is added into the natural gas and is composed of the following components at volume ratio: 25-28% of solvent oil, 14-18% of anhydrous ethanol or carbinol, 16-20% of isopropanol or n-butyl alcohol, 14-16% of dimethylbenzene, 18-22% of rosin water and 1.5-2% of Catoc-ene; the ratio of the natural gas to the catalysis assistant is characterized is that 10-12 ml of the catalysis assistant is added in each cube of natural gas.

Owner:CHONGQING HENGSHENG ENERGY DEV

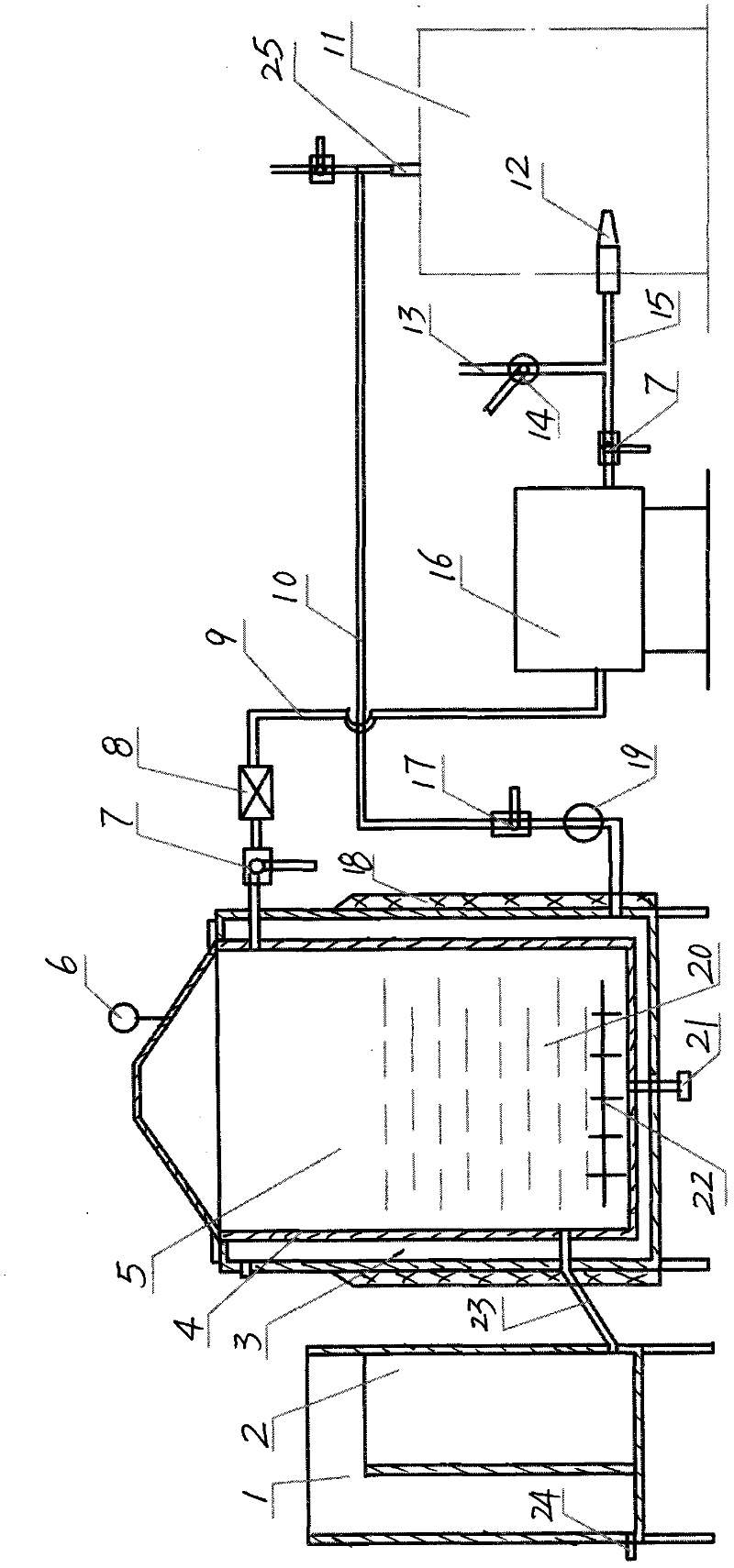

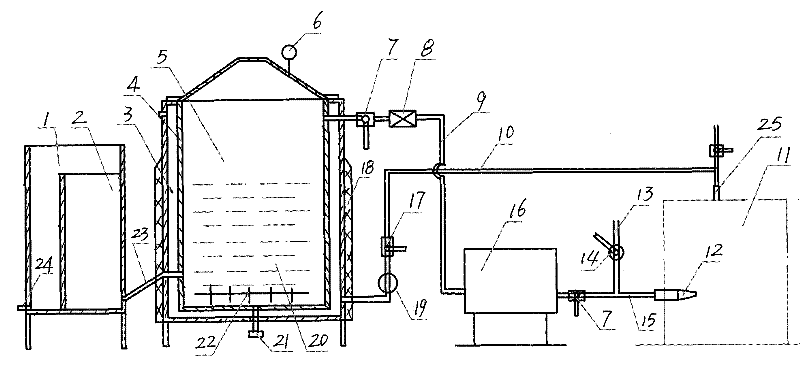

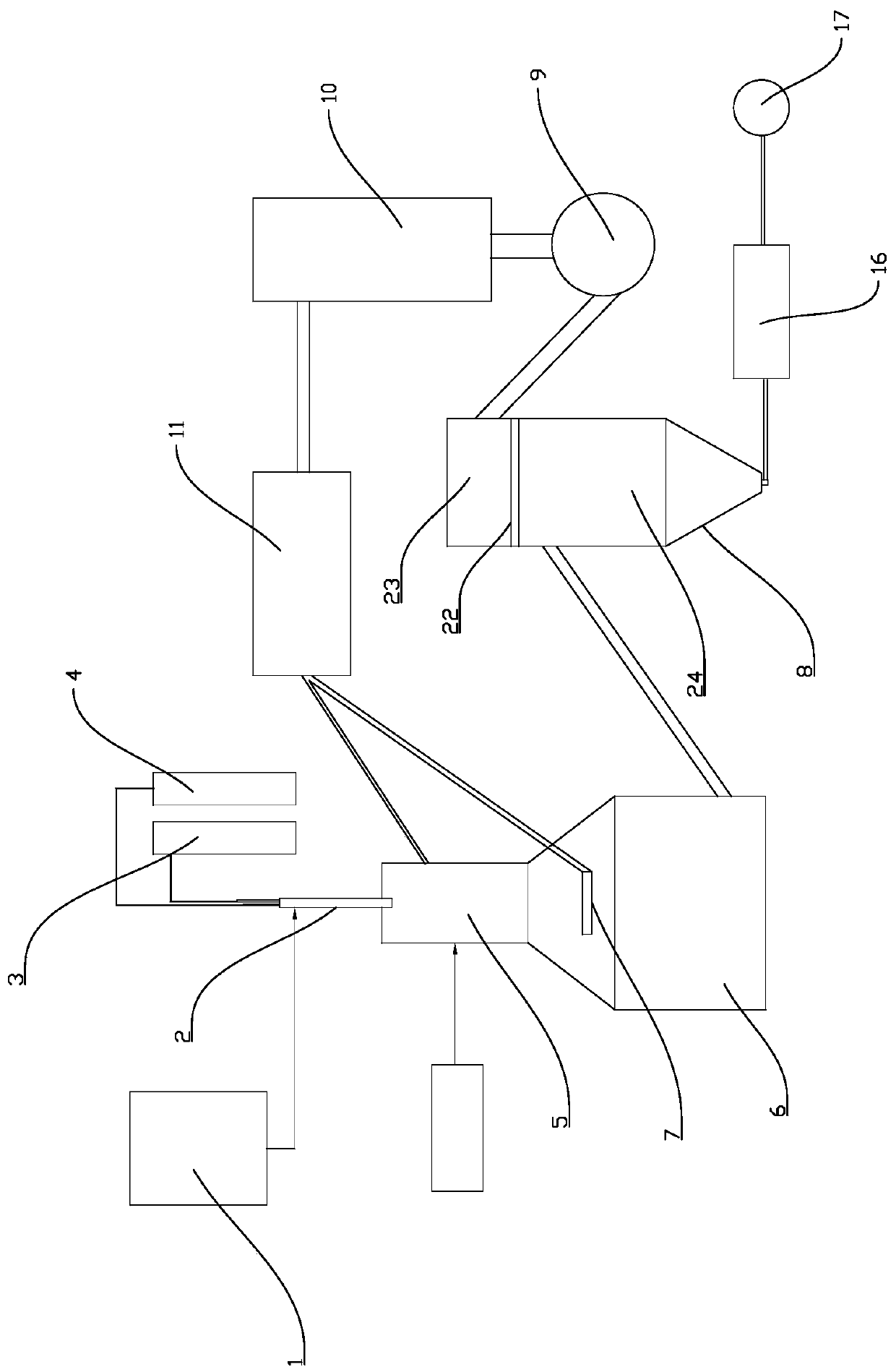

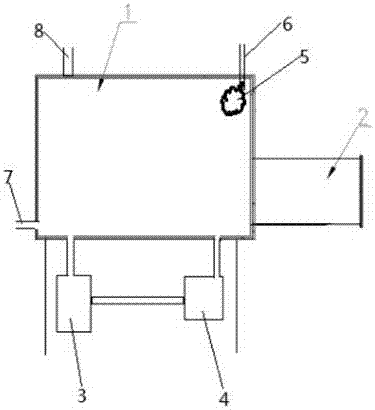

Method and device for applying methane to industrial hating furnace

InactiveCN102162000AEnsure usabilityEnsure requirementsBioreactor/fermenter combinationsBiological substance pretreatmentsAir compressionProcess engineering

The invention discloses a method and device for applying methane to an industrial hating furnace. The device comprises a methane tank (4) and a heating chamber (3), wherein the methane tank is communicated with a bucket (2); the methane tank is connected with a methane storeroom (16) through a delivery pipe (9); the methane storeroom is connected with a flame gun (12) positioned in the industrial heating furnace through an output pipe (15); the output pipe is connected with an air compression pipe (13); and the heating chamber is connected with a hot air discharging pipe (25) in the industrial heating furnace through a hot air pipe (10). By utilizing the device, a fermentation material is filled in the methane tank firstly, the methane tank is heated to 50-80 DEG C so that the fermentation material is fermented and decomposed at high temperature to generate methane, then the methane is stored and delivered to the industrial heating furnace so as to be ignited, and then compressed air is introduced to the methane so that the methane sufficiently combusts in the industrial heating furnace after being mixed with the compressed air. By utilizing the method and device provided by the invention, the quality of the combusted product can be ensured, the gas cost can be greatly reduced, energy sources are saved, waste materials are sufficiently utilized, and the environmental pollution is reduced.

