Method and device for massively preparing silicon nanomaterial

A silicon nanometer and silicon nanowire technology, which is applied in the field of large-scale preparation of silicon nanomaterials, can solve the problems of high temperature and the inability to realize industrialization requirements of large-scale preparation of silicon nanomaterials, so as to save gas costs, increase effective air intake, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

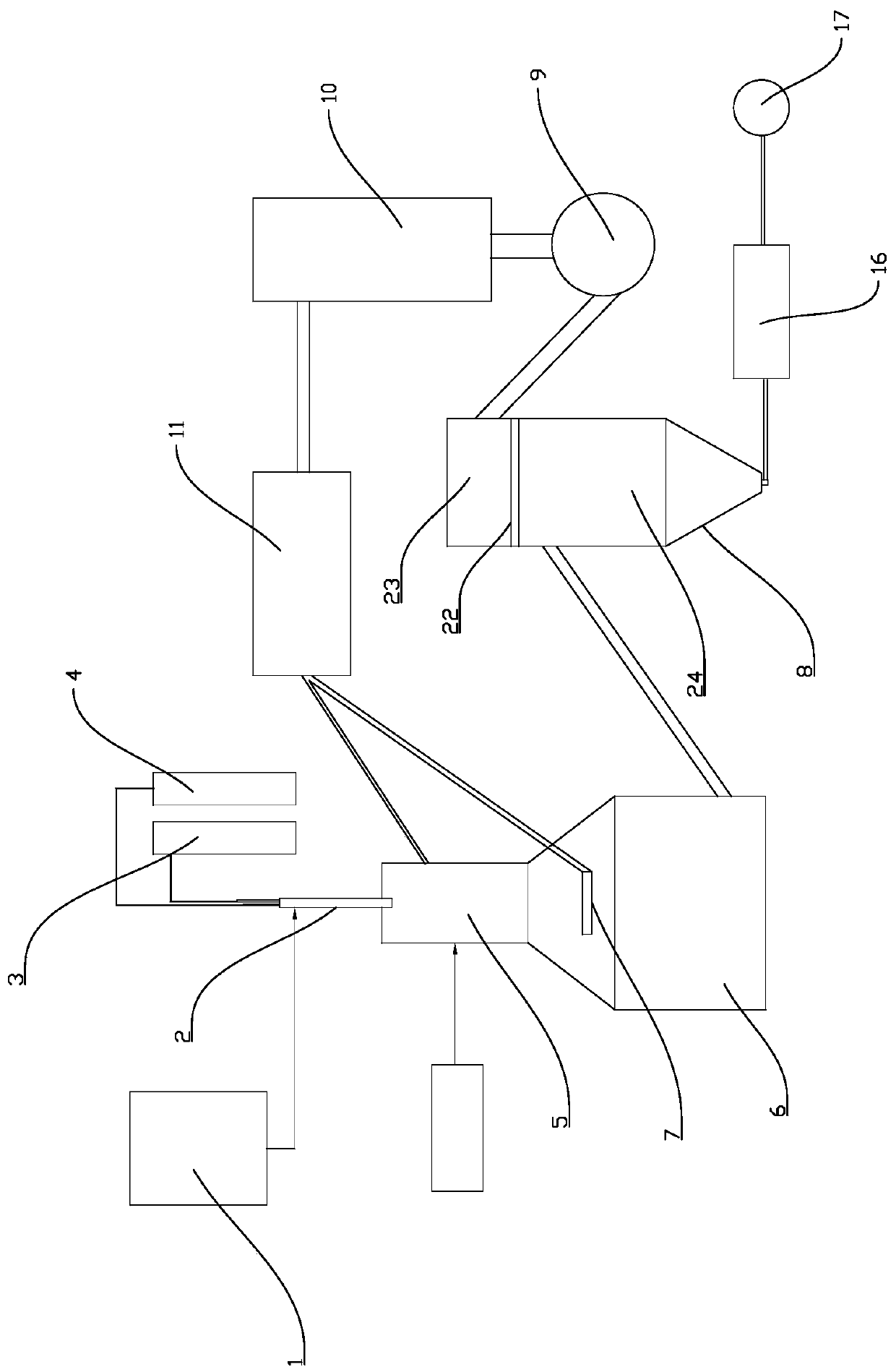

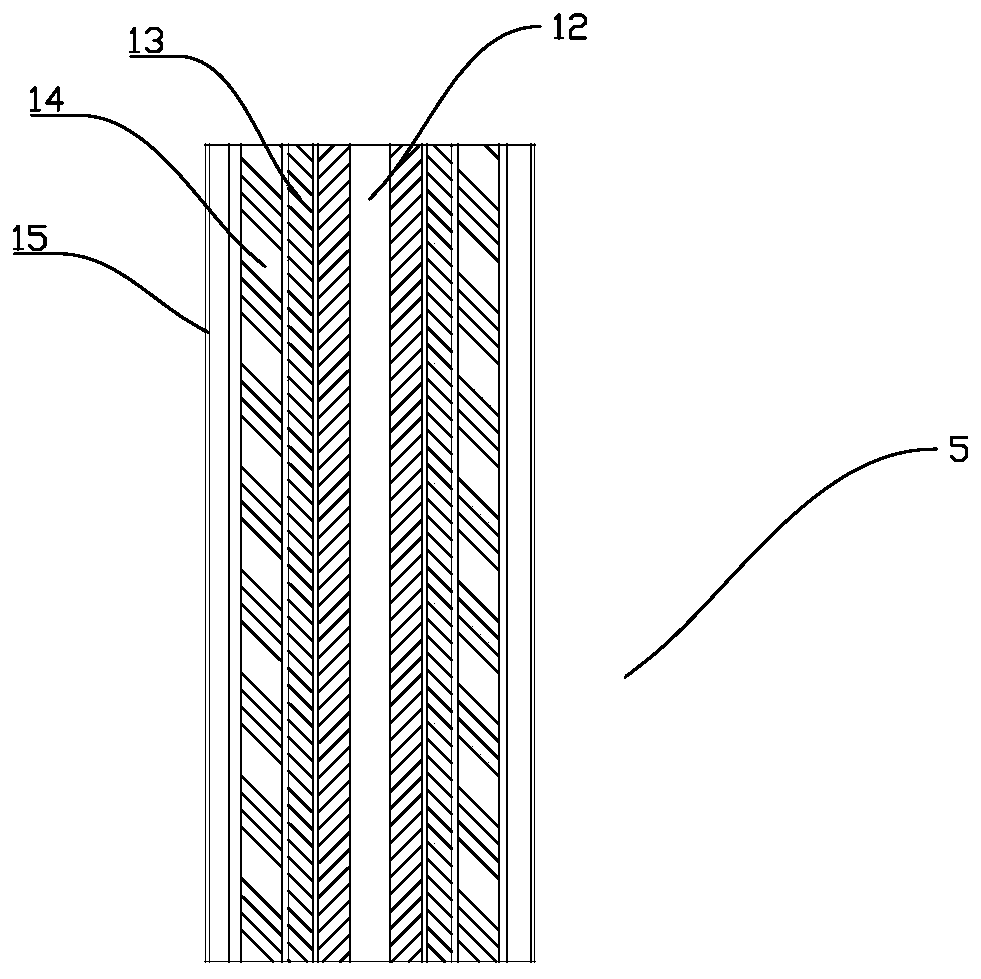

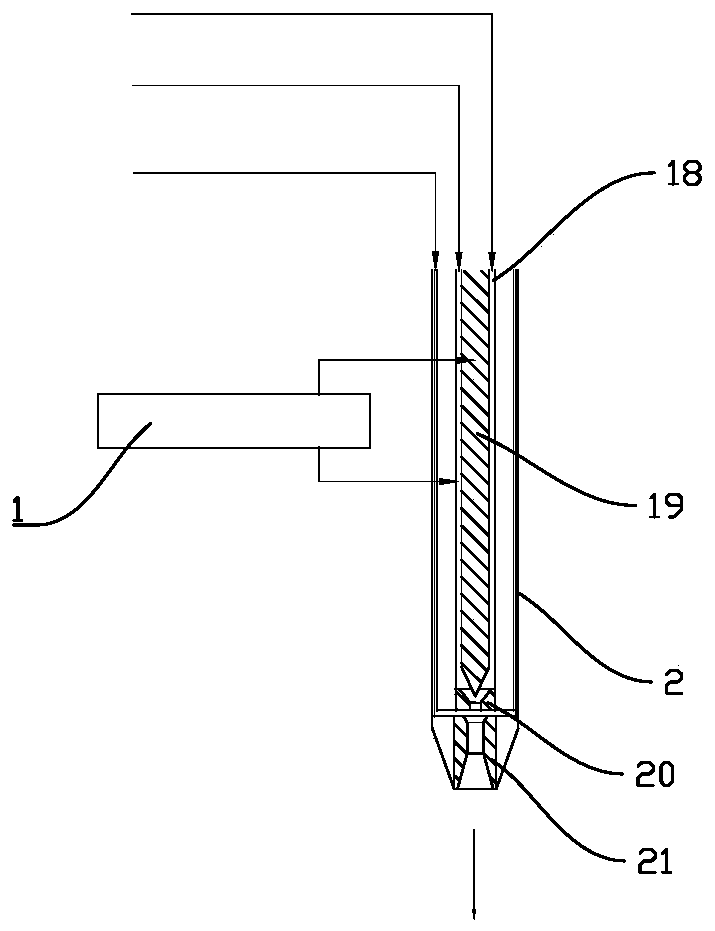

[0044] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-3 .

[0045] A device for preparing silicon nanomaterials in large quantities, comprising a plasma gun 2 controlled by a plasma power source 1, the inner cavity of the plasma gun 2 is connected with an inert gas storage tank 3 and a silicon source storage tank 4, and the lower end of the plasma gun 2 is arranged There is a growth controller 5, the lower end of the growth controller 5 is provided with a cooling container 6, and a gas cooling ring 7 is arranged in the cooling container 6, and the cooling container 6 is connected to a gas-solid separator 8 and is provided with an air suction device 9, the The gas outlet of the gas-solid separator 8 is sequentially connected to the heat exchanger 10 and the mixed gas storage tank 11, and the mixed gas storage tank 11 is connected to the gas cooling ring 7 to output the cooled mixed gas.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com