Controllable discharge ablation processing method for flammable and difficult-to-process materials with adjustable combustion-supporting gas concentration

A combustion-supporting gas and processing method technology, applied in metal processing equipment, electric processing equipment, circuits, etc., can solve the problems of low efficiency in the EDM process, reduce gas cost, improve processing efficiency, and reduce gas mixing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

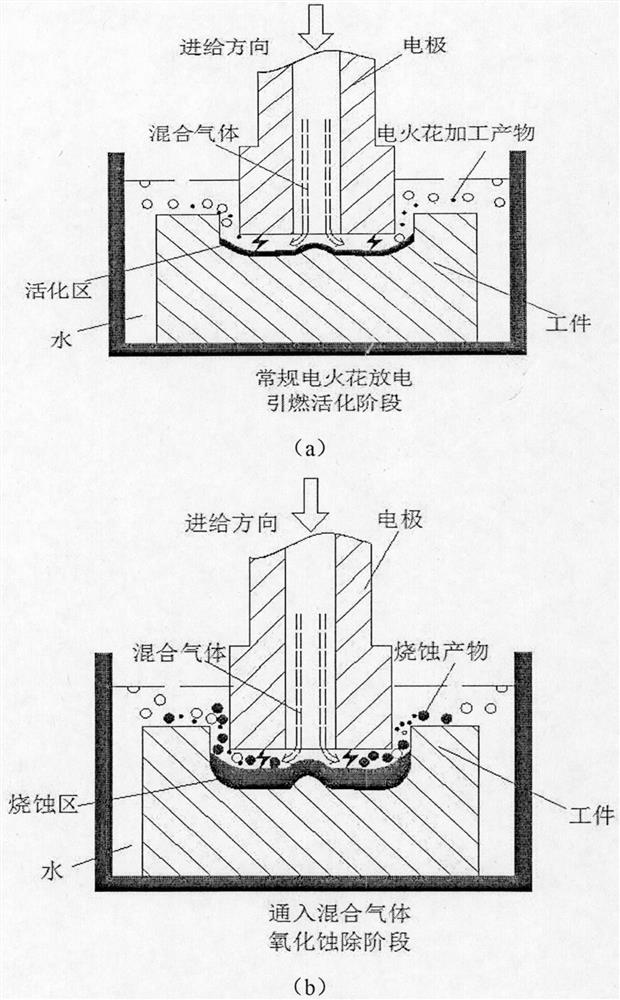

[0045] The present invention will be further described below by taking discharge ablation forming as an example.

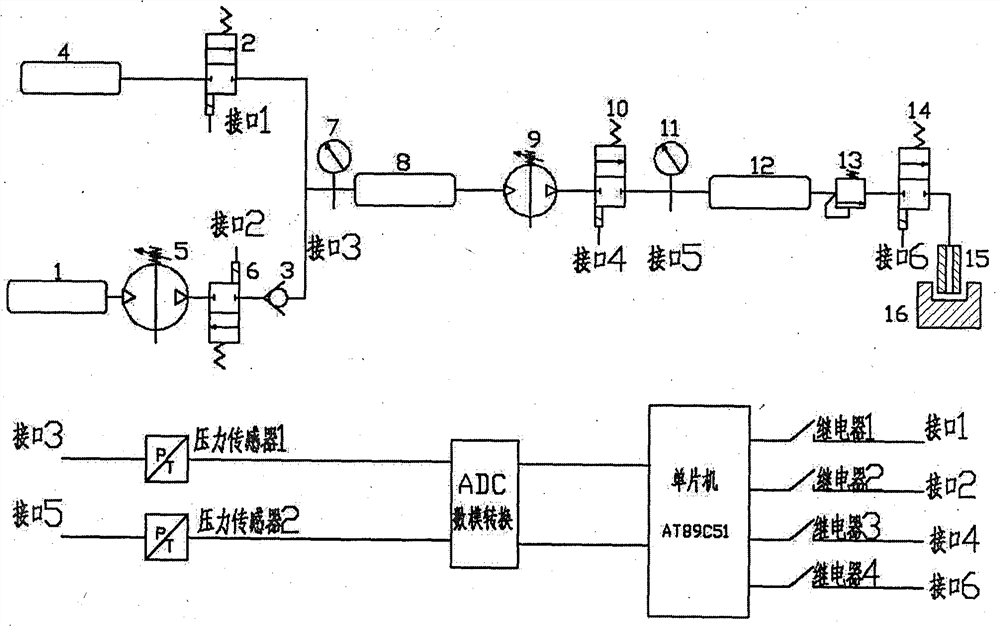

[0046] The system schematic diagram of the mixed gas medium generating device with adjustable combustion-supporting gas concentration used in the specific embodiment of discharge ablation forming processing according to the present invention is as follows figure 2 shown.