Owner:刘达苏

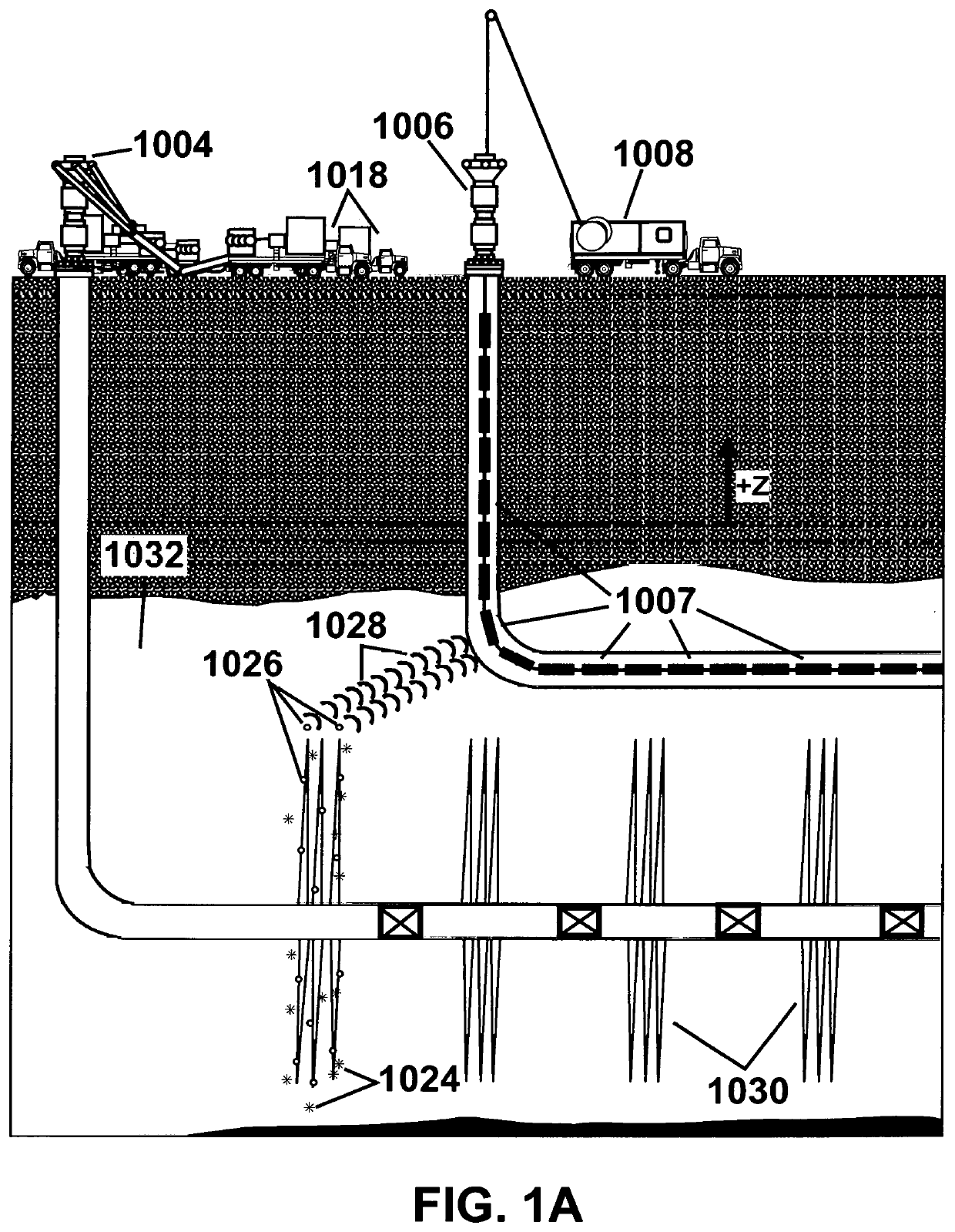

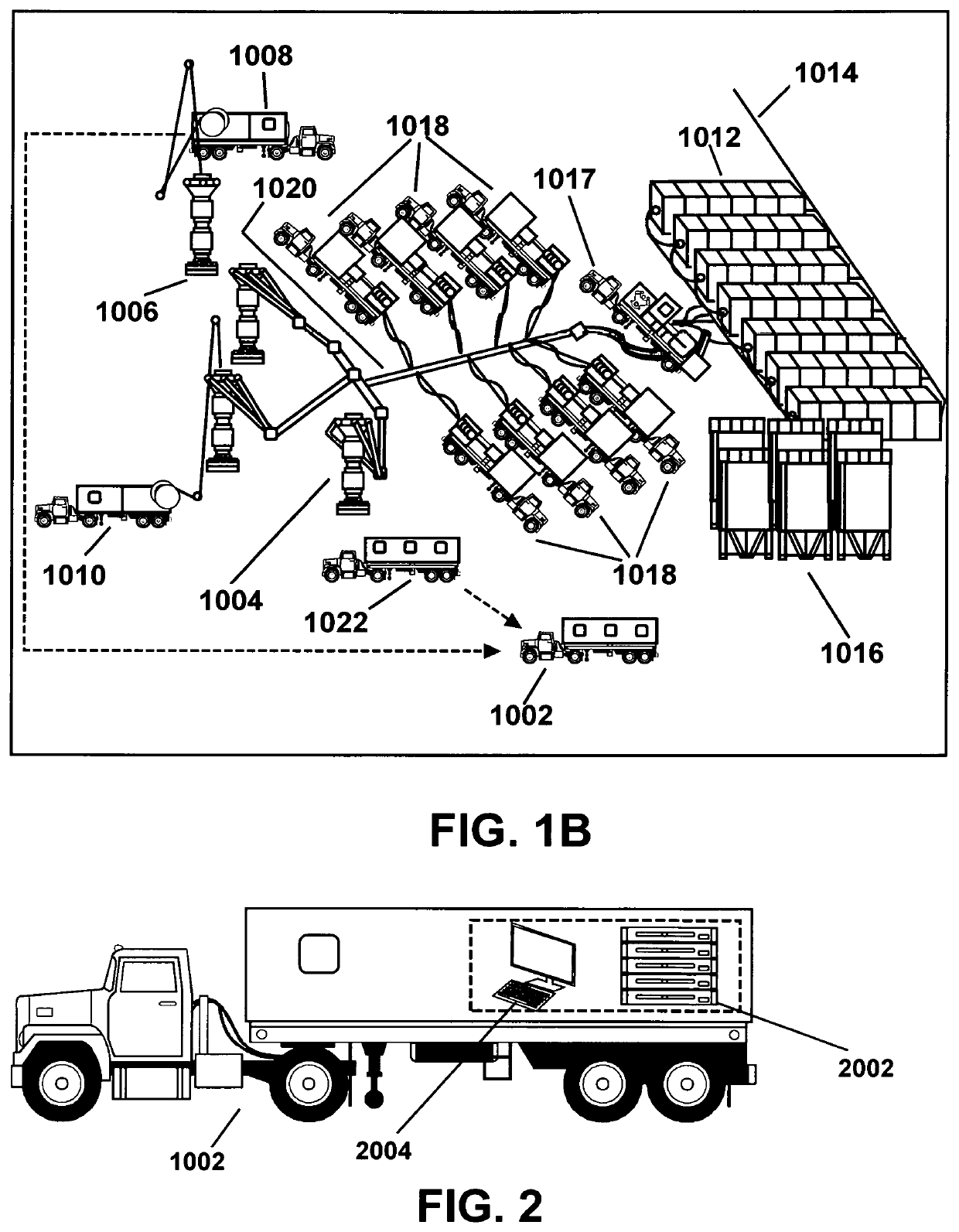

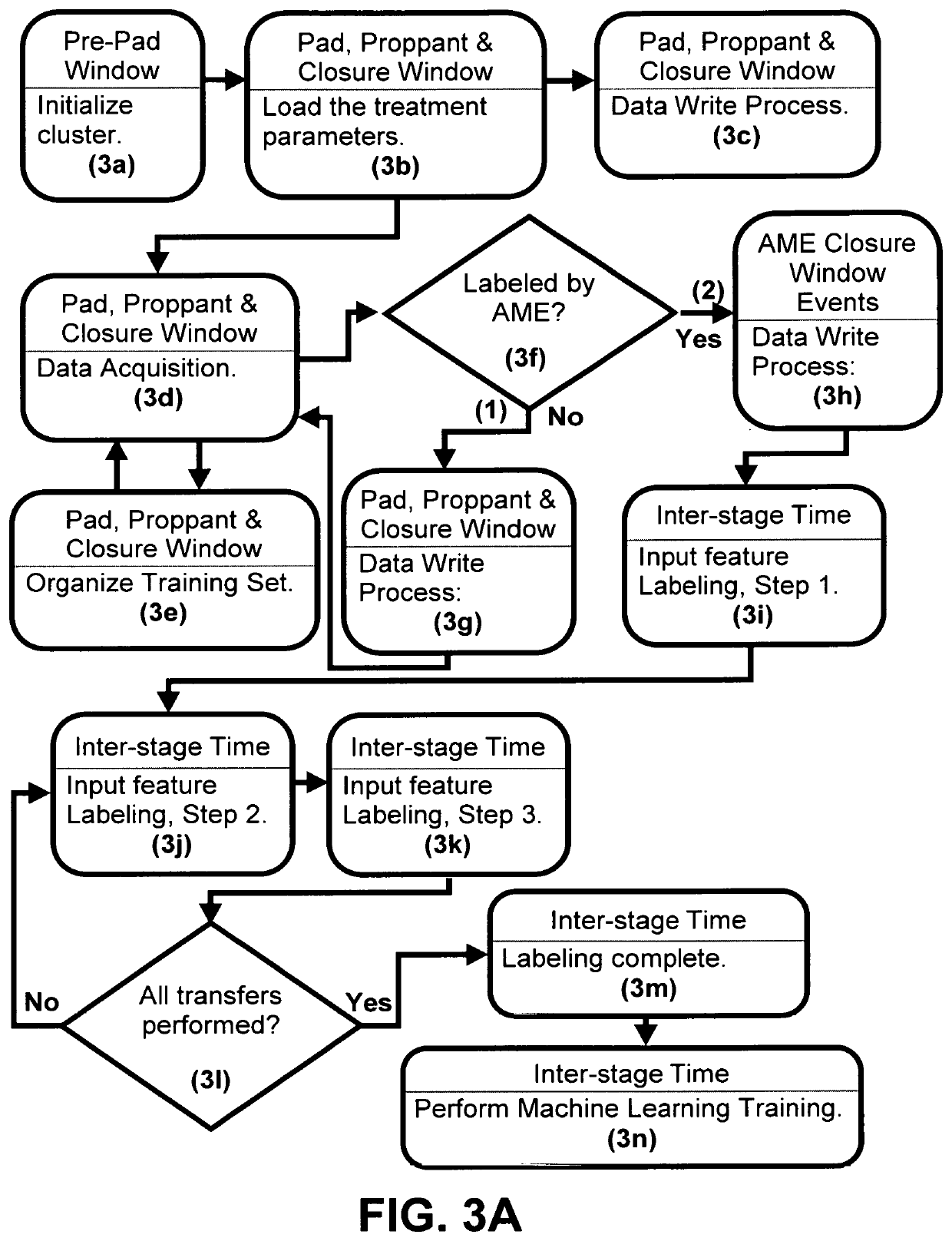

Systems and processes for labeling hydraulic fracture data using acoustic emitters for supervised learning algorithm mapping and classifying of hydraulic fractures in wells

ActiveUS10572829B1Reduce in quantitySave gas costFluid removalSeismic signal processingAlgorithmEngineering

The new art includes a system, process and means to label microseisms generated by hydraulic fracture operations and detected by acoustic sensors so a that machine learning process may be trained to perform mapping of propped hydraulic fracture dimensions in real-time or near-real time. This labeling process creates a labeled training set that enables any supervised machine learning process to be tested and trained whereby the process may perform real-time mapping of propped and unpropped fractures in subsequent treatment stage(s).

Owner:WILLINGER JONATHAN R

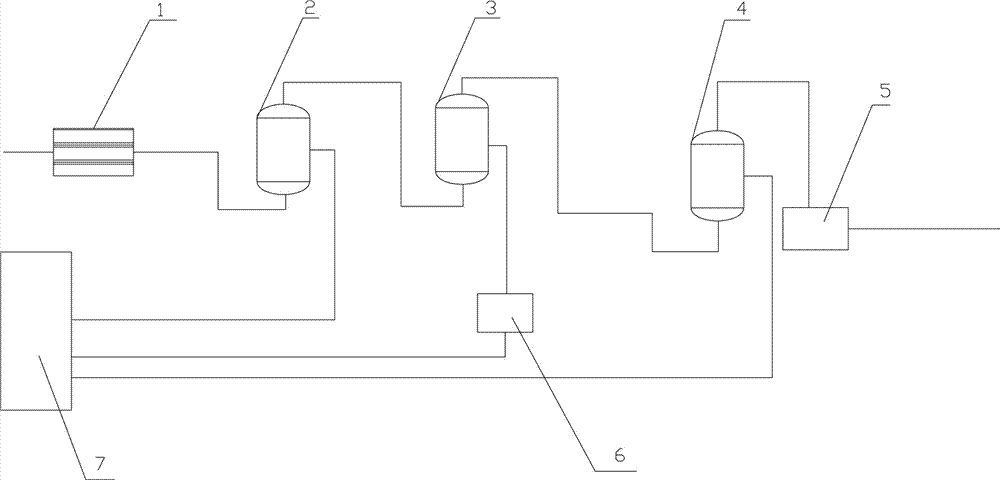

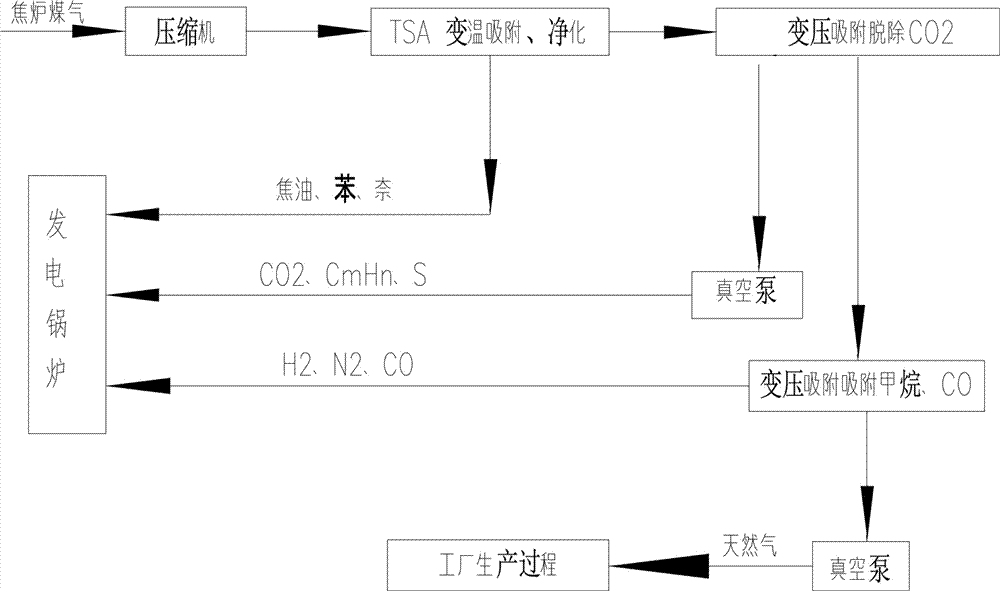

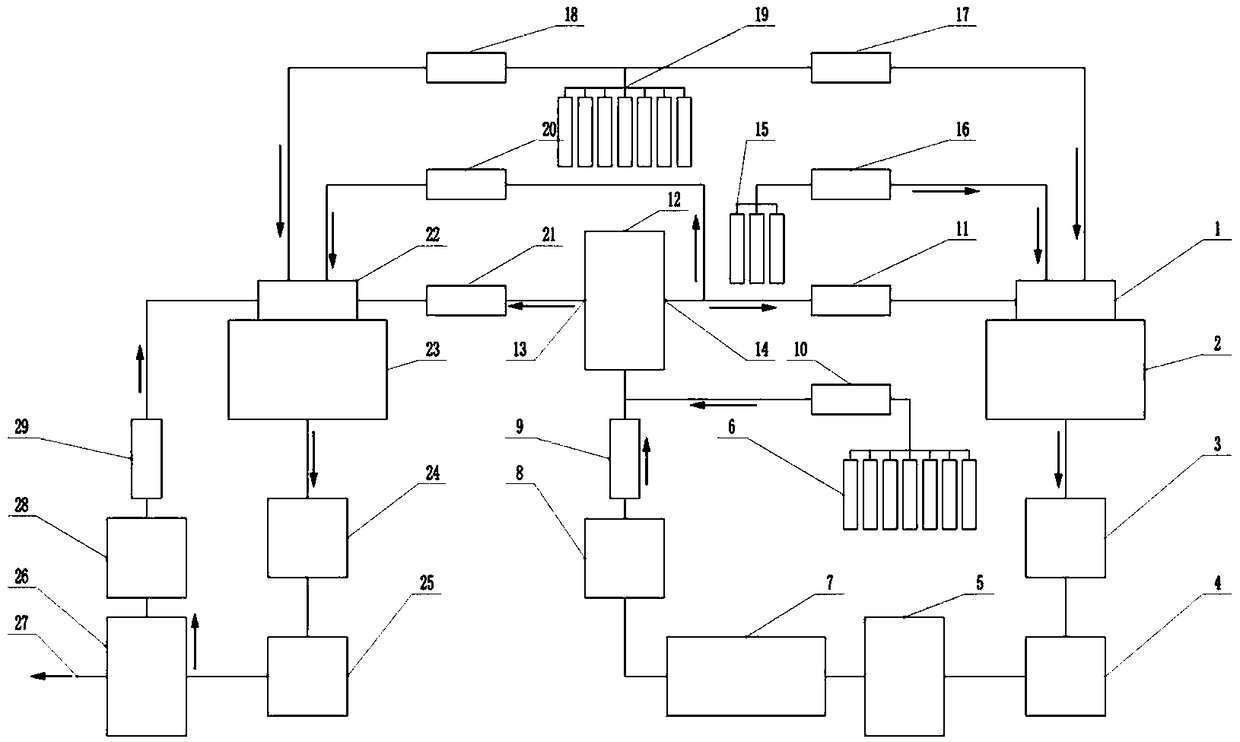

System for producing natural gas from coke oven gas

The invention relates to the field of comprehensive utilization of coke oven gas, in particular to a system for producing natural gas from coke oven gas. The system comprises a compressor, wherein the compressor is connected with a temperature swing adsorption device through a pipeline, the temperature swing adsorption device is connected with a first pressure swing adsorption device through a pipeline, the first pressure swing adsorption device is connected with a second pressure swing adsorption device through a pipeline, and the second pressure swing adsorption device is connected with a first vacuum pump through a pipeline; the first pressure swing adsorption device is connected with a second vacuum pump through a pipeline. The temperature swing adsorption device, the second pressure swing adsorption device and the second vacuum pump are connected with a power generating boiler through pipelines. Residual gas after extraction of natural gas is not treated further and used for generating power, the coke oven gas is treated with the pressure swing adsorption method for extraction of the natural gas, and the total energy consumption of the device is low.

Owner:湖北和远气体股份有限公司

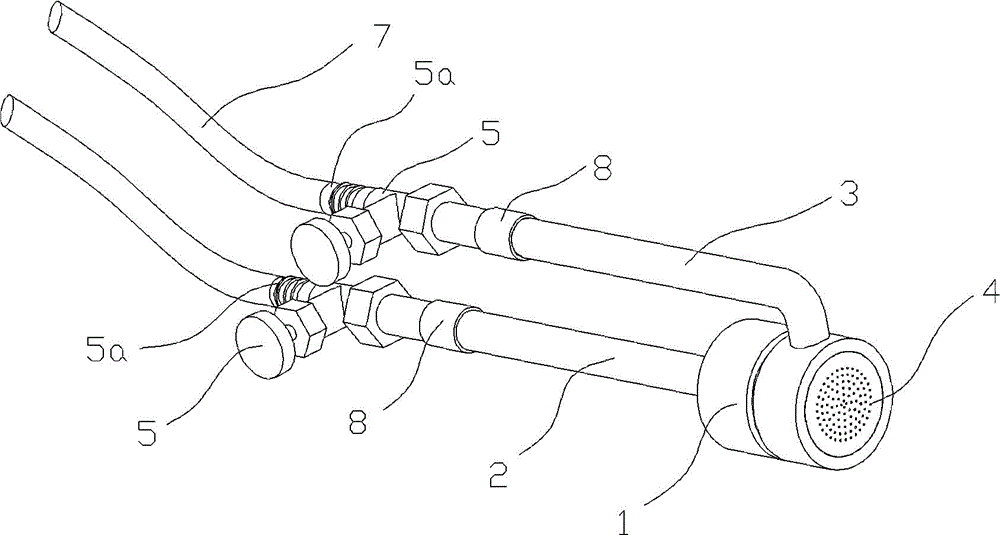

External-mixing polishing gun for glass ware

InactiveCN104791798AHigh combustion valueBurn fullyBurner safety arrangementsGaseous fuel burnerEngineeringMechanical engineering

The invention discloses an external-mixing polishing gun for a glass ware. The external-mixing polishing gun for the glass ware comprises a gun body with an inside hollow cavity. A group of air outlet holes are formed in one end face of the gun body. The other end face of the gun body is communicated with a main gas pipe. The side face of the gun body is communicated with a combustion-supporting gas pipe. The main gas pipe and the combustion-supporting gas pipe are both matched and communicated with the inside hollow cavity of the gun body. The external-mixing polishing gun for the glass ware is characterized in that the inside hollow cavity of the gun body is separated into a first cavity and a second cavity through a separator, and the two cavities are independent relatively; a group of gas-guide pipes are arranged at the end faces of the air outlet holes; the gas-guide pipes penetrate through the separator and communicate the first cavity and the outside world, the air outlet holes communicate the second cavity and the outside world. The external-mixing polishing gun for the glass ware has the advantages that the safety is good, tempering is avoided, and the service life is long; the defect like bubbling does not occur to a product; the combustion value is high, the firepower is concentrate, the flame is stable, gas can be burned sufficiently, and the fuel gas cost is saved effectively.

