Gas mixing route acetylene black cracking furnace

A technology of acetylene carbon black and cracking furnace, applied in fibrous fillers and other directions, can solve the problems of increasing production and operation costs and investment, difficulty in large-scale cooling and softening water, and high labor costs, and achieves expansion of single-line production capacity, good social benefits, and reduction of consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

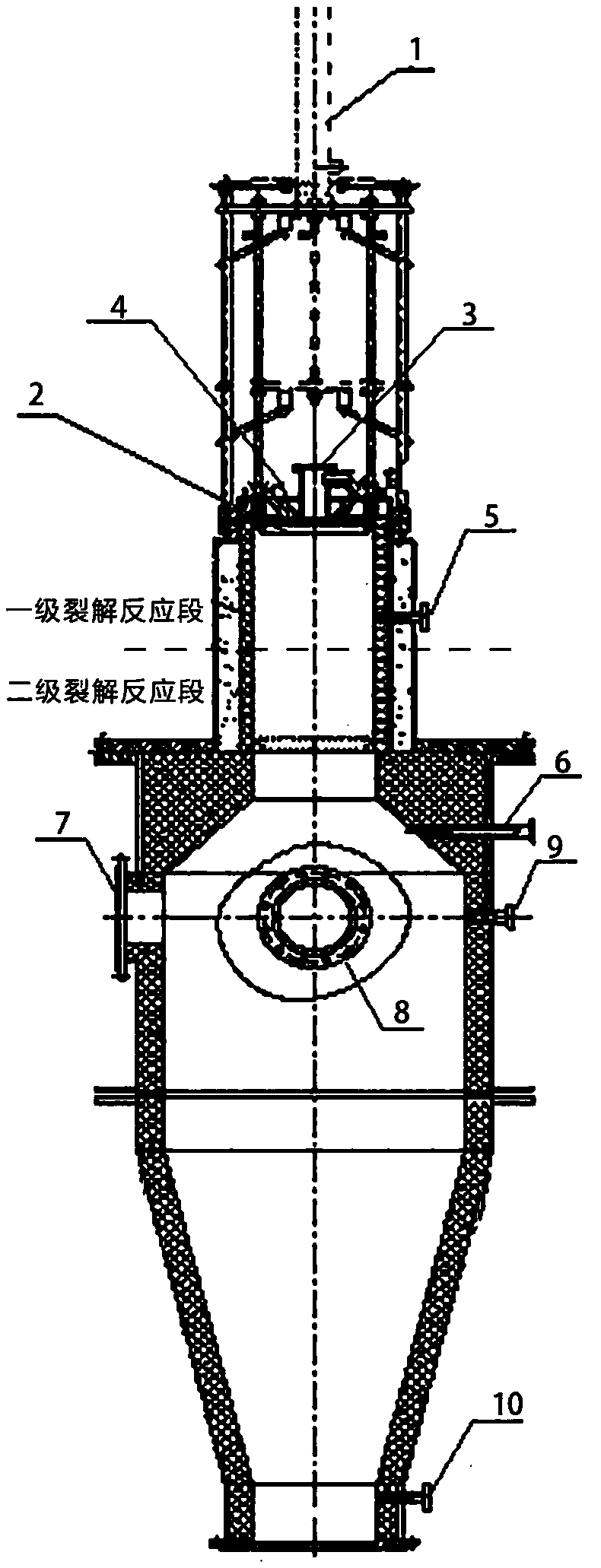

[0021] A gas-mixing route acetylene carbon black cracking furnace, comprising a cracking furnace body, which is divided into a gas decoking section, a cracking primary and secondary reaction section, a cooling section and a residence section from top to bottom, and the top of the cracking furnace body is A transmission device 1 is provided, and the inner layer of the cracking primary and secondary reaction sections, the cooling section and the residence section are lined with refractory materials; the transmission device 1 is a hydraulic cylinder, and the hydraulic cylinder is provided with a scraper device 2, a first Raw material gas inlet 3 and second raw material gas inlet 4, the first raw material gas inlet 3 is connected to the gas source of acetylene gas, the second raw material gas inlet 4 is connected to the single-ring aromatic hydrocarbon gas source, and the second raw material gas inlet 4 is provided with a flow valve, the scraper device 2 and the first feed gas inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com