A large -capacity Lyocell cellulose raw solution and its continuous preparation process

A preparation process and cellulose technology, applied in the field of large-capacity Lyocell cellulose stock solution and its continuous preparation process, can solve problems such as difficulty in capacity expansion and downstream production interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

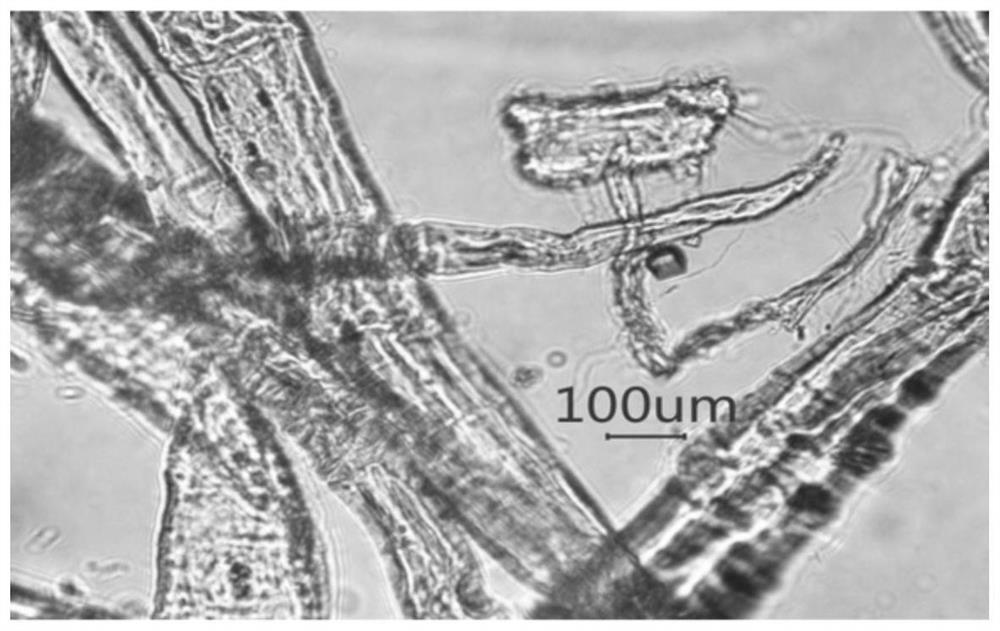

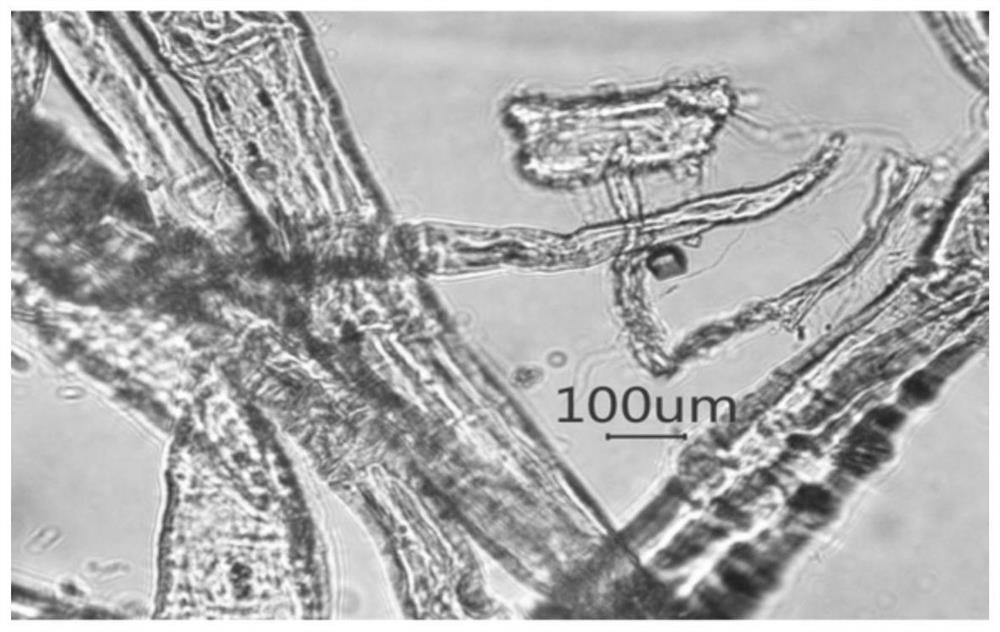

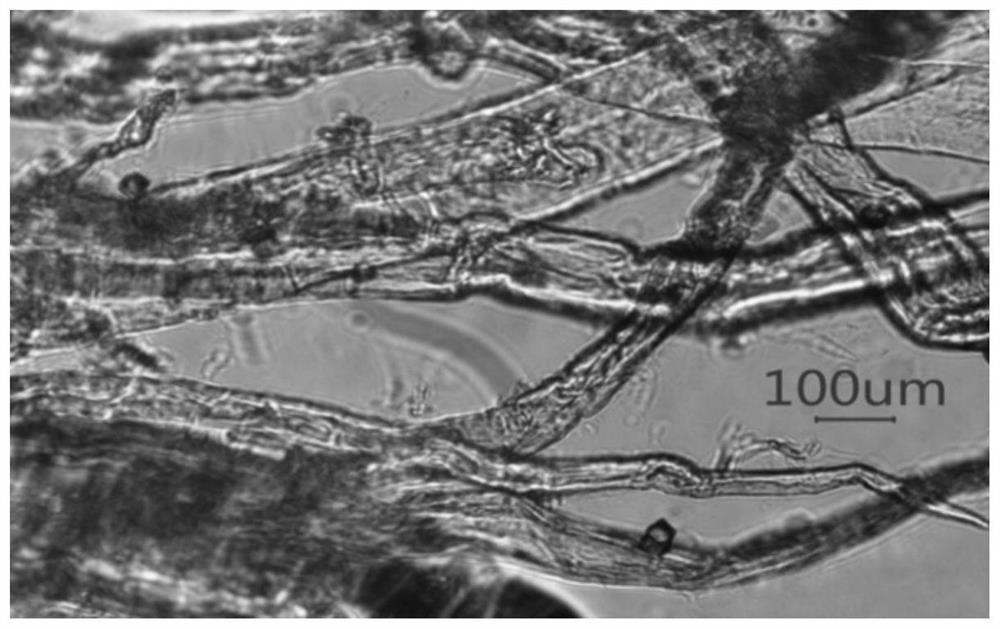

Image

Examples

Embodiment 1

[0058] To prepare Lyocell cellulose stock solution:

[0059] S1: The packaged pulp board is sent to the conveying roller of the pulp feeding system with a forklift, and the pulp wrapping paper and the wrapped wire are removed by unpacking, and the metal detection system ensures that no residual metal material enters the downstream equipment. Then the pulp board of 2400kg is determined by weighing and enters the pulper;

[0060] S2: The pulp board enters the pulp pulper to form a pulp water suspension with a concentration of 4.5wt%, and stays in the pulper for 40 minutes to make the pulping sufficient;

[0061] S3: The pulp suspension enters the activation tank, and the pH of the pulp suspension is adjusted with sodium hydroxide solution to be alkaline, and the pH value is 8; the residence time of the pulp suspension in the activation tank is 40min;

[0062] S4: The pulp suspension soaked in alkali solution is transported to the press through a centrifugal pump, and physically...

Embodiment 2

[0069] To prepare Lyocell cellulose stock solution:

[0070] S1: The packaged pulp board is sent to the conveying roller of the pulp feeding system with a forklift, and the pulp wrapping paper and the wrapped wire are removed by unpacking, and the metal detection system ensures that no residual metal material enters the downstream equipment. Then the pulp board of 2400kg is determined by weighing and enters the pulper;