Owner:BENGBU JINGHUI GLASSWARE FACTORY

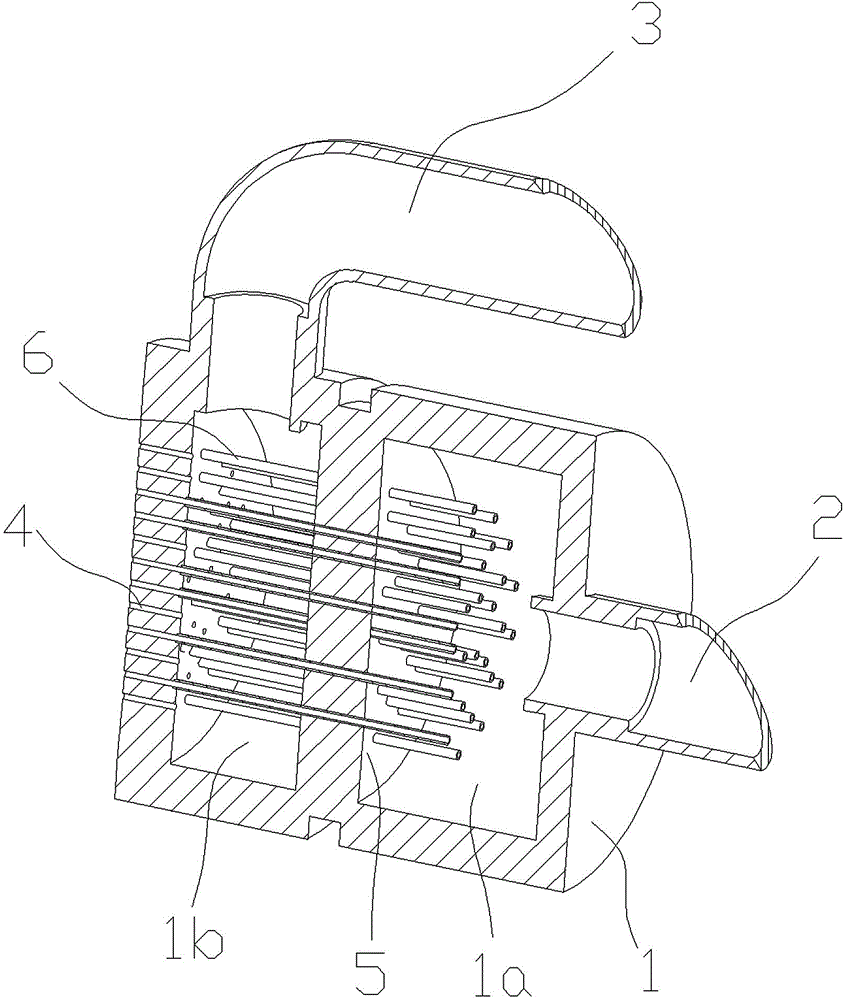

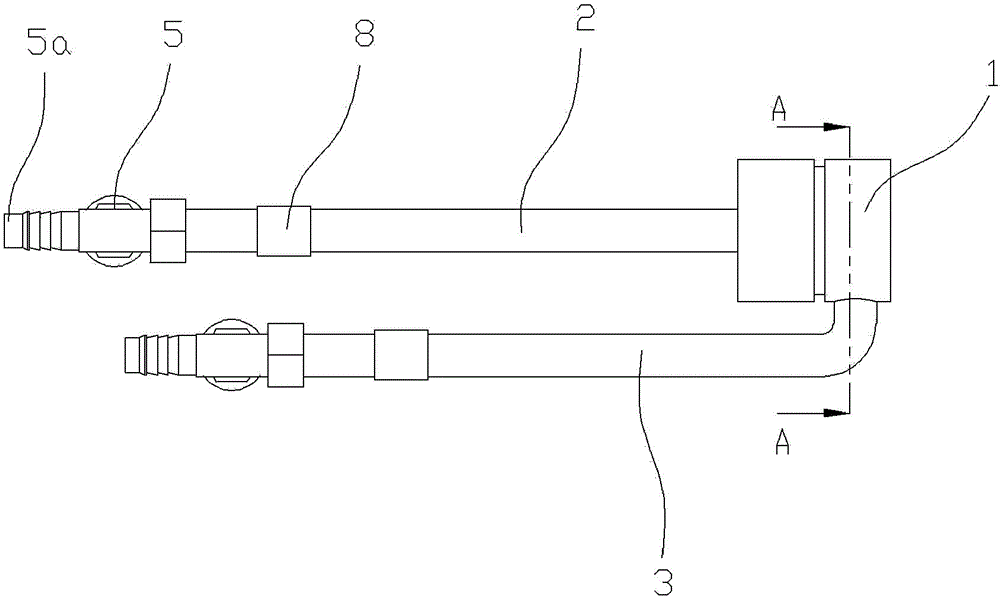

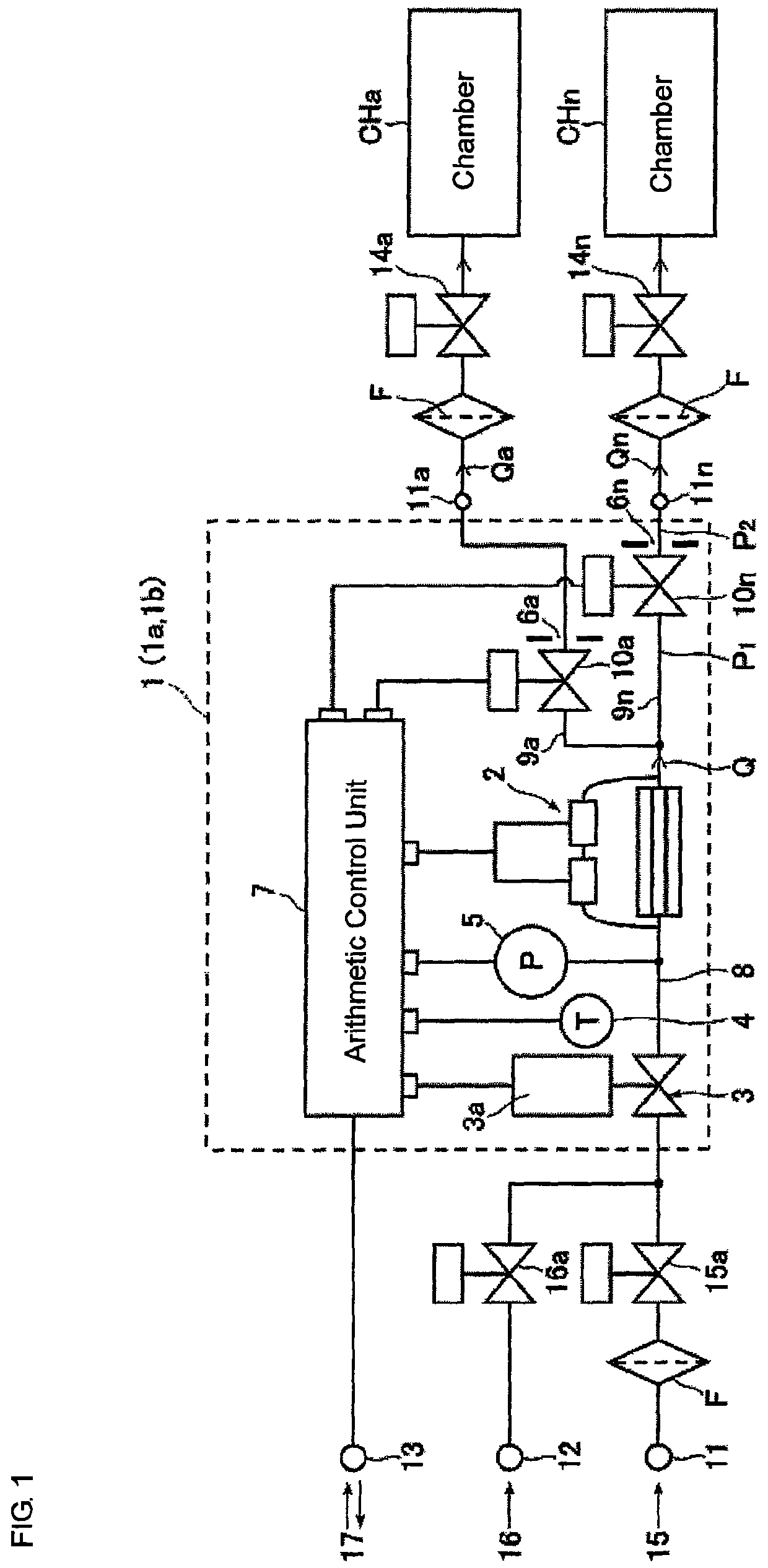

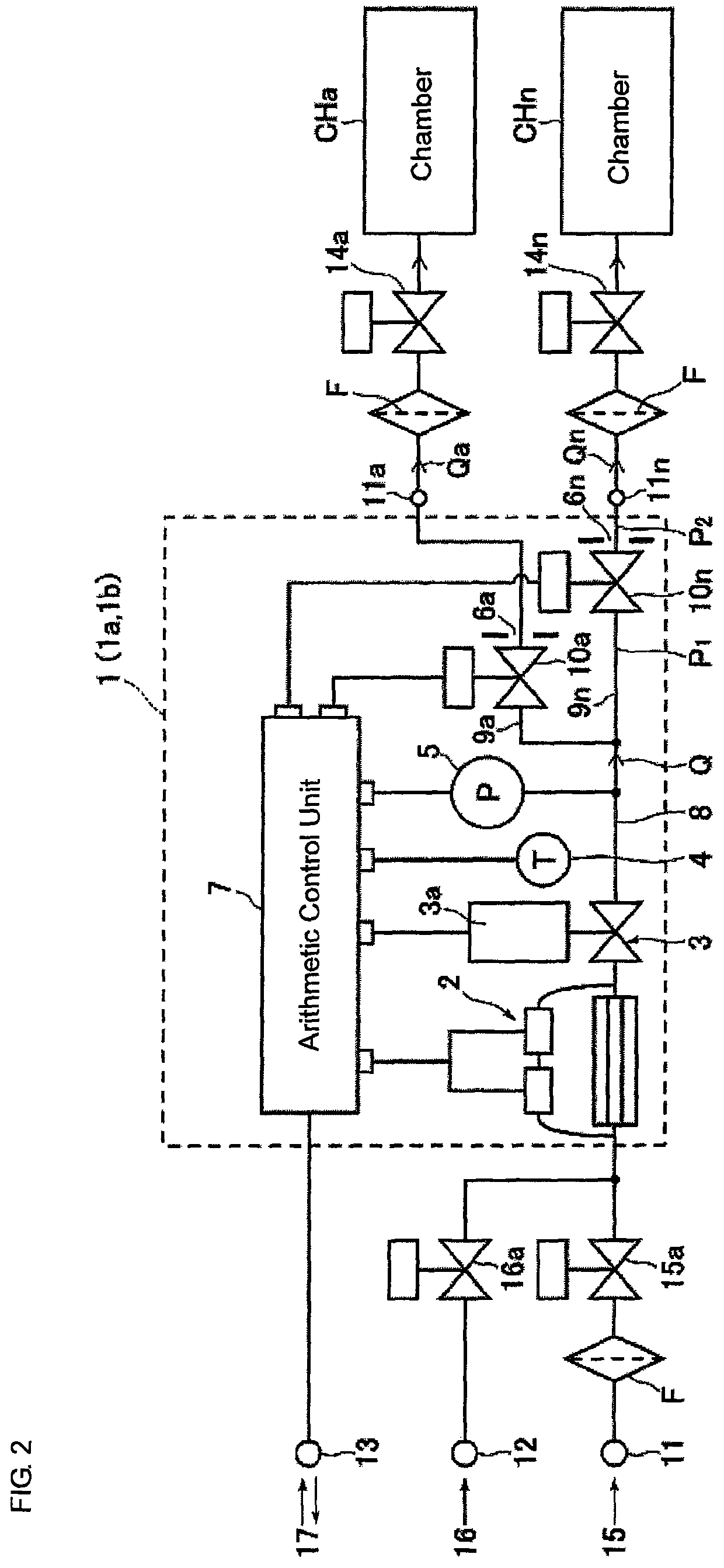

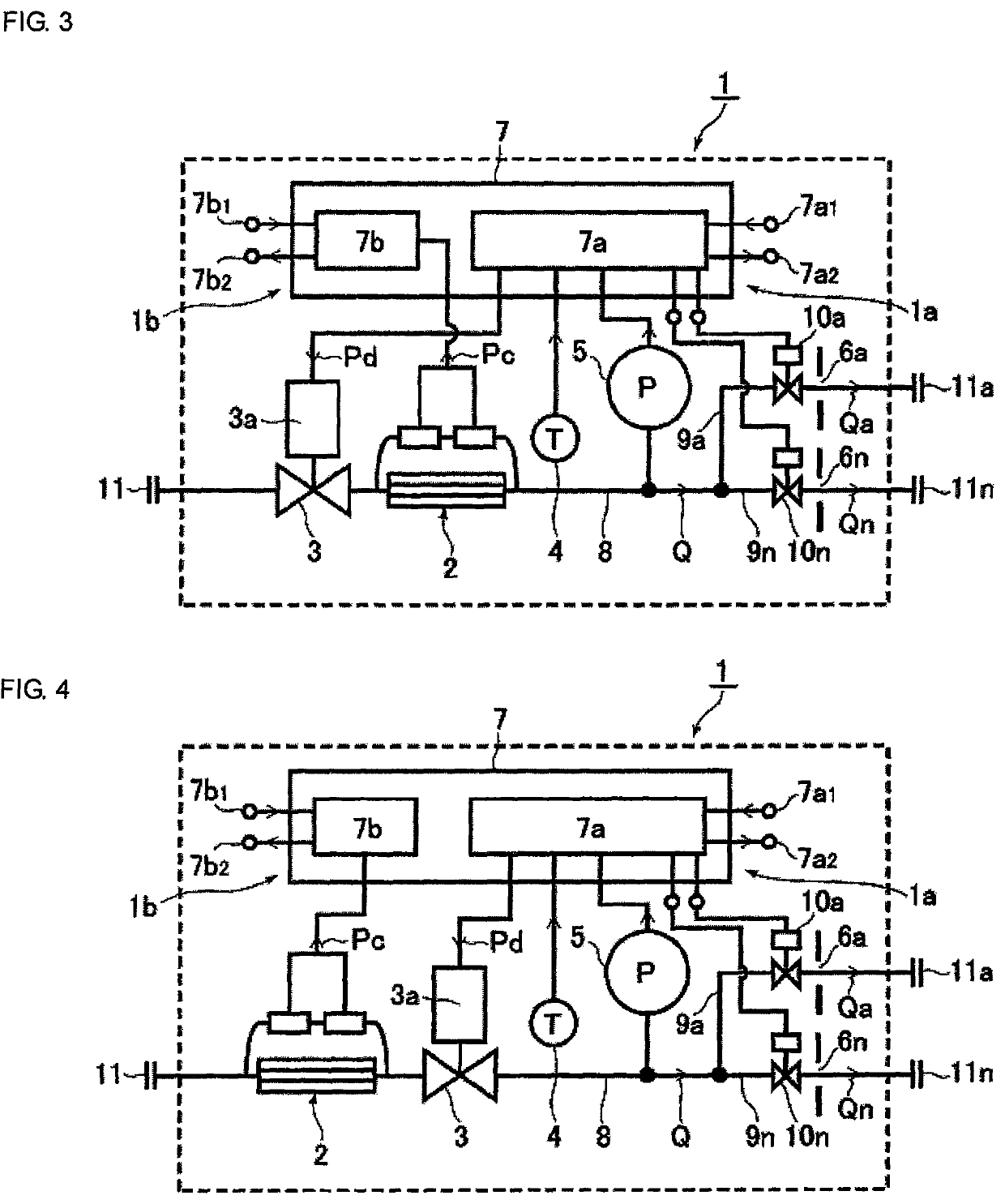

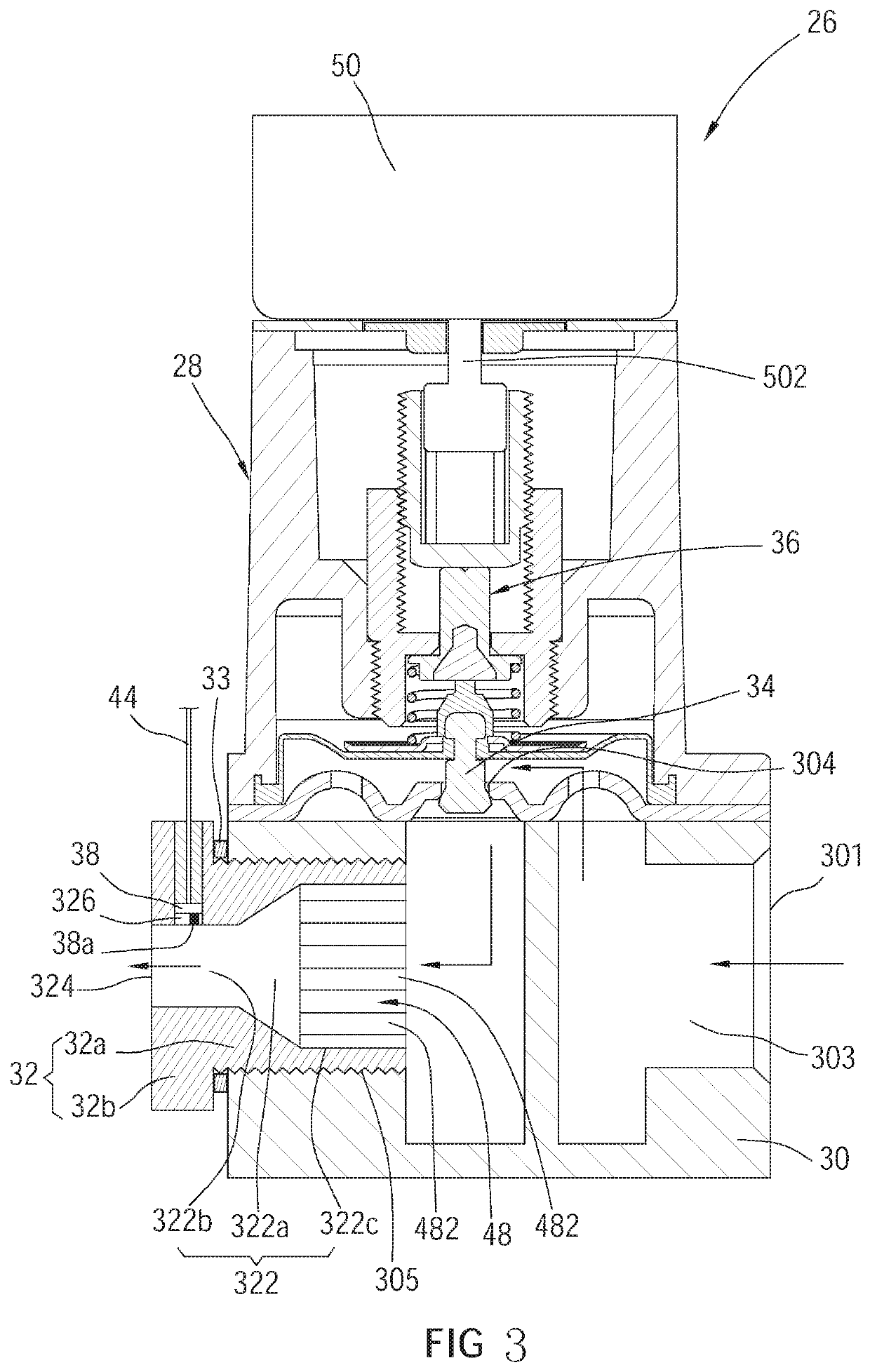

Gas divided flow supplying apparatus for semiconductor manufacturing equipment

ActiveUS10534376B2Simplification and downsizing of structureEasy to switchFlow control using electric meansSemiconductor/solid-state device manufacturingControl cellProcess engineering

A gas divided flow supplying apparatus, including a control valve 3, a pressure type flow control unit 1a connected to a process gas inlet 11, a gas supply main pipe 8 connected to the downstream side of control valve 3, a plurality of branched pipe passages 9a, 9n connected in parallel to the downstream side of main pipe 8, opening and closing valves 10a, 10n interposed in the respective branched pipe passages 9a, 9n, orifices 6a, 6n provided on the downstream sides of valves 10a, 10n, a temperature sensor 4 provided near the process gas passage between the control valve 3 and the orifices 6a, 6n, a pressure sensor 5 provided in the process gas passage between the control valve 3 and the orifices 6a, 6n, divided gas flow outlets 11a, 11n provided on the outlet sides of the orifices 6a, 6n, and an arithmetic and control unit 7.

Owner:FUJIKIN INC

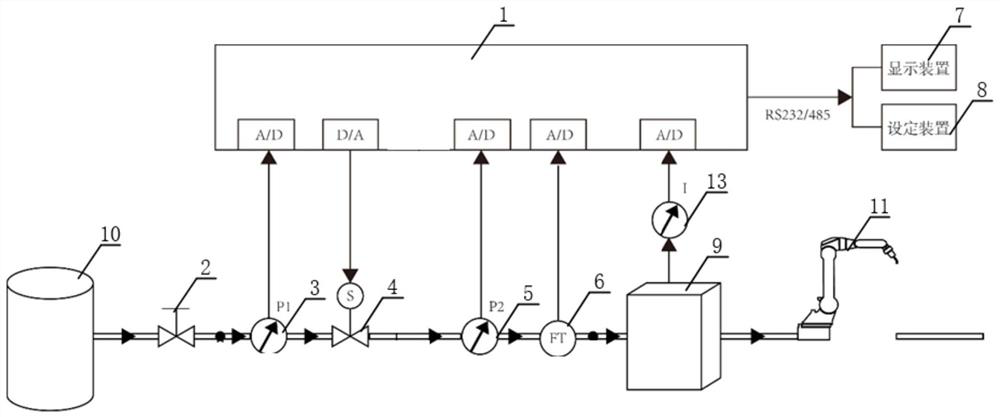

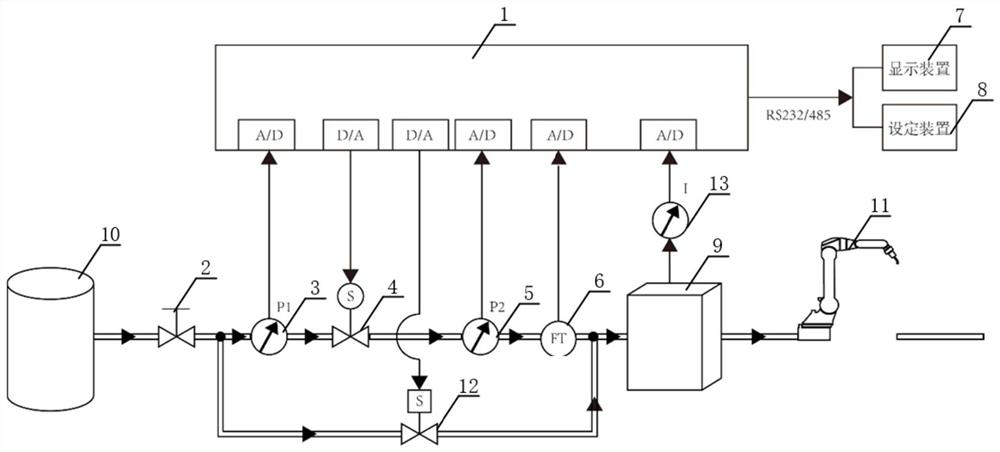

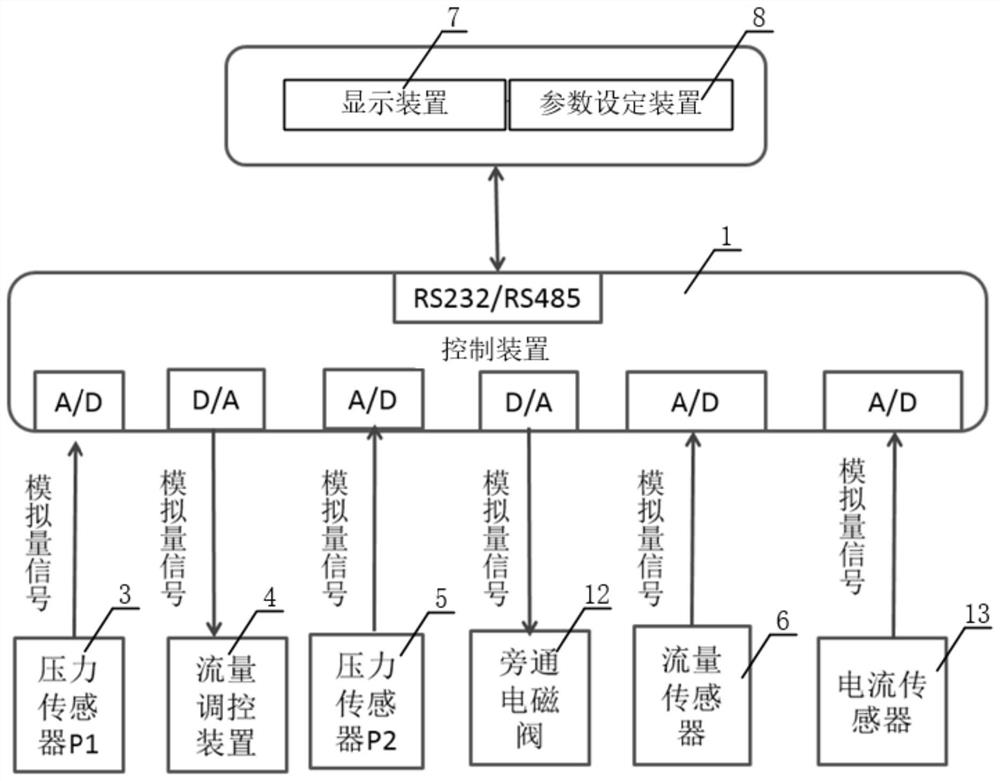

Gas control system for welding, gas control method for gas control system as well as welding system

InactiveCN111790967ARealize parallel controlImprove resource utilizationShielding gas supply/evacuation devicesControl systemControl engineering

The invention discloses a gas control system for welding, a gas control method for the gas control system and a welding system. The gas control system for welding comprises a control device, a safetyrelief device, a first pressure sensor, a flow regulating and controlling device, a second pressure sensor and a flow sensor, wherein the input end of the safety relief device is connected with a gassource; the output end of the safety relief device is connected with the input end of the flow regulating and controlling device; the output end of the flow regulating and controlling device is connected with the gas supply end of welding equipment; the first pressure sensor is arranged on a gas path between the safety relief device and the flow regulating and controlling device; the second pressure sensor and the flow sensor are arranged on a gas path between the flow regulating and controlling device and the welding equipment; and the control device is respectively and electrically connectedwith the flow regulating and controlling device, the first pressure sensor, the second pressure sensor, the flow sensor and the signal output end of a current sensor for collecting welding current ofthe welding equipment. The gas control system, the gas control method and the welding system disclosed by the invention realize the gas saving effect by dynamically regulating the flow of protectivegases, so that the utilization rate of energy is improved.