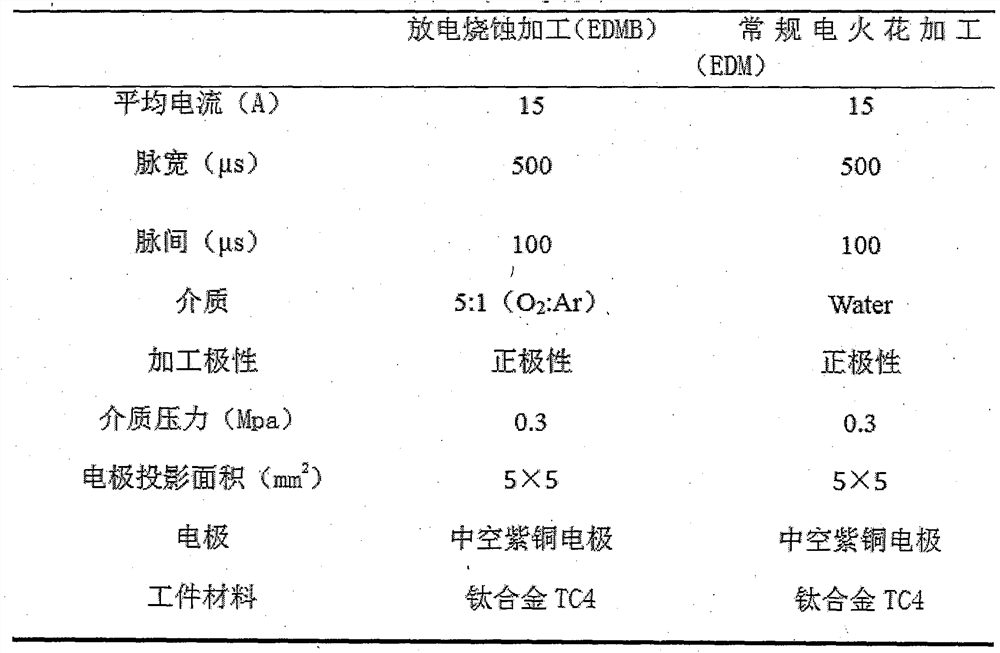

[0047] The workpiece material is made of titanium alloy TC4 for EDM processing. The specific processing parameters are as follows: figure 1 shown.

[0048] In this example, the combustion-supporting gas is oxygen, and the impurity gas is argon.

[0049] The gas concentration adjustable titanium alloy discharge ablation processing method of the present invention, the specific steps are as follows:

[0050] The first is the generation of mixed gas for discharge ablation machining, refer to figure 2 The mixed gas generation device system with adjustable combustion-supporting gas concentration...

Embodiment example 2

[0056] In this example, nitrogen is selected as the impurity gas, and oxygen is selected as the combustion-supporting gas. The source of nitrogen is air, and the proportion of nitrogen in the air is 78%. Therefore, during the ablation process of titanium alloy, air can provide abundant nitrogen. source of impurity gases. Nitrogen accounts for the vast majority in the air, and oxygen accounts for 21%. Therefore, when using the mixed gas medium generator system of the present invention for mixing, the oxygen content in the air medium needs to be considered. In this case, it is assumed that the pressure ratio of nitrogen and oxygen in the mixed gas is 1:5, and the volume percentages of nitrogen and oxygen in the air are 78% and 21% respectively. Based on the above data, the relevant formulas are obtained, as follows: specific derivation process.

[0057] Suppose x is the pressure of nitrogen in the mixed gas, y is the pressure of air mixed in, and the pressure of pure oxygen int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com