Manufacturing method of foamed ceramic plate

A technology of foamed ceramics and a manufacturing method, which is applied in the direction of ceramic products, ceramic material production, clay products, etc., can solve the problems of insufficiency, pollution, occupying a large area of land, etc., to improve comprehensive performance indicators, reduce production costs, shorten The effect of the firing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

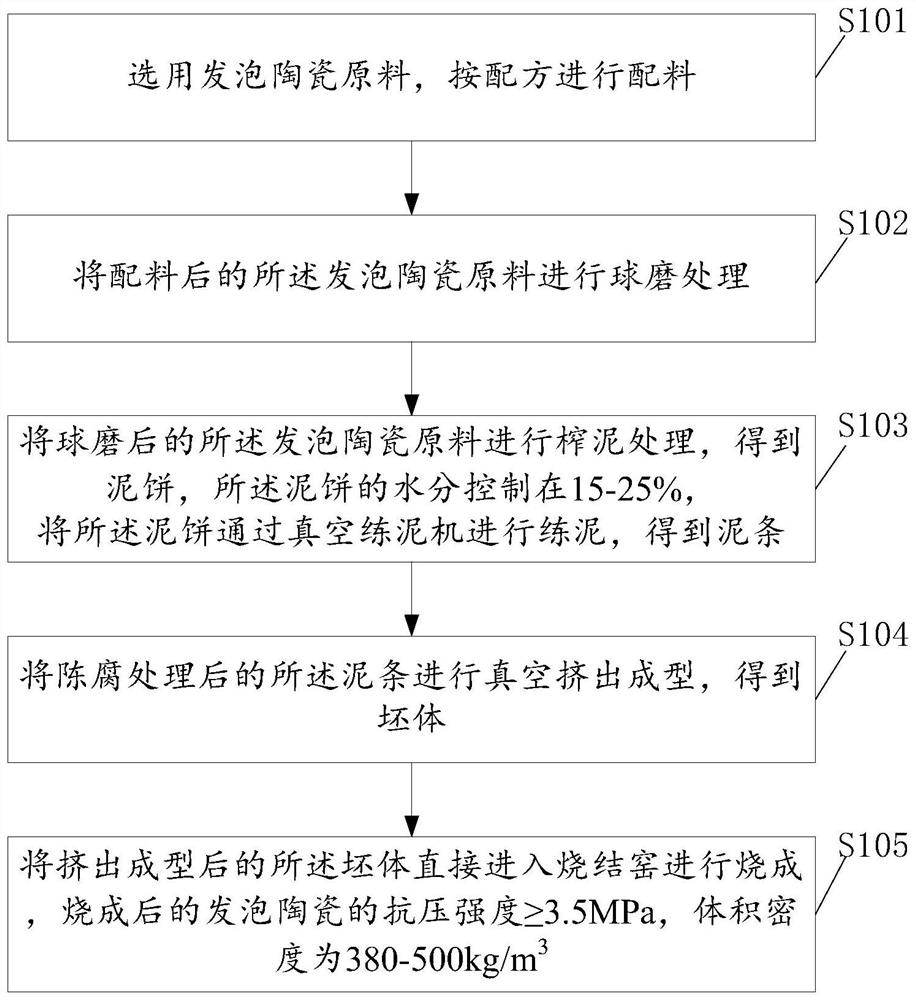

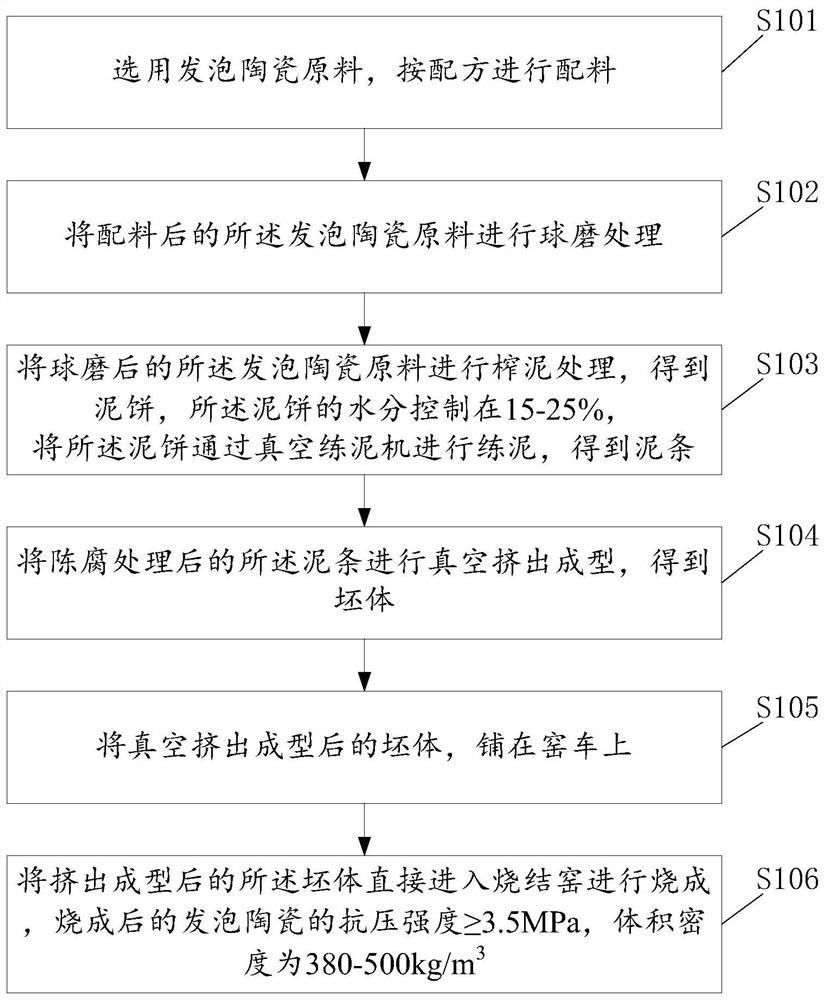

Method used

Image

Examples

Embodiment 1

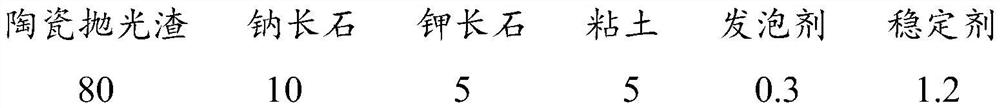

[0134] 1. Formula (unit kg):

[0135]

[0136] 2. Preparation method

[0137] (1) Select foamed ceramic raw materials, and carry out ingredients according to the formula;

[0138] (2) Add the foamed ceramic raw materials to the ball mill for ball milling, control the mud moisture at 33%, the flow rate for 30 seconds, the slurry fineness of 250 mesh sieves and the remaining 0.8%, and the specific gravity of the slurry to 1.5. Sieve, the slurry is aged for 6 hours;

[0139] (3) the foamed ceramic raw material after the ball milling is subjected to a mud pressing process to obtain a mud cake, and the moisture of the mud cake is controlled at 16%; then the mud cake is subjected to mud refining by a vacuum mud refining machine to obtain a mud bar; The mud sticks were stale for 24 hours in a damp environment;

[0140] (4) vacuum extrusion is carried out to the described mud strip after the stale treatment, and obtaining thickness is 3cm blank;

[0141] (5) Directly enter the ...

Embodiment 2

[0150] 1. Formula (unit kg):

[0151]

[0152] 2. Preparation method

[0153] (1) Select foamed ceramic raw materials, and carry out ingredients according to the formula;