Owner:何苗

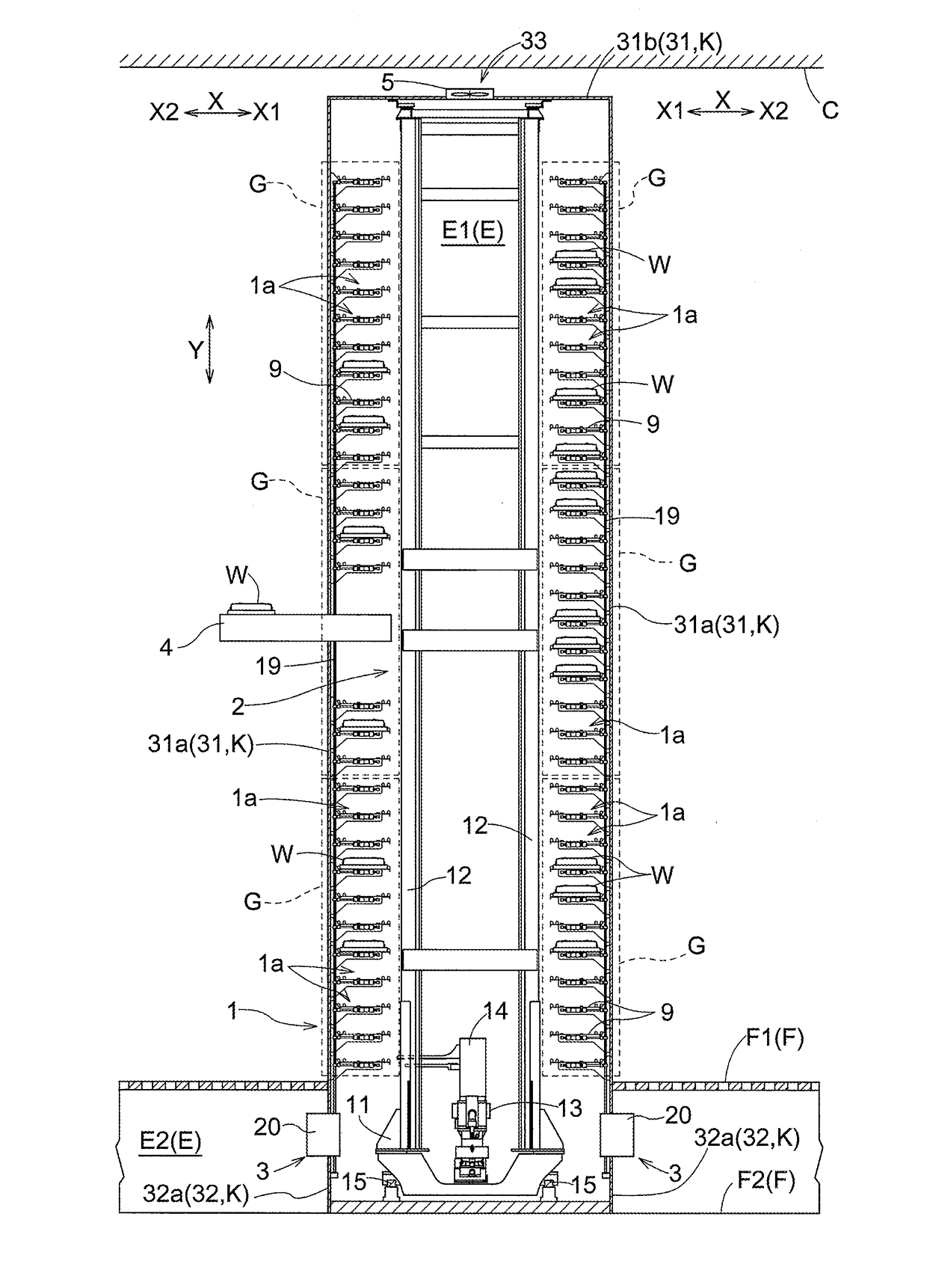

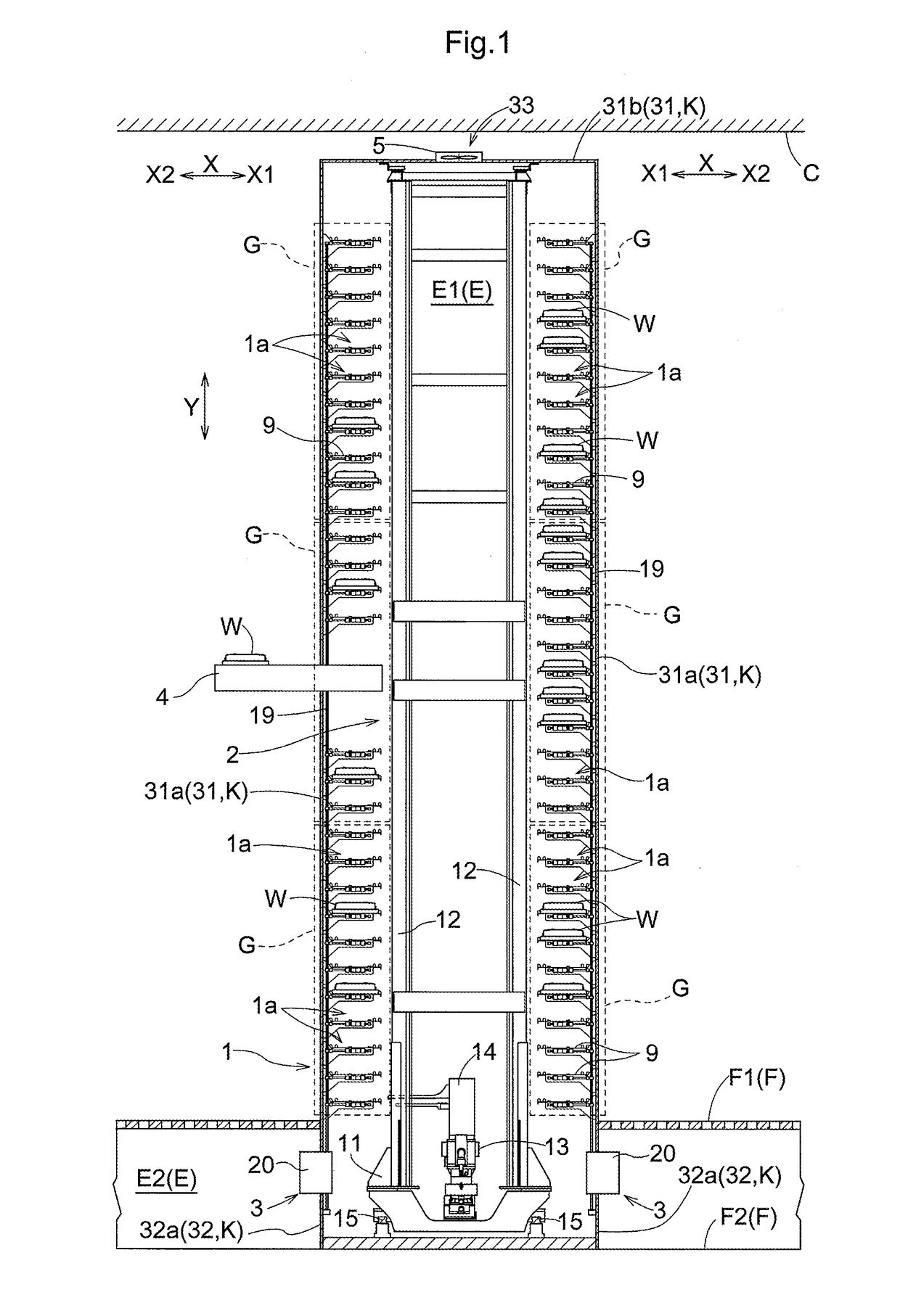

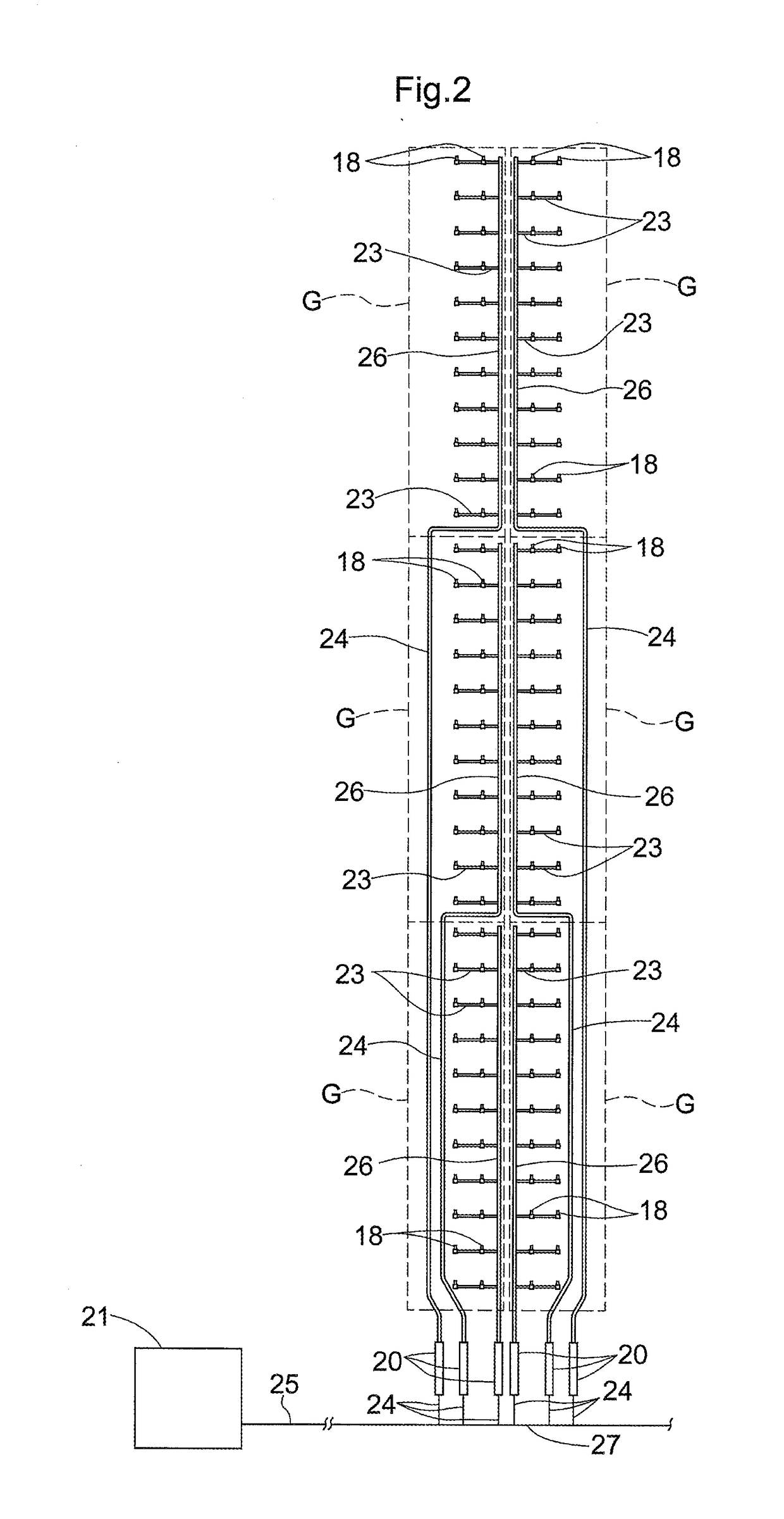

Container Storage Facility

ActiveUS20170283170A1Reduce manufacturing costEasy to installConveyorsSemiconductor/solid-state device manufacturingSupply StorageProcess engineering

A gas supplying device has a plurality of connectors each of which is configured to be connected to a container stored in the corresponding one of supplying storage sections, supply lines configured to divide and supply gas to the plurality of connectors, and a mass flow controller configured to control a flow rate of gas that flows through one of the supply lines. The supply lines include first supply lines each of which is installed to a corresponding supplying storage sections, a second supply line installed upstream of the first supply lines, and a branching supply line for dividing gas supplied from the second supply line into the first supply lines. The mass flow controller is installed in the second supply line and in an installation area.

Owner:DAIFUKU CO LTD

Gas circulating system for preparing high-quality diamond and application method thereof

ActiveCN108914088AHigh cycle supplyHigh purityChemical vapor deposition coatingMaterials preparationHydrogen

The invention relates to a gas circulating system for preparing high-quality diamond and an application method thereof, belonging to the field of material preparation. The gas circulating system comprises direct current jetted plasma chemical vapor deposition systems, a gas supply system, a tail gas circulating system and a gas purification system. The gas supply system supplies feed gas for two direct current jetted plasma chemical vapor deposition systems. The tail gas circulating system can pump out tail gas in the deposition systems and supply the tail gas to the gas purification system composed of a hydrogen purification apparatus. After the tail gas is purified, high-purity hydrogen and a gas mixture containing argon and carbon are separated, wherein the high-purity hydrogen is supplied for deposition devices, and the tail gas containing argon and carbon being used as the feed gas is supplied for one deposition device to deposit heat-sink grade diamond. Another deposition devicecan realize the supply of high-purity gas to deposit an optical-grade diamond film. By the process, the gas circulating system realizes the recycling of the high-purity hydrogen, can meet the preparation demand of a high-quality diamond film, and can also reduce the preparation cost.

Owner:UNIV OF SCI & TECH BEIJING

Industrial welding and cutting gas with environmental-protective and energy-saving functions

ActiveCN1896200AExpand the scope of useNot easy to explodeGaseous fuelsFuel additivesMethoxypropaneProduct gas

An environmental-protective and energy-saving welding and cutting gas consist of liquefied petroleum gas containing C3 and C4 and improver, the improver comprises 2-methoxy-propane and diamylene and other organic compounds mixed. It is safe, convenient and cheap, has better combustion stability and no environmental pollution.

Owner:BENFANG SCI & TECH DEV BEIJING

Material mixture for producing a fireproof material, fireproof molded body and method for the manufacturing thereof

InactiveUS8530364B2Suitably producedAdvantageously producedContinuous combustion chamberCasings/liningsSpinelRefractory

Owner:SIEMENS AG

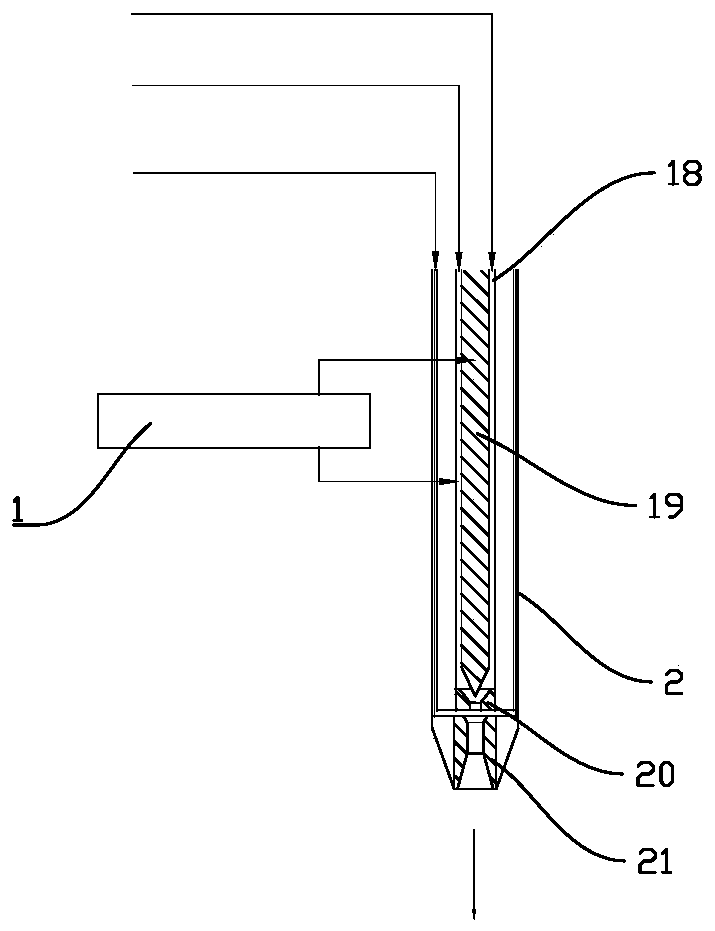

Method and device for massively preparing silicon nanomaterial

PendingCN110156022AIncrease the effective air intakeLower gas costsMaterial nanotechnologySiliconSilicon nanowiresThermal decomposition

The invention belongs to the technical field of nanomaterials, and relates to a method for massively preparing a silicon nanomaterial. The method comprises the following steps: a silicon-containing gas and an inert gas are input into a plasma gun, and are ionized and thermally decomposed in the plasma gun to obtain silicon ions and hydrogen ions; the silicon ions and hydrogen ions obtained throughionization and thermal decomposition enter a growth controller to afresh generate silicon nanowires and / or silicon nanoparticles; and the afresh generated silicon nanowires and / or silicon nanoparticles enter a cooling container, and are rapidly cooled and stably molded by a cooling gas released by a cooling gas ring. The invention also provides a device for massively preparing the silicon nanomaterial. The method and the device for massively preparing the silicon nanomaterial realize the industrial preparation of the silicon nanomaterial especially the silicon nanowires, and greatly reduce the manufacturing cost of the material.