[0071] S2: The pulp board enters the pulp pulper to form a pulp water suspension with a concentration of 4.0 wt%, and stays in the pulper for 35 minutes to make the pulping sufficient;

[0072] S3: The pulp suspension enters the activation tank, and the pH of the pulp suspension is adjusted with sodium hydroxide solution to be alkaline, and the pH value is 10.5; the residence time of the pulp suspension in the activation tank is 50min;

[0073] S4: The pulp suspension soaked in alkali solution is transported to the press through a centrifugal pump, and physic...

Embodiment 3

[0080] To prepare Lyocell cellulose stock solution:

[0081] S1: The packaged pulp board is sent to the conveying roller of the pulp feeding system with a forklift, and the pulp wrapping paper and the wrapped wire are removed by unpacking, and the metal detection system ensures that no residual metal material enters the downstream equipment. Then the pulp board of 3000kg is determined by weighing and enters the pulper;

[0082] S2: the pulp board enters the pulp pulper to form a pulp water suspension with a concentration of 5.0wt%, and stays in the pulper for 35min to make the pulping sufficient;

[0083] S3: The pulp suspension enters the activation tank, and the pH of the pulp suspension is adjusted with sodium hydroxide solution to be alkaline, and the pH value is 11; the residence time of the pulp suspension in the activation tank is 35min;

[0084] S4: The pulp suspension soaked in lye is transported to the press through a centrifugal pump, and physically pressed by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com