Underwater laser repairing device and method based on metal matrix composite material preparation

A composite material, underwater laser technology, applied in the field of laser repair, can solve the problems of wire feeding repair cladding layer quality cannot meet service performance, reduce cladding quality, adverse effects, etc., achieve light weight, wide application range, prevent embrittlement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

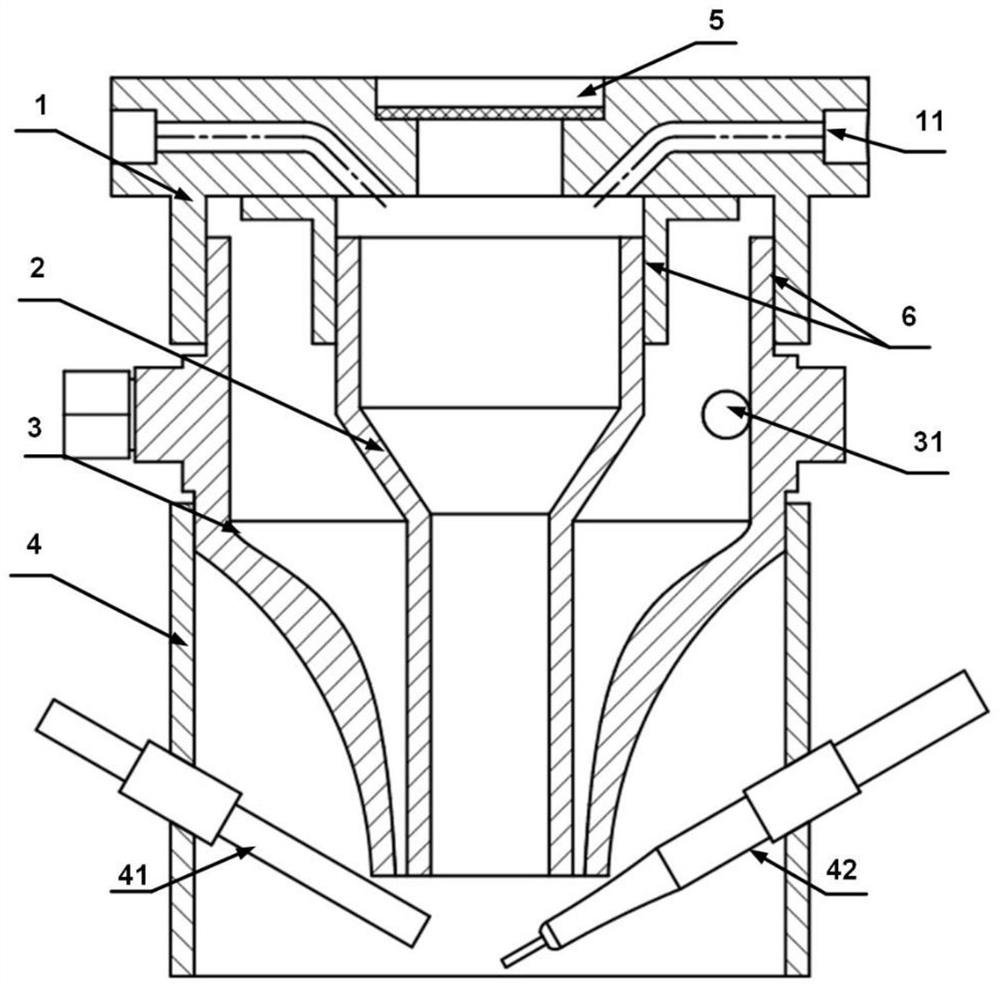

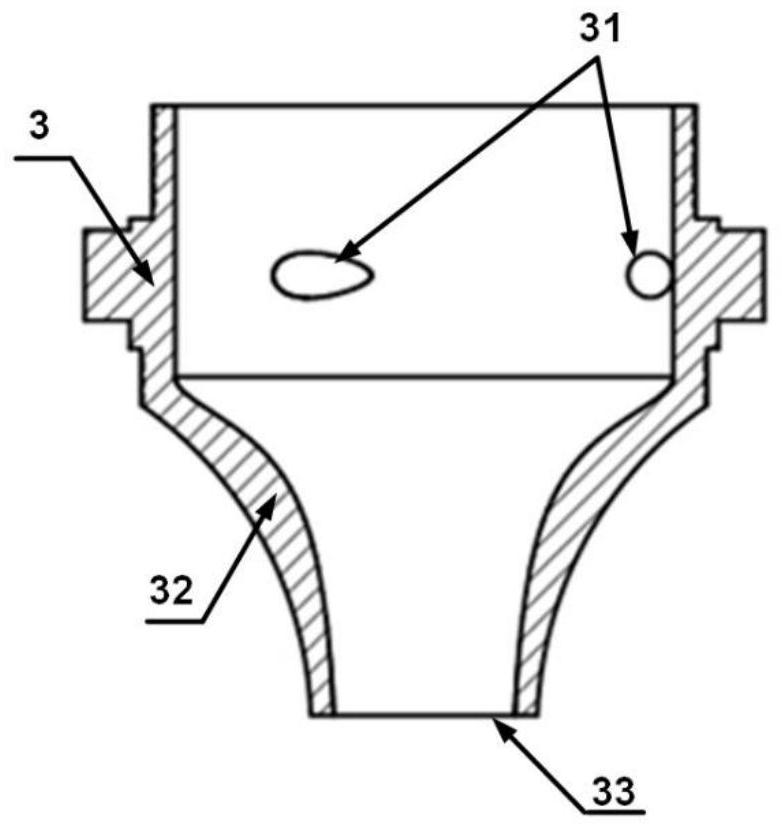

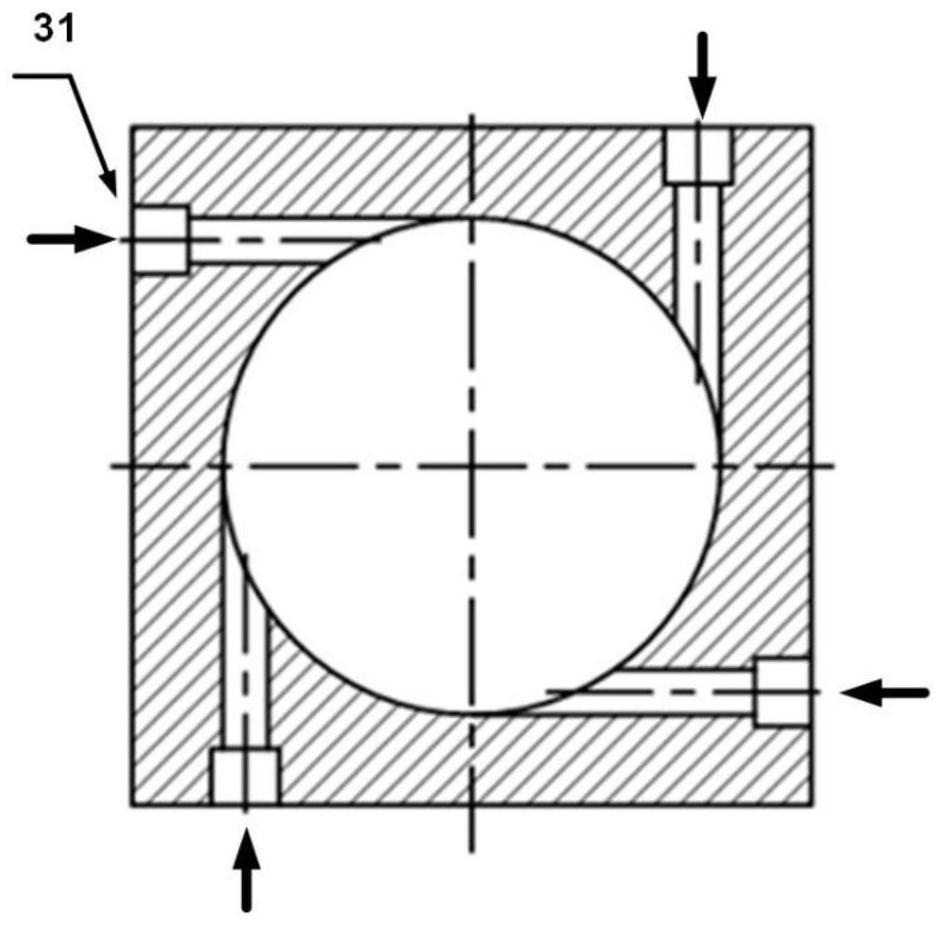

[0042] Such as Figures 1 to 5As shown, this embodiment provides an underwater laser repair device based on metal matrix composite materials. In a dry space formed by a double-layer high-rigidity air curtain drainage device, underwater silk-powder co-feeding laser 11 cladding is carried out. The metal matrix composite material cladding layer 8 is formed. On the one hand, its advantage is that the outer cavity of the drainage device can quickly discharge water, and a high-rigidity air curtain is formed to prevent water from overflowing into the inner cavity, creating a stable dry area. Improve the stability of underwater laser 11 cladding process. On the other hand, metal matrix composites were prepared by underwater silk powder co-feeding laser 11 cladding process in the drainage device, which improved the service performance of the repaired area. The present invention provides a high-quality, high-efficiency method and device for repairing the underwater laser 11 of marine e...

Embodiment 2

[0049] This embodiment provides a method based on the underwater laser repair device prepared based on the metal matrix composite material in the first embodiment, including the following steps:

[0050] a. Select wire material and powder material 10 and their ratio according to the material and service performance requirements of the workpiece 7 to be repaired;

[0051] b. Install the double-layer high-rigidity air curtain drainage device on the laser 11 cladding movement device, and make the drainage device above the surface of the workpiece 7 to be repaired by changing the posture of the movement device;

[0052] c. Set the process parameters, change the height of the device by adjusting the lifting screw 6 to adjust the defocus amount; and set the laser 11 power, scanning speed, wire feeding speed, powder spraying speed, compressed air flow rate and argon protection airflow respectively speed;

[0053] d. Put compressed air and argon protective gas into the drainage devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com