Owner:金雪莉

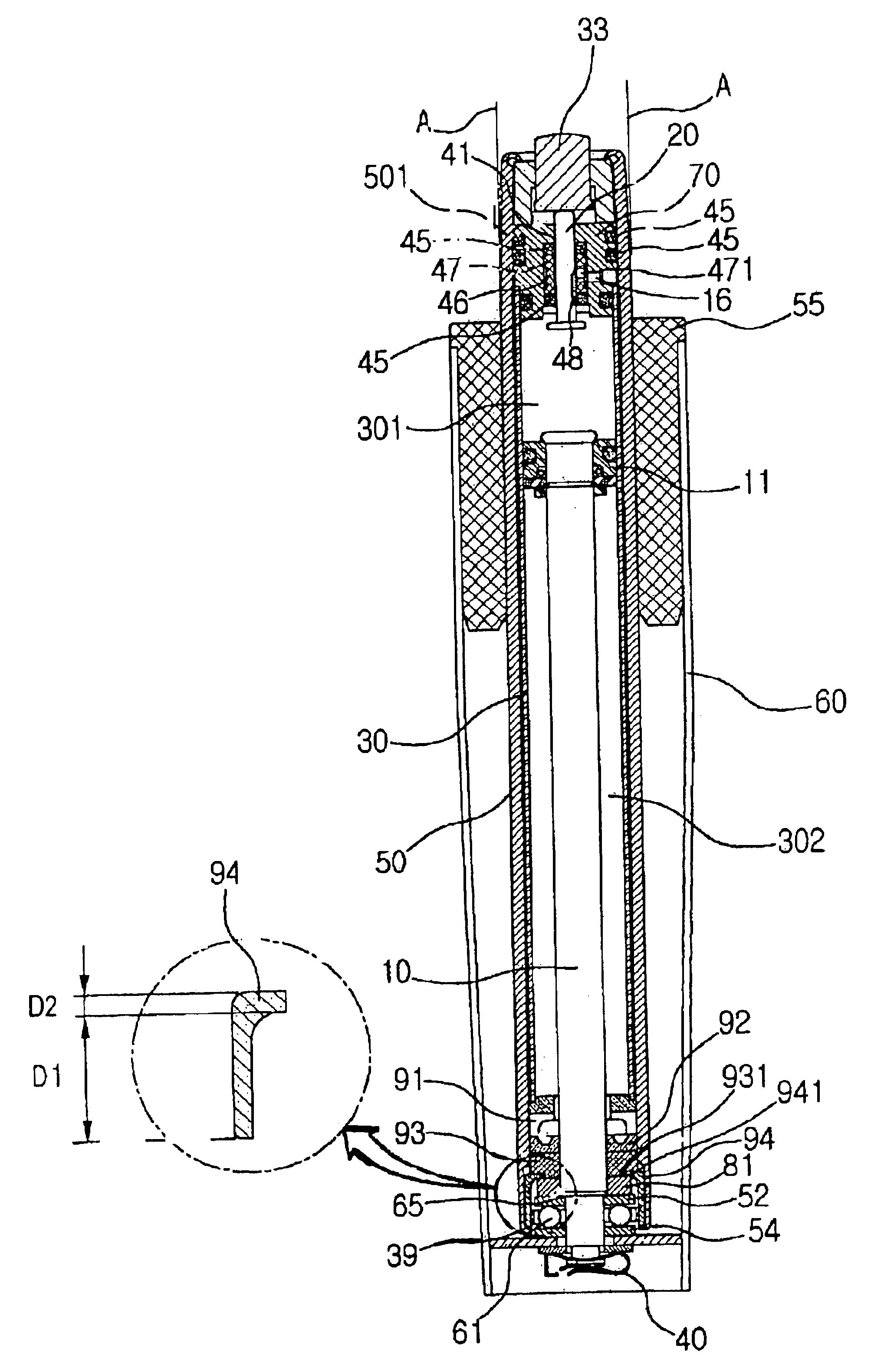

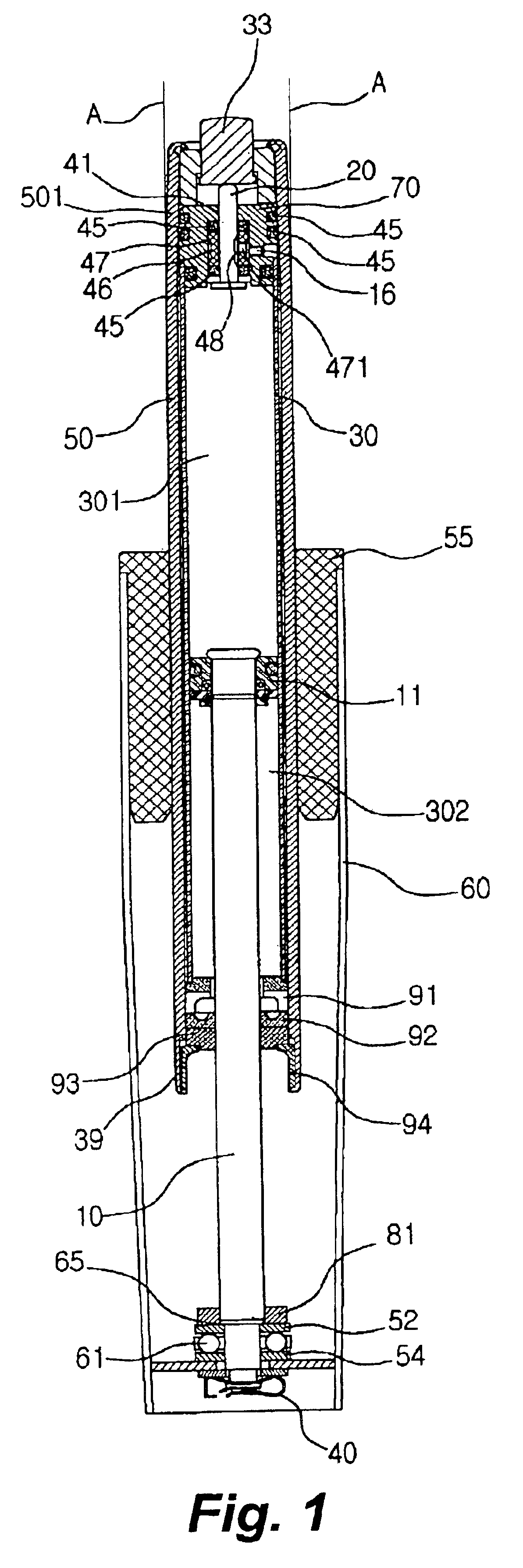

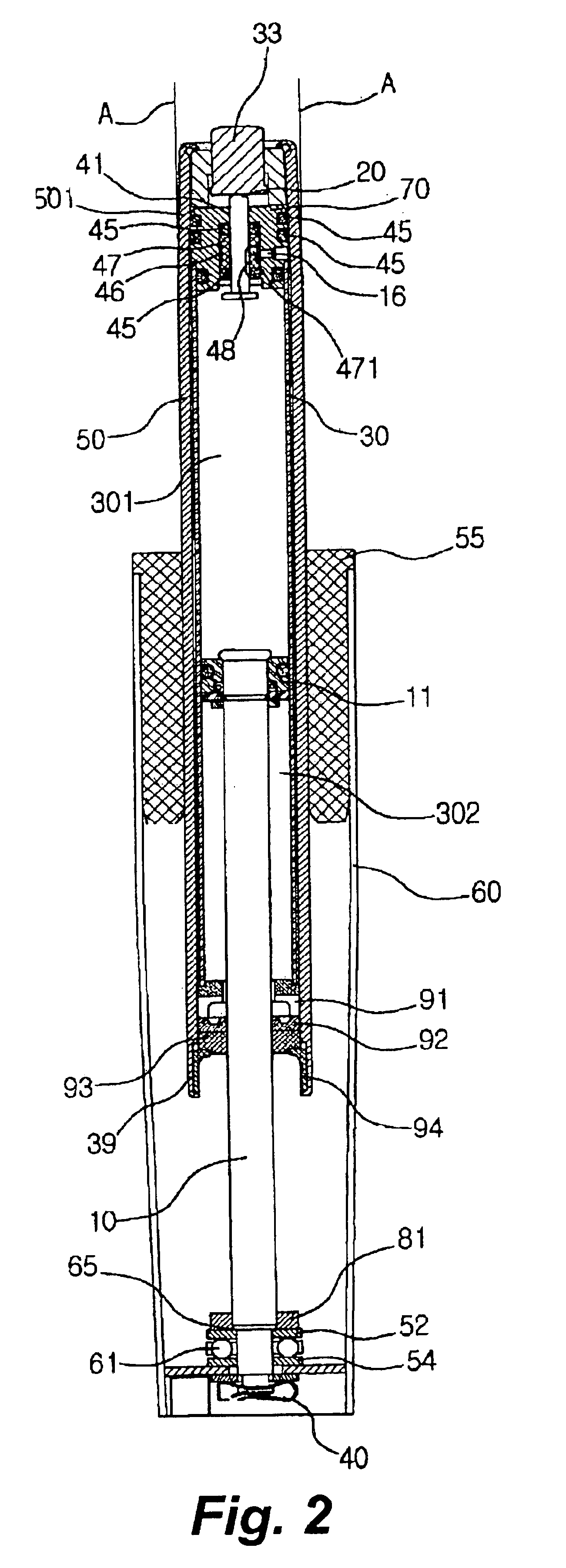

Gas cylinder

InactiveUS6840484B2Stroke distance can be maximizedSave gas costFurniture partsAdjustable chairsGas cylinderEngineering

Disclosed is a gas cylinder including: a spindle at least having a flange washer of a cavity shape having a region D1 and a region D2 whose inner diameters are different; a piston inserted to the open inside of the spindle; a piston rod whose one end is fixed in the piston; a base tube having a mounting member on which the lower end of the spindle is mounted with the mounting member inserted to the flange washer; and a pipe holder inserted to the tapered portion in the upper part of the spindle.

Owner:SAMHONGSA

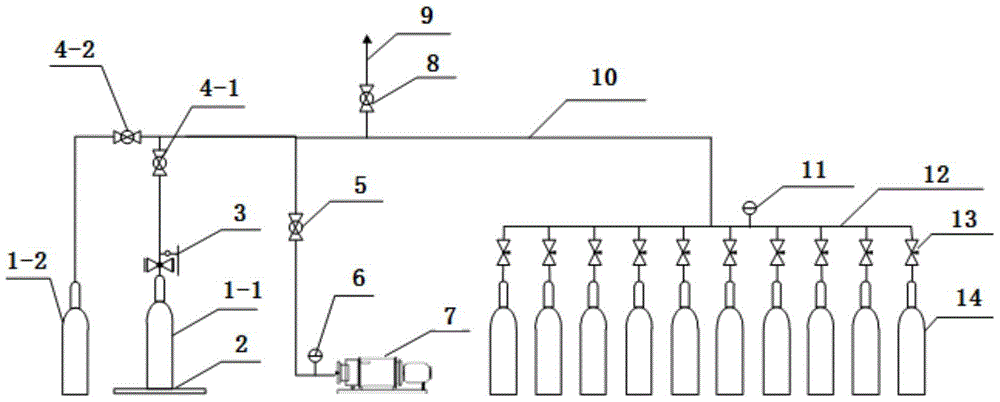

A device and method for preparing multi-bottle mixed gas

ActiveCN104888635BReduce mistakesImprove gas distribution accuracyMixer accessoriesMixing gases with gases/vapoursGas cylinderBottle

The invention discloses a device and method for preparing multi-bottle mixed gas, belonging to the field of mixed gas distribution. The device includes dilution gas raw material gas cylinders, component gas raw material gas cylinders, weighing devices, pressure reducing valves, first ball valves, second ball valves, high vacuum baffle valves, vacuum pressure gauges, vacuum pumps, venting control valves, exhaust Empty pipelines, raw material gas main pipelines, precision pressure gauges, product gas manifolds, needle valves, and product gas cylinders; the product gas manifold contains multiple gas pipelines, and the number of needle valves and product gas cylinders is the same as the number of gas pipelines. The quantity is equal. The steps of the method are as follows: Step 1, pipeline connection; Step 2, pipeline evacuation; Step 3, pipeline gas replacement; Step 4, mixed gas preparation; Step 5, pipeline evacuation. The low-concentration gas is prepared by using the device and method of the invention, which reduces the weighing error, improves the gas distribution accuracy, has fast gas distribution speed, is suitable for mass production, and saves the gas distribution cost. And the device is simple, and the method is easy to operate.

Owner:PERIC SPECIAL GASES CO LTD

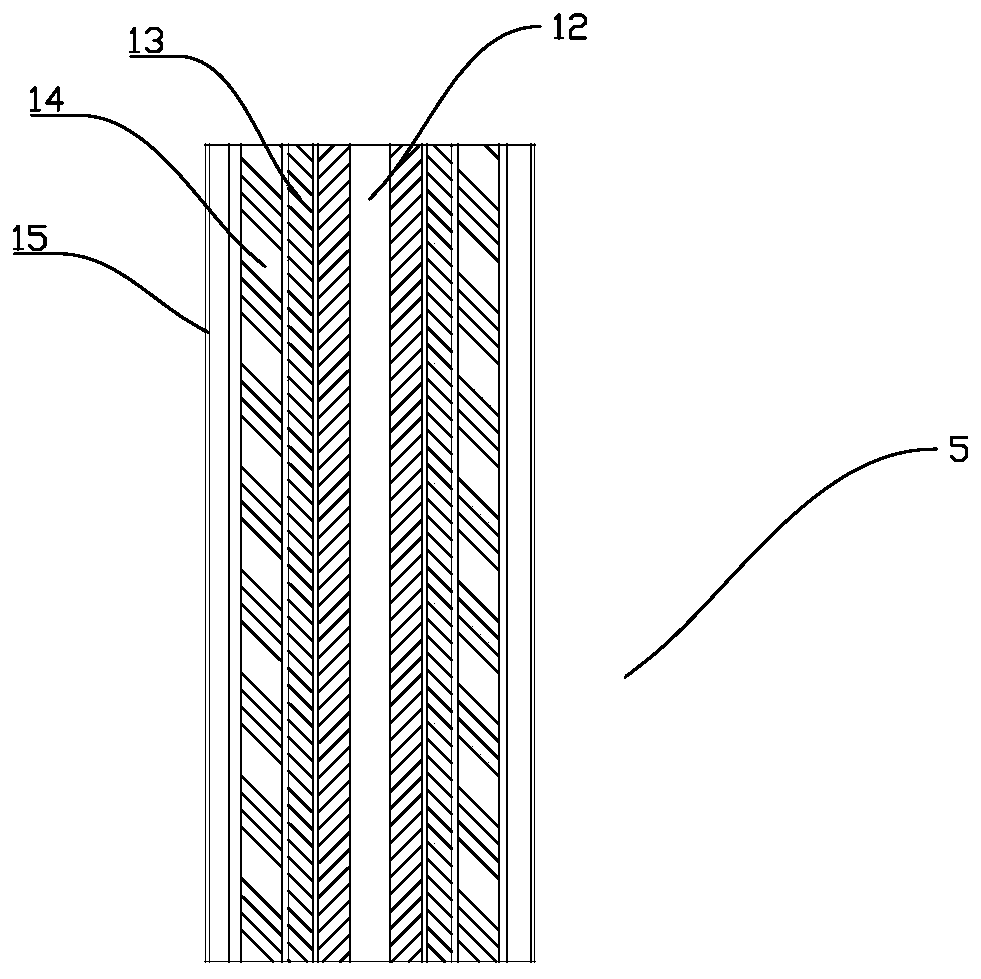

Underwater laser repairing device and method based on metal matrix composite material preparation

ActiveCN114561640AGuarantee the quality of workmanshipSave gas costIncreasing energy efficiencyMetallic material coating processesMaterials preparationLaser processing

The invention discloses an underwater laser repairing device and method based on metal matrix composite material preparation, and relates to the technical field of laser repairing, the underwater laser repairing device comprises an upper end cover body, an inner layer drainage cylinder, an outer layer drainage cylinder and a water retaining cover; the upper end cover body is arranged at the top of the inner-layer drainage cylinder and the top of the outer-layer drainage cylinder, the inner-layer drainage cylinder is arranged in the outer-layer drainage cylinder, and the water retaining cover is arranged at the outer bottom of the outer-layer drainage cylinder; an inner drainage cavity is defined by the upper end cover body and the inner-layer drainage cylinder, and an outer drainage cavity is defined by the upper end cover body, the inner-layer drainage cylinder and the outer-layer drainage cylinder; the upper end cover body is provided with a protection lens right above the inner drainage cavity; the inner drainage cavity and the outer drainage cavity are both communicated with the interior of the water retaining cover; and a powder feeding nozzle and a wire feeding nozzle are arranged on the water retaining cover. The device solves the problem that the service quality of the underwater laser repairing cladding layer is poor. The reachability is high, and the application range is wide. And the device is small in size and light in weight, and can enter a narrow space to work by matching with the flexible characteristic of laser processing.

Owner:HUAZHONG UNIV OF SCI & TECH

Gas detection apparatus

InactiveUS8293179B2Reduce power consumptionLow costChemical analysis using combustionMaterial analysis by optical meansSignal processing circuitsEngineering

A gas detection apparatus A comprises a signal processing circuit 20, a Wheatstone bridge circuit 21, integrating circuits 22 and 23, a differential amplification circuit 24, a direct current power supply circuit 25, a heater voltage application circuit 26. The Wheatstone bridge circuit 21 is configured of parallel combination of series circuits: one composed of a catalytic combustion type gas sensor 1 and a load resistor R1, and the other composed of a resistor R2, a variable resistor VR1 and a resistor R3. The heater voltage application circuit 26 is configured to generate a pulsed heater voltage by switching a direct current voltage of the direct current power supply circuit 25 through a transistor TR1 for applying the pulsed heater voltage to the Wheatstone bridge circuit 21. The integrating circuit 22 integrates a voltage at a connection point between the gas sensor 1 and the load resistor R1. The integrating circuit 23 integrates a voltage at a connection point between the variable resistor VR1 and the resistor R3. The differential amplification circuit 24 is configured to amplify a differential voltage between the output voltages of the integrating circuits 22 and 23. The signal processing circuit 20 is configured to determine a concentration of a flammable gas from an output voltage of the differential amplification circuit 24.