[0154] (2) Add the foamed ceramic raw materials into the ball mill for ball milling, control the mud moisture at 35%, the flow rate for 50 seconds, the slurry fineness of 250 mesh sieve, the sieve remaining 1.0%, and the slurry specific gravity of 1.6. Sieve, the slurry is aged for 10 hours;

[0155] (3) the foamed ceramic raw material after the ball milling is subjected to a mud pressing process to obtain a mud cake, and the moisture of the mud cake is controlled at 17%; then the mud cake is subjected to mud refining by a vacuum mud refining machine to obtain a mud bar; The mud sticks were stale for 30 hours in a cloudy and humid environment;

[0156] (4) vacuum extrusion is carried out to the described mud strip after the stale treatment, to obtain a green body with a thickness of 3cm;

[0157] (5)...

Embodiment 3

[0166] 1. Formula (unit kg):

[0167]

[0168] 2. Preparation method

[0169] (1) Select foamed ceramic raw materials, and carry out ingredients according to the formula;

[0170] (2) Add the foamed ceramic raw materials to the ball mill for ball milling, control the mud moisture at 36%, the flow rate for 60 seconds, the slurry fineness of 250 mesh sieves and the remaining 1.2%, and the specific gravity of the slurry to 1.5. Sieve, the slurry is aged for 10 hours;

[0171] (3) the foamed ceramic raw material after the ball milling is subjected to a mud pressing process to obtain a mud cake, and the moisture of the mud cake is controlled at 21%; then the mud cake is subjected to mud refining by a vacuum mud refining machine to obtain a mud bar; The mud sticks were stale for 24 hours in a damp environment;

[0172] (4) vacuum extrusion is carried out to the described mud strip after the stale treatment, to obtain a green body with a thickness of 4.5cm;

[0173] (5) Direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com