Owner:FIDELITY NATIONAL INFORMATION SERVICES

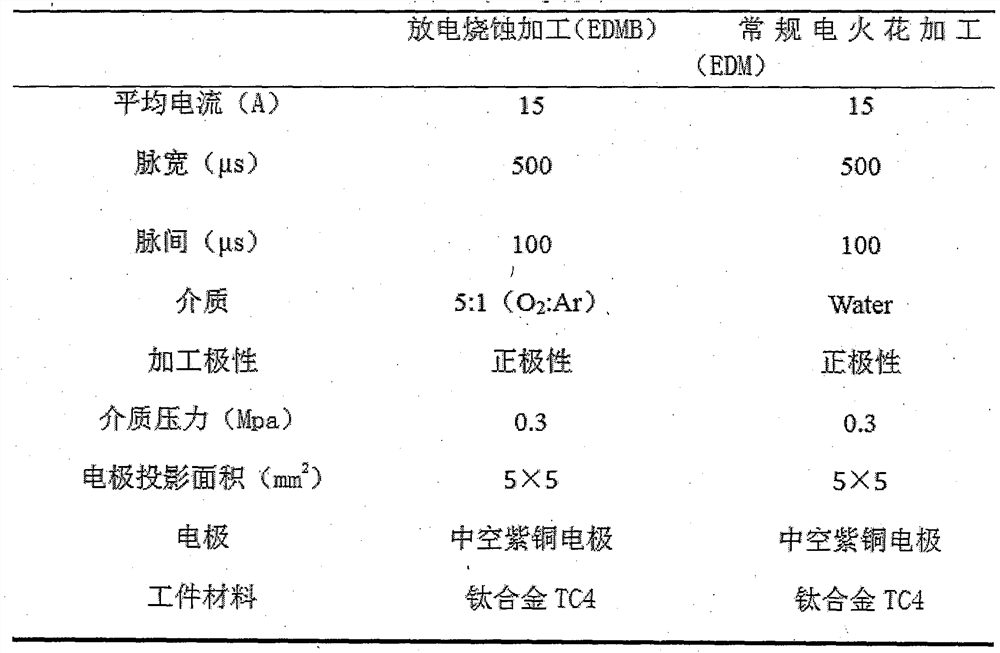

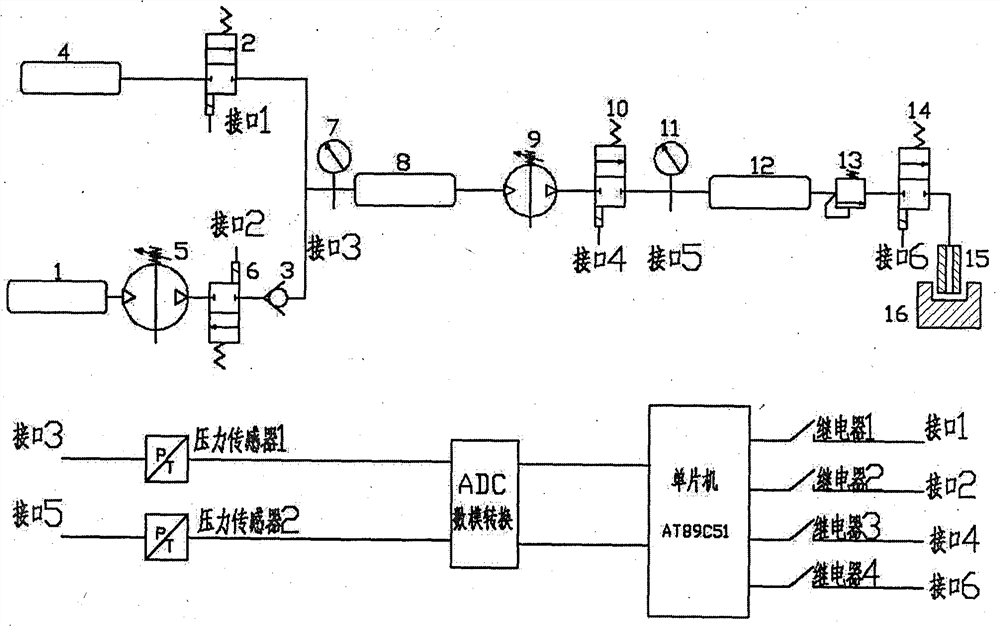

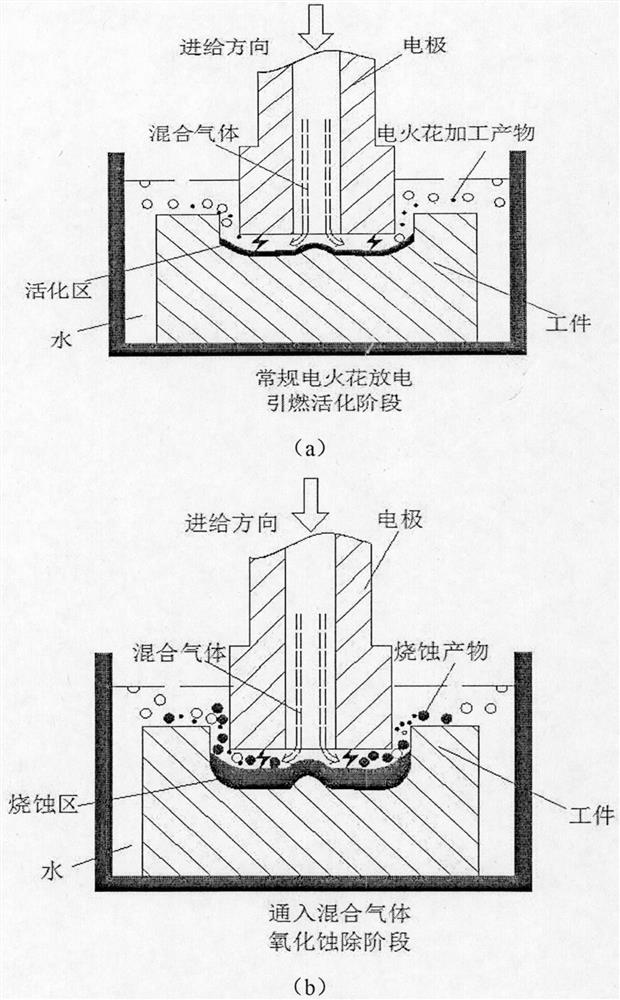

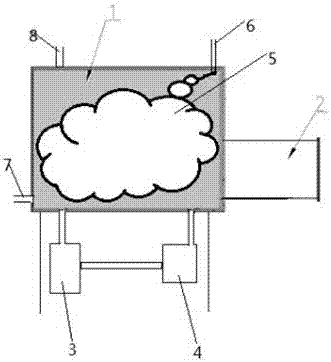

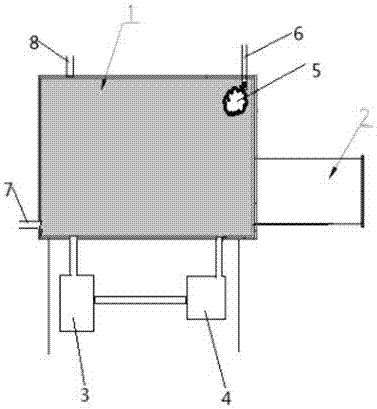

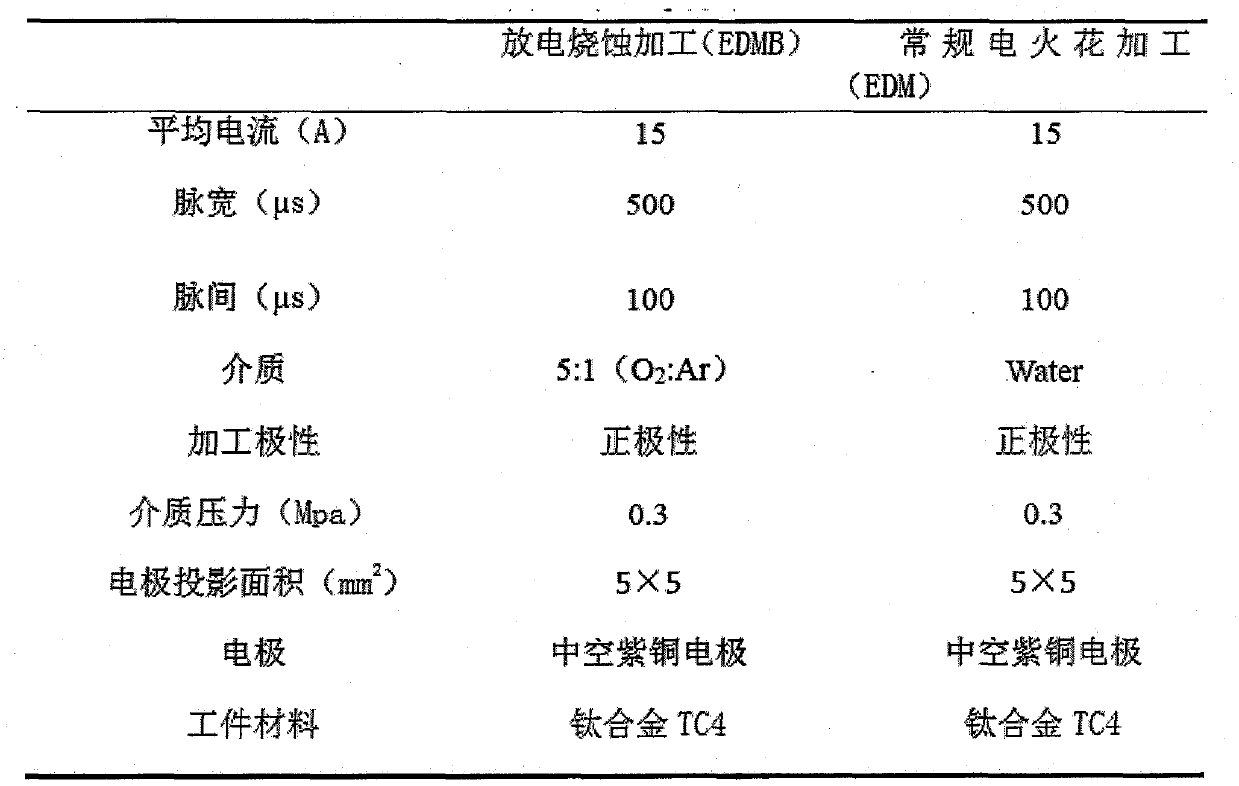

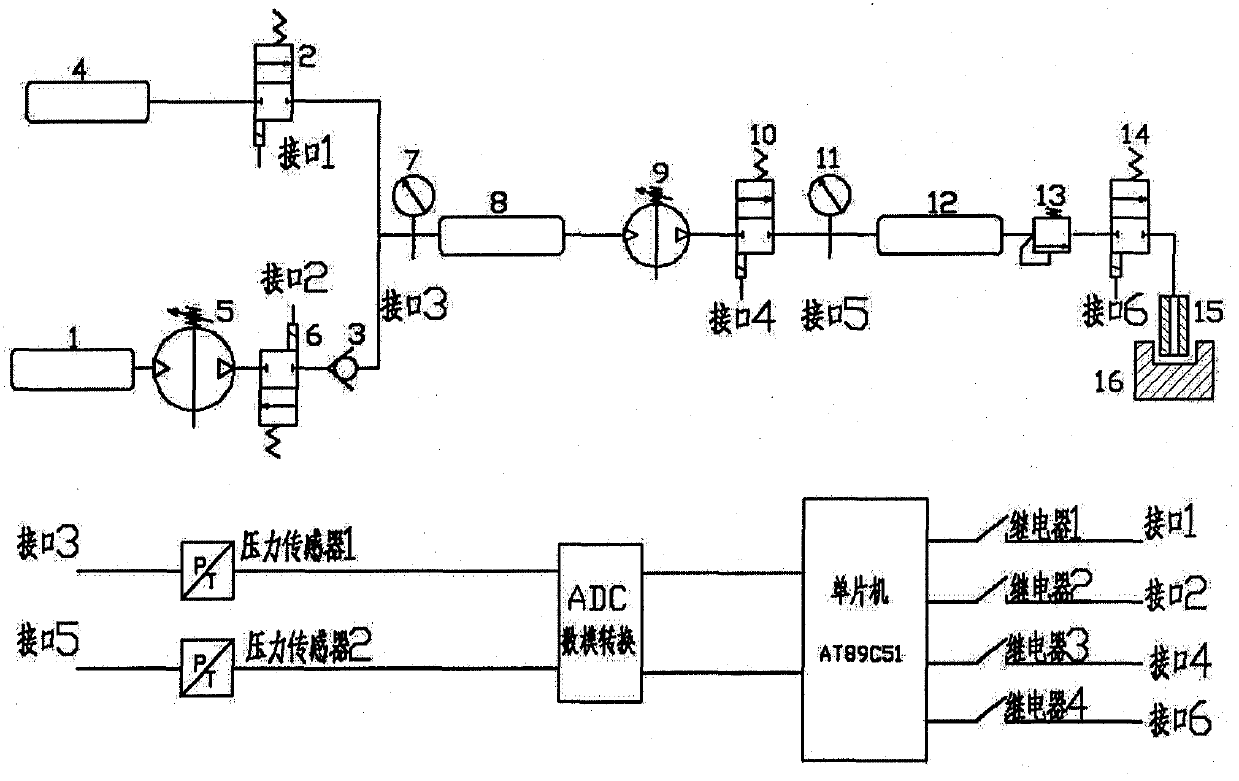

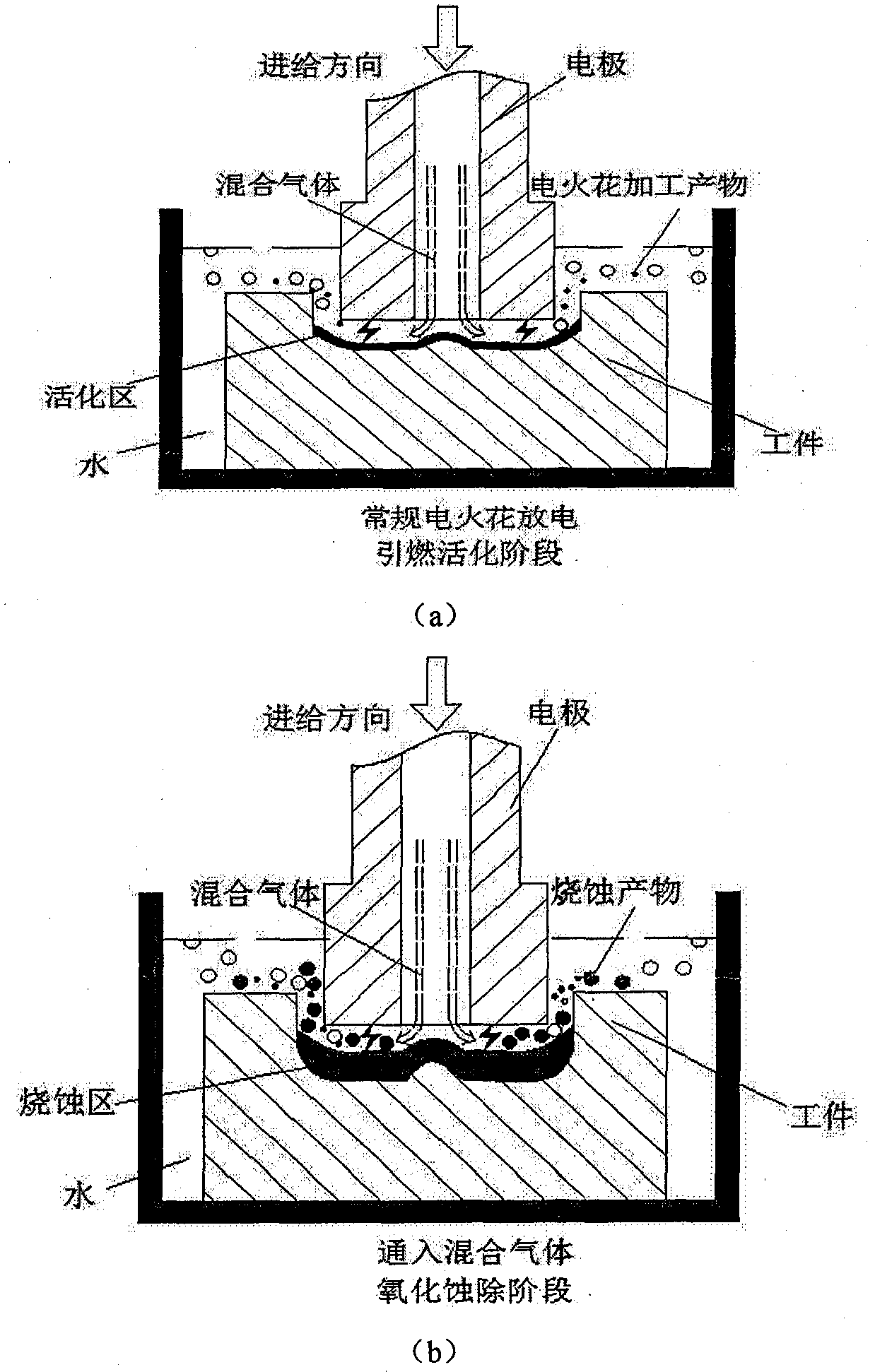

Controllable discharge ablation processing method for flammable and difficult-to-process materials with adjustable combustion-supporting gas concentration

ActiveCN110605442BPrevent uncontrollable explosionsEfficient processingElectric circuitsChemical reactionCombustion

The invention provides a controllable discharge ablation method for a combustible difficult-to-process material and with adjustable combustion-supporting gas concentration. The method is characterizedin that a mixed gas medium provided by a special combustion-supporting gas concentration adjustable gas supply device is introduced before processing; during processing, inter-pole voltage required to breakdown the mixed gas medium is supplied to two poles through a pulse power supply, and required energy is provided for melting and gasification of an inter-pole workpiece material; after a metalmaterial forms a high-temperature molten material, the high-temperature molten material and combustion-supporting gas in the mixed gas medium are subjected to a severe oxidation chemical reaction, a large amount of chemical energy is generated, extra ablation energy is introduced for efficient material ablation, and therefore the material removal rate of the combustible difficult-to-process material is improved under the condition that the discharge energy of the pulse power supply is certain. By means of the special gas supply device, the concentration of the combustion-supporting gas participating in the oxidation reaction is controlled, the explosion phenomenon caused by violent combustion in the processing process is avoided, the damage of a machined workpiece is avoided, and controllable and efficient processing of the combustible difficult-to-process material is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gas appliance, gas valve and control method thereof

ActiveUS11060724B2Sensed accurately and rapidlyGas flow rate could be controlled more accuratelyFuel supply regulationCombustion regulation systemsCombustorElectric machinery

A gas appliance includes a burner, a gas valve, and a control device, wherein the gas valve includes a valve body, a flow regulator, a hot film anemometer, and a stepper motor. The valve body communicates with the burner and a gas source. The flow regulator is driven by the stepper motor to change a gas flow rate supplying to the burner. The hot film anemometer is disposed in the valve body and includes a probe exposed to the outlet passage. The control device executes a control method for the gas valve: sensing the gas flow rate in the outlet passage with the hot film anemometer; comparing the gas flow rate sensed by the hot film anemometer with a predetermined gas flow rate, and controlling the stepper motor to drive the flow regulator based on the comparison result, whereby to stabilize the gas flow rate.

Owner:GRAND MATE

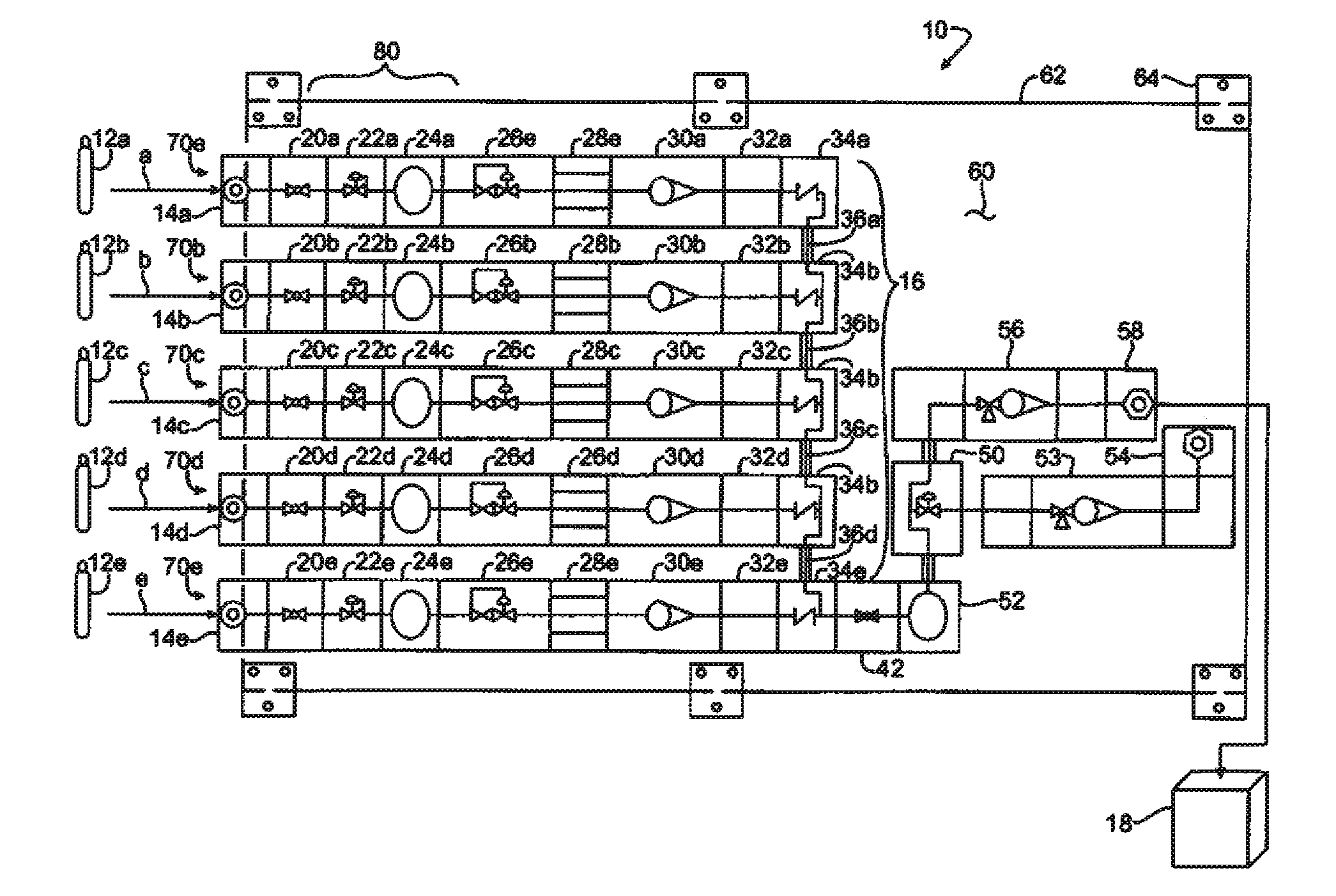

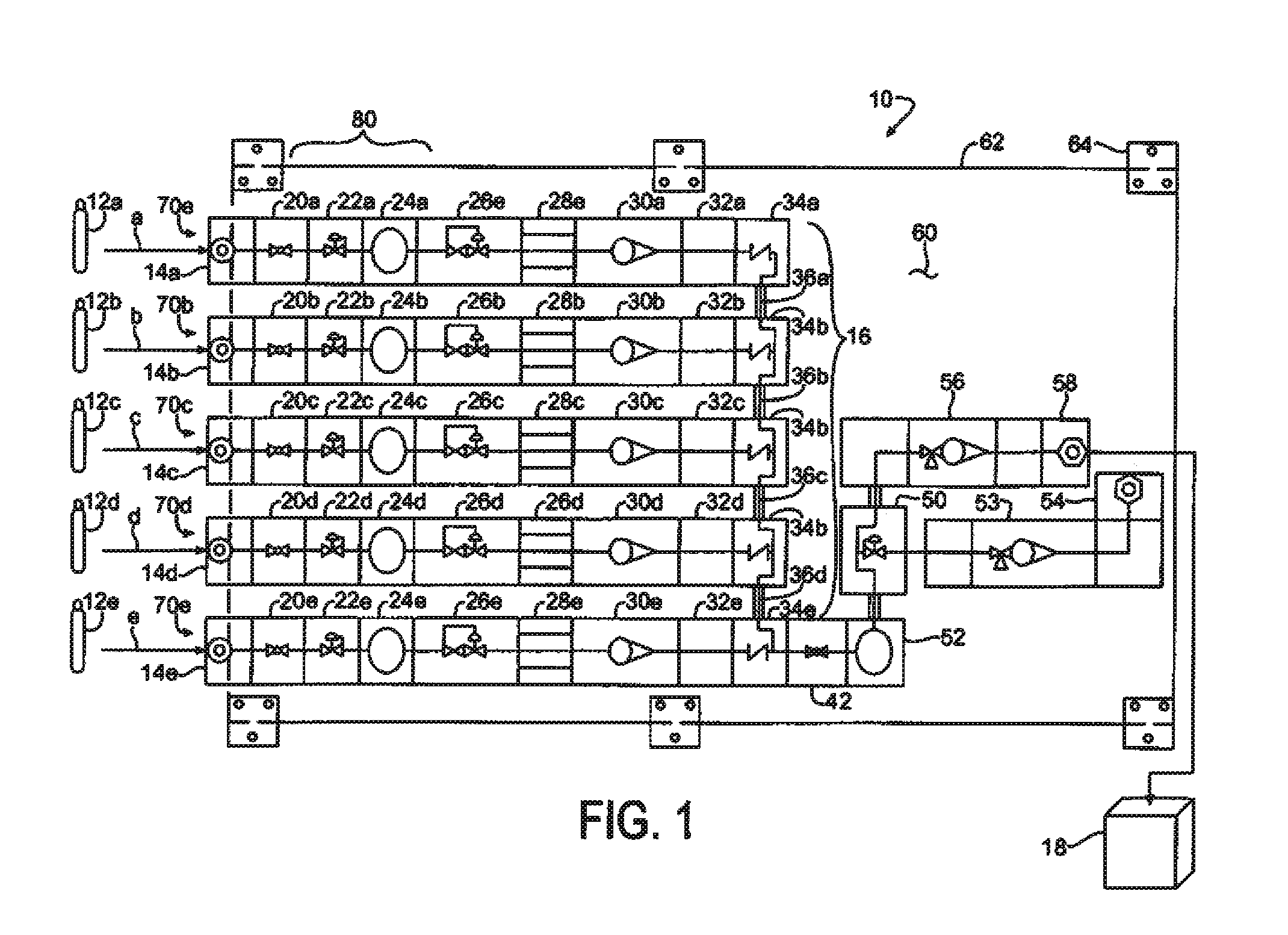

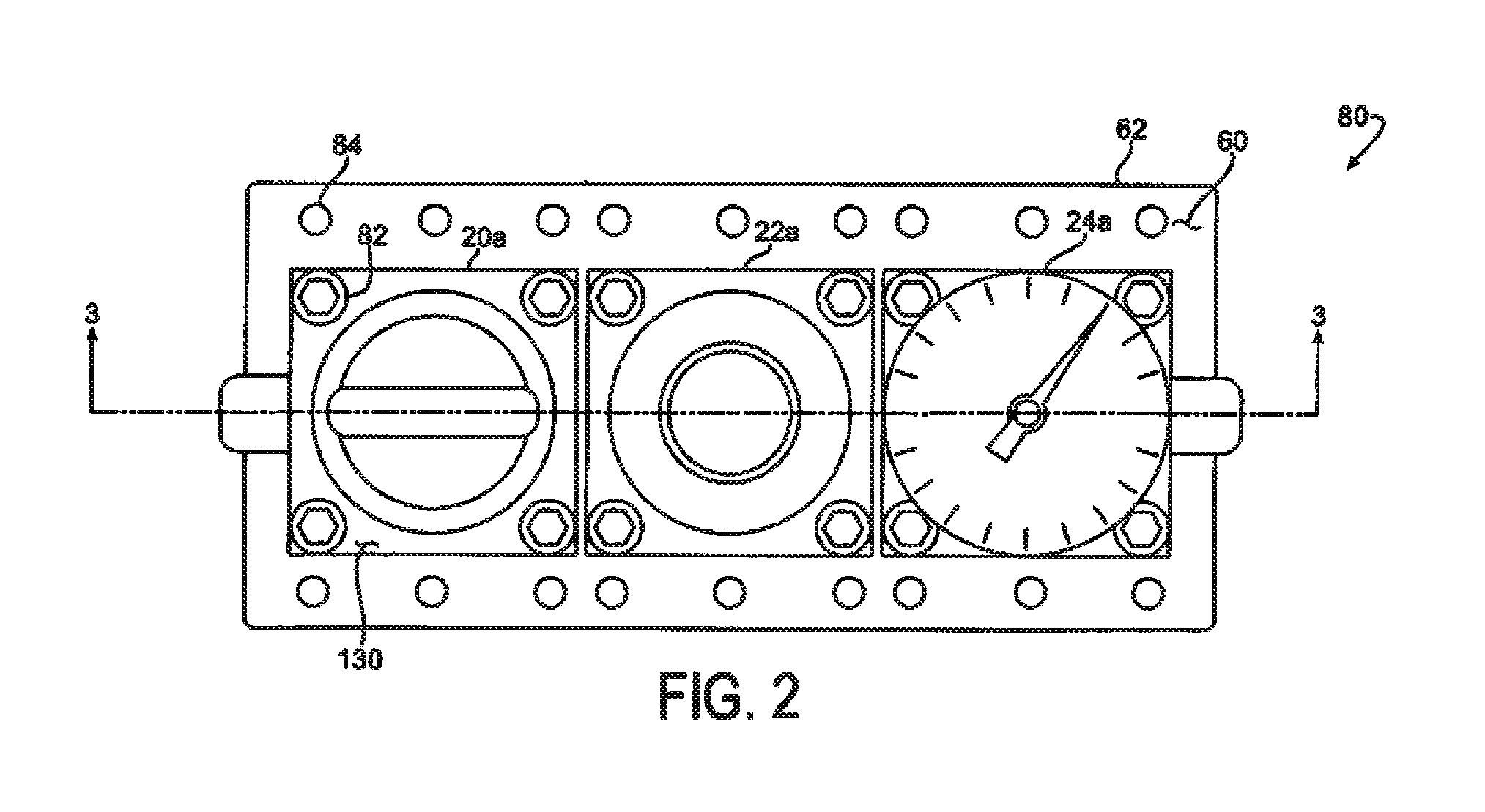

Modular fluidic mixing system

InactiveUS20120298238A1Reduce in quantityEasy to changeFlow mixersMixer accessoriesBiomedical engineering

Modular fluidic mixing system for delivering a fluid mixture from separate sources to a point of use. The system includes a mounting board and a series of rows of substrate fittings mounted on the board. Each row has a first end fitting connected to one of the fluid sources and a second end fitting. Each of the fittings in a row is connected in fluid communication to an adjacent one of the fittings in the row to define a fluid flow path from the one of the fluid sources to the second end fitting. Each second end fitting in each row is connected in fluid communication to an adjacent second end fitting in an adjacent row to define a mixing header. The fluids are mixed within the header and exit as a mixture. Fluid flow components for controlling flow from the fluid sources are mounted to the fittings.

Owner:PARKER HANNIFIN CORP

Built-in airbag type glove box and method for cleaning glove box in airbag manner

The invention provides a built-in airbag type glove box and a method for cleaning the glove box in an airbag manner. An airbag capable of being filled with air is arranged in a box body of the glove box. An air inflation and deflation connector of the airbag is located on the outer portion of the glove box. The inner air of the airbag does not communicate with inner air of the glove box. According to the built-in airbag type glove box and the method for cleaning the glove box in the airbag manner, when a water-free and oxygen-free environment is restored after initial assembly and unpacking maintenance of the glove box, the cleaning air amount can be greatly reduced and is even only 1 / 10 of the original air amount, and the use cost is greatly reduced.

Owner:VIGOR GAS PURIFICATION TECHNOLOGIES (SUZHOU) CO LTD

Controllable discharge ablation method for combustible difficult-to-process material and with adjustable combustion-supporting gas concentration

ActiveCN110605442APrevent uncontrollable explosionsEfficient processingElectric circuitsChemical reactionMaterial removal

The invention provides a controllable discharge ablation method for a combustible difficult-to-process material and with adjustable combustion-supporting gas concentration. The method is characterizedin that a mixed gas medium provided by a special combustion-supporting gas concentration adjustable gas supply device is introduced before processing; during processing, inter-pole voltage required to breakdown the mixed gas medium is supplied to two poles through a pulse power supply, and required energy is provided for melting and gasification of an inter-pole workpiece material; after a metalmaterial forms a high-temperature molten material, the high-temperature molten material and combustion-supporting gas in the mixed gas medium are subjected to a severe oxidation chemical reaction, a large amount of chemical energy is generated, extra ablation energy is introduced for efficient material ablation, and therefore the material removal rate of the combustible difficult-to-process material is improved under the condition that the discharge energy of the pulse power supply is certain. By means of the special gas supply device, the concentration of the combustion-supporting gas participating in the oxidation reaction is controlled, the explosion phenomenon caused by violent combustion in the processing process is avoided, the damage of a machined workpiece is avoided, and controllable and efficient processing of the combustible difficult-to-process material is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

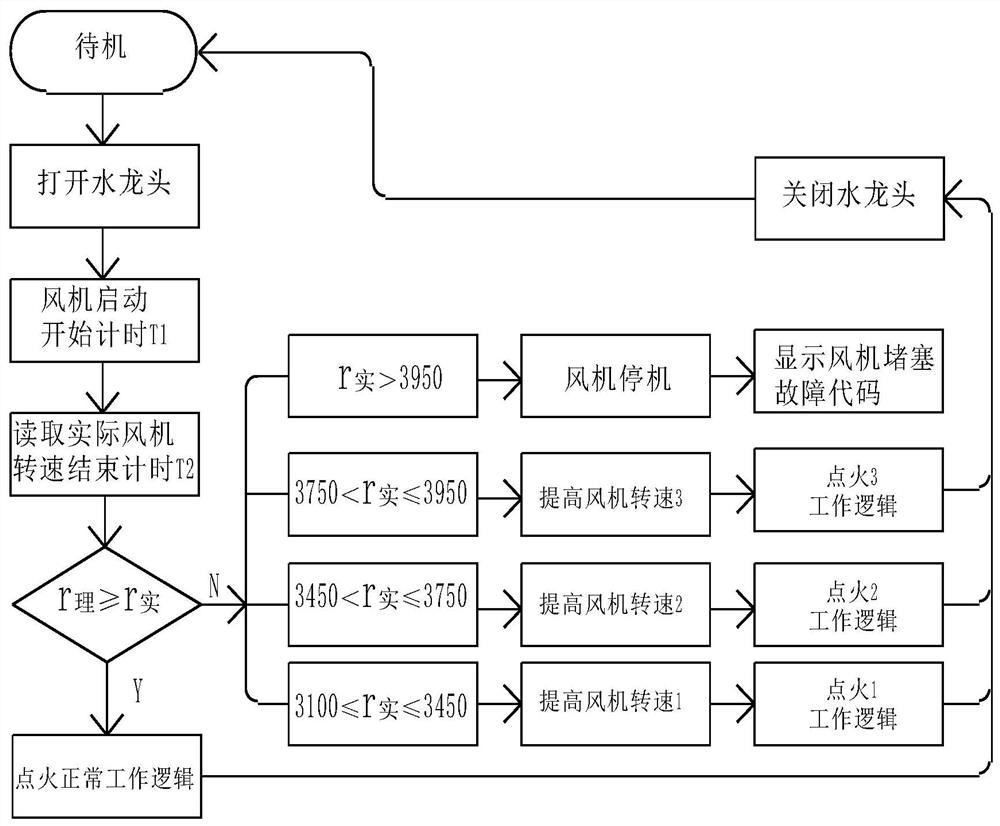

Ignition control method for gas water heater and wall-hung boiler adaptive to flue pressure change

ActiveCN109612073BImprove the safety of useImprove combustion efficiencyWater heatersThermodynamicsThermal water

The invention discloses an ignition control method for a gas water heater and a wall-hanging stove with adaptive flue pressure change. The ignition control method for the water heater and the wall-hanging stove with the adaptive flue pressure change includes the following steps that S1, when the gas water heater or the wall-hanging stove is on standby, a hot water tap is turned on, a fan is started, and an actual fan rotation speed is obtained; S2, a size relation between the actual fan rotation speed and a theoretical fan rotation speed is judged, and the theoretical fan rotation speed is a fan rotation speed when external pressure of the flue of the gas water heater or the wall-hanging stove is equal to internal pressure of the flue, the actual fan rotation speed is the fan rotation speed when the external pressure of the flue of the gas water heater or the wall-hanging stove is not equal to the internal pressure of the flue; and S3, the fan rotation speed and ignition logic of the gas water heater or the wall-hanging stove are adjusted according to the judgment result of S2, so that the gas water heater or the wall-hanging stove can be ignited and operated normally; and the rotation speed of the fan can be compensated quickly according to blockage of the flue or the external wind pressure and a high and reliable ignition success rate is realized.

Owner:成都前锋电子有